Abstract

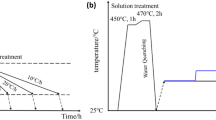

The 7075 aluminum alloy was subjected to deep cryogenic treatment (DCT) at –196°C with liquid nitrogen for different hours. The wear and corrosion behaviors of the alloy were investigated by hardness, friction and wear, intergranular corrosion (IGC), and electrochemical corrosion tests. The microstructure of the alloy was observed by transmission electron microscope (TEM). The results showed that both the wear and corrosion resistance of the alloy treated with DCT could be improved. After the DCT 12 h, the matrix precipitates of the alloy were fine and homogeneously distributed, and the grain boundary precipitates of the alloy were discontinued, so that the alloy performed better comprehensive properties.

Similar content being viewed by others

REFERENCES

Tian, W., Li, S.M., Chen, X., Liu, J.H., and Yu, M., Intergranular corrosion of spark plasma sintering assembled bimodal grain sized AA7075 aluminum alloys, Corros. Sci., 2016, vol. 107, pp. 211–224.

Heinz, A., Haszler, A., Keidel, C., Moldenhauer, S., Benedictus, R., and Miller, W.S., Recent development in aluminium alloys for aerospace applications, Mater. Sci. Eng., A, 2000, vol. 280, no. 1, pp. 102–107.

Williams, J.C. and Starke, E.A., Progress in structural materials for aerospace systems, Acta Mater., 2003, vol. 51, no. 19, pp. 5775–5799.

El-Amoush, A.S., Intergranular corrosion behavior of the 7075-T6 aluminum alloy under different annealing conditions, Mater. Chem. Phys., 2011, vol. 126, no. 3, pp. 607–613.

Mikhail, P.K., Paul, K.C., Abdul, M.Q., Leonid, M.L., Marina, Y.K., and Petr, B.K., Obtaining of Al–Si foundry alloys using amorphous microsilica—crystalline silicon production waste, J. Alloys Compd., 2019, vol. 806, pp. 806–813.

Mahathaninwong, N., Plookphol, T., Wannasin, J., and Wisutmethangoon, S., T6 heat treatment of rheocasting 7075 Al alloy, Mater. Sci. Eng., A, 2012, vol. 532, pp. 91–99.

Su, R.M., Qu, Y.D., and Li, R.D., Effect of aging treatments on the mechanical and corrosive behaviors of spray-formed 7075 alloy, J. Mater. Eng. Perform., 2014, vol. 23, no. 11, pp. 3842–3848.

Rokni, M.R., Zarei-Hanzaki, A., Roostaei, A.A., and Abedi, H.R., An investigation into the hot deformation characteristics of 7075 aluminum alloy, Mater. Des., 2011, vol. 32, no. 4, pp. 2339–2344.

Reboul, M.C. and Baroux, B., Metallurgical aspects of corrosion resistance of aluminium alloys, Mater. Corros., 2011, vol. 62, no. 3, pp. 215–233.

El-Amoush, A.S., Investigation of corrosion behaviour of hydrogenated 7075-T6 aluminum alloy, J. Alloys Compd., 2007, vol. 443, pp. 171–177.

Bertoncello, J.C.B., Manhabosco, S.M., and Dick, L.F.P., Corrosion study of the friction stir lap joint of AA7050-T76511 on AA2024-T3 using the scanning vibrating electrode technique, Corros. Sci., 2015, vol. 94, pp. 359–367.

Chemin, A., Marques, D., Bisanha, L., Motheo, A.J., Filho, W.W.B., and Ruchert, C.O.F., Influence of Al7Cu2Fe intermetallic particles on the localized corrosion of high strength aluminum alloys, Mater. Des., 2014, vol. 53, pp. 118–123.

Cavanaugh, M.K., Li, J.C., Birbilis, N., and Buchheit, R.G., Electrochemical characterization of intermetallic phases common to aluminum alloys as a function of solution temperature, J. Electrochem. Soc., 2014, vol. 161, no. 12, pp. C535–C543.

Ye, Z.Y., Liu, D.X., Li, C.Y., Zhang, X.M., Yang, Z., and Lei, M.X., Effect of shot peening and plasma electrolytic oxidation on the intergranular corrosion behavior of 7A85 aluminum alloy, Acta Metall. Sin. (Engl. Lett.), 2014, vol. 27, no. 4, pp. 705–713.

Qin, G., Chen, R.R., Liaw, P.K., Gao, Y.F., Li, X.Q., Zheng, H.T., Wang, L., Su, Y.Q., Guo, J.J., and Fu, H.Z., A novel face-centered-cubic high-entropy alloy strengthened by nanoscale precipitates, Scr. Mater., 2019, vol. 172, pp. 51–55.

Wang, S.S., Huang, I.W., Yang, L., Jiang, J.T., Chen, J.F., Dai, S.L., Seidman, D.N., Frankel, G.S., and Zhen, L., Effect of Cu content and aging conditions on pitting corrosion damage of 7xxx series aluminum alloys, J. Electrochem. Soc., 2015, vol. 162, no. 4, pp. C150–C160.

Rasool, M.S., Aripin, M.S.M., Thamizhmanii, S., Hasan, S.B., and Sathiaraj, D., Deep cryogenic treatment on aluminum silicon carbide (Al–SiC) composite, Adv. Mater. Res., 2011, vols. 383–390, pp. 3320–3324.

Cabeza, M., Feijoo, I., Merino, P., and Trillo, S., Effect of the deep cryogenic treatment on the stress corrosion cracking behaviour of AA 2017-T4 aluminium alloy, Mater. Corros., 2016, vol. 67, no. 5, pp. 504–512.

Li, C.M., Cheng, N.P., Chen, Z.Q., Guo, N., and Zeng, S.M., Deep-cryogenic-treatment-induced phase transformation in the Al–Zn–Mg–Cu alloy, Int. J. Miner., Metall. Mater., 2015, vol. 22, no. 1, pp. 68–77.

Mikhail, P.K., Larionov, L.M., Marina, Y.K., Victor, V.K., Alina, S.K., Paul, K.C., Abdul, M.Q., and Jia, Q.R., New methods of obtaining Al–Si alloys using amorphous microsilica, Int. J. Metalcast., 2019, vol. 14, no. 1, pp. 207–217.

Arunachalam, S.R., Dorman, S.E.G., Buckley, R.T., Conrad, N.A., and Fawaz, S.A., Effect of electrical discharge machining on corrosion and corrosion fatigue behavior of aluminum alloys, Int. J. Fatigue, 2018, vol. 111, pp. 44–53.

Li, J.F., Zheng, Z.Q., Li, S.C., Chen, W.J., Ren, W.D., and Zhao, X.S., Simulation study on function mechanism of some precipitates in localized corrosion of Al alloys, Corros. Sci., 2007, vol. 49, no. 6, pp. 2436–2449.

Li, J.F., Peng, Z.W., Li, C.X., Jia, Z.Q., Chen, W.J., and Zheng, Z.Q., Mechanical properties, corrosion behaviors and microstructures of 7075 aluminium alloy with various aging treatments, Trans. Nonferrous Met. Soc. China, 2008, vol. 18, no. 4, pp. 755–762.

Qin, G., Xue, W.T., Fan, C.L., Chen, R.R., Wang, L., Su, Y.Q., Ding, H.S., and Guo, J.J., Effect of Co content on phase formation and mechanical properties of (AlCoCrFeNi) (100 – x) Co-x high-entropy alloys, Mater. Sci. Eng., A, 2018, vol. 710, pp. 200–205.

Fooladfar, H., Hashemi, B., and Younesi, M., The effect of the surface treating and high-temperature aging on the strength and SCC susceptibility of 7075 aluminum alloy, J. Mater. Eng. Perform., 2010, vol. 19, no. 6, pp. 852–859.

Deng, Y., Yin, Z., Zhao, K., Duan, J.Q., and He, Z.B., Effects of Sc and Zr microalloying additions and aging time at 120°C on the corrosion behaviour of an Al–Zn–Mg alloy, Corros. Sci., 2012, vol. 65, pp. 288–298.

ACKNOWLEDGMENTS

This research was financially supported by the program for National Key Research and Development Plan (2017YFB1104000), the National Natural Science Foundation of China (51 574 167), and the Research Fund for the Doctoral Program of Liaoning Province (20 170 520 337).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors state that they have no conflict of interest.

About this article

Cite this article

Siyi Ma, Su, R., Wang, K. et al. Effect of Deep Cryogenic Treatment on Wear and Corrosion Resistance of an Al–Zn–Mg–Cu Alloy. Russ. J. Non-ferrous Metals 62, 89–96 (2021). https://doi.org/10.3103/S1067821221010144

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1067821221010144