Abstract

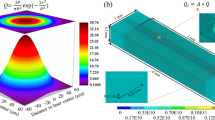

In this study, a thermal–elastic–plastic finite element model is proposed to investigate the effect of volume energy density on the temperature field, molten pool size, and residual stress distribution in the selective laser melting (SLM) process of Inconel 718 alloy. A temperature-dependent thermal–mechanical property of materials is considered, as well as the properties conversion between powder layer and solidified alloy. Within the scope of the study parameters, the simulated molten pool size increases with increasing volume energy density and exhibits linear growth relationship, which are validated by the experimental results and show a good agreement. In addition, five scanning strategies are adopted to study the effect of these scanning strategies on the residual stress distribution in this research. The results show that the residual stress distribution of SLM Inconel 718 specimen largely depends on the scanning strategy. Finally, to reveal the mechanism of residual stress formation, the restraint bar model is used to further analyze the formation mechanism of residual stress during the SLM process.

Similar content being viewed by others

References

K.N. Amato, S.M. Gaytan, L.E. Murr, E. Martinez, P.W. Shindo, J. Hernandez, S. Collins, and F. Medina: Microstructures and mechanical behavior of Inconel 718 fabricated by selective laser melting. Acta Mater. 60, 2229 (2012).

G. Cam and M. Kocak: Progress in joining of advanced materials. Int. Mater. Rev. 43, 1 (1998).

F.C. Liu, X. Lin, C.P. Huang, M.H. Song, G.L. Yang, J. Chen, and W.D. Huang: The effect of laser scanning path on microstructures and mechanical properties of laser solid formed nickel-base superalloy Inconel 718. J. Alloy. Comp. 509, 4505 (2011).

S.H. Chang: In situ TEM observation of γ, γ, and δ precipitations on Inconel 718 superalloy through HIP treatment. J. Alloy. Comp. 486, 716 (2009).

T. Rong, D.D. Gu, Q.M. Shi, S.N. Cao, and M.J. Xia: Effects of tailored gradient interface on wear properties of WC/Inconel 718 composites using selective laser melting. Surf. Coat. Technol. 307, 418 (2016).

H. Ali, L. Ma, H. Ghabeigi, and K. Mumtaz: In situ residual stress reduction, martensitic decomposition and mechanical properties enhancement through high temperature powder bed pre-heating of Selective Laser Melted Ti6Al4V. Mater. Sci. Eng., A 695, 211 (2017).

P. Mercelis and J.P. Kruth: Residual stresses in selective laser sintering and selective laser melting. Rapid Prototyp. J. 12, 254 (2006).

S.A. Khairallah and A. Anderson: Mesoscopic simulation model of selective laser melting of stainless steel powder. J. Mater. Process. Technol. 214, 2627 (2014).

K. Zeng, D. Pal, and B. Stucker: A review of thermal analysis methods in laser sintering and selective laser melting. SFF Samposium, Vol. 769 (2012).

S. Das: Physical aspects of process control in selective laser sintering of metals. Adv. Eng. Mater. 5, 701 (2003).

B. Song, S.J. Dong, H.L. Liao, and C. Coddet: Process parameter selection for selective laser melting of Ti6Al4V based on temperature distribution simulation and experimental sintering. Int. J. Adv. Manuf. Technol. 61, 967 (2012).

L. Thijs, F. Verhaeghe, T. Craeghs, J. Van Humbeeck, and J.P. Kruth: A study of the micro structural evolution during selective laser melting of Ti–6Al–4V. Acta Mater. 58, 3303 (2010).

G.Q. Yu, D.D. Gu, D.H. Dai, M.J. Xia, C.L. Ma, and Q.M. Shi: On the role of processing parameters in thermal behavior, surface morphology and accuracy during laser 3D printing of aluminum alloy. J. Phys. D: Appl. Phys. 49, 135501 (2016).

C. Li, C. Fu, Y. Guo, and F. Fang: A multiscale modeling approach for fast prediction of part distortion in selective laser melting. J. Mater. Process. Technol. 229, 703 (2016).

B. Cheng, S. Shrestha, and K. Chou: Stress and deformation evaluations of scanning strategy effect in selective laser melting. Addit. Manuf. 12, 240 (2016).

H. Ali, H. Ghadbeigi, and K. Mumtaz: Effect of scanning strategies on residual stress and mechanical properties of Selective Laser Melted Ti6Al4V. Mater. Sci. Eng., A 712, 175 (2018).

L. Zhang, W.H. Wu, L. Lu, X.Q. Ni, B.B. He, Q.Y. Yang, G.L. Zhu, and Y.Y. Gu: Effect of heat input parameters on temperature field in Inconel 718 alloy during selective laser melting. J. Mater. Eng. 46, 29 (2018).

H. Ali, H. Ghadbeigi, and K. Mumtaz: Residual stress development in selective laser-melted Ti6Al4V: A parametric thermal modelling approach. Int. J. Adv. Manuf. Technol. 97, 2621 (2018).

J. Goldak, A. Chakravarti, and M. Bibby: A new finite element model for welding heat sources. Metall. Mater. Trans. B 15, 299 (1984).

J. Goldak, M. Bibby, J. Moore, R. House, and B. Patel: Computer modeling of heat flow in welds. Metall. Mater. Trans. B 17, 587 (1986).

J. Song, W.H. Wu, L. Zhang, B.B. He, L. Lu, X.Q. Ni, Q.L. Long, and G.L. Zhu: Role of scanning strategy on residual stress distribution in Ti–6Al–4V alloy prepared by selective laser melting. Optik 170, 342 (2018).

C.H. Lee, K.H. Chang, and J.U. Park: Three-dimensional finite element analysis of residual stresses in dissimilar steel pipe welds. Nucl. Eng. Des. 256, 160 (2013).

Acknowledgments

This work is supported by the project to strengthen industrial development at the grass-roots level (Project No. TC160A310/19), Natural Science Foundation of Shanghai (Project No. 17ZR1409200), Shanghai Rising-star program (Project No. 18QB1400600), and Shanghai Materials Genome Institute No. 5 (Project No. 16DZ2260605).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Song, J., Zhang, L., Wu, W. et al. Understanding processing parameters affecting residual stress in selective laser melting of Inconel 718 through numerical modeling. Journal of Materials Research 34, 1395–1404 (2019). https://doi.org/10.1557/jmr.2018.504

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2018.504