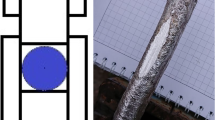

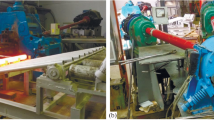

Based on the results of experimental radial-shear rolling of continuously cast anodic copper billets (rods) using a 10-30 mini-mill at 750 and 850°C, a part-through fracturing from within the billets has been discovered. The volume of cavities formed as a result of such fracturing appears to be more significant at 750°C. A simulation of rolling under experimental conditions was performed using DEFORM software, and the efficiency of applying a finite-element analysis computing environment for predicting fracturing was evaluated. An adequate correlation was established between the obtained estimates of the metal ductility under different deformation temperatures, as well as the probability of formation and dimensions of discontinuities and experimental data. The comparison between the shrinkage cavity depths of the billets based on the results of computer simulation has shown that the ductility of the rod material is higher at 800°C. Based on the analysis of variation in values of the rigidity coefficient under stress condition along the radius of the billet near the end of it, as well as analysis of the path described by the points located along the billet radius in the “cumulative deformation – rigidity coefficient under stress condition” coordinates while in the deformation zone, obtained as a result of computer simulation, it has been established that fracturing at 750°C should be more significant than at 800°C. Recommendations are provided regarding further use of the results of computer simulation to estimate the size of the regions, within which fracturing is expected to occur under the given rolling conditions.

Similar content being viewed by others

References

A. N. Nikulin, Screw Rolling. Stresses and Strains [in Russian], Metallurgizdat, Moscow (2015).

I. N. Potapov and P. I. Polukhin, Screw Rolling Technology [in Russian], Metallurgia, Moscow (1990).

S. P. Galkin, B. A. Romantsev, and E. A. Kharitonov, “Putting into practice innovative potential in the universal radial-shear rolling process,” CIS Iron and Steel Review, 2014, Issue 9, 35–39 (2014).

S. P. Galkin, Theory and Technology of Stationary Screw Rolling of Billets and Rods Made of Low-Ductility Steels and Alloys, D. Sc. Dissertation, Moscow (1998).

Modelling of the Mannesmann Effect in Tube Piercing, Padua@Research URL: http://paduaresearch.cab.unipd.it/1552/ (access date: January 16, 2018).

M. M. Skripalenko, B. A. Romantsev, S. P. Galkin, et al., “Predicting metal fracturing during screw rolling in a two-roll mill,” Metallurg, No. 11, 11–18 (2017).

A. Gryc, T. Bajor, and H. Dyha, “The analysis of influence of the parameters of rolling process in three high skew rolling mill of AZ31 magnesium alloy bars on temperature distribution,” Metalurgia, 55, No. 4, 772–774 (2016).

G. X. Huang, B. S. Sun, W. F. Peng, et al., “Research on stable forming of titanium alloy bar using three-roll skew rolling,” Advanced Materials Research, 1095, 837–841 (2015).

A. Stefanik, P. Szota, S. Mroz, and H. Dyja, “Application of the three-high skew rolling to magnesium rods production,” Mat. Testing, 58, No. 5, 438–441 (2016).

N. Lopatin, “Effect of hot rolling by screw mill on microstructure of a Ti–6Al–4V titanium alloy,” Int. J. Material Forming, 6, No. 4, 459–465 (2012).

N. Lopatin, G. Salishchev, and S. Galkin, “Mathematical modeling of radial-shear rolling of the VT6 titanium alloy under conditions of formation of a globular structure,” Russian J. Non-Ferrous Metals, 52, No. 5, 442–447 (2011).

S. P. Galkin, “Trajectory of deformed metal as basis for controlling the radial-shift and screw rolling,” Stal, 7, 63–66 (2004).

F. Yabo, C. Jing, and C. Zhiqiang, “Cracks of Cu–Cr–Zr alloy bars under planetary rolling,” Rare Metal Materials and Eng., 44, No. 3, 567–570 (2015).

S. Zhi, W. Meng Hua, L. Wei, and B. Ding, “Research on the tendency of inner crack during 3-Roll skew rolling process of round billets,” Advanced Materials Research, 145, 238–242 (2011).

B. A. Romantsev, S. P. Galkin, V. K. Mikhajlov, et al., “Bar micromill,” Stal, 2, 40–42 (1995).

B. V. Karpov, M. M. Skripalenko, S. P. Galkin, et al., “Studying the nonstationary stages of screw rolling of billets with profiled ends,” Metallurgist, 61, No. 3-4, 257–264 (2017).

G. V. Kozhevnikova, Theory and Practice of Cross-Wedge Rolling [in Russian], Belarusskaya Nauka, Minsk (2010).

S. P. Galkin, V. A. Fadeyev, and A. Yu. Gander, “Comparative analysis of geometry of mini-mills for radial-shear (screw) rolling,” Proiz. Prokata, 12, 19–25 (2015).

A. V. Vlasov, “Calculation of metal damage during cold radial forging based on the results of finite-element simulation using DEFORM-3D software,” in: Proc. Int. Sci. Tech. Conf. “Engineering Systems – 2009,” Moscow (2009), pp. 204–217.

V. L. Kolmogorov, Mechanics of Metal Treatment Under Pressure [in Russian], UGTU-UPI publishing, Yekaterinburg (2001).

V. A. Belevitin, Development and Improvement of Experimental Mechanics Techniques to Optimize Technological Processes of Metal Treatment Under Pressure, D. Sc. Dissertation, JSC “Ufaley metallurgical machine-building plant,” Verkhnii Ufaley (1997).

A. Bogatov and D. Pavlov, “Study of metal strained state during workpiece reduction in a three-roll screw-rolling mill,” Metallurgist, 61, No. 3-4, 311–317 (2017).

A. V. Belevich, Modeling of Ductility and Deformation Resistance Parameters of Steels and Alloys: Technological Mechanics Workshop, Vladimir State University, VlGU Publishing, Vladimir (2005).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Metallurg, Vol. 62, No. 9, pp. 7–12, September, 2018.

Rights and permissions

About this article

Cite this article

Skripalenko, M.M., Galkin, S.P., Sung, H.J. et al. Prediction of Potential Fracturing During Radial-Shear Rolling of Continuously Cast Copper Billets by Means of Computer Simulation. Metallurgist 62, 849–856 (2019). https://doi.org/10.1007/s11015-019-00728-8

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11015-019-00728-8