Abstract

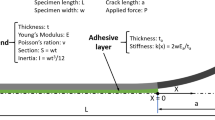

The double cantilever beam (DCB) cleavage technique developed by many investigators(1–5) has been applied for measuring the surface energy 0,4–8) and the crack velocity(3,9) in brittle materials. The authors investigated the crack behavior in the DCB cleavage specimen at constant strain rate.

Résumé

Pour mesurer l'énergie de surface et la vitesse de fissuration dans les matériaux fragiles, on a appliqué la technique, utilisée par plusieurs chercheurs, de la mise en clivage d'une éprouvette en forme de double poutre cantilever. Les auteurs ont analysé le comportement de fissures dans ce type d'éprouvettes à vitesse de déformation constante.

Zusammenfassung

Das Doppelkantileverproben-Spaltverfahren (DCB), welches von verschiedenen Verfassern (1–5) entwickelt worden ist, wurde für die Messung der Oberflächenenergie [1, 4–8] und der Rißausbreitungsgeschwindigkeit [3,9] in spröden Materialien angewandt. Die Verfasser untersuchten das Rissverhalten in DCB-Proben bei konstanter Verformungsgeschwindigkeit.

Similar content being viewed by others

References

J. J. Gilman, Direct Measurements of the Surface Energies of Crystals, Jour. Appl. Phys., 31 (12), 2208, (1960).

J. J. Gilman, Cleavage, Ductility, and Tenacity in Crystals, pp 193 in Fracture, Edited by B. L. Averback and others. Technology Press of M.I.T., Cambridge, Mass. and John Wiley & Sons Inc., New York, 1959.

P. P. Gillis and J. J. Gilman, Double-Cantilever Cleavage Mode of Crack Propagation, Jour. Appl. Phys., 35, (3), 647, (1964).

P. P. Gillis, Surface-Energy Determination by Cleavage, Jour. Appl. Phys., 36 (4), 1374, (1965).

J. P. Berry, Determination of Fracture Surface Energy by the Cleavage Technique, Jour. Appl. Phys., 34, (1), 62, (1963).

A. R. C. Westwood and T. T. Hitch, Surface Energy of (100 Potassium Chloride), Jour. Appl. Phys., 34, (10), 3085, (1963).

P. L. Gutshall and G. E. Gross, Cleavage Surface Energy, of NaCl and MgO in Vacuum, Jour. Appl. Phys., 36, (8), 2459, (1965).

S. M. Wiederhorn, Fracture Surface Energy of Glass, Jour. Appl. Phys., 52, (2), 99, (1969).

S. M. Wiederhorn, Influence of Water Vapor on Crack Propagation in Soda-Lime Glass, Jour. Am. Ceram. Soc., 50, (8), 407, (1968).

A. A. Griffith, Phenomena of Rupture and Flow in Solids, Phil. Trans. Roy. Soc. (London), A221, 163, (1921).

Author information

Authors and Affiliations

Rights and permissions

About this article

Cite this article

Matsui, M., Oda, I. & Yamamoto, N. A note on the crack behavior in brittle materials under the double cantilever beam cleavage at constant strain rate. Int J Fract 7, 447–450 (1971). https://doi.org/10.1007/BF00189114

Received:

Revised:

Issue Date:

DOI: https://doi.org/10.1007/BF00189114