Abstract

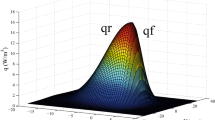

To determine the parameters of the double-ellipsoidal heat source model (DEHSM) in welding simulations, a technique is developed to extract the parameters of weld pool shape from the simulation results. The technique is developed based on the knowledge of the isoparametric transformation and computer graphics, and its validity is verified by a graphic comparison. It is shown that the technique can effectively extract and reflect the shape of weld pools without interrupting the solution process of the DEHSM parameters. Second, using this technique in conjunction with the optimization method, an approach is proposed to determine the DEHSM parameters. Next, using the proposed method, the DEHSM parameters associated with four different welding conditions are determined. Finally, with these parameters, their corresponding weld widths and penetrations are compared with the measured ones. The results demonstrate that the proposed method can efficiently determine the DEHSM parameters with a relatively high accuracy.

Similar content being viewed by others

References

Goldak J, Chakravarti A, Bibby M (1984) A new finite element model for welding heat sources. Metall Trans B 15(2):299–305. https://doi.org/10.1007/BF02667333

Mondal AK, Biswas P, Bag S (2017) Prediction of welding sequence induced thermal history and residual stresses and their effect on welding distortion. Weld World 61(4):711–721. https://doi.org/10.1007/s40194-017-0468-3

Gu Y, Li YD, Qiang B, Boko-Haya DD (2017) Welding distortion prediction based on local displacement in the weld plastic zone. Weld World 61(2):333–340. https://doi.org/10.1007/s40194-016-0418-5

Guo XK, Li PL, Chen JM, Lu H (2009) Inversing parameter values of double ellipsoid source model during multiple wires submerged arc welding by using Step Acceleration Method. Trans China Weld Inst 30(2):53–56+155. https://doi.org/10.3321/j.issn:0253-360X.2009.02.014

Guo XK (2009) Inversing parameter values of double ellipsoid source model during multiple wires submerged arc welding by using Pattern Search Method. Dissertation, Shanghai Jiaotong University

Gery D, Long H, Maropoulos P (2005) Effects of welding speed, energy input and heat source distribution on temperature variations in butt joint welding. J Mater Process Technol 167(2–3):393–401. https://doi.org/10.1016/j.jmatprotec.2005.06.018

Li PL, Lu H (2011) Influence of multi-wire submerged arc welding process on heat source parameters. Trans China Weld Inst 32(6):13–16+20

Price JWH, Paradowska A, Joshi S, Finlayson T (2006) Residual stresses measurement by neutron diffraction and theoretical estimation in a single weld bead. Int J Press Vessel Pip 83(5):381–387. https://doi.org/10.1016/j.ijpvp.2006.02.015

Joshi S, Hildebrand J, Aloraier AS, Rabczuk T (2013) Characterization of material properties and heat source parameters in welding simulation of two overlapping beads on a substrate plate. Comput Mater Sci 69:559–565. https://doi.org/10.1016/j.commatsci.2012.11.029

Azar AS, As SK, Akselsen OM (2012) Determination of welding heat source parameters from actual bead shape. Comput Mater Sci 54:176–182. https://doi.org/10.1016/j.commatsci.2011.10.025

Li PL, Lu H (2011) Sensitivity analysis and prediction of double ellipsoid heat source parameters. Trans China Weld Inst 31(11):89–91+95+117

Guo GF, Wang Y, Han T, Jia PY (2013) Application of double-ellipsoid heat source parameters adjustment on prediction of pool size of in-service welding. Pressure Vessel Technol 30(1):15–19+39. https://doi.org/10.3969/j.issn.1001-4837.2013.01.002

Wang Y, Zhao HY, Wu S, Zhang JQ (2003) Shape parameter determination of double ellipsoid heat source model in numerical simulation of high energy beam welding. Trans China Weld Inst 24(2):67–70+1. https://doi.org/10.3321/j.issn:0253-360X.2003.02.018

Sharma A, Chaudhary AK (2009) Estimation of heat source model parameters for twin-wire submerged arc welding. Int J Adv Manuf Technol 45(11–12):1096–1103. https://doi.org/10.1007/s00170-009-2046-3

Wahab MA, Painter MJ, Davies MH (1998) The prediction of the temperature distribution and weld pool geometry in the gas metal arc welding process. J Mater Process Technol 77(1–3):233–239. https://doi.org/10.1016/S0924-0136(97)00422-6

Rosenthal D (1941) Mathematical theory of heat distribution during welding and cutting. Weld J 20(5):220–234

Rouquette S, Guo J, Le Masson P (2007) Estimation of the parameters of a Gaussian heat source by the Levenberg–Marquardt method: application to the electron beam welding. Int J Therm Sci 46(2):128–138. https://doi.org/10.1016/j.ijthermalsci.2006.04.015

Jia X, Xu J, Liu Z, Huang S, Fan Y, Sun Z (2014) A new method to estimate heat source parameters in gas metal arc welding simulation process. Fusion Eng Des 89(1):40–48. https://doi.org/10.1016/j.fusengdes.2013.11.006

Li PL, Lu H (2012) Hybrid heat source model designing and parameter prediction on tandem submerged arc welding. Int J Adv Manuf Technol 62(5–8):577–585. https://doi.org/10.1007/s00170-011-3829-x

Deng D, Murakawa H (2006) Numerical simulation of temperature field and residual stress in multi-pass welds in stainless steel pipe and comparison with experimental measurements. Comput Mater Sci 37(3):269–277. https://doi.org/10.1016/j.commatsci.2005.07.007

Brickstad B, Josefson BL (1998) A parametric study of residual stresses in multi-pass butt-welded stainless steel pipes. Int J Press Vessel Pip 75(1):11–25. https://doi.org/10.1016/s0308-0161(97)00117-8

Zhang X, Xiong J, Hao X, Lai R (2008) Topological optimization of slide of machining center based on ANSYS. Manuf Technol Mach Tool (6):67–70. https://doi.org/10.3969/j.issn.1005-2402.2008.06.020

Yoo HH, Cho JE, Chung J (2006) Modal analysis and shape optimization of rotating cantilever beams. J Sound Vib 290(1–2):223–241. https://doi.org/10.1016/j.jsv.2005.03.014

Yuan B, Ren FM, Zhong GQ, Zhou J (2011) Optimal design of spatial grid structure using group search optimization. Adv Mater Res 243-249(2011):6044–6048. https://doi.org/10.4028/www.scientific.net/amr.243-249.6044

Radaj D (2012) Heat effects of welding: temperature field, residual stress, distortion. Springer Science & Business Media

Beck A (2017) First-order methods in optimization, vol 25. SIAM

Li PL (2012) Study on the simulation of multi-wire submerged arc welding heat source model and appearance of weld. Dissertation, Shanghai Jiaotong University

Funding

The authors gratefully acknowledge the support provided by the National Natural Science Foundation of China (Grant Nos. 51708467 and 51378430) and the Doctoral Found of Southwest University of Science and Technology (Grant No. 16zx7134).

Author information

Authors and Affiliations

Corresponding author

Additional information

Recommended for publication by Commission XV - Design, Analysis, and Fabrication of Welded Structures

Rights and permissions

About this article

Cite this article

Gu, Y., Li, Y.D., Yong, Y. et al. Determination of parameters of double-ellipsoidal heat source model based on optimization method. Weld World 63, 365–376 (2019). https://doi.org/10.1007/s40194-018-00678-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40194-018-00678-w