Abstract

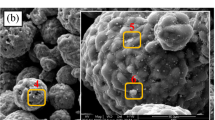

The organosilane-epoxy coating material is used for metal protection against corrosion as it has strong adhesion property on a metal substrate due to its multi coordinate sites. In the present paper, the corrosion resistance of organosilane-epoxy coating was improved by the addition of a zinc phosphate pigment. As compared to the pure organosilane-epoxy coating on Al alloy 6101, the mechanical property and electrochemical impedance spectroscopy studies on the organosilane-epoxy coating with addition of a zinc phosphate pigment at a concentration 0.6 wt % show that the modified coatings on Al alloy 6101 have stronger peeling off force than the pure coating on Al alloy 6101, which is increased by 55%. The corrosion protection efficiency of the zinc phosphate pigment modified coating is enhanced by at least 98% comprehensively, in an alkaline solution of NaOH with pH 11, via all tests including mass loss, potentiodynamic polarization, and electrochemical impedance spectroscopy. Scanning electron microscope and X-ray energy dispersive spectroscopy mapping show a good dispersed distribution of the zinc pigment in the coating.

Similar content being viewed by others

REFERENCES

Kim, H.-J., Jeung, D.-G., and Oh, J.-M., Random array of inorganic nanoparticles on polymer surface for anti-biofouling property through cost-effective and high-performance dip-coating, Colloids Surf. B, 2020, vol. 188, p. 110788. https://doi.org/10.1016/j.colsurfb.2020.110788

Twite, R.L. and Bierwagen, G.P., Review of alternatives to chromate for corrosion protection of aluminum aerospace alloys, Prog. Org. Coat., 1998, vol. 33, no 2, p. 91. https://doi.org/10.1016/S0300-9440(98)00015-0

Sharma, V., Goyat, M.S., Hooda, A., Pandey, J.K., et al., Recent progress in nano-oxides and CNTs based corrosion resistant superhydrophobic coatings: A critical review, Prog. Org. Coat., 2020, vol. 140, p. 105512. https://doi.org/10.1016/j.porgcoat.2019.105512

Alibakhshi, E., Ghasemi, E., and Mahdavian, M., Corrosion inhibition by lithium zinc phosphate pigment, Corros. Sci., 2013, vol. 77, p. 222. https://doi.org/10.1016/j.corsci.2013.08.005

Przywecka, K., Grzmil, B., Kowalczyk, K., and Sreńscek-Nazzal, J., Studies on preparation of phosphate pigments for application in composite protective coatings, Prog. Org. Coat., 2018, vol. 119, p. 44. https://doi.org/10.1016/j.porgcoat.2018.02.009

Sørensen, P.A., Kiil, S., Dam-Johansen, K., and Weinell, C.E., Anticorrosive coatings: A review, J. Coat. Technol. Res., 2009, vol. 6, p. 135. https://doi.org/10.1007/s11998-008-9144-2

Hao, Y., Liu, F., Han, E.H., Anjum, S., et al., The mechanism of inhibition by zinc phosphate in an epoxy coating, Corros. Sci., 2013, vol. 69, p. 77. https://doi.org/10.1016/j.corsci.2012.11.025

Grundmeier, G., Rossenbeck, B., Roschmann, K., Ebbinghaus, P., et al., Corrosion protection of Zn-phosphate containing water borne dispersion coatings: Part 2: Investigations of the corrosive de-adhesion of model latex coatings on iron, Corros. Sci., 2006, vol. 48, no 11, p. 3716. https://doi.org/10.1016/j.corsci.2006.01.007

Shao, Y., Jia, C., Meng, G., Zhang, T., et al., The role of a zinc phosphate pigment in the corrosion of scratched epoxy-coated steel, Corros. Sci., 2009, vol. 51, p. 371.

Naderi, R. and Attar, M., The role of zinc aluminum phosphate anticorrosive pigment in protective performance and cathodic disbondment of epoxy coating, Corros. Sci., 2010, vol. 52, p. 1291.

Attar, M., Investigation on zinc phosphate effectiveness at different pigment volume concentrations via electrochemical impedance spectroscopy, Electrochim. Acta, 2005, vol. 50, p. 4645.

Naderi, R. and Attar, M., Electrochemical study of protective behavior of organic coating pigmented with zinc aluminum polyphosphate as a modified zinc phosphate at different pigment volume concentrations, Prog. Org. Coat., 2009, vol. 66, p. 314.

Emad, S.G.R., Zhou, X., Morsch, S., Lyon, S., et al., How pigment volume concentration (PVC) and particle connectivity affect leaching of corrosion inhibitive species from coatings, Prog. Org. Coat., 2019, vol. 134, p. 360.

Abdelkader, A. and White, J., Comparison of internal stresses in coatings cured on rigid substrates and on unrestrained thin substrates, Prog. Org. Coat., 2002, vol. 44, p. 121.

Jiang, M.-Y., Wu, L.-K., Hu, J.-M., and Zhang, J.-Q., Silane-incorporated epoxy coatings on aluminum alloy (AA2024). Part 1: Improved corrosion performance, Corros. Sci., 2015, vol. 92, p. 118.

Grzmil, B., Kic, B., and Lubkowski. K., Studies on obtaining of zinc phosphate nanomaterials, Rev. Adv. Mater. Sci., 2007, vol. 14, p. 46.

Sharma, K., Goyat, M.S., and Vishwakarma P., Synthesis of polymer nano-composite coatings as corrosion inhibitors: A quick review, IOP Conf. Ser.: Mater. Sci. Eng., 2020, vol. 983, no. 1, p. 012016.

Hooda, A., Goyat, M.S., Pandey, J. K., Kumar A., et al., A review on fundamentals, constraints and fabrication techniques of superhydrophobic coatings, Prog. Org. Coat., 2020, vol. 142, p. 105557. https://doi.org/10.1016/j.porgcoat.2020.105557

Pryor, M. and Keir, D., Galvanic corrosion: II. Effect of pH and dissolved oxygen concentration on the aluminum-steel couple, J. Electrochem. Soc., 1958, vol. 105, p. 629.

Hernandez, M., Galliano, F., and Landolt, D., Mechanism of cathodic delamination control of zinc–aluminum phosphate pigment in waterborne coatings, Corros. Sci., 2004, vol. 46, p. 2281.

Peng, Z., Wang, C., Chen, L., and Chen, S., Peeling behavior of a viscoelastic thin-film on a rigid substrate, Int. J. Solids Struct., 2014, vol. 51, p. 4596.

Peng, Z., Wang, C., Yang, Y., and Chen, S., Effect of relative humidity on the peeling behavior of a thin film on a rigid substrate, Phys. Rev. E, 2016, vol. 94, p. 032801.

Zubielewicz, M. and Gnot, W., Mechanisms of non-toxic anticorrosive pigments in organic waterborne coatings, Prog. Org. Coat., 2004, vol. 49, p. 358.

Golru, S.S., Attar, M., and Ramezanzadeh, B., Effects of surface treatment of aluminium alloy 1050 on the adhesion and anti-corrosion properties of the epoxy coating, Appl. Surf. Sci., 2015, vol. 345, p. 360.

Xavier, J.R., Electrochemical, mechanical and adhesive properties of surface modified NiO-epoxy nanocomposite coatings on mild steel, Mater. Sci. Eng.: B, 2020, vol. 260, p. 114639. https://doi.org/10.1016/j.mseb.2020.114639

Hu, J., He, S., Wang, Z., Zhu, J., et al., Stearic acid-coated superhydrophobic Fe2O3/Fe3O4 composite film on N80 steel for corrosion protection, Surf. Coat. Technol., 2019, vol. 359, p. 47.

Shi, C., Shao, Y., Wang, Y., Liu, B., et al., Evolutions of the protection performances of epoxy coatings containing different concentrations of submicron-sheet zinc phosphate pigment, Colloids Surf. A, 2019, vol. 577, p. 378.

Attar, M.M., Investigation on zinc phosphate effectiveness at different pigment volume concentrations via electrochemical impedance spectroscopy, Electrochim. Acta, 2005, vol. 50, no. 24, p. 4645.

Hao, Y., Liu, F., Han, E.H., Anjum, S., et al., The mechanism of inhibition by zinc phosphate in an epoxy coating, Corros. Sci., 2013, vol. 69, p. 77.

Wan, H., Song, D., Li, X., Zhang, D., et al., Effect of zinc phosphate on the corrosion behavior of waterborne acrylic coating/metal interface, Materials, 2017, vol. 10, no. 6, p. 654.

Dagdag, O., El Gana, L., Hamed, O., Jodeh, S., et al., Anticorrosive formulation based of the epoxy resin–polyaminoamide containing zinc phosphate inhibitive pigment applied on sulfo-tartaric anodized AA 7075-T6 in NaCl medium, J. Bio- Tribo-Corros., 2019, vol. 5, no. 1, p. 25.

Shi, C., Shao, Y., Wang, Y., Meng, G., et al., Influence of submicron-sheet zinc phosphate synthesised by sol–gel method on anticorrosion of epoxy coating, Prog. Org. Coat., 2018, vol. 117, p. 102.

Ahsan Riaz Khan, Zheng, M., Cui, Y., and Hongwu Zhang, Protection properties of organosilane-epoxy coating on Al alloy 6101 in alkaline solution, Surf. Eng. Appl. Electrochem., 2022, vol. 58, no. 3, p. 281. https://doi.org/10.3103/S1068375522030036

Funding

This research has been funded by Shaanxi Province Key Research Fund under the grant number 2019GY-157 and by the Wisteria Scientific Research Cooperation Special Project of Northwest University, China.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors declare that they have no conflicts of interest.

About this article

Cite this article

Ahsan Riaz Khan, Zheng, M., Cui, Y. et al. Improvement of Corrosion Resistances of Organosilane-Epoxy Coating on Al Alloy 6101 with Addition of Zinc Phosphate Pigment. Surf. Engin. Appl.Electrochem. 58, 720–730 (2022). https://doi.org/10.3103/S1068375522060096

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1068375522060096