Abstract

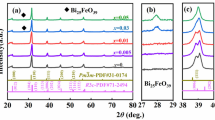

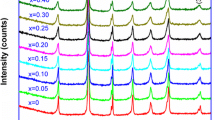

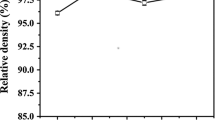

This work focuses on the effects of Bi compensation on the phase structure, microstructure, ferroelectric, and piezoelectric performances of new 0.69Bi1 + xFeO3-0.31BaTiO3 (x, 0–0.08) piezoceramics fabricated by traditional sintering techniques. X-ray diffraction (XRD) results indicated that Bi compensation has slight influences on the phase structure and all the ceramics locate near the morphotropic phase boundary of rhombehedral–pseudocubic phase coexistence. The rhombehedral phase fraction of all the ceramics fluctuates slightly in the range of 41.7–49.1 %. X-ray photoelectron spectroscopy (XPS) results confirmed that Bi compensation favors the decrease in the percentage of oxygen vacancy in the ceramics. An appropriate content of Bi compensation facilitates the densification, grain growth as well as enhancement of piezoelectric property of the materials. In addition, Bi compensation makes the materials “soft” along with the lower EC compared with the no compensation ceramics. Significantly, the excellent piezoelectric performance (d33 = 207 pC/N) was achieved in the 0.69Bi1.04FeO3-0.31BaTiO3 ceramics, which is higher than the results obtained in the previously reported BiFeO3-BaTiO3-based ceramics. This work would trigger further study on the BiFeO3-BaTiO3-based piezoceramics for practical application.

Similar content being viewed by others

Data availability

The data and material will be provided under reasonable request.

References

T. Zheng, J. Wu, D. Xiao, J. Zhu, Prog. Mater Sci. 98, 552–624 (2018)

M.H. Lee, D.J. Kim, J.S. Park, S.W. Kim, T.K. Song, M.H. Kim, W.J. Kim, D. Do, I.K. Jeong, Adv. Mater. 27, 6976–6982 (2015)

S. Cheng, L. Zhao, B.P. Zhang, K.K. Wang, Ceram. Int. 45, 10438–10447 (2019)

D. Lin, Q. Zheng, Y. Li, Y. Wan, Q. Li, W. Zhou, J. Eur. Ceram. Soc. 33, 3023–3036 (2013)

H. Yang, C. Zhou, X. Liu, Q. Zhou, G. Chen, W. Li, H. Wang, J. Eur. Ceram. Soc. 33, 1177–1183 (2013)

C. Zhou, A. Feteira, X. Shan, H. Yang, Q. Zhou, J. Cheng, W. Li, H. Wang, Appl. Phys. Lett. 101, 032901 (2012)

S. Murakami, N.T.A.F. Ahmed, D. Wang, A. Feteira, D.C. Sinclair, I.M. Reaney, J. Eur. Ceram. Soc. 38, 4220–4231 (2018)

T. Zheng, J. Wu, J. Alloy. Compd. 676, 505–512 (2016)

S.O. Leontsev, R.E. Eitel, J. Am. Ceram. Soc. 92, 2957–2961 (2009)

J. Wei, D. Fu, J. Cheng, J. Chen, J. Mater. Sci. 52, 10726–10737 (2017)

Q. Li, J. Cheng, J. Chen, J. Mater. Sci. Mater. Electron. 28, 1370–1377 (2016)

L.F. Zhu, B.P. Zhang, J.Q. Duan, B.W. Xun, N. Wang, Y.C. Tang, G.L. Zhao, J. Eur. Ceram. Soc. 38, 3463–3471 (2018)

L.F. Zhu, B.P. Zhang, Z.C. Zhang, S. Li, L.J. Wang, L.J. Zheng, J. Mater. Sci.: Mater. Electron. 29, 2307–2315 (2018)

B.W. Xun, N. Wang, B.P. Zhang, X.Y. Chen, Y.Q. Zheng, W.S. Jin, R. Mao, K. Liang, Ceram. Int. 45, 24382–24391 (2019)

K. Tong, C. Zhou, Q. Li, J. Wang, L. Yang, J. Xu, G. Chen, C. Yuan, G. Rao, J. Eur. Ceram. Soc. 38, 1356–1366 (2018)

Y. Sun, H. Yang, S. Guan, Y. Cao, M. Jiang, X. Liu, Q. Chen, M. Li, J. Xu, J. Alloy. Compd. 819, 153058 (2020)

T. Zheng, Y. Ding, J. Wu, J. Mater. Sci. Mater. Electron. 28, 11534–11542 (2017)

Q. Li, J. Wei, T. Tu, J. Cheng, J. Chen, J. Am. Ceram. Soc. 100, 5573–5583 (2017)

J. Íñiguez, D. Vanderbilt, L. Bellaiche, Phys. Rev. B 67, 224107 (2003)

J.B. Neaton, C. Ederer, U.V. Waghmare, N.A. Spaldin, K.M. Rabe, Phys. Rev. B 71, 014113 (2005)

C. Zhou, H. Yang, Q. Zhou, G. Chen, W. Li, H. Wang, J. Mater. Sci. Mater. Electron. 24, 1685–1689 (2012)

Y.S. Sung, J.M. Kim, J.H. Cho, T.K. Song, M.H. Kim, T.G. Park, Appl. Phys. Lett. 98, 012902 (2011)

R. Zuo, S. Su, Y. Wu, J. Fu, M. Wang, L. Li, Mater. Chem. Phys. 110, 311–315 (2008)

J. Chen, J. Cheng, J. Alloy. Compd. 589, 115–119 (2014)

W. Yi, Z. Lu, X. Liu, D. Huang, Z. Jia, Z. Chen, X. Wang, H. Zhu, J. Mater. Sci. Mater. Electron. (2021). https://doi.org/10.1007/s10854-021-05490-9

L. Lutterotti, MAUD, Material Analysis Using Diffraction (2019). http://www.ing.unitn.it/~maud/index.html. Accessed 20 July 2019

Y. Wei, X. Wang, J. Zhu, X. Wang, J. Jia, J. Am. Ceram. Soc. 96, 3163–3168 (2013)

T. Rojac, M. Kosec, B. Budic, N. Setter, D. Damjanovic, J. Appl. Phys. 108, 74107 (2010)

T. Zheng, Y. Ding, J. Wu, RSC Adv. 6, 90831–90839 (2016)

Acknowledgements

This work was supported by the R & D Projects in Key Fields of Guangdong Province (2020B0109380001; 2019B040403004; 2019B040403006); Science and Technology Planning Project of Guangxi Zhuang Autonomous Region (No. AA18118034); National Natural Science Foundation of China (Grant No.51577070 and U1601208); Science and Technology Program of Guangzhou (No. 201704030095).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Yi, W., Lu, Z., Liu, X. et al. Excellent piezoelectric performance of Bi-compensated 0.69BiFeO3-0.31BaTiO3 lead-free piezoceramics. J Mater Sci: Mater Electron 32, 22637–22644 (2021). https://doi.org/10.1007/s10854-021-06748-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-021-06748-y