Abstract

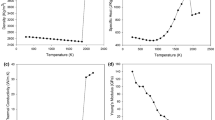

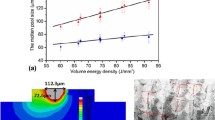

The finite element model was established to predict the thermal and stress fields in selective laser melting of Ti55531 alloy. The temperature distribution, melt pool dimension, and solidification parameters on the different scanning speeds were evaluated and analyzed. The results show that the temperature and dimension of the melt pool decrease as the scanning speed increases. The maximum cooling rate and solidification rate are about 1.38 × 104 ℃/s and 0.95 mm/s, respectively, obtained at scanning speed of 1000 mm/s, while the minimum cooling rate and solidification rate are approximately 5.80 × 103 ℃/s and 0.2 mm/s, respectively, obtained at scanning speed of 200 mm/s. Relatively high scanning speed improves the instability of the solid/liquid interface and is beneficial for obtaining fine grains. In addition, the thermal stress exhibits a tendency to increase with the laser moves forward, and the residual stress increases sharply mainly during the cooling period. The maximum residual stress reached 878 MPa with a scanning speed of 1000 mm/s. The simulations and experiment results exhibit good agreement. A surface heat source with Gaussian distribution was used to realize the numerical simulation of SLM under different scanning speeds, which provides a good reference for the optimization of deposition parameters of Ti55531 alloy and the production of good-quality deposited components in the future.

Similar content being viewed by others

References

Chen F, Xu G, Zhang X, Zhou K (2017) Isothermal kinetics of β ↔ α transformation in Ti-55531 alloy influenced by phase composition and microstructure[J]. Mater Design 130:302–316. https://doi.org/10.1016/j.matdes.2017.05.078

Deng H, Chen L, Qiu W, Zheng Z, Tang Y, Hu Z, Wei Y, Xia Z, Le G, Tang J, Cui X (2019) Microstructure and mechanical properties of as-deposited and heat treated Ti–5Al–5Mo–5V–3Cr–1Zr (Ti-55531) alloy fabricated by laser melting deposition[J]. J Alloy Compd 810:151792. https://doi.org/10.1016/j.jallcom.2019.151792

Sharma D, Parfitt D, Chen B, Roebuck B, Venero DA, Kada SR, Fabijanic D, Fitzpatrick ME (2021) Influence of cooling rate on the precipitation kinetics of nanoscale isothermal ω-phase in metastable β-Ti alloy, Ti–5Al–5Mo–5V–3Cr[J]. J Alloy Compd 859157822. https://doi.org/10.1016/j.jallcom.2020.157822

Manikandan R, Raja Annamalai A (2022) Tungsten heavy alloys processing via microwave sintering, spark plasma sintering, and additive manufacturing: a review[J]. Processes 10(11):2352. https://doi.org/10.3390/pr10112352

Papazoglou EL, Karkalos NE, Karmiris-Obratański P, Markopoulos AP (2021) On the modeling and simulation of SLM and SLS for metal and polymer powders: a Review[J]. Arch Comput Methods Eng 29(2):941–973. https://doi.org/10.1007/s11831-021-09601-x

Liu S, Shin YC (2019) Additive manufacturing of Ti6Al4V alloy: a review[J]. Mater Design 164:107552. https://doi.org/10.1016/j.matdes.2018.107552

Razavykia A, Brusa E, Delprete C, Yavari R (2020) An Overview of Additive Manufacturing Technologies-A Review to Technical Synthesis in Numerical Study of Selective Laser Melting[J]. Mater (Basel) 13(17). https://doi.org/10.3390/ma13173895

Ngo TD, Kashani A, Imbalzano G, Nguyen KTQ, Hui D (2018) Additive manufacturing (3D printing): a review of materials, methods, applications and challenges[J]. Compos Part B: Eng 143:172–196. https://doi.org/10.1016/j.compositesb.2018.02.012

Shipley H, McDonnell D, Culleton M, Coull R, Lupoi R, O’Donnell G, Trimble D (2018) Optimisation of process parameters to address fundamental challenges during selective laser melting of Ti-6Al-4V: a review[J]. Int J Mach Tools Manuf 128:1–20. https://doi.org/10.1016/j.ijmachtools.2018.01.003

Colombo-Pulgarín JC, Biffi CA, Vedani M, Celentano D, Sánchez-Egea A, Boccardo AD, Ponthot JP (2021) Beta titanium alloys processed by laser powder bed fusion: a review[J]. J Mater Eng Perform 30(9):6365–6388. https://doi.org/10.1007/s11665-021-05800-6

Moghimian P, Poirié T, Habibnejad-Korayem M, Zavala JA, Kroeger J, Marion F, Larouche F (2021) Metal powders in additive manufacturing: a review on reusability and recyclability of common titanium, nickel and aluminum alloys[J]. Addit Manuf 43:102017. https://doi.org/10.1016/j.addma.2021.102017

Lavery NP, Cherry J, Mehmood S, Davies H, Girling B, Sackett E, Brown SGR, Sienz J (2017) Effects of hot isostatic pressing on the elastic modulus and tensile properties of 316L parts made by powder bed laser fusion[J]. Mater Sci Engineering: A 693:186–213. https://doi.org/10.1016/j.msea.2017.03.100

Hussein A, Hao L, Yan C, Everson R (2023) Finite element simulation of the temperature and stress fields in single layers built without-support in selective laser melting[J]. Materials & Design (1980–2015) 52:638–647. https://doi.org/10.1016/j.matdes.2013.05.070

Haubrich J, Gussone J, Barriobero-Vila P, Kürnsteiner P, Jägle EA, Raabe D, Schell N, Requena G (2019) The role of lattice defects, element partitioning and intrinsic heat effects on the microstructure in selective laser melted Ti-6Al-4V[J]. Acta Mater 167:136–148. https://doi.org/10.1016/j.actamat.2019.01.039

Wang Z, Xiao Z, Tse Y, Huang C, Zhang W (2019) Optimization of processing parameters and establishment of a relationship between microstructure and mechanical properties of SLM titanium alloy[J]. Opt Laser Technol 112:159–167. https://doi.org/10.1016/j.optlastec.2018.11.014

Li Y, Gu D (2014) Thermal behavior during selective laser melting of commercially pure titanium powder: Numerical simulation and experimental study[J]. Addit Manuf 1–499. https://doi.org/10.1016/j.addma.2014.09.001

Guo M, Gu D, Xi L, Du L, Zhang H, Zhang J (2019) Formation of scanning tracks during selective laser melting (SLM) of pure tungsten powder: morphology, geometric features and forming mechanisms[J]. Int J Refract Met Hard Mater 79:37–46. https://doi.org/10.1016/j.ijrmhm.2018.11.003

Bai R, Liang G, Cheng H, Naceur H, Coutellier D, Zhao J, Luo J, Pu H, Yi J (2023) Optimizing additive manufacturing path pattern for Ti-6Al-4V thin rods using a combinatorial radial basis function surrogate-assisted genetic algorithm[J]. Mater Design 236. https://doi.org/10.1016/j.matdes.2023.112447

Pu H, Liang G, Naceur H, Zhao J, Yi J, Luo J, Coutellier D, Wang L, Bai R (2023) Thermo-mechanical analysis of Ti-6Al-4V Taylor bar using advanced joint path strategies based on additive manufacturing[J]. Cirp J Manuf Sci Tec 40:167–179. https://doi.org/10.1016/j.cirpj.2022.11.009

Bartlett JL, Li X (2019) An overview of residual stresses in metal powder bed fusion[J]. Addit Manuf 27:131–149. https://doi.org/10.1016/j.addma.2019.02.020

Zhang J, Liou F, Seufzer W, Taminger K (2016) A coupled finite element cellular automaton model to predict thermal history and grain morphology of Ti-6Al-4V during direct metal deposition (DMD)[J]. Addit Manuf 11:32–39. https://doi.org/10.1016/j.addma.2016.04.004

Yang Q, Zhang P, Cheng L, Min Z, Chyu M, To AC (2016) Finite element modeling and validation of thermomechanical behavior of Ti-6Al-4V in directed energy deposition additive manufacturing[J]. Addit Manuf 12:169–177. https://doi.org/10.1016/j.addma.2016.06.012

Wagner V, Harzallah M, Baili M, Dessein G, Lallement D (2020) Experimental and numerical investigations of the heating influence on the Ti5553 titanium alloy machinability[J]. J Manuf Process 58:606–614. https://doi.org/10.1016/j.jmapro.2020.08.018

Baykasoğlu C, Akyildiz O, Tunay M, To AC (2020) A process-microstructure finite element simulation framework for predicting phase transformations and microhardness for directed energy deposition of Ti6Al4V[J]. Addit Manuf 35:101252. https://doi.org/10.1016/j.addma.2020.101252

Li B, Du J, Sun Y, Zhang S, Zhang Q (2023) On the importance of heat source model determination for numerical modeling of selective laser melting of IN625[J]. Opt Laser Technol 158:108806. https://doi.org/10.1016/j.optlastec.2022.108806

Luo Z, Zhao Y (2018) A survey of finite element analysis of temperature and thermal stress fields in powder bed fusion Additive Manufacturing[J]. Addit Manuf 21:318–332. https://doi.org/10.1016/j.addma.2018.03.022

Li Z, Yang S, Liu B, Liu W, Kuai Z, Nie Y (2021) Simulation of temperature field and stress field of selective laser melting of multi-layer metal powder[J]. Opt Laser Technol 140:140106782. https://doi.org/10.1016/j.optlastec.2020.106782

Du Y, You X, Qiao F, Guo L, Liu Z (2019) A model for predicting the temperature field during selective laser melting[J]. Results Phys 12:52–60. https://doi.org/10.1016/j.rinp.2018.11.031

Li R, Wang G, Zhao X, Dai F, Huang C, Zhang M, Chen X, Song H, Zhang H (2021) Effect of path strategy on residual stress and distortion in laser and cold metal transfer hybrid additive manufacturing[J]. Addit Manuf 46:102203. https://doi.org/10.1016/j.addma.2021.102203

Zuo H, Deng H, Zhou L, Qiu W, Xu P, Chen H, Liu W, Tang J (2023) The anisotropy of corrosion and passive behavior in selective laser melted Ti-5Al-5Mo-5 V-3Cr-1Zr alloy[J]. Mater Charact 112954. https://doi.org/10.1016/j.matchar.2023.112954

Deng H, Qiu W, Cao S, Chen L, Hu Z, Wei Y, Xia Z, Zhou L, Cui X, Tang J (2021) Heat-treatment induced microstructural evolution and enhanced mechanical property of selective laser melted near β Ti-5Al-5Mo-5 V-3Cr-1Zr alloy[J]. J Alloy Compd 858:158351

Todaro CJ, Easton MA, Qiu D, Zhang D, Bermingham MJ, Lui EW, Brandt M, StJohn DH, Qian M (2020) Grain structure control during metal 3D printing by high-intensity ultrasound[J]. Nat Commun 11(1):142. https://doi.org/10.1038/s41467-019-13874-z

Cao Y, Li N, Luo Y, Tang H, Xie Q, Fu A (2022) A novel ultra-high strength titanium alloy via hierarchical α/α′ precipitation strengthening[J]. Mater Sci Engineering: A 142878. https://doi.org/10.1016/j.msea.2022.142878

Ho CY, Wen MY (2004) Distribution of the intensity absorbed by the keyhole wall in laser processing[J]. J Mater Process Technol 145(3):303–310. https://doi.org/10.1016/j.jmatprotec.2003.07.009

Li Y, Založnik M, Zollinger J, Dembinski L, Mathieu A (2021) Effects of the powder, laser parameters and surface conditions on the molten pool formation in the selective laser melting of IN718[J]. J Mater Process Technol 289:116930

Bock FE, Herrnring J, Froend M, Enz J, Kashaev N, Klusemann B (2021) Experimental and numerical thermo-mechanical analysis of wire-based laser metal deposition of Al-Mg alloys[J]. J Manuf Process 64:982–995. https://doi.org/10.1016/j.jmapro.2021.02.016

DebRoy T, Wei HL, Zuback JS, Mukherjee T, Elmer JW, Milewski JO, Beese AM, Wilson-Heid A, De A, Zhang W (2018) Additive manufacturing of metallic components – process, structure and properties[J]. Prog Mater Sci 92:112–224. https://doi.org/10.1016/j.pmatsci.2017.10.001

Tan C, Weng F, Sui S, Chew Y, Bi G (2021) Progress and perspectives in laser additive manufacturing of key aeroengine materials[J]. Int J Mach Tools Manuf 17:0103804. https://doi.org/10.1016/j.ijmachtools.2021.103804

Lin ZD, Song KJ, Yu XH (2021) A review on wire and arc additive manufacturing of titanium alloy[J]. J Manuf Process 70:24–45. https://doi.org/10.1016/j.jmapro.2021.08.018

Kobryn PA, Semiatin SL (2003) Microstructure and texture evolution during solidification processing of Ti–6Al–4V[J]. J Mater Process Technol 135(2–3):330–339. https://doi.org/10.1016/s0924-0136(02)00865-8

Zhang Y, Zou D, Wang X, Li Y, Jiang Y, Zhang W, Tong L (2022) Influence of cooling rate on δ-ferrite/γ-austenite formation and precipitation behavior of 18Cr–Al–Si ferritic heat-resistant stainless steel[J]. J Mater Res Technol 18:1855–1864. https://doi.org/10.1016/j.jmrt.2022.03.060

Ali T, Wang L, Cheng XW, Cheng HW, Yang Y, Liu AJ, Xu XF, Zhou Z, Ning ZX, Xu ZQ, Min XH (2021) Mechanical (compressive) form of driving force triggers the phase transformation from beta to omega & alpha ‘’ phases in metastable beta phase-field Ti-5553 alloy[J]. J Mater Sci Technol 78:238–246. https://doi.org/10.1016/j.jmst.2020.11.033

Lai MJ, Li T, Raabe D (2018) ω phase acts as a switch between dislocation channeling and joint twinning- and transformation-induced plasticity in a metastable β titanium alloy[J]. Acta Mater 151:67–77. https://doi.org/10.1016/j.actamat.2018.03.053

Akbari M, Kovacevic R (2019) Closed loop control of melt pool width in robotized laser powder–directed energy deposition process[J]. Int J Adv Manuf Technol 104(5–8):2887–2898. https://doi.org/10.1007/s00170-019-04195-y

Khobzi A, Farhang Mehr F, Cockcroft S, Maijer D, Sing SL, Yeong WY (2022) The role of block-type support structure design on the thermal field and deformation in components fabricated by laser powder Bed Fusion[J]. Addit Manuf 51:102644

Müller Av, Schlick G, Neu R, Anstätt C, Klimkait T, Lee J, Pascher B, Schmitt M, Seidel C (2019) Additive manufacturing of pure tungsten by means of selective laser beam melting with substrate preheating temperatures up to 1000 ∘C[J]. Nuclear Mater Energy 19:184–188. https://doi.org/10.1016/j.nme.2019.02.034

Bai RQ, Liang G, Naceur H, Coutellier D, Zhao JL, Yi J, Luo J, Wang L, Pu HY (2023) Influence of the advanced joint path strategies on the energy absorption capacity of Ti-6Al-4V Taylor bar based on additive manufacturing[J]. J Therm Stresses 46(2):140–162. https://doi.org/10.1080/01495739.2022.2149646

Bai R, Pu H, Liang G, Naceur H, Coutellier D, Du Y, Zhao J, Yi J, Li X, Yuan S, Luo J, Lin J (2023) Exact forming for additive manufacturing using an irregular element-based compensating approach: Simulation, experiment, and detection[J]. Mech Adv Mater Struct 1–12. https://doi.org/10.1080/15376494.2023.2246191

Funding

This work was supported by Department of Science and Technology of Sichuan Province (No. 2020YFG0138).

Author information

Authors and Affiliations

Contributions

Ping Xu: conceptualization, investigation, validation, visualization, writing—original draft, review and editing. Hanyang Zuo: resources, data curation, investigation. Lvjun Zhou: resources, data curation, investigation, formal analysis. Wenbin Qiu: writing—review and editing, formal analysis. Jun Tang: writing—review and editing, supervision, project administration.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Xu, P., Zuo, H., Zhou, L. et al. Finite element simulation and experimental validation of the thermomechanical behavior in selective laser melting of Ti55531 alloy. Int J Adv Manuf Technol (2024). https://doi.org/10.1007/s00170-024-13711-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s00170-024-13711-8