Abstract

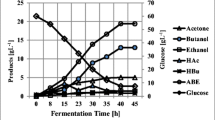

In these studies, butanol (acetone butanol ethanol or ABE) was produced from wheat straw hydrolysate (WSH) in batch cultures using Clostridium beijerinckii P260. In control fermentation 48.9 g L−1 glucose (initial sugar 62.0 g L−1) was used to produce 20.1 g L−1 ABE with a productivity and yield of 0.28 g L−1 h−1 and 0.41, respectively. In a similar experiment where WSH (60.2 g L−1 total sugars obtained from hydrolysis of 86 g L−1 wheat straw) was used, the culture produced 25.0 g L−1 ABE with a productivity and yield of 0.60 g L−1 h−1 and 0.42, respectively. These results are superior to the control experiment and productivity was improved by 214%. When WSH was supplemented with 35 g L−1 glucose, a reactor productivity was improved to 0.63 g L−1 h−1 with a yield of 0.42. In this case, ABE concentration in the broth was 28.2 g L−1. When WSH was supplemented with 60 g L−1 glucose, the resultant medium containing 128.3 g L−1 sugars was successfully fermented (due to product removal) to produce 47.6 g L−1 ABE, and the culture utilized all the sugars (glucose, xylose, arabinose, galactose, and mannose). These results demonstrate that C. beijerinckii P260 has excellent capacity to convert biomass derived sugars to solvents and can produce over 28 g L−1 (in one case 41.7 g L−1 from glucose) ABE from WSH. Medium containing 250 g L−1 glucose resulted in no growth and no ABE production. Mixtures containing WSH + 140 g L−1 glucose (total sugar approximately 200 g L−1) showed poor growth and poor ABE production.

Similar content being viewed by others

References

Ezeji TC, Qureshi N, Karcher P, Blaschek HP (2006) Production of butanol from corn. In: Minteer S (ed) Alcoholic fuels. Taylor and Francis Group, LLC, CRC Press, Boca Raton, pp 99–122

Zverlov VV, Berezina O, Velikodvorskaya GA, Schwarz WH (2006) Bacterial acetone butanol production by industrial fermentation in Soviet Union: use of hydrolyzed agricultural waste fro biorefining. Appl Microbiol Biotechnol 71:587–597

Formanek J, Mackie R, Blaschek HP (1997) Enhanced butanol production by Clostridium beijerinckii BA101 grown in semi-defined P2 medium containing 6 percent maltodextrin or glucose. Appl Environ Microbiol 63:2306–2310

Parekh M, Formanek J, Blaschek HP (1998) Development of cost-effective glucose-corn steep medium for the production of butanol by Clostridium beijerinckii. J Ind Microbiol Biotechnol 21:187–191

Parekh M, Formanek J, Blaschek HP (1999) Pilot-scale production of butanol by Clostridium beijerinckii BA101 using low-cost fermentation medium based on corn steep water. Appl Microbiol Biotechnol 51:152–157

Ezeji TC, Qureshi N, Blaschek HP (2005) Industrially relevant fermentation. In: Durre P (ed) Handbook on Clostridia. Taylor & Francis Group, CRC Press, Boca Raton, pp 797–812

Ladisch MR (1991) Fermentation derived butanol and scenarios for its uses in energy-related applications. Enzyme Microbial Technol 13:280–283

Durre P (1998) New insights and novel developments in clostridial acetone/butanol/isopropanol fermentation. Appl Microbiol Biotechnol 49:639–648

Qureshi N, Li X-L, Hughes S, Saha BC, Cotta MA (2006) Butanol production from corn fiber xylan using Clostridium acetobutlycum. Biotechnol Prog 22:673–680

Ezeji TC, Qureshi N, Blaschek HP (2004) Acetone–butanol–ethanol production from concentrated substrate: reduction in substrate inhibition by fed-batch technique and product inhibition by gas stripping. Appl Micriobiol Biotechnol 63:653–658

Qureshi N, Maddox IS (1992) Application of novel technology to the ABE fermentation process: an economic analysis. Appl Biochem Biotechnol 34:441–448

Qureshi N, Blaschek HP (2000) Economics of butanol fermentation using hyper-butanol producing Clostridium beijerinckii BA101. Trans Inst Chem Eng (Trans IChemE): (Chem Eng Res Design) 78:139–144

Qureshi N, Blaschek HP (2001) Evaluation of recent advances in butanol fermentation, upstream, and downstream processing. Bioproc Biosys Eng 24:219-226

Tabka MG, Herpoel-Gimbert I, Monod F, Asther M, Sigoillot JC (2006) Enzymatic saccharification of wheat straw for bioethanol production by a combined cellulose xylanase and feruloyl esterase treatment. Enzyme Microb Technol 39:897–902

Esteghlalian A, Hashimoto AG, Fenske JJ, Penner AH (1997) Modeling and optimization of dilute-sulfuric-acid pretreatment of corn stover, poplar, and switchgrass. Biores Technol 59:129–136

Qureshi N, Blaschek HP (2005) Butanol production from agricultural biomass. In: Shetty K, Pometto A, Paliyath G (eds) Food biotechnology. Taylor & Francis Group plc, Boca Raton, pp 525–551

Jones DT, Woods DR (1986) Acetone–butanol fermentation revisited. Microbiol Rev 50:484–524

Ebener J, Qureshi N, Blaschek HP (2003) Corn fiber hydrolysis and fermentation to butanol using Clostridium beijerinckii BA101. In: 25th Biotechnology Symposium for Fuels and Chemicals, Breckenridge, May 4–7

Qureshi N, Ebener J, Ezeji TC, Dien B, Cotta MA, Blaschek HP (2007) Butanol production by Clostridium beijerinckii BA101. Part I: Use of acid and enzyme hydrolysed corn fiber. Biores Technol (Submitted)

Ezeji TC, Qureshi N, Blaschek HP (2007) Butanol production from agricultural residues: Impact of degradation products on Clostridium beijerinckii growth and butanol fermentation. Biotechnol Bioeng (in press)

Feedstuffs (2006) BP, Dupont to develop biofuels, June 26, p 20

Industrial Bioprocessing (2006) Dupont and BP will produce butanol for motor fuel, July issue, 28(7)

Ennis BM, Maddox IS (1985) Use of Clostridium acetobutylicum P262 for production of solvents from whey permeate. Biotechnol Lett 7:601–606

Qureshi N, Blaschek HP (1999) Butanol recovery from model solution/fermentation broth by pervaporation: evaluation of membrane performance. Biomass Bioenergy 17:175–184

Ezeji TC, Qureshi N, Blaschek HP (2003) Production of butanol by Clostridium beijerinckii BA101 and in-situ recovery by gas stripping. World J Microbiol Biotechnol 19:595–603

Qureshi N, Li X, Hughes SR, Saha BC, Cotta MA (2006) Production of acetone butanol ethanol from corn fiber xylan using Clostridium acetobutylicum. Biotechnol Prog 22:673–680

Maddox IS, Qureshi N, Roberts-Thomson K (1995) Production of acetone–butanol–ethanol from concentrated substrates using Clostridium acetobutylicum in an integrated fermentation-product removal process. Process Biochem 30:209–215

Qureshi N, Maddox IS (2005) Reduction in butanol inhibition by perstraction: utilization of concentrated lactose/whey permeate by Clostridium acetobutylicum to enhance butanol fermentation economics. Official J Eur Fed Chem Eng (formerly Trans IChemE; Chem Eng Res Design): Food Bioproducts Processing C 83(C1):43–52

Qureshi N, Blaschek HP (1999) Production of acetone–butanol–ethanol (ABE) by hyper-butanol producing mutant strain of Clostridium beijerinckii BA101 and recovery by pervaporation. Biotechnol Prog 15:594–602

Qureshi N, Maddox IS, Friedl A (1992) Application of continuous substrate feeding to the ABE fermentation: relief of product inhibition using extraction, perstraction, stripping and pervaporation. Biotechnol Prog 8:382–390

Acknowledgments

N. Qureshi would like to thank Professor David Jones (University of Otago, Dunedin, New Zealand) for his generous gift of C. beijerinckii P260. N. Qureshi would also like to thank Marsha Ebener for reading and formatting this manuscript. Help from John Michael Henderson, Mark Maroon, and Gregory Kennedy for preparing WSH and conducting some of the experiments is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Additional information

Mention of trade names or commercial products in this article is solely for the purpose of providing scientific information and does not imply recommendation or endorsement by the United States Department of Agriculture.

Rights and permissions

About this article

Cite this article

Qureshi, N., Saha, B.C. & Cotta, M.A. Butanol production from wheat straw hydrolysate using Clostridium beijerinckii . Bioprocess Biosyst Eng 30, 419–427 (2007). https://doi.org/10.1007/s00449-007-0137-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00449-007-0137-9