Abstract

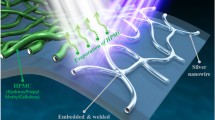

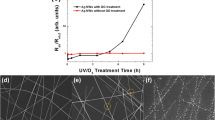

Graphene oxide and silver nanowires were bar coated onto PET substrates and then welded using an ultraviolet (UV)-assisted flash light irradiation process to achieve both high electrical conductivity and low haze. The irradiation process connected adjacent silver nanowires by welding, while simultaneously reducing the graphene oxide to graphene. This process was performed using a custom UV-assisted flash light welding system at room temperature under ambient conditions and was extremely rapid, with processing time of several milliseconds. The effects of varying the weight fractions of the silver nanowires and graphene oxide and of varying the UV-assisted flash light welding conditions (light energy and pulse duration) were investigated. The surface morphologies of the welded silver nanowire/graphene films were analyzed using scanning electron microscopy. Optical characterizations, including transmittance and haze measurements, were also conducted using a spectrophotometer. To test their resistance to oxidation, the welded silver nanowire/graphene films were subjected to high temperature in a furnace (100 °C), and their sheet resistances were measured every hour. The flash light welding process was found to yield silver nanowire/graphene films with high oxidation resistance, high conductivity (14.35 Ω·sq–1), high transmittance (93.46%), and low haze (0.9%). This material showed uniform temperature distribution when applied as a resistive heating film.

Similar content being viewed by others

References

Arledge, J. K.; Swirbel, T. J. Flexible liquid crystal display with integrated driver circuit and display electrodes formed on opposite sides of folded substrate. U.S. Patents 5,436,744, July 25, 1995.

Bae, S.; Kim, H.; Lee, Y.; Xu, X. F.; Park, J.-S.; Zheng, Y.; Balakrishnan, J.; Lei, T.; Kim, H. R.; Song, Y. I. et al. Roll-to-roll production of 30-inch graphene films for transparent electrodes. Nat. Nanotechnol. 2010, 5, 574–578.

Wang, X.; Zhi, L. J.; Müllen, K. Transparent, conductive graphene electrodes for dye-sensitized solar cells. Nano Lett. 2008, 8, 323–327.

Choi, K. H.; Kim, J. Y.; Lee, Y. S.; Kim, H. J. ITO/Ag/ITO multilayer films for the application of a very low resistance transparent electrode. Thin Solid Films 1999, 341, 152–155.

Lei, B.-X.; Liao, J.-Y.; Zhang, R.; Wang, J.; Su, C.-Y.; Kuang, D.-B. Ordered crystalline TiO2 nanotube arrays on transparent FTO glass for efficient dye-sensitized solar cells. J. Phys. Chem. C 2010, 114, 15228–15233.

Pang, S. P.; Hernandez, Y.; Feng, X. L.; Müllen, K. Graphene as transparent electrode material for organic electronics. Adv. Mater. 2011, 23, 2779–2795.

Hu, L. B.; Kim, H. S.; Lee, J.-Y.; Peumans, P.; Cui, Y. Scalable coating and properties of transparent, flexible, silver nanowire electrodes. ACS Nano 2010, 4, 2955–2963.

Hecht, D. S.; Heintz, A. M.; Lee, R.; Hu, L. B.; Moore, B.; Cucksey, C.; Risser, S. High conductivity transparent carbon nanotube films deposited from superacid. Nanotechnology 2011, 22, 075201.

Lee, J.-Y.; Connor, S. T.; Cui, Y.; Peumans, P. Solutionprocessed metal nanowire mesh transparent electrodes. Nano Lett. 2008, 8, 689–692.

Kaempgen, M.; Duesberg, G.; Roth, S. Transparent carbon nanotube coatings. Appl. Surf. Sci. 2005, 252, 425–429.

Tokuno, T.; Nogi, M.; Karakawa, M.; Jiu, J. T.; Nge, T. T.; Aso, Y.; Suganuma, K. Fabrication of silver nanowire transparent electrodes at room temperature. Nano Res. 2011, 4, 1215–1222.

Liu, C.-H.; Yu, X. Silver nanowire-based transparent, flexible, and conductive thin film. Nanoscale Res. Lett. 2011, 6, 75.

Garnett, E. C.; Cai, W. S.; Cha, J. J.; Mahmood, F.; Connor, S. T.; Christoforo, M. G.; Cui, Y.; McGehee, M. D.; Brongersma, M. L. Self-limited plasmonic welding of silver nanowire junctions. Nat. Mater. 2012, 11, 241–249.

Voigt, M. M.; Mackenzie, R. C. I.; King, S. P.; Yau, C. P.; Atienzar, P.; Dane, J.; Keivanidis, P. E.; Zadrazil, I.; Bradley, D. D. C.; Nelson, J. Gravure printing inverted organic solar cells: The influence of ink properties on film quality and device performance. Solar Energy Mater. Solar Cells 2012, 105, 77–85.

Liu, Y.; Zhang, J. M.; Gao, H.; Wang, Y.; Liu, Q. X.; Huang, S. Y.; Guo, C. F.; Ren, Z. F. Capillary-force-induced cold welding in silver-nanowire-based flexible transparent electrodes. Nano Lett. 2017, 17, 1090–1096.

Yoon, S. S.; Khang, D. Y. Room-temperature chemical welding and sintering of metallic nanostructures by capillary condensation. Nano Lett. 2016, 16, 3550–3556.

Ahn, J.; Seo, J. W.; Kim, J. Y.; Lee, J.; Cho, C.; Kang, J.; Choi, S. Y.; Lee, J. Y. Self-supplied nano-fusing and transferring metal nanostructures via surface oxide reduction. ACS Appl. Mater. Interfaces 2016, 8, 1112–1119.

Choi. S.; Park. J.; Hyun. W.; Kim. J.; Kim, J.; Lee, Y. B.; Song, C.; Hwang, H. J.; Kim, J. H.; Hyeon, T. et al. Stretchable heater using ligand-exchanged silver nanowire nanocomposite for wearable articular thermotherapy. ACS Nano 2015, 9, 6626–6633.

Spechler, J. A.; Arnold, C. B. Direct-write pulsed laser processed silver nanowire networks for transparent conducting electrodes. Appl. Phys. A 2012, 108, 25–28.

Song, T.-B.; Chen, Y.; Chung, C.-H.; Yang, Y.; Bob, B.; Duan, H.-S.; Li, G.; Tu, K.-N.; Huang, Y.; Yang, Y. Nanoscale joule heating and electromigration enhanced ripening of silver nanowire contacts. ACS Nano 2014, 8, 2804–2811.

Kim, H.-S.; Dhage, S. R.; Shim, D.-E.; Hahn, H. T. Intense pulsed light sintering of copper nanoink for printed electronics. Appl. Phys. A 2009, 97, 791–798.

Chung, W.-H.; Hwang, H.-J.; Lee, S.-H.; Kim, H.-S. In situ monitoring of a flash light sintering process using silver nano-ink for producing flexible electronics. Nanotechnology 2013, 24, 035202.

Chung, W.-H.; Hwang, H.-J.; Kim, H.-S. Flash light sintered copper precursor/nanoparticle pattern with high electrical conductivity and low porosity for printed electronics. Thin Solid Films 2015, 580, 61–70.

Park, S.-H.; Jang, S.; Lee, D.-J.; Oh, J.; Kim, H.-S. Two-step flash light sintering process for crack-free inkjet-printed Ag films. J. Micromech. Microeng. 2013, 23, 015013.

Chung, W.-H.; Kim, S.-H.; Kim, H.-S. Welding of silver nanowire networks via flash white light and UV-C irradiation for highly conductive and reliable transparent electrodes. Sci. Rep. 2016, 6, 320086.

Akhavan, O.; Abdolahad, M.; Esfandiar, A.; Mohatashamifar, M. Photodegradation of graphene oxide sheets by TiO2 nanoparticles after a photocatalytic reduction. J. Phys. Chem. C 2010, 114, 12955–12959.

Williams, G.; Seger, B.; Kamat, P. V. TiO2-graphene nanocomposites. UV-assisted photocatalytic reduction of graphene oxide. ACS Nano 2008, 2, 1487–1491.

Putri, L. K.; Ong, W. J.; Chang, W. S.; Chai, S. P. Enhancement in the photocatalytic activity of carbon nitride through hybridization with light-sensitive AgCl for carbon dioxide reduction to methane. Catal. Sci. Technol. 2016, 6, 744–754.

Yun, Y. S.; Kim, D. H.; Kim, B.; Park, H. H.; Jin, H. J. Transparent conducting films based on graphene oxide/silver nanowire hybrids with high flexibility. Synth. Metal. 2012, 162, 1364–1368.

Pasricha, R.; Gupta, S.; Srivastava, A. K. A facile and novel synthesis of Ag-graphene-based nanocomposites. Small 2009, 5, 2253–2259.

Nguyen, V. H.; Kim, B. K.; Jo, Y. L.; Shim, J. J. Preparation and antibacterial activity of silver nanoparticles-decorated graphene composites. J. Supercrit. Fluids 2012, 72, 28–35.

Tien, H. W.; Hsiao, S. T.; Liao, W. H.; Yu, Y. H.; Lin, F. C.; Wang, Y. S.; Li, S. M.; Ma, C. C. M. Using self-assembly to prepare a graphene-silver nanowire hybrid film that is transparent and electrically conductive. Carbon 2013, 58, 198–207.

Bashouti, M. Y.; Resch, S.; Ristein, J.; Macković, M.; Spiecker, E.; Waldvogel, S. R.; Christiansen, S. H. functionalization of silver nanowires surface using Ag–C bonds in a sequential reductive method. ACS Appl. Mater. Interfaces 2015, 7, 21657–21661.

Sahu, S. R.; Devi, M. M.; Mukherjee, P.; Sen, P.; Biswas, K. Optical property characterization of novel graphene-X (X=Ag, Au and Cu) nanoparticle hybrids. J. Nanomater. 2013, 2013, 232409.

Seo, T. H.; Kim, B. K.; Shin, G.; Lee, C.; Kim, M. J.; Kim, H.; Suh, E. K. Graphene-silver nanowire hybrid structure as a transparent and current spreading electrode in ultraviolet light emitting diodes. Appl. Phys. Lett. 2013, 103, 051105.

Li, J.; Liu, C. Y. Ag/graphene heterostructures: Synthesis, characterization and optical properties. Eur. J. Inorgan. Chem. 2010, 2010, 1244–1248.

Joo, S. J.; Hwang, H. J.; Kim, H. S. Highly conductive copper nano/microparticles ink via flash light sintering for printed electronics. Nanotechnology 2014, 25, 265601.

Park, S. H.; Chung, W. H.; Kim, H. S. Temperature changes of copper nanoparticle ink during flash light sintering. J. Mater. Process. Technol. 2014, 214, 2730–2738.

Babar, S.; Weaver, J. Optical constants of Cu, Ag, and Au revisited. Appl. Opt. 2015, 54, 477–481.

Weber, J. W.; Calado, V. E.; Van de Sanden, M. C. M. Optical constants of graphene measured by spectroscopic ellipsometry. Appl. Phys. Lett. 2010, 97, 091904.

van der Vegt, A. K.; Govaert, L. E. Polymeren van keten tot kunststof; VSSD: Nederlands, 2005.

Seol, J. H.; Jo, I.; Moore, A. L.; Lindsay, L.; Aitken, Z. H.; Pettes, M. T.; Li, X. S.; Yao, Z.; Huang, R.; Broido, D. et al. Two-dimensional phonon transport in supported graphene. Science 2010, 328, 213–216.

Acknowledgements

This work was supported by the Nano-Convergence Foundation (www.nanotech2020.org) funded by the Ministry of Science, ICT, and Future Planning (MSIP, Republic of Korea) and the Ministry of Trade, Industry, and Energy (MOTIE, Republic of Korea) (No. R201502510). Also, this work was supported by the National Research Foundation of Korea (NRF), funded by the Ministry of Education (Nos. 2015R1D1A1A09058418 and 2012R1A6A1029029). This research was supported by the Commercializations Promotion Agency for R&D Outcomes (COMPA) funded by the Ministry of Science, ICT and Future Planning (MISP) (No. 2016K000131).

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

12274_2017_1837_MOESM1_ESM.pdf

UV-assisted flash light welding process to fabricate silver nanowire/graphene on a PET substrate for transparent electrodes

Rights and permissions

About this article

Cite this article

Chung, WH., Park, SH., Joo, SJ. et al. UV-assisted flash light welding process to fabricate silver nanowire/graphene on a PET substrate for transparent electrodes. Nano Res. 11, 2190–2203 (2018). https://doi.org/10.1007/s12274-017-1837-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12274-017-1837-3