Abstract

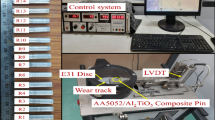

In this research, the mechanical and tribological behavior of aluminum–graphite (Al–Gr) composite has been investigated in order to determine the optimum composition of reinforcement. The materials were fabricated by a powder metallurgy process and three different weight percentages of Gr were chosen as a reinforcement in pure Al at 3, 5 and 7 wt % to identify its potential for self-lubricating property under dry sliding conditions. The mechanical properties examined included hardness, tensile strength and flexural strength. The wear tests were conducted by using a pin-on-disc tribometer to evaluate the tribological behavior of the composite and to determine the optimum content of graphite for its minimum wear rate. The results show that the mechanical properties decreased with the addition of Gr. However, 3 wt % Gr reinforced composite offers better mechanical properties as compared to that of other compositions. The wear rate and coefficient of friction also decreased with the addition of Gr and reaches its minimum value at 3 wt % Gr. A smooth graphite layer was observed in the worn surface of the 3 wt % Gr reinforced composite demonstrates superiority in terms of wear properties as compared to base material and other composites compositions.

Similar content being viewed by others

REFERENCES

Deaquino-Lara, R., Gutiérrez-Castañed, E., Estrada-Guel, I., Hinojosa-Ruiz, G., García-Sánchez, E., Herrera-Ramírez, J.M., Pérez-Bustamante, R., and Martínez-Sánchez, R., Structural characterization of aluminium alloy 7075–graphite composites fabricated by mechanical alloying and hot extrusion, Mater. Design, 2014, vol. 53, pp. 1104–1111.

Baradeswaran, A. and Perumal, A., Wear and mechanical characteristics of Al 7075/graphite composites, Compos. Part B, 2014, vol. 56, pp. 472–476.

Chu, H.S., Liu, K.S., and Yeh, J.W., An in situ composite of Al (graphite, Al4C3) produced by reciprocating extrusion, Mater. Sci. Eng., 2000, vol. 277A, pp. 25–32.

Guo, M.L. and Tsao, C., Tribological behavior of aluminum/SiC/nickel-coated graphite hybrid composites, Mater. Sci. Eng., 2002, vol. 333, pp. 134–145.

Ames, W. and Alpas, A.T., Wear mechanisms in hybrid composites of graphite-20Pct SiC in A356 aluminium alloy (Al-7 Pct Si-03 Pct Mg), Metall. Mater. Trans. A, 1995, vol. 26A, pp. 85–98.

Kestursatya, M., Kim, J.K., and Rohatgi, P.K., Wear performance of copper-graphite composite and leaded copper alloy, Mater. Sci. Eng., 2003, vol. A339, pp. 150–158.

Basavarajappa, S., Chandramohan, G., Mahadevan, A., Thangavelu, M., Subramanian, R., and Gopalakrishnan, P., Influence of sliding speed on the dry sliding wear behaviour and the subsurface deformation on hybrid metal matrix composite, Wear, 2007, vol. 262, nos. 7–8, pp. 1007–1012.

Yang, J.B., Lin, C.B., Wang, T.C., and Chu, H.Y., The tribological characteristics of A356.2Al alloy/Gr(p) composites, Wear, 2004, vol. 257, pp. 941–52.

Suresha, S. and Sridhara, B.K., Effect of silicon carbide particulates on wear resistance of graphitic aluminium matrix composite, Mater. Design, 2010, vol 31, no. 9, pp. 4470–4477.

Bansal, S. and Saini, J.S., Mechanical and wear properties of SiC/graphite reinforced Al359 alloy-based metal matrix composite, Def. Sci. J., 2015, vol. 65, pp. 330–338.

Leng, J., Jiang, L., Wu, G., Tian, S., and Chen, G., Effect of graphite particle reinforcement on dry sliding wear of SiC/Gr/Al composites, Rare Metal. Mater. Eng., 2009, vol. 38, pp. 1894–1898.

Ames, W. and Alpas, A.T., Wear mechanism in hybrid composites of graphite-20 pct SiC in A356 aluminium alloy (A1–7 pct Si–0.3 pct Mg), Metall. Mater.Trans., 1995, vol. 26A, pp. 85–98.

Riahi, A.R. and Alpas, A.T., The role of tribo-layers on the sliding wear behavior of graphitic aluminum matrix composites, Wear, 2001, vol. 251, pp. 1396–1407.

Chawla, N. and Shen, Y-L., Mechanical behavior of particle reinforced metal matrix composites, Adv. Eng. Mater., 2001, vol. 3, pp. 357–370.

Selvaraj, N., Mechanical and tribological behavior of particulate reinforced aluminum metal matrix composites—a review, J. Miner. Mater. Char. Eng., 2011, vol. 10, pp. 59–91.

Rahimian, M., Parvin, N., and Ehsani, N., The effect of production parameters on microstructure and wear resistance of powder metallurgy Al–Al2O3 composite, Mater. Design, 2011, vol. 32, 1031–1038.

Ge, D. and Gu, M., Mechanical properties of hybrid reinforced aluminum based composites, Mater. Lett., 2001, vol. 49, no. 6, pp. 334–339.

Iqbal, A.A., Chen, S., Arai, Y., and Araki, W., Study on stress evolution in SiC particles during crack propagation in cast hybrid metal matrix composites using Raman spectroscopy, Eng. Fail. Anal., 2015, vol. 52, pp. 109–115.

Rosso, M., Ceramic and metal matrix composites: Routes and properties, J. Mater. Process. Technol., 2006, vol. 175, pp. 364–375.

Reihani, S.M., Processing of squeeze cast Al6061–30 vol % SiC composites and their characterization, Mater. Design, 2006, vol. 27, pp. 216–222.

William, C. and Harrigan, J., Commercial processing of metal matrix composites, Mater. Sci. Eng. A, 1998, vol. 244, pp. 75–79.

Wan-li, G., Bulk Al/SiC nanocomposite prepared by ball milling and hot pressing method, Trans. Nonfer. Met. Soc. China, 2006, vol. 16, pp. 398–401.

Akhlaghi, F., Lajevardi, A., and Maghanaki, H.M., Effects of casting temperature on the microstructure and wear resistance of compocast A356/SiCp composites: a comparison between SS and SL routes, J. Mater. Process. Technol., 2004, vol. 155–156, pp. 1874–1880.

Iqbal, A.A., Arai, Y., and Araki, W., Effect of hybrid reinforcement on crack initiation and early propagation mechanism in cast metal matrix composites during low cycle fatigue, Mater. Design, 2013, vol. 45, pp. 241–252.

Onat, A., Akbulut, H., and Yilmaz, F., Production and characterisation of silicon carbide particulate reinforced aluminium- copper alloy matrix composites by direct squeeze casting method, J. Alloys Compd., 2007, vol. 436, pp. 375–382.

Prashant, S.N., Madeva, N., and Auradi, V., Preparation and evaluation of mechanical and wear properties of Al6061 reinforced with graphite and SiC particulate metal matrix composites, Int. J. Mech. Eng. Robot. Res., 2012, vol. 1, pp. 106–112.

Hasan, A.M., Tashtoush, G.M., and Ahmed, A.K.J., Effect of graphite and/or silicon carbide particles addition on the hardness and surface roughness of Al–4 wt % Mg alloy, J. Compos. Mater., 2007, vol. 41, pp. 453–465.

Akhlaghi, F. and Bidaki, Z.A., Influence of graphite content on dry sliding and oil impregnated sliding wear behaviour of Al2024–Gr composite produced by in situ powder metallurgy method, Wear, 2009, vol. 266, pp. 37–45.

ACKNOWLEDGMENTS

The authors gratefully acknowledge University Malaysia Pahang (UMP) for providing financial support under project no RDU 160371 during this research work.

Author information

Authors and Affiliations

Corresponding author

About this article

Cite this article

Norul Amierah Binti Nor Zamani, AKM Asif Iqbal & Nuruzzaman, D.M. Mechanical and Tribological Behavior of Powder Metallurgy Processed Aluminum–Graphite Composite. Russ. J. Non-ferrous Metals 60, 274–281 (2019). https://doi.org/10.3103/S1067821219030179

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1067821219030179