Abstract

The effects of pH and lanthanide (La, Y) concentration were investigated on the release of iron from Ca-bentonite crystal structure. XRF results revealed that during the Ca–H cation exchange procedure iron loss was not observed. In the case of lanthanide modifications, the pH has low influence, meanwhile the concentration of lanthanide has high influence on iron loss. Thus, high amount of trivalent lanthanides cause the structural iron release.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

Introduction

Bentonite is favored because it is low-cost. It has many good properties [1,2,3] e.g. high exchange capacity thanks to the high amount (> 50 mass%) of montmorillonite content. The montmorillonite is a layer silicate clay mineral. This mineral has permanent negative charge because of isomorphic substitution which means that the cations (e.g. Al3+ ion) in the layer may be exchanged by smaller charged cations e.g. Mg2+ or Fe2+ ions [4]. The ion exchange capacity depends on the number of these substitutions. The higher the clay mineral’s ion exchange capacity, the more it affects its physical properties by changing its water-absorbing capacity, and thus, its technological behavior [5]. The negative layer charge of the crystal lattice can be neutralized by cations attracted to the interlayer space. This interlayer space can call as nano laboratory’ where cation exchange takes place which may modify the properties of the bentonites. Interlayer cations may be exchanged to lanthanide cations in the so-called nano laboratory. Lanthanide cations are used as model ions during the study of interactions between soil and transuranium ions. These radionuclides are produced during the fission of 235U in nuclear power plants [6].

Bentonite is considered as candidate engineer barrier material—among others—for the safe disposal of high-level radioactive waste [7]. The structural analyses of bentonite have been investigated under different conditions to figure out the stability of the structure. The main points of these studies have been to characterize the clays before and after the modifying experiments and to determine the possible differences in nature or structural stability [8,9,10,11]. The important aspect of the interactions between lanthanides (Lns) and clays in the environment is the storage or disposal of nuclear waste. The studies on Ln-clay interactions may eminently be useful in evaluating the adequacy of proposed materials for the engineer barrier of nuclear waste.

Research papers talk about the dissolution of bentonite where the main point of the research is to modify the properties of the bentonite for different reasons [12,13,14,15,16,17,18,19,20,21,22,23,24,25,26,27,28,29,30,31]. The treatment of the bentonite happens usually with inorganic acids (HCl, H2SO4, HNO3) to replace mainly divalent ions (Ca2+) to monovalent ion (H+) and to leach out Fe2+/Fe3+, Mg2+ and Al3+ ions, thus modifying the smectite layers and increase the specific surface area, and the porosity. The authors usually use inorganic acids in wide range of concentration (0.25–6 mol dm−3) and the treatment time is usually between 1 and 36 h at different temperature (from 25 °C, up to 100 °C). The results revealed that the dissolution of octahedral sheet is faster than tetrahedral sheets [23, 24]. Kooli and Yan [21, 22] observed about 5% of Mg2+, Fe3+ and Al3+ reduction. Upon acid treatments, protons enter the mineral layer and harms the structural OH-groups. Krupskaya et al. [28] treated bentonites with HCl and HNO3 solutions. The study concluded an interlayer modification which occurs even at early stages of the treatment. Further treatment leads to further modification of the montmorillonite structure accompanied by intense leaching of cations from the octahedral positions into interlayer space. These transformations changes layer charge and CEC.

The aim of this work was to prepare La, and Y exchanged bentonites and to characterize the possible changes in the structure of bentonite. In our previous study [32] La ions showed extreme values of sorption while iron quantity of La bentonite was less than that of initial Ca-bentonite. The conclusion was that lanthanum ions can somehow supersede iron from the octahedral positions of crystal lattice. We assume that the departure of positively charged iron ions from the lattice increases the negative layer charge and the cation exchange capacity. This can motivate the enhance sorption of lanthanum.

All the lanthanides releases iron, less than La, and Y. This observation is surprising in the scientific word, no similar scientific result have found about the releases of the structural iron during Ln modification of bentonite. Therefore, in this work the change of the composition in the Ca bentonite was studied depending on the pH during the Ca–H, Ca–Y and Ca–La cation exchange procedure. The change in the chemical composition (mainly the concentration of Y3+, La3+, Ca2+, Fe3+ ions) in the bentonite was analyzed by X-ray fluorescence spectrometry.

Experimental

The starting material Ca-montmorillonite was collected from Istenmezeje, Hungary. Elemental analysis of the original Ca-bentonite resulted in the following composition: 73.29% SiO2, 18.71% Al2O3, 2.98% Fe-oxide, 1.54% CaO and 3.48% MgO. The mineral composition was determined by means of X-ray powder diffraction (XRD) analysis using a Philips PW1710 diffractometer (Philips, (today PANalytical B.V.) De Schakel 18 5651 GH Eindhoven, Netherland), which is operating at 30 mA and 40 kV using Cu Kα radiation source and a graphite monochromator. The scanning rate was 2°2θ/min. The mineral composition was calculated on the basis of the relative intensities of the reflections characteristic of the minerals, applying the literature or experimental corundum factors on minerals [33,34,35,36]. The mineral composition was as it follows: 72% montmorillonite, 6 m/m% cristobalite, opal CT, 3 m/m% plagioclase, 4 m/m% mica, 2 m/m% K-feldspar, 2 m/m% quartz, 2 m/m% kaolinite, and 2 m/m% calcite. The basal space d(001) of montmorillonite was 1.465 nm showing the dioctahedral character of the smectites. The CEC, as determined by the ammonium acetate method [37], was 2.7 × 10−4 mol g−1 for trivalent cations.

Complexometric titration [32, 38] was used to determine the concentration of Ln(ClO4)3 solutions and energy dispersive X-ray fluorescence spectroscopy (XRF) was used to follow the chemical changes (mainly the concentration of Y3+, La3+, Ca2+, Fe3+ ions) in bentonite [39, 40]. Instrumental parameters were: Si(Li) detector with 20 mm2 surface and 3.5 mm evaporated layer (Atomki, Debrecen, Hungary),Canberra DSA 1000 digital spectrum analyzer (Camberra Industries, Meriden, CT 06450, USA), Canberra Genie 2000 3.0 spectroscopy software (Camberra Industries, Meriden, CT 06450, USA).

The Kα-lines of the lanthanide elements was excited with 185 MBq 241Am radioactive source. In addition to the lanthanides, samples were also analyzed for iron, and calcium using a tungsten X-ray tube (type: S6000, Oxford Instruments, Scotts Valley, CA 95066, USA), operating at 60 kV and 1 mA.

The structural modifying effect of lanthanum, and yttrium ions were investigated depending on the pH during cation exchange of Ca-bentonite procedure without and with Ln3+ ions. Therefore, the behavior of Ca bentonite was investigated in acidic medium without Ln3+ ions, i.e., Ca–H cation exchange procedure was carried out by suspending 200 mg of Ca-bentonite in 20 cm3 HClO4 solution at pH 2.8–5.2, and at 25 °C. The suspension was shaken for 2 h, filtered (0.45 µm, nylon, Labex Ltd. Filter-Bio), washed by tridistilled water and then air-dried. Equilibrium is set in half an hour based on our previous experiments [41].

The combined effect of pH and lanthanide concentration on the bentonite structure was studied by the addition of different concentrated lanthanide perchlorate solutions (1 × 10−4–2 × 10−1 mol dm−3), at pH 3.5–5.5. However, in the case of pH < 3, the structure of bentonite can be destroyed. Thus, the ion exchange experiments were carried out in the pH range of 3.5–5.5. In a series of experiments, either the pH or the lanthanide concentration were changed. Different pH was adjusted by 1 × 10−4 mol dm−3 Hexamethylenetetramine, and by 1 × 10−4 mol dm−3 HClO4.

The Ln-bentonites were produced by suspending 200 mg of Ca-bentonite and 20 cm3 Ln perchlorate solution [32]. The ion exchange procedure was carried out only one time, stirring time was 2 h, and different pH and initial concentration of Ln(ClO4)3 were used.

Results and discussion

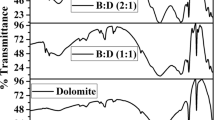

Ca–H ion exchange

Based on our previous experience [32] during Ca–Ln cation exchange procedure structural iron loss was detected. Thereupon, the influence of the pH of the iron reduction was investigated in this study. In order to investigate the structural modifying effect of lanthanide ions, the effect of pH on cation exchange procedure had to be known. Therefore, the Ca–H cation exchange procedure was first examined in acidic medium without Ln3+ ions and then during Ca–Ln cation exchange procedure was examined with La3+ and Y3+ ions.

Figure 1 shows the concentration change of Ca2+ ions in mol g−1 as a function of pH of initial HClO4 solutions. As the concentration of hydrogen ion increases, more and more calcium ions are exchanged, thus, calcium-hydrogen bentonite is formed.

Figure 2 shows the amount of iron ion on Ca bentonite after treatment of HClO4 solution of solid phase at different pH. Comparing the results with the Fe content of the starting Ca-bentonite (5.2 × 10−4 mol g−1), it can be concluded that the Fe content of bentonite does not change within acceptable error limits (< 5%) after the treatment with HClO4 solution. That is, since structural iron is not suppressed by the acidic effect, so lanthanide ions are responsible for the decrease of iron concentration.

Ca–La ion exchange

Therefore, in a similar experiment, different pH values and different initial concentrations of La3+ ion were used to follow the structural change during Ca–La cation exchange procedure. The concentrations of these mentioned ions are shown in Figs. 3, 4 and 5 at three different initial concentrations of La(ClO4)3 after the ion exchange procedure at different pHs.

Figure 3 shows that the calcium ion content of each sample is significantly reduced. The reduction is inversely proportional to the initial lanthanum ion concentration. Cca. 90% of Ca2+ ions are exchanged to La3+ ions.

Figure 4 shows that the exchange of La3+ ions are independent of pH, but the effect of the lanthanum concentration is robust.

The change in structural iron content (Fig. 5) is not influenced by the pH, only by the lanthanum concentration. The released iron content is about 15–25% compared to Ca-bentonite. So, the structural iron is suppressed by the trivalent lanthanum. This requires at least 5 × 10−3 mol dm−3 lanthanum ion concentration.

Ca–Y ion exchange

Similar experiment was performed with Y3+ ion exchange. The experiments were also carried out in the pH range of 3.5–5.5, but the concentration of yttrium ion was further increased. The results can be found in Figs. 6, 7 and 8. Similarly to lanthanum ion, the ion exchange between Ca2+–Y3+ ions is not affected by the pH, but with as the concentration of Y3+ ions increases more and more Y3+ ions are sorbed on the bentonite (Fig. 7).

At the same time, with increasing concentration, more and more calcium ions are exchanged, using 0.2 mol dm−3 Y(ClO4)3 solution, almost 100% of the calcium ion is dissolved (Fig. 6).

Structural iron content (Fig. 8) shows that the pH has a slightly effect, but the concentration of yttrium ion has a significant effect. The released iron content is about 22–33% compared to Ca-bentonite. The higher release of iron content in case of yttrium ion compare to lanthanum ion is because the higher yttrium ion concentration during the acidic treatment.

Thus, in the case of both ions (lanthanum and yttrium ion), it can be concluded that the cation exchange of Ca–Ln is essentially independent of pH and depends on the concentration of Ln ion. Ln3+ ions at high concentrations almost exchange interlayer Ca2+ cations, displacing 30% of the structural iron from the octahedral layer. Some of the leaving iron ions enter the interlayer space [42], and the other part precipitates in the form of FeO–OH which is deposited on the wall of the laboratory vessels during the exchange procedure [32]. Therefore, Ln3+ ion is responsible for the effect, since there was no similar result during Ca–H cation exchange.

Conclusions

The aim of this study was to investigate the cause of the structural iron decrease during Ca–La, and Y cation exchange procedure. Therefore, the combined effect of pH and concentration on the bentonite structure was studied during Ca–H, Ca–Y, and Ca–La cation exchange procedure.

This study has proved that during Ca–Ln-cation exchange procedure (in case of Y, and La) iron released from octahedral position of montmorillonite which is not due to the pH but La, and Y concentration.

This study strongly confirms our previous study. However, further studies are needed to be aware of the mechanisms between the Ln and the structural composition of the bentonite. Kinetic studies planned to see the structural change by the time at different temperatures.

References

Allo WA, Murray HH (2004) Mineralogy, chemistry and potential applications of a white bentonite in Sam Juan Province, Argentina. Appl Clay Sci 25:237–243

Hanuláková D, Zeman J, Vašíček R, Přikryl R, Kuchovský T (2013) Determination of pore water composition during long term interaction of bentonite substrates with water media: comparative study. Appl Clay Sci 80:69–75

Sidhoum DA, Socías-Viciana MM, Ureña-Amate MD, Derdour A, Gonzalez-Pradas E, Debbagh-Boutarbough N (2013) Removal of paraquat form water by an Algerian bentonite. Appl Clay Sci 83:441–448

Kaufhold S, Dohrmanna R (2013) The variable charge of dioctahedral smectites. J Colloid Interface Sci 390:225–233

Schoonheydt RA, Johnston CT (2011) The surface properties of clay minerals. EMU Notes Mineral 11(10):337–373

Lesnov FP (2010) Chapter 6: Indicator properties of rare earth elements and their role in studies of genesis of rocks and minerals from mafic-ultramafic complexes. In: Taylor and Francis Group (ed) Rare earth elements in ultramafic and mafic rocks and their minerals: main types of rocks. Rock-forming minerals. CRC Press, New York, pp 513–532

S Kränbränslehantering AB (2010) Spent nuclear fuel for disposal in the KBS-3 repository. Technical report (TR-10-13)

Aref A, Hongping H, Chen X, Jianxi Z, Wei X, Runliang Z, Hailong W (2019) Understanding the role of natural clay minerals as effective adsorbents and alternative source of rare earth elements: adsorption operative parameters. Hydrometallurgy 185:149–161

Guomin Y, Ivars N, Luis M, Susan W (2016) Density functional theory of electrolyte solutions in slit-like nanopores II. Applications to forces and ion exchange. Appl Clay Sci 132–133:561–570

Chen Y, Zhu C, Duan H, Ye WM, Wu D (2012) Adsorption of La(III) onto GMZ bentonite: effct of contact time, bentonite content, pH value and ionic strength. J Radioanal Nucl Chem 292(3):1339–1347

Gladysz-Plaska A, Majdan M, Grabias E (2014) Adsorption of La, Eu and Lu on raw and modified red clay. J Radioanal Nucl Chem 301(1):33–40

Krupskaya V, Novikova L, Tyupina E, Belousov P, Dorzhieva O, Zakusin S, Kim K, Roessner F, Badetti E, Brunelli A, Belchinskaya L (2019) The influence of acid modification on the structure of montmorillonites and surface properties of bentonites. Appl Clay Sci 172:1–10

Komadel P (2016) Acid activated clays: materials in continuous demand. Appl Clay Sci 131:84–99

Luca V, MacLachlan DJ (1992) Site occupancy in nontronite studied by acid dissolution and Mössbauer-spectroscopy. Clay Clay Miner 40:1–7

Vicente MA, López-González JD, Baňares-Muňoz MA (1995) Influence of the free silica generated during acid activation of a sepiolite on absorbent and textural properties of the resulting solids. J Mater Chem 5:127–132

Komadel P, Modejová J, Janek M, Gates WP, Kirkpatrick RJ, Stuki JW (1996) Dissolution of hectorite in inorganic acids. Clay Clay Miner 44:228–236

Madejová J, Bujdák J, Janek M, Komadel P (1998) Comparative FT-IR study of structural modification during acid treatment of dioctahedral smectites and hectorite. Spectrochim Acta A 54:397–1406

Madejová J, Pentrák M, Pálková H, Komadel P (2009) Near-infrared spectroscopy: a powerful tool in studies of acid-treated clay minerals. Vib Spectrosc 49:211–218

Steudel A, Batenburg LH, Fischer HR, Weidler PG, Emmerich K (2009) Alteration of non-swelling clay minerals and magadiite by acid activation. Appl Clay Sci 44:105–115

Novák I, Čičel B (1978) Dissolution of smectites in hydrochloric acid: II. Dissolution rate as a function of crystallochemical composition. Clay Clay Miner 26:341–344

Kooli F, Yan L (2013) Chemical and thermal properties of organoclays derived from highly stable bentonite in sulfuric acids. Appl Clay Sci 83–84:349–356

Kooli F, Yan L, Al-Faze R, Al Suhaimi A (2015) Removal enhancement of basic blue 41 by brick waste from an aqueous solution. Arab J Chem 8:333–342

Osthaus BB (1954) Chemical determination of tetrahedral ions in nontronite and montmorillonite. Clay Clay Miner 2:404–417

Osthaus BB (1956) Kinetic studies on montmorillonite and nontronite by the acid dissolution technique. Clay Clay Miner 4:301–321

Tomić ZP, Antić Mladenović SB, Babić BM, Poharc Logar VA, Đorđević AR, Cupać SB (2011) Modification of smectite structure by sulfuric acid and characteristics of the modified smectite. J Agric Sci 56(1):25–35

Timofeeva MN, Volcho KP, Mikhalchenko OS, Panchenko VN, Krupskaya VV, Tsybulya SV, Gil A, Vicente MA, Salakhutdinov NF (2015) Synthesis of octahydro-2H-chromen-4-ol from vanillin and isopulegol over acid modified montmorillonite clays: effect of acidity on the Prins cyclization. J Mol Cat Anal A Chem. https://doi.org/10.1016/j.molcata.2014.11.016

Timofeeva MN, Panchenko VN, Krupskaya VV, Gil A, Vicente MA (2016) Effect of nitric acid modification of montmorillonite clay on synthesis of solketal from glycerol and acetone. Catal Commun 1:1. https://doi.org/10.1016/j.catcom.2016.11.020

Krupskaya VV, Zakusin SV, Tyupina EA, Dorzhieva OV, Zhukhlistov AP, Belousov PE, Timofeeva MN (2017) Experimental study of montmorillonite structure and transformation of its properties under treatment with inorganic acid solutions. Miner 7:49

Bishop EM, Doug H, Glasser P, Briggs RB, Pentrak M, Stuki WJ, Boyanov IM, Kemner MK, Kovarik L (2019) Reactivity of redox cycled Fe-bearing subsurface sediments towards hexavalent chromium reduction. Geochim Cosm Acta 252:88–106

Schaeter MV, Gorski CA, Scherer MM (2011) Spectroscopic evidenc for interfacial Fe(II)–Fe(III) electron transfer in a clay mineral. Environ Sci Technol 45:540–545

Taylor RW, Shem S, Bleam WF, Tu S-I (2000) Chromate removal by dihionite-rediced clays: evidence from direct X-ray adsorption near edge spectroscopy (XANES) of chromate reduction at clay surfaces. Clay Clay Miner 48:648–654

Kovács EM, Baradács E, Kónya P, Kovács-Pálffy P, Harangi S, Kuzmann E, Kónya J, Nagy N (2017) Preparation and structure’s analyses of lanthanide (Ln)-exchanged bentonites. Colloid Surf A Physicochem Eng Asp 522:287–294

Klug HP, Alexander LE (1954) X-ray diffraction procedures polycrystalline and amorphous materials. Wiley, New York, p 716

Náray-Szabó I, Zsoldos L, Kálmán A (1965) Bevezetés a röntgendiffrakciós szerkezet kutatásba, jegyzet (in English: Introduction to the X-ray structural studies, lecture notes). Budapest, Magyar Kémikusok Egyesülete, p 305

Rischák G, Viczián I (1974) Agyagásványok bázisreflexióinak intenzitását meghatározó tényezők (in English: Mineralogical factors determining the intensity of basal reflections of clay minerals). —A Magyar Állami Földtani Intézet Évi Jelentése 1972-ről, Budapest, pp 229–256

Rischák G (1989) Kőzetek és talajok amorf fázisának közvetlen röntgendiffraktometrikus meghatározása (in English: Direct X-ray diffraction analysis of the amorphous phase in rocks and soils). A Magyar Állami Földtani Intézet Évi Jelentése 1987-ről, Budapest, pp 377–394

Richards LA (1957) Diagnosis and improvement of saline and alkaline. US Dept. Agr. Handbook 60

Barge A, Cravotto G, Gianolio E, Fedeli F (2006) How to determine free Gd and free ligand in solution of Gd chelates. A technical note. Contrast Med Mol Imaging 1:184–188

Gastuche MC, Toussaint F, Fripiat JJ, Touilleaux R, van Meersche M (1963) Study of intermediate stages in the kaoilin-metakaolin transformation. Clay Miner Bull 5:227–236

Romero-Dávila E, Miranda J, de Lucio OG, Pineda JC (2018) PIXE and XRF elemental analysis of breakfast cereals consumed in Mexico. J Radioannal Nucl Chem 318(2):887–895

Kónya K, Nagy NM, Szabó K (1988) The study of the ion exchange processes in system of zinc ions and calcium-bentonite, clay soil, humate and sand by radioisotopic labelling method. React Polym 7:203–209

Kuzmann E, Singh L, Garg V, Oliveira D, Kovács EM, Molnár Á, Homonnay Z, Kónya P, Nagy N, Kónya J (2016) Mössbauer study of the effect of rare earth substitution into montmorillonite. Hyperfine Interact 237(2):1–8

Acknowledgements

Open access funding provided by University of Debrecen (DE).This study was financed by the EU and co-financed by the European Regional Development (GINOP-2.3.2-15-2016-00008); the Hungarian National Research, Development, and Innovation Office (NKFIH K 120265).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Kovács, E.M., Kónya, J. & Nagy, N.M. Structural curiosities of lanthanide (Ln)-modified bentonites analyzed by radioanalytical methods. J Radioanal Nucl Chem 322, 1747–1754 (2019). https://doi.org/10.1007/s10967-019-06765-6

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10967-019-06765-6