Abstract

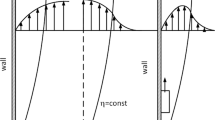

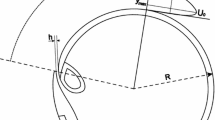

A method is proposed for calculating the convective heat transfer when a single circular jet interacts with a plane surface. The differences between this method and those currently existing are noted. The energy-dynamic potential of a flux and the energy-dynamic power of a flux are introduced. These concepts may be used to determine the rate of convective heat transfer at the gas–solid boundary. The differences between the proposed concepts and the existing concepts of the heat-flux density and heat flux are noted. The fundamental difference between the heat-flux density q and the energy-dynamic potential qe is as follows. The heat-flux density q for convective heat transfer is the heat transferred from a liquid to a solid surface (or conversely) in unit time through unit area of heat-transfer surface. Thus, q characterizes the rate of convective heat transfer at a phase boundary. By contrast, the energy-dynamic potential qe characterizes a property of the flux as a source or carrier of heat. Specifically, qe characterizes the unit power of the liquid flux. In calculating the heat transfer, the jet interacting with the surface may be divided into two parts: before interaction, a simple jet; after interaction, a fan-like flux. It is not entirely correct to calculate the convective heat transfer in jet heating on the basis of the Reynolds number calculated from the characteristics of the gas leaving the nozzle. Instead, characteristics of the fan-like flux must be used: specifically, the initial mean velocity Ufan of the fan-like flux; and the distance from the critical point of the jet (the point of intersection of the jet’s vertical axis and the surface) to the current radius downstream. To assess the change in the basic characteristics of the free jets with different distances from the nozzle outlet to the boundary surface, we present expressions for the expansion coefficient of the jet; the injection coefficient of the jet; the velocity coefficient for any cross section of the jet (including or excluding the nozzle’s outlet cross section); and the ratio of the Reynolds numbers. Our findings confirm the need to calculate the heat transfer on the basis of the characteristics of the fan-like flux.

Similar content being viewed by others

REFERENCES

Astsaturov, V.N. and Krasnokutskii, P.G., Heat transfer during jet heating of billets, Izv. Vyssh. Uchebn. Zaved., Chern. Metall., 1978, no. 1, pp. 56–58.

Astsaturov, V.N., Berkovskaya, P.S., and Krasnokutskii, P.G., Investigation of metal heating by attacking jets in the development of multi-row furnaces, in Pechi i sushila v mashinostroitel’noi promyshlennosti (Furnaces and Dryers in the Machine Engineering Industry), Moscow: Vses. Nauchno-Issled. Proekt. Inst. Teploproekt, 1978, no. 45, pp. 3–10.

Vokhmyakov, A.M., Kazyaev, M.D., and Kazyaev, D.M., Investigation of convective heat transfer in a through furnace equipped with high-speed burners, Tsvetn. Met., 2011, no. 12, pp. 89–93.

Pribytkov, I.A., Energy-saving methods of metal heating based on the use of jets, in Avtomatizirovannye pechnye agregaty i energosberegayushchie tekhnologii v metallurgii (Automated Furnaces and Energy-Saving Technologies in Metallurgy), Moscow: Mosk. Inst. Stali Splavov, 2002, pp. 375–390.

Timoshpol’skii, V.I., Trusova, I.A., and Ratnikov, P.E., Possibilities of application of metal jet heating before rolling, Lit’e Metall., 2007, no. 2, pp. 63–66.

Yudaev, B.N., Mikhailov, M.S., and Savin, V.K., Teploobmen pri vzaimodeistvii strui s pregradami (Heat Transfer at the Interaction of Jets with Obstacles), Moscow: Mashinostroenie, 1977.

Lisienko, V.G. and Shleimovich, E.M., Improving the thermal characteristics of furnaces and the operating conditions of the lining by improving direct-flame-impingement methods for intensifying the heating of metal, Refract. Ind. Ceram., 2013, vol. 54, no. 3, pp. 188–195.

Biryukov, A.B. and Gnitiev, P.A., Intensification of convective heat exchange in heating and thermal furnaces, Chern. Metall., Byull. Nauchno-Tekh. Ekon. Inf., 2017, no. 3, pp. 105–112.

Pribytkov, I.A. and Titova, G.V., Features of jet heating of thermally thin metal, Izv. Vyssh. Uchebn. Zaved., Chern. Metall., 1993, nos. 9–10, pp. 51–54.

Pribytkov, I.A., Calculation of metal thermal state at pulse-speed heating, Izv. Vyssh. Uchebn. Zaved., Chern. Metall., 1995, no. 1, pp. 53–56.

Kurnosov, V.V. and Shul’ts, L.A., High temperature nonoxidizing nondecarburizing heating of steel in combined fuel furnaces: problems and decisions, Izv. Vyssh. Uchebn. Zaved., Chern. Metall., 2012, no. 11, pp. 10–14.

Astsaturov, V.N., Intensification of thermal work of heating furnaces, in Avtomatizirovannye pechnye agregaty i energosberegayushchie tekhnologii v metallurgii (Automated Furnaces and Energy-Saving Technologies in Metallurgy), Moscow: Mosk. Inst. Stali Splavov, 2002, pp. 36–40.

Leprevost, J.-C., Lefèvre, A., Brancher, J.-P., and Saatdjian, E., Chaotic mixing and heat transfer in a periodic 2D flow, C. R. Acad. Sci., Ser. IIb: Mec., Phys., Chim., Astron., 1997, vol. 325, pp. 519–526.

Crow, S.C. and Champagne, F.H., Orderly structure in jet turbulence, J. Fluid Mech., 1971, vol. 48, pp. 547–591.

Gusovskii, V.L. and Lifshits, A.E., Metodika rascheta nagrevatel’nykh i termicheskikh pechei: Uchebno-spravochnoe izdanie (Calculation of Heating and Thermal Furnaces: Manual and Handbook), Moscow: Teplotekhnik, 2004.

Abramovich, G.N., The Theory of Turbulent Jets, Cambridge, Ma: MIT Press, 1963.

Michalke, A., On spatially growing disturbances in an inviscid shear layer, J. Fluid Mech., 1965, vol. 23, no. 3, pp. 521–544.

Liepmann, D. and Gharib, M., The role of streamwise vorticity in the near-field entrainment of round jets, J. Fluid Mech., 1992, vol. 245, pp. 643–68.

Abramovich, G.N., Prikladnaya gazovaya dinamika: Ucheb rukovodstvo dlya vtuzov (Applied Gas Dynamics: Manual for Higher Educational Technical Institutions), Moscow: Nauka, 1991, vol. 1.

Krivandin, V.A., Arutyunov, V.A., and Belousov, V.V., Teplotekhnika metallurgicheskogo proizvodstva (Heat Engineering of Metallurgical Production), Moscow: Mosk. Inst. Stali Splavov, 2001, vol. 1.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Translated by Bernard Gilbert

About this article

Cite this article

Pribytkov, I.A., Kondrashenko, S.I. Convective Heat Transfer in Jet Interaction with a Boundary Surface. Steel Transl. 49, 152–156 (2019). https://doi.org/10.3103/S0967091219030100

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S0967091219030100