Abstract

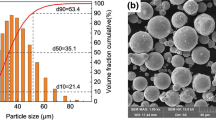

The present research evaluates the microstructure and hot corrosion performance of HVOF and D-gun sprayed Cr3C2-25NiCr, and ceria (0.4 wt.%) blended Cr3C2-25NiCr coatings on TP347H superheater tube material. All the specimens were subjected to Na2SO4-60%V2O5 environment for 50 cycles at 900 °C. The corroded samples were evaluated using thermogravimetric analysis, XRD, scanning electron microscopy with energy dispersive spectroscopy, and x-ray mapping. Moreover, the weight gain versus oxidation time and oxide scale growth rate was subsequently examined. Microstructural results revealed that the ceria-added coating with the D-gun method provided better coating features, such as microhardness, surface roughness, and microporosity than its counterparts. Among the four coatings, D-gun sprayed Ce 0.4 wt.% added Cr3C2-25NiCr coating (D2) proved to be better due to the thin and dense oxide scale of Cr2O3, Cr23C6, NiCr2O4, Ce2O3, and CeVO4. Moreover, the presence of ceria in the carbide coating reduces the development of the NiCr2O4 phase resulting in compact oxide scale of Cr2O3 developed on the coating surface.

Similar content being viewed by others

References

S. Agarwal, A. Suhane, Study of boiler maintenance for enhanced reliability of system a review. Mater. Today: Proc. 4(2), 1542–1549 (2017). https://doi.org/10.1016/j.matpr.2017.01.177

A. Agüero, P. Audigié, S. Rodríguez, V. Encinas-Sánchez, M.T. de Miguel, F.J. Pérez, Protective coatings for high temperature molten salt heat storage systems in solar concentration power plants. AIP Conf. Proc. 2033, 090001 (2018). https://doi.org/10.1063/1.5067095

M.S. Alam, A.K. Das, Hot corrosion behavior of plasma-sprayed WC-CoCr coatings on AISI 316L steel substrate in Na2SO4-25% NaCl salt environment. High Temp. Corros. Mater. 99(5–6), 415–430 (2023). https://doi.org/10.1007/s11085-023-10162-6

M. Bajt Leban, M. Vončina, T. Kosec, R. Tisu, M. Barborič, J. Medved, Comparison of cycling high temperature corrosion at 650 °C in the presence of NaCl of various austenitic stainless steels. Oxid. Metals. (2022). https://doi.org/10.1007/s11085-022-10138-y

G. Balakrishnan, O.A. Petrenko, M.R. Lees, D.M.K. Paul, Single crystals of the anisotropic Kagomé staircase compounds Ni3V2O8 and Co3V2O8. J. Phys. Condens. Matter. 16(29), L347–L350 (2004). https://doi.org/10.1088/0953-8984/16/29/L02

V. Balaram, Rare earth elements: a review of applications, occurrence, exploration, analysis, recycling, and environmental impact. Geosci. Front. 10(4), 1285–1303 (2019). https://doi.org/10.1016/j.gsf.2018.12.005

R.S. Bangari, S. Sahu, P.C. Yadav, Comparative evaluation of hot corrosion resistance of nanostructured AlCrN and TiAlN coatings on cobalt-based superalloys. J. Mater. Res. 33(8), 1023–1031 (2018). https://doi.org/10.1557/jmr.2018.53

M. Benegra, M. Magnani, H. Goldenstein, O. Maranho, G. Pintaude, Abrasion and corrosion resistance of new Ni–based coating deposited by HVOF thermal spray process. Surf. Eng. 26(6), 463–468 (2010). https://doi.org/10.1179/026708410X12550773058144

S.S. Chatha, H.S. Sidhu, B.S. Sidhu, The effects of post-treatment on the hot corrosion behavior of the HVOF-sprayed Cr3C2-NiCr coating. Surf. Coat. Technol. 206(19–20), 4212–4224 (2012). https://doi.org/10.1016/j.surfcoat.2012.04.026

L. Chen, Y. Zhao, C. Guan, T. Yu, Effects of CeO2 addition on microstructure and properties of ceramics reinforced Fe-based coatings by laser cladding. Int. J. Adv. Manuf. Technol. 115(7–8), 2581–2593 (2021). https://doi.org/10.1007/s00170-021-07297-8

J.L. Cocking, G.R. Johnston, Characterisation of Oxidised Surfaces, in Surface Analysis Methods in Materials Science. ed. by D. John O’Connor, B.A. Sexton, C. Roger St, Smart, (Springer Berlin Heidelberg, Berlin, Heidelberg, 2003), p.455–471. https://doi.org/10.1007/978-3-662-05227-3_19

K. Derelizade, A. Rincon, F. Venturi, R.G. Wellman, A. Kholobysov, T. Hussain, High temperature (900 °C) sliding wear of CrNiAlCY coatings deposited by high velocity oxy fuel thermal spray. Surface Coat. Technol. 432, 128063 (2022). https://doi.org/10.1016/J.SURFCOAT.2021.128063

S. Deshpande, S. Sampath, H. Zhang, Mechanisms of oxidation and its role in microstructural evolution of metallic thermal spray coatings—Case study for Ni–Al. Surf. Coat. Technol. 200(18–19), 5395–5406 (2006). https://doi.org/10.1016/j.surfcoat.2005.07.072

N. Di Salvia, M.P. Malavasi, G. Di Salvia, A. Vaccari, Formation of Ni and Mg vanadates during the flameless oxy-combustion of heavy fuels. Fuel Process. Technol. 138, 534–539 (2015). https://doi.org/10.1016/j.fuproc.2015.06.033

N. Di Salvia, M.P. Malavasi, G. Di Salvia, A. Vaccari, Formation of Ni and Mg vanadates during the flameless oxy-combustion of heavy fuels. Fuel Proc. Technol. 138, 534–539 (2015). https://doi.org/10.1016/j.fuproc.2015.06.033

H. Du, W. Hua, J. Liu, J. Gong, C. Sun, L. Wen, Influence of process variables on the qualities of detonation gun sprayed WC–Co coatings. Mater. Sci. Eng. A. 408(1), 202–210 (2005). https://doi.org/10.1016/j.msea.2005.08.008

H. Gada, D. Mudgal, B. Ahmad, Experimental evaluation of high temperature corrosion performance of 75Ni25Cr coated and bare 347H SS in air and simulated husk fired boiler environment. J. Phys. Conf. Ser. 1240(1), 012129 (2019). https://doi.org/10.1088/1742-6596/1240/1/012129

J. Gao, Z. Tang, C. Wang, M. Guo, Y. Cui, Microstructure, mechanical and oxidation characteristics of detonation gun and HVOF sprayed MCrAlYX coatings. Trans. Nonferrous Metals Soc. China. 25(3), 817–823 (2015). https://doi.org/10.1016/S1003-6326(15)63668-8

F. Ghadami, A. Zakeri, A.S.R. Aghdam, R. Tahmasebi, Structural characteristics and high-temperature oxidation behavior of HVOF sprayed nano-CeO2 reinforced NiCoCrAlY nanocomposite coatings. Surf. Coat. Technol. 373, 7–16 (2019). https://doi.org/10.1016/j.surfcoat.2019.05.062

B. Grégoire, C. Oskay, T.M. Meißner, M.C. Galetz, Corrosion mechanisms of ferritic-martensitic P91 steel and Inconel 600 nickel-based alloy in molten chlorides. Part I: NaCl–KCl binary system. Solar Energy Mater. Solar Cells. 215, 110659 (2020). https://doi.org/10.1016/j.solmat.2020.110659

N. Gupta, S.K. Singh, S.M. Pandey, Tribological characterisation of thermal sprayed CrC alloyed coating—A review. Adv. Mater. Process. Technol. 7(4), 660–683 (2021). https://doi.org/10.1080/2374068X.2020.1793262

M. Hagarová, G. Baranová, M. Fujda, M. Matvija, P. Horňak, J. Bednarčík, D. Yudina, High temperature oxidation behavior of creep resistant steels in water vapour containing environments. Materials. 15(2), 616 (2022). https://doi.org/10.3390/ma15020616

M. Hao, B. Sun, H. Wang, High-temperature oxidation behavior of Fe–1Cr–0.2Si steel. Materials. 13(3), 509 (2020). https://doi.org/10.3390/ma13030509

J. He, M. Ice, E. Lavernia, Particle melting behavior during high-velocity oxygen fuel thermal spraying. J. Therm. Spray Technol. 10(1), 83–93 (2001). https://doi.org/10.1361/105996301770349547

C. Howes, An overview of thermal spray processes. Mater. Technol. 11(5), 188–191 (1996). https://doi.org/10.1080/10667857.1996.11752697

A.M. Huntz, Stresses in NiO, Cr2O3 and Al2O3 oxide scales. Mater. Sci. Eng. A. 201(1–2), 211–228 (1995). https://doi.org/10.1016/0921-5093(94)09747-X

M.H. Hussin, N.A. Che Lah, Selective oxide deposition on fe-based alloys in dry high temperature environment—a review. J. Adv. Res. Fluid Mech. Thermal Sci. 72(2), 25–40 (2020). https://doi.org/10.37934/arfmts.72.2.2540

A. Inam, M.A. Raza, M.A. Hafeez, S.B. Shah, M. Ishtiaq, M.H. Hassan, M. Irfan, A. Nasik, I. Siddique, O.M. Butt, A. Maqbool, W. Haider, Effect of voltage and spray–off distance of electric-arc spray technique on surface properties of nickel–chrome (Ni–Cr) coating developed on 304L stainless steel. Mater. Res. Express. 7(1), 016525 (2020). https://doi.org/10.1088/2053-1591/ab6112

J. Jedliński, M.J. Bennett, H.E. Evans, Experimental data on the spallation of protective oxide scales: a brief literature survey. Mater. High Temp. 12(2–3), 169–175 (1994). https://doi.org/10.1080/09603409.1994.11689483

K.P. Jonnalagadda, S. Mahade, N. Curry, X.-H. Li, N. Markocsan, P. Nylén, S. Björklund, R.L. Peng, Hot corrosion mechanism in multi-layer suspension plasma sprayed Gd2Zr2O7/YSZ thermal barrier coatings in the presence of V2O5 + Na2SO4. J. Therm. Spray Technol. 26(1–2), 140–149 (2017). https://doi.org/10.1007/s11666-016-0486-5

S. Kamal, R. Jayaganthan, S. Prakash, Hot corrosion behaviour of D-gun sprayed NiCoCrAlYTa coated superalloys at 900 °C in molten salt environment. Surf. Eng. 26(6), 453–462 (2010). https://doi.org/10.1179/026708410X12459349720132

S. Kamal, R. Jayaganthan, S. Prakash, S. Kumar, Hot corrosion behavior of detonation gun sprayed Cr3C2–NiCr coatings on Ni and Fe-based superalloys in Na2SO4–60% V2O5 environment at 900 °C. J. Alloy. Compd. 463(1–2), 358–372 (2008). https://doi.org/10.1016/j.jallcom.2007.09.019

S. Kamal, K.V. Sharma, P. Srinivasa Rao, O. Mamat, Thermal Spray Coatings for Hot Corrosion Resistance, in Engineering Applications of Nanotechnology. ed. by V.S. Korada, B. Nor Hisham Hamid (Springer International Publishing, Cham, 2017), p.235–268. https://doi.org/10.1007/978-3-319-29761-3_10

S. Kant, M. Kumar, V. Chawla, S. Singh, Study of high temperature oxidation behavior of wire arc sprayed coatings. Mater. Today: Proc. 21, 1741–1748 (2020). https://doi.org/10.1016/j.matpr.2020.01.226

M. Kawakami, K.S. Goto, R.A. Rapp, Accelerated oxidation (Hot Corrosion) of alloys by molten salt. Trans. Iron Steel Inst. Japan. 20(9), 646–658 (1980). https://doi.org/10.2355/isijinternational1966.20.646

P.R.L. Keating, D.O. Scanlon, G.W. Watson, The nature of oxygen states on the surfaces of CeO2 and La-doped CeO2. Chem. Phys. Lett. 608(May), 239–243 (2014). https://doi.org/10.1016/j.cplett.2014.05.094

H. Kildahl, H. Cao, Y. Ding, Thermochemical splitting of carbon dioxide by lanthanum manganites - understanding the mechanistic effects of doping. Energy Storage and Saving. 1(4), 309–324 (2022). https://doi.org/10.1016/j.enss.2022.09.001

M. Kumar, S. Kant, S. Kumar, Corrosion behavior of wire arc sprayed Ni-based coatings in extreme environment. Mater. Res. Express. (2019). https://doi.org/10.1088/2053-1591/ab3bd8

M. Kumar, D. Mudgal, L. Ahuja, Evaluation of high temperature oxidation performance of bare and coated T91 steel. Mater. Today: Proc. 28, 620–624 (2020). https://doi.org/10.1016/j.matpr.2019.12.232

S. Kumar, M. Kumar, A. Handa, Combating hot corrosion of boiler tubes—A study. Eng. Fail. Anal. 94(May), 379–395 (2018). https://doi.org/10.1016/j.engfailanal.2018.08.004

S. Kumar, M. Kumar, A. Handa, Comparative study of high temperature oxidation behavior and mechanical properties of wire arc sprayed Ni–Cr and Ni–Al coatings. Eng. Fail. Anal. 106(July), 104173 (2019). https://doi.org/10.1016/j.engfailanal.2019.104173

S. Kumar, M. Kumar, A. Handa, Erosion corrosion behaviour and mechanical properties of wire arc sprayed Ni-Cr and Ni-Al coating on boiler steels in a real boiler environment. Mater. High Temp. 37(6), 370–384 (2020). https://doi.org/10.1080/09603409.2020.1810922

B. Li, Z. Zhang, T. Liu, Z. Qiu, Y. Su, J. Zhang, C. Lin, L. Wang, Recent progress in functionalized coatings for corrosion protection of magnesium alloys—a review. Materials. 15(11), 3912 (2022). https://doi.org/10.3390/ma15113912

X. Lian, J. Zhu, R. Wang, T. Liu, J. Xu, D. Xu, H. Dong, Effects of rare earth (Ce and La) on steel corrosion behaviors under wet-dry cycle immersion conditions. Metals. 10(9), 1–14 (2020). https://doi.org/10.3390/met10091174

B.S. Lutz, N.M. Yanar, G.R. Holcomb, G.H. Meier, Fireside corrosion of alumina-forming austenitic (AFA) stainless steels. Oxid. Metals. 87(3), 575–602 (2016). https://doi.org/10.1007/S11085-016-9687-Z

H.P. Lv, J. Wang, Y.G. Yan, Q.Z. An, P.L. Nie, B.D. Sun, Characterisation of detonation sprayed Mo–Co–Cr–B alloy coatings. Mater. Sci. Technol. 26(8), 950–955 (2010). https://doi.org/10.1179/026708309X12459430509373

G. Madhu, K.M. Mrityunjaya Swamy, D.A. Kumar, C.D. Prasad, U. Harish, Evaluation of hot corrosion behavior of HVOF thermally sprayed Cr3C2-35NiCr coating on SS 304 boiler tube steel. AIP Conf. Proc. 1, 2316 (2021). https://doi.org/10.1063/5.0038279

R.A. Mahesh, R. Jayaganthan, S. Prakash, Microstructural characterization and hardness evaluation of HVOF sprayed Ni–5Al coatings on Ni- and Fe-based superalloys. J. Mater. Process. Technol. 209(7), 3501–3510 (2009). https://doi.org/10.1016/j.jmatprotec.2008.08.009

V. Mannava, A. SambasivaRao, M. Kamaraj, R.S. Kottada, Influence of two different salt mixture combinations of Na2SO4-NaCl-NaVO3 on hot corrosion behavior of Ni-base superalloy Nimonic263 at 800 °C. J. Mater. Eng. Perform. 28(2), 1077–1093 (2019). https://doi.org/10.1007/s11665-019-3866-4

E. Medvedovski, Advanced ceramics and coatings for erosion-related applications in mineral and oil and gas production: a technical review. Int. J. Appl. Cer. Technol. 20(2), 612–659 (2022). https://doi.org/10.1111/ijac.14240

R. Mittal, H. Singh, Evaluation of the behavior of D-gun spray coatings on T-11 boiler steel at high and moderate temperature. Mater. Today: Proc. 41, 893–901 (2021). https://doi.org/10.1016/j.matpr.2020.09.457

T. Moriomoto, R. Oka, K. Minagawa, T. Masui, Novel near-infrared reflective black inorganic pigment based on cerium vanadate. RSC Adv. 12(26), 16570–16575 (2022). https://doi.org/10.1039/D2RA02483G

D. Mudgal, S. Singh, S. Prakash, Evaluation of ceria-added Cr3C2-25(NiCr) coating on three superalloys under simulated incinerator environment. J. Therm. Spray Technol. 24(3), 496–514 (2015). https://doi.org/10.1007/s11666-014-0209-8

H.P. Nielsen, F.J. Frandsen, K. Dam-Johansen, L.L. Baxter, The implications of chlorine-associated corrosion on the operation of biomass-fired boilers. Prog. Energy Combust. Sci. 26(3), 283–298 (2000). https://doi.org/10.1016/S0360-1285(00)00003-4

Nilsson, E. A. A. (2017). Degradation mechanisms of heat resistant steel at elevated temperatures in an iron ore pelletizing industry. Eng. Failure Anal. (Vol. 110).

A. Nouri, A. Sola, Powder morphology in thermal spraying. J. Adv. Manuf. Proc. 1(3), e10020 (2019). https://doi.org/10.1002/amp2.10020

Q. Pang, Z.L. Hu, G.H. Wu, Preparation and oxidation performance of Y and Ce-modified Cr coating on open-cell Ni-Cr-Fe alloy foam by the pack cementation. J. Mater. Eng. Perform. 25(12), 5189–5200 (2016). https://doi.org/10.1007/s11665-016-2362-3

X. Peng, Metallic coatings for high-temperature oxidation resistance, in Thermal Barrier Coatings. (Elsevier, 2011), p.53–74. https://doi.org/10.1533/9780857090829.1.53

F. Pettit, Hot corrosion of metals and alloys. Oxid. Met. 76(1–2), 1–21 (2011). https://doi.org/10.1007/s11085-011-9254-6

S. Phokha, E. Swatsitang, S. Maensiri, Room-temperature ferromagnetism in pure CeO2 nanoparticles prepared by a simple direct thermal decomposition. Electron. Mater. Lett. 11(6), 1012–1020 (2015). https://doi.org/10.1007/s13391-015-4164-4

J. Pirso, M. Viljus, S. Letunovits, K. Juhani, Reactive carburizing sintering—A novel production method for high quality chromium carbide–nickel cermets. Int. J. Refract Metal Hard Mater. 24(3), 263–270 (2006). https://doi.org/10.1016/j.ijrmhm.2005.06.002

M.J. Pomeroy, Coatings for gas turbine materials and long term stability issues. Mater. Des. 26(3), 223–231 (2005). https://doi.org/10.1016/j.matdes.2004.02.005

D. Pradhan, G.S. Mahobia, K. Chattopadhyay, V. Singh, Severe hot corrosion of the superalloy IN718 in mixed salts of Na2SO4 and V2O5 at 700 °C. J. Mater. Eng. Perform. 27(8), 4235–4243 (2018). https://doi.org/10.1007/s11665-018-3501-9

S. Purkayastha, D.K. Dwivedi, Abrasive and erosive wear performance of rare earth oxide doped Ni/WC coatings. J. Tribol. 136(1), 1–9 (2014). https://doi.org/10.1115/1.4025099

A. Rahman, R. Jayaganthan, Study of nanostructured CeO2 coatings on superalloy. Surf. Eng. 32(10), 771–778 (2016). https://doi.org/10.1080/02670844.2016.1148381

P. Rajendran, A. Muthuraj, N.E. Rajagounder, Review on CeO2 -based corrosion coatings. Trans. Ind. Ceramic Soc. 45, 1–17 (2022). https://doi.org/10.1080/0371750X.2022.2149623

R.F. Reidy, R.L. Jones, Thermogravimetric analysis of the reaction of CeO2 with the NaVO3—SO3 system. J. Electrochem. Soc. 142(4), 1353–1357 (1995). https://doi.org/10.1149/1.2044177

E. Rocca, L. Aranda, M. Moliere, P. Steinmetz, Nickel oxide as a new inhibitor of vanadium-induced hot corrosion of superalloys—comparison to MgO-based inhibitor. J. Mater. Chem. 12(12), 3766–3772 (2002). https://doi.org/10.1039/B205746H

S. Saladi, J. Menghani, S. Prakash, A study on the cyclic oxidation behavior of detonation-Gun-sprayed Ni-5Al coatings on inconel-718 at 900 °C. J. Mater. Eng. Perform. 23(12), 4394–4403 (2014). https://doi.org/10.1007/s11665-014-1240-0

S. Sampath, X. Jiang, J. Matejicek, L. Prchlik, A. Kulkarni, A. Vaidya, Role of thermal spray processing method on the microstructure, residual stress and properties of coatings: an integrated study for Ni–5 wt.%Al bond coats. Mater. Sci. Eng. A. 364(1–2), 216–231 (2004). https://doi.org/10.1016/j.msea.2003.08.023

P. Sapkota, A. Aprahamian, K.Y. Chan, B. Frentz, K.T. Macon, S. Ptasinska, D. Robertson, K. Manukyan, Irradiation-induced reactions at the CeO2/SiO2/Si interface. J. Chem. Phys. 152(10), 543 (2020). https://doi.org/10.1063/1.5142619

M. Schütze, Stress Effects in High Temperature Oxidation, in Shreir’s Corrosion. (Elsevier, UK, 2010), p.153–179

P. Sheppard, H. Koiprasert, Effect of W dissolution in NiCrBSi–WC and NiBSi–WC arc sprayed coatings on wear behaviors. Wear. 317(1–2), 194–200 (2014). https://doi.org/10.1016/j.wear.2014.06.008

S. Shrivastava, R. Upadhyaya, Study of fracture toughness and bend test morphologies of HVOF sprayed Cr3C2-25% NiCr coating after heat treatment. IOP Conf. Series: Mater. Sci. Eng. (2018). https://doi.org/10.1088/1757-899X/346/1/012026

H.S. Sidhu, B.S. Sidhu, S. Prakash, Cyclic hot corrosion of high-velocity oxy fuel sprayed coatings on steel at 900 °C. Corrosion. 62(11), 1028–1038 (2006). https://doi.org/10.5006/1.3278230

T.S. Sidhu, A. Malik, S. Prakash, R.D. Agrawal, Oxidation and hot corrosion resistance of HVOF WC-NiCrFeSiB Coating on Ni- and Fe-based Superalloys at 800 °C. J. Therm. Spray Technol. 16(5–6), 844–849 (2007). https://doi.org/10.1007/s11666-007-9106-8

T.S. Sidhu, S. Prakash, R.D. Agrawal, Hot corrosion resistance of high-velocity oxyfuel sprayed coatings on a nickel-base superalloy in molten salt environment. J. Therm. Spray Technol. 15(3), 387–399 (2006). https://doi.org/10.1361/105996306X124392

T.S. Sidhu, S. Prakash, R.D. Agrawal, Performance of high-velocity oxyfuel-sprayed coatings on an Fe-based superalloy in Na2so4-60%V2O5 environment at 900 °C part II: hot corrosion behavior of the coatings. J. Mater. Eng. Perform. 15(1), 130–138 (2006). https://doi.org/10.1361/105994906X83411

P.D. Silva-Leon, O. Sotelo-Mazon, G. Salinas-Solano, J. Porcayo-Calderon, J.G. Gonzalez-Rodriguez, S. Valdez, L. Martinez-Gomez, Hot corrosion behavior of Ni20Cr alloy in NaVO3 molten salt. J. Mater. Eng. Perform. 28(8), 5047–5062 (2019). https://doi.org/10.1007/s11665-019-04235-4

G. Singh, N. Bala, V. Chawla, Microstructural analysis and hot corrosion behavior of HVOF-sprayed Ni-22Cr-10Al-1Y and Ni-22Cr-10Al-1Y-SiC (N) coatings on ASTM-SA213-T22 steel. Int. J. Miner. Metall. Mater. 27(3), 401–416 (2020). https://doi.org/10.1007/s12613-019-1946-y

G. Singh, N. Bala, V. Chawla, Y.K. Singla, Hot corrosion behavior of HVOF-sprayed carbide based composite coatings for boiler steel in Na2SO4–60 % V2O5 environment at 900 °C under cyclic conditions. Corros. Sci. 190(July), 109666 (2021). https://doi.org/10.1016/j.corsci.2021.109666

S. Singh, K. Goyal, R. Bhatia, Mechanical and microstructural properties of yttria-stabilized zirconia reinforced Cr3C2-25NiCr thermal spray coatings on steel alloy. J. Electrochem. Sci. Eng. 12(5), 819–828 (2022). https://doi.org/10.5599/jese.1278

S. Singh, K. Goyal, R. Goyal, Performance of Cr3C2-25(Ni-20Cr) and Ni-20Cr coatings on T91 boiler tube steel in simulated boiler environment at 900 °C. Chem. Mater. Eng. 4(4), 57–64 (2016). https://doi.org/10.13189/cme.2016.040401

R. Sivakumar, B.L. Mordike, High temperature coatings for gas turbine blades: a review. Surface Coatings Technol. 37(2), 139–160 (1989). https://doi.org/10.1016/0257-8972(89)90099-6

B. Somasundaram, R. Kadoli, M.R. Ramesh, Hot corrosion behaviour of HVOF sprayed (Cr3C2–35 % NiCr) + 5 % Si coatings in the presence of Na2SO4–60 % V2O5 at 700 °C. Trans. Indian Inst. Met. 68(2), 257–268 (2015). https://doi.org/10.1007/s12666-014-0453-0

V. Sreenivasulu, M. Manikandan, High-temperature corrosion behaviour of air plasma sprayed Cr3C2-25NiCr and NiCrMoNb powder coating on alloy 80A at 900 °C. Surf. Coat. Technol. 337, 250–259 (2018). https://doi.org/10.1016/j.surfcoat.2018.01.011

V. Sreenivasulu, M. Manikandan, Hot corrosion studies of HVOF sprayed carbide and metallic powder coatings on alloy 80A at 900 °C. Mater. Res. Express. 6(3), 036519 (2018). https://doi.org/10.1088/2053-1591/aaf65d

M. Sridharan, T. Maiyalagan, G. Panomsuwan, R. Techapiesancharoenkij, Enhanced electrocatalytic activity of cobalt-doped ceria embedded on nitrogen, sulfur-doped reduced graphene oxide as an electrocatalyst for oxygen reduction reaction. Catalysts. 12(1), 6 (2022). https://doi.org/10.3390/catal12010006

V. Stetsovych, F. Pagliuca, F. Dvořák, T. Duchoň, M. Vorokhta, M. Aulická, J. Lachnitt, S. Schernich, I. Matolínová, K. Veltruská, T. Skála, D. Mazur, J. Mysliveček, J. Libuda, V. Matolín, Epitaxial cubic Ce2O3 films via Ce-CeO2 interfacial reaction. J. Phys. Chem. Lett. 4(6), 866–871 (2013). https://doi.org/10.1021/jz400187j

S. Sun, H. Fu, X. Ping, X. Guo, J. Lin, Y. Lei, W. Wu, J. Zhou, Effect of CeO2 addition on microstructure and mechanical properties of in-situ (Ti, Nb)C/Ni coating. Surf. Coat. Technol. 359, 300–313 (2019). https://doi.org/10.1016/j.surfcoat.2018.12.083

X. Sun, S. Chen, Y. Wang, Z. Pan, L. Wang, Mechanical properties and thermal shock resistance of HVOF sprayed NiCrAlY coatings without and with nano ceria. J. Therm. Spray Technol. 21(5), 818–824 (2012). https://doi.org/10.1007/s11666-012-9760-3

J.G. Thakare, C. Pandey, R.S. Mulik, M.M. Mahapatra, Microstructure and mechanical properties of D-Gun sprayed Cr3 C2 -NiCr coating on P91 steel subjected to long term thermal exposure at 650 °C. Mater. Res. Express. 6(11), 1165h1 (2019). https://doi.org/10.1088/2053-1591/ab5265

A. Trelka, W. Żórawski, Ł Maj, P. Petrzak, D. Soboń, A. Góral, The effect of the substrate on the microstructure and tribological properties of cold sprayed (Cr3C2-25(Ni20Cr))-(Ni-graphite) cermet coatings. Materials. 15(3), 994 (2022). https://doi.org/10.3390/ma15030994

T. Tzvetkoff, P. Gencheva, Mechanism of formation of corrosion layers on nickel and nickel-based alloys in melts containing oxyanions—a review. Mater. Chem. Phys. 82(3), 897–904 (2003). https://doi.org/10.1016/j.matchemphys.2003.08.001

T. Tzvetkoff, A. Girginov, M. Bojinov, Corrosion of nickel, iron, cobalt and their alloys in molten salt electrolytes. J. Mater. Sci. 30(22), 5561–5575 (1995). https://doi.org/10.1007/BF00356688

A. Verstak, B.Q. Wang, A. Beliaev, S. Lowrie, Composite coatings for elevated temperature erosion-corrosion protection in fossil-fueled boilers. Corrosion. 98, 98193 (1998)

J. Vicenzi, C.M. Marques, C.P. Bergmann, Hot and cold erosive wear of thermal sprayed NiCr-based coatings: influence of porosity and oxidation. Surf. Coat. Technol. 202(15), 3688–3697 (2008). https://doi.org/10.1016/j.surfcoat.2008.01.010

G.C. Wood, I.G. Wright, J.M. Ferguson, The oxidation of Ni and Co and of Ni/Co alloys at high temperatures. Corros. Sci. 5(9), 645–661 (1965). https://doi.org/10.1016/S0010-938X(65)90203-9

Y. Xiao, L. Li, M. Huang, Y. Liu, J. Xu, Z. Xu, Y. Lei, Treating waste with waste: metals recovery from electroplating sludge using spent cathode carbon combustion dust and copper refining slag. Sci. Total. Environ. 838, 156453 (2022). https://doi.org/10.1016/j.scitotenv.2022.156453

Z. Xu, Z. Wang, J. Chen, Y. Qiao, J. Zhang, Y. Huang, Effect of rare earth oxides on microstructure and corrosion behavior of laser-cladding coating on 316L stainless steel. Coatings. 9(10), 636 (2019). https://doi.org/10.3390/coatings9100636

N. Yadav, Cerium oxide nanostructures: properties, biomedical applications and surface coatings. 3 Biotech. 12(5), 121 (2022). https://doi.org/10.1007/s13205-022-03186-3

Y.Q. Yang, Y.C. Zhao, Z.X. Wen, G.X. Lu, H.Q. Pei, Z.F. Yue, Synergistic effect of multiple molten salts on hot corrosion behaviour of Ni-based single crystal superalloy. Corros. Sci. 204, 110381 (2022). https://doi.org/10.1016/j.corsci.2022.110381

Z. Yang, W. Ren, L. Zhu, Y. Qing, Z. Huang, F. Luo, W. Zhou, Electromagnetic-wave absorption property of Cr2O3–TiO2 coating with frequency selective surface. J. Alloy. Compd. 803, 111–117 (2019). https://doi.org/10.1016/j.jallcom.2019.06.106

P.F. You, X. Zhang, H.L. Zhang, H.J. Liu, C.L. Zeng, Effect of CeO2 on oxidation and electrical behaviors of ferritic stainless steel interconnects with Ni–Fe coatings. Int. J. Hydrogen Energy. 43(15), 7492–7500 (2018). https://doi.org/10.1016/j.ijhydene.2018.02.178

S. You, S. Xing, C. Jiang, Synergistic optimization of microstructures and properties of electrodeposited Ni–CeO2 composite coatings with CeO2 microparticles and CeO2 nanoparticles. J. Market. Res. 29, 181–195 (2024). https://doi.org/10.1016/j.jmrt.2024.01.061

W.-J. Zhang, R. Sharghi-Moshtaghin, Revisit the type II corrosion mechanism. Metall. Mater. Trans. A. 49(9), 4362–4372 (2018). https://doi.org/10.1007/s11661-018-4755-4

Y.J. Zhang, X.F. Sun, H.R. Guan, Z.Q. Hu, 1050 °C isothermal oxidation behavior of detonation gun sprayed NiCrAlY coating. Surf. Coat. Technol. 161(2–3), 302–305 (2002). https://doi.org/10.1016/S0257-8972(02)00468-1

M. Zinkevich, D. Djurovic, F. Aldinger, Thermodynamic modelling of the cerium-oxygen system. Solid State Ionics. 177(11–12), 989–1001 (2006). https://doi.org/10.1016/j.ssi.2006.02.044

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Singh, H., Chatha, S.S. & Sidhu, B.S. High Temperature Corrosion Performance of HVOF and D-gun Formulated Cr3C2-NiCr and Rare Earth Element Doped Cr3C2-NiCr Coating on TP347H Austenite Steel. J Fail. Anal. and Preven. (2024). https://doi.org/10.1007/s11668-024-01932-8

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11668-024-01932-8