Abstract

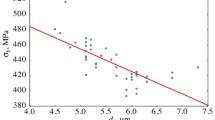

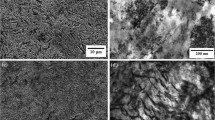

Exploitation of the Arctic calls for the creation of economical high-strength steel capable of operating at low temperatures. Research shows that, to that end, means of controlling the steel structure must be identified, so as to create quasi-isotropic fragmented nanostructure within the metal. The formation of finegrain structure is possible by a combination of intense plastic deformation with recrystallization and phase transformations. To confirm the theoretical and experimental preconditions for this process, experiments are conducted on the Gleeble-3800 instrument and a Kvarto-800 four-high rolling mill. Experimental steel melts with a carbon equivalent Cequ = 0.44–0.87% are investigated. In simulation on the Gleeble-3800 instrument, compressive deformation is applied in two stages: roughing at 1080–1100°C; and finishing at 950 and 820°C. That simulates the deformation cycle in industrial Kvarto-5000 four-high mills. The grain size in the steel is decreased from 6.5 to 2.2 μm after deformation at 950°C and 1.1 μm after deformation at 810°C. Fragments smaller than 500 nm constitute 20–37% of the steel structure. In the steel with Cequ = 0.44–0.65%, the yield point is 500–700 MPa, which is 40% greater than the standard values. In the steel with Cequ = 0.65–0.87%, the yield point is 700–1150 MPa. These values are obtained with increase in nickel content in the steel to 3%. At higher Ni concentrations, no improvement in yield point is seen. After rolling on the Kvarto-800 mill, with Cequ = 0.60–0.87% in one pass (with 70% reduction) at 1100°C and direct quenching with subsequent tempering at 600°C, the yield point is 1060 MPa. In this case, variation in the Ni content and Cequ has little influence on the yield point. The steel consists of bainite (mean grain size 6.9–8.3 μm), with a large dislocation density (1–2) × 1015 m–2 and considerable fragmentation within the grain. On the basis of the new technology, a group of low-temperature steels with yield points of 270–690 MPa and Cequ = 0.32–0.65% is created. The thickness of the steel sheet is up to 130 mm; it may operate at temperatures as low as –60°C. Such steel may be used for atomic icebreakers, other Arctic vessels, and fixed and floating drilling platforms for oil and gas extraction from Russia’s Arctic shelf. This research demonstrates the possibility of creating structural steels with relatively little alloying (up to 20–30%) and with standardized chemical composition.

Similar content being viewed by others

References

Oryshchenko, A.S., Khlusova, E.I., and Sharapov, M.G., Metallovedenie konstruktsionnykh svarivaemykh stalei (Metal Science of Constructional Welded Steels), St. Petersburg: S.-Peterb. Gos. Politekh. Univ., 2012.

Gorynin, I.V. and Khlusova, E.I., Nanostructured steels for developing the shelf of the Arctic Ocean, Herald Russ. Acad. Sci., 2010, vol. 80, no. 6, pp. 507–513.

Rybin, V.V., Bol’shie plasticheskie deformatsii i vyazkoe razrushenie (Large Plastic Deformations and Viscous Fracture), Moscow: Metallurgiya, 1986.

GOST (State Standard) R 52927-2015: Rolled of Normal, Increased-and High-Strength Steel for Shipbuilding. Specifications, Moscow: Standartinform, 2015.

Kruglova, A.A., Orlov, V.V., Khlusova, E.I., and Golovanov, A.V., Influence of thermomechanical processing parameters on the structure and properties of hotrolled thick-plate low-alloyed steel with improved weldability, Proizvod. Prokata, 2006, no. 3, pp. 21–28.

Efron, L.I., Metallovedenie v “bol’shoi” metallurgii. Trubnye stali (Metal Science in “Big” Metallurgy: Pipe Steels), Moscow: Metallurgizdat, 2012.

Schastlivtsev, V.M., Tabatchikova, T.I., Yakovleva, I.L., Klyueva, S.Yu., Kruglova, A.A., Orlov, V.V., and Khlusova, E.I., Microstructure and properties of lowcarbon weld steel after thermomechanical strengthening, Phys. Met. Metallogr., 2012, vol. 113, no. 5, pp. 480–488.

Khlusova, E.I., Kruglova, A.A., and Orlov, V.V., Effect of hot plastic deformation in the austenite interval on structure formation in low-alloyed low-carbon steel, Metal Sci. Heat Treat., 2007, vol. 49, nos. 11–12, pp. 556–560.

Khlusova, E.I., Mikhailov, M.S., and Orlov, V.V., Features of structure formation of thick-plate low-carbon steel at thermomechanical processing, Deform. Razrushenie Mater., 2007, no. 6, pp. 18–25.

Golosienko, S.A., Soshina, T.V., and Khlusova, E.I., New high-strength steels for arctic applications, Proizvod. Prokata, 2014, no. 2, pp. 17–25.

Bashaev, A.K., Zykov, V.V., Legostaev, Yu.L., and Tishkov, V.Ya., Welded cold-resistant steels for marine stationary platform Prirazlomnaya, Nauchno-Tekh. Sb. Ross. Morsk. Registra Sudokhodstva, 2000, no. 23, pp. 114–137.

Matrosov, Yu.I., Litvinenko, D.A., and Golovanenko, S.A., Stal’ dlya magistral’nykh truboprovodov (Steel for Main Pipelines), Moscow: Metallurgiya, 1989.

Sych, O.V., Khlusova, E.I., Orlov, V.V., and Kruglova, A.A., Improvement of chemical composition and production regimes for manufacture of K65–K70 (X80–X90) strip based on simulation, Metallurgist, 2013, vol. 57, nos. 1–2, pp. 113–122.

Korotovskaya, S.A., Nesterova, E.V., Orlov, V.V., and Khlusova, E.I., Influence of the parameters of plastic deformation on formation of ultrafine-grained structure in low-alloyed bainitic steels, Vopr. Materialoved., 2011, no. 1 (65), pp. 100–109.

Korotovskaya, S.V., Orlov, V.V., and Khlusova, E.I., Control of structure formation during thermomechanical treatment of shipbuilding and pipe steels of unified chemical composition, Metallurgist, 2014, vol. 58, nos. 5–6, pp. 406–414.

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © A.S. Oryshchenko, 2017, published in Izvestiya Vysshikh Uchebnykh Zavedenii, Chernaya Metallurgiya, 2017, No. 11, pp. 919–924.

About this article

Cite this article

Oryshchenko, A.S. Creating Weldable High-Strength Structural Steel with Nanostructuring. Steel Transl. 47, 717–721 (2017). https://doi.org/10.3103/S0967091217110080

Received:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S0967091217110080