Abstract

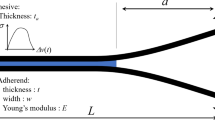

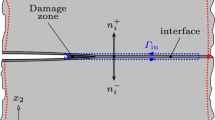

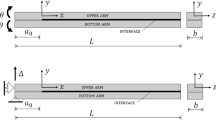

Double-Cantilever Beam (DCB) testing is a common protocol to evaluate bonded interface toughness. The data-analysis procedures are initially based on the classical Linear Elastic Fracture Mechanics (LEFM) and have been extended to deal with plastic behavior. Nevertheless, those analyses are not suitable when time-dependent behavior is involved in the crack propagation process. In this paper, an analysis of crack propagation along a viscoelastic interface during a DCB test is conducted, assuming a Standard Linear Solid (SLS) model for the adhesive. During the self-similar crack propagation regime, a steady-state stress–strain distribution is achieved ahead of the crack tip and a Eulerian description is used. A finite-difference scheme is implemented to solve the set of differential equations from which stress–strain evolutions along the bondline are determined as the specimen deforms. The crack propagation response under stationary loading conditions is then simulated and the energy-based failure criteria are evaluated comparing both local and global estimations of the Strain-Energy Release Rate (SERR).

Similar content being viewed by others

Data Availability

All data generated or analyzed during this study are included in this published article.

Abbreviations

- DCB:

-

Double-Cantilever Beam

- LEFM:

-

Linear Elastic Fracture Mechanics

- SLS:

-

Standard Linear Solid

- SERR, \(G\) :

-

Strain-Energy Release Rate

- CZM:

-

Cohesive-Zone Modeling

- DIC:

-

Digital Image Correlation

- ENF:

-

End-Notched Flexure

- FD:

-

Finite Difference

- \(w\) :

-

adherend width

- \(t\) :

-

adherend thickness

- \(C\) :

-

compliance

- \(\Delta \) :

-

opening displacement

- \(P\) :

-

applied force

- \(a\) :

-

crack length

- \(E\) :

-

adherend Young’s modulus

- \(I\) :

-

quadratic moment

- \(G_{c}\) :

-

critical strain-energy release rate

- CBBM:

-

Compliance-Based Beam Method

- \(M\) :

-

bending moment

- \(T\) :

-

shear force

- \(\sigma \) :

-

peel stress

- \(X\) :

-

position along the specimen

- \(\varphi \) :

-

beam cross-sectional rotation

- \(v\) :

-

deflection

- \(G\) :

-

adherend shear modulus

- \(S\) :

-

adherend cross section

- \(\kappa \) :

-

shear correction factor

- \(K\) :

-

interface stiffness

- \(E^{*}\) :

-

apparent elastic modulus

- \(E_{a}\) :

-

bonded interface modulus

- DOE:

-

Differential Ordinary Equation

- \(N\) :

-

number of discrete points

- \(\Delta X\) :

-

spatial step

- \(L\) :

-

specimen length

- \(t_{a}\) :

-

bonded interface thickness

- \(\lambda _{\sigma}\) :

-

characteristic wavenumber for flexible adherend

- \(\lambda _{\gamma}\) :

-

characteristic wavenumber for shear deformable adherend

- SLS:

-

Standard Linear Solid

- \(\Delta v_{tot}\) :

-

relative normal displacement across the interface

- \(\Delta v_{e}\) :

-

elastic contribution to \(\Delta v\)

- \(\Delta v_{ve}\) :

-

viscoelastic contribution to \(\Delta v\)

- \(K_{e}\) :

-

elastic stiffness

- \(K_{ve}\) :

-

elastic stiffness

- \(\eta_{ve}\) :

-

dynamic viscosity

- \(\tau_{r}\) :

-

characteristic relaxation time

- \(\tau _{c}\) :

-

characteristic creep time

- \(K_{0}\) :

-

charged interface stiffness

- \(K_{\infty}\) :

-

relaxed interface stiffness

- \(da/dt\) :

-

crack propagation rate

- \(x(t)\) :

-

distance to the instant crack-tip position

- \(v_{max}\) :

-

ultimate deflection criteria

- \(l^{PZ}\) :

-

process-zone length

- \(\varepsilon \) :

-

strain

- \(\dot{\varepsilon} \) :

-

strain rate

- ℛ:

-

relaxation function

- \(d\Delta/dt\) :

-

opening displacement rate

- \(F^{*}\) :

-

critical applied force

- \(\Delta^{*}\) :

-

critical opening deflection

- \(G_{LEFM}\) :

-

critical strain energy based on LEFM

- \(G_{VE}\) :

-

critical strain energy based on stress versus strain curve

- \(SERR^{*}\) :

-

Reference SERR related to the relaxed interface stiffness

References

Anderson, T.L.: Fracture Mechanics: Fundamentals and Applications. Taylor and Francis Group, Boca Raton (2005)

ASTM D3433-99: Standard test method for fracture strength in cleavage of adhesives in bonded metal joints. ASTM International, West Conshohocken, PA (2020). www.astm.org

ASTM D3762-03: Standard test method for adhesive-bonded surface durability of aluminum (wedge test). ASTM International, West Conshohocken, PA (2010). www.astm.org

Berrekheroukh, N., Sereir, Z., Vivet, A., et al.: Experimental and numerical models to study the creep behavior of the unidirectional Alfa fiber composite strength by the photoelasticity method. Mech. Time-Depend. Mater. (2021)

Blackman, B.R.K., Hadavinia, H., Kinloch, A.J., Williams, J.G.: The use of a cohesive zone model to study the fracture of fibre composites and adhesively-bonded joints. Int. J. Fract. 119(1), 25–46 (2003)

Bocchieri, R.T.: Time-dependent deformation of a nonlinear viscoelastic rubber-toughened fiber composite with growing damage. PhD Thesis, The University of Texas at Austin, USA (2001)

Bonelli, S.: Modèles Rhéologiques et Lois de Comportement – Aide Mémoire (2019). hal-02608379

Budzik, M., Jumel, J., Imielińska, K., Shanahan, M.E.R.: Accurate and continuous adhesive fracture energy determination using an instrumented wedge test. Int. J. Adhes. Adhes. 29(7), 694–701 (2009)

Carneiro Neto, R.M., Akhavan-Safar, A., Sampaio, E.M., Assis, J.T., da Silva, L.F.M.: Assessment of the creep life of adhesively bonded joints using the end notched flexure samples. Eng. Fail. Anal. 133, 105969 (2022a)

Carneiro Neto, R.M., Akhavan-Safar, A., Sampaio, E.M., Assis, J.T., da Silva, L.F.M.: Effect of creep on the mode II residual fracture energy of adhesives. J. Appl. Polym. Sci. 138(47), 51387 (2022b)

Chauffaille, S.: Durability of bonded assemblies: mechanical and physico-chemical aspects. PhD Thesis, Bordeaux University I, France (2011)

Chaves, F.J.P., Da Silva, L.F.M., de Moura, M.F.S.F., Dillard, D.A., Esteves, V.H.C.: Fracture mechanics tests in adhesively bonded joints: a literature review. J. Adhes. 90(12), 955–992 (2014)

Chen, Y., Smith, L.V.: A nonlinear viscoelastic–viscoplastic constitutive model for adhesives under creep. Mech. Time-Depend. Mater. (2021)

Creton, C., Ciccotti, M.: Fracture and adhesion of soft materials: a review. Rep. Prog. Phys. 79, 046601 (2016)

Dumont, S., Rizzoni, R., Lebon, F., Sacco, E.: Soft and hard interface models for bonded elements. Composites, Part B, Eng. 153, 480–490 (2018)

Fahimifar, A., Karami, M., Fahimifar, A.: Modifications to an elasto-visco-plastic constitutive model for prediction of creep deformation of rock samples. Soil Found. 55(6), 1364–1371 (2015)

Fourton, P.: Dynamic adhesion breaking in laminated glass – effect of interfaces and polymer’s rheology. Chemical Physics [physics.chem-ph]. PhD Thesis, Paris University of Sciences and Letters, France (2019)

Gallegos, C., Martinez Boza, J.F.: Linear Viscoelasticity. Rheology, vol. 1 (2010)

Griffith, A.A.: The phenomena of rupture and flow in solids. Philos. Trans. R. Soc. Lond., Ser. A, Contain. Pap. Math. Phys. Character 221, 163–198 (1921)

Guojun, H., Tay, A.A., Yongwei, Z., Chew, S.: Experimental and numerical study of the effect of viscoelasticity on delamination in a plastic IC package. In: 2007 Proceedings 57th Electronic Components and Technology Conference, pp. 1062–1068 (2007). IEEE

Holmes, D.W., Loughran, J.G., Suehrcke, H.: Constitutive model for large strain deformation of semicrystalline polymers. Mech. Time-Depend. Mater. 10(4), 281–313 (2006)

ISO 10354:1992(en): Adhesives – characterization of durability of structural-adhesive-bonded assemblies – wedge rupture test. International Organization for Standardization, Geneva, Switzerland. https://www.iso.org

ISO 25217:2009(en): Adhesives – determination of the mode 1 adhesive fracture energy of structural adhesive joints using double cantilever beam and tapered double cantilever beam specimens. International Organization for Standardization, Geneva, Switzerland. https://www.iso.org

Jaillon, A., Jumel, J., Lachaud, F., Paroissien, E.: Cohesive zone model identification in mode I for bonded composites: identification methods’ review and sensitivity analysis. In: JNC21 – 21èmes Journées Nationales sur les Composites 2019, 1 July 2019–3 July 2019, Bordeaux, France (2019)

Jhin, G., Azari, S., Ameli, A., Datla, N.V., Papini, M., Spelt, J.K.: Crack growth rate and crack path in adhesively bonded joints: comparison of creep, fatigue and fracture. Int. J. Adhes. Adhes. 46, 74–84 (2013)

Ji, S.S., Genin, G.M., Paris, P.C., Berkel, T.R., Rubin, A.M.: Polymer/metal interfacial crack growth characterized by C*. Int. J. Fract. 129(1), 63–73 (2004)

Jumel, J.: Crack propagation along interface having randomly fluctuating mechanical properties during DCB test finite difference implementation – evaluation of \(G_{c}\) distribution with effective crack length technique. Composites, Part B 116, 253–265 (2017)

Langtangen, H.P., Linge, S.: Finite Difference Computing with PDEs: A Modern Software Approach. Texts in Computational Science and Engineering. Springer, Berlin (2017)

LeVeque, R.J.: Finite Difference Methods for Ordinary and Partial Differential Equations: Steady-State and Time-Dependent Problems. Other Titles in Applied Mathematics. SIAM, Philadelphia (2007)

Maimí, P., Camanho, P.P., Mayugo, J.A., Dávila, C.G.: A continuum damage model for composite laminates: Part II – computational implementation and validation. Mech. Mater. 39(10), 909–919 (2007)

Majda, P., Skrodzewicz, N.: A modified creep model of epoxy adhesive at ambient temperature. Int. J. Adhes. Adhes. 29, 396–404 (2009)

Marquez Costa, J.P.: Characterisation and modeling of interfaces in laminated organic composites at high temperature – application to fire resistance of aeronautical structures. PhD Thesis, Paris Saclay University, France (2021)

Mostovoy, S., Ripling, E.J.: Fracture toughness of an epoxy system. J. Appl. Polym. Sci. 10(9), 1351–1371 (1966)

Nicolas, A., Jumel, J.: Double cantilever beam tests on a viscoelastic adhesive: effects of the loading rate. Proc. Struct. Integrity 2, 261–276 (2016)

Park, S., Liechti, K.M., Roy, S.: A nonlinear viscoelastic fracture analysis of concrete/FRP delamination in aggressive environments. Int. J. Fract. 142(1), 9–27 (2006)

Plausinis, D., Spelt, J.K.: Designing for time-dependent crack growth in adhesive joints. Int. J. Adhes. Adhes. 15(3), 143–154 (1995a)

Plausinis, D., Spelt, J.K.: Application of a new constant G load-jig to creep crack growth in adhesive joints. Int. J. Adhes. Adhes. 15(4), 225–232 (1995b)

Possart, W., Krüger, J.K., Wehlack, C., Müller, U., Petersen, C., Bactavatchalou, R., Meiser, A.: Formation and structure of epoxy network interphases at the contact to native metal surfaces. C. R., Chim. 9(1), 60–79 (2006)

Rizov, V.: Non-linear fracture behavior of double cantilever beam. Eng. Mech. 22(2), 95–102 (2015)

Rochefort, M.A.: Nonlinear viscoelastic characterisation of structural adhesive. Faculty of the Virginia Polytechnic Institute and State University, United States (1983)

Rouleau, L., Pirk, R., Pluymers, B., Desmet, W.: Characterization and modeling of the viscoelastic behavior of a self-adhesive rubber using dynamic mechanical analysis tests. J. Aerosp. Technol. Manag. 7(2), 200–208 (2015)

Saeimi Sadigh, M.A., Paygozar, B., Da Silva, L.F.M., Vakili Tahami, F.: Creep deformation simulation of adhesively bonded joints at different temperature levels using a modified power-law model. Polym. Test. 79, 106087 (2019)

Salençon, J.: Viscoélasticité pour le calcul des structures. Palaiseau: Éd. de l’École polytechnique les Presses des Ponts et chaussée. Print. (2009)

Sangtabi, M.R., Kiasat, M.S.: Long-term viscoelastic properties of an adhesive and molding compound, characterization and modeling. Polymer 116, 204–217 (2017)

Saxena, A.: Creep and creep–fatigue crack growth. Int. J. Fract. 191(1–2), 31–51 (2015)

Schapery, R.A.: Correspondence principles and a generalized J integral for large deformation and fracture analysis of viscoelastic media. Int. J. Fract. 25(3), 195–223 (1984)

Schapery, R.A.: On some path independent integrals and their use in fracture of nonlinear viscoelastic media. In: Non-Linear Fracture, pp. 189–207. Springer, Dordrecht (1990)

Schrader, P., Schmandt, C., Marzi, S.: Mode I creep fracture of rubber-like adhesive joints at constant crack driving force. Int. J. Adhes. Adhes. 113, 103079 (2022)

Škec, L., Alfano, G., Jelenić, G.: Complete analytical solutions for double cantilever beam specimens with bi-linear quasi-brittle and brittle interfaces. Int. J. Fract. 215, 1–37 (2019)

Torop, V., Orynyak, I.: Determination of the J-integral on double cantilever beam specimens at crack start and arrest. Sov. Mater. Sci. 22(2), 144–150 (1986)

Yu, M., Liu, B., Sun, J., Feng, W., Wang, F.: Study on improved nonlinear viscoelastic-plastic creep model based on the Nishihara model. Geotech. Geolog. Eng. 38, 3203–3214 (2019)

Zhang, J., Li, B., Zhang, C., Li, P.: Nonlinear viscoelastic–plastic creep model based on coal multistage creep tests and experimental validation. Energies 12(18), 3468 (2019)

Zhao, W.: Mode I Delamination fracture characterization of polymeric composites under elevated temperature (2011)

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Márquez Costa, J.P., Jumel, J., Badulescu, C. et al. Self-similar crack propagation along a viscoelastic interface in a double-cantilever beam test. Mech Time-Depend Mater (2022). https://doi.org/10.1007/s11043-022-09559-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11043-022-09559-8