Abstract

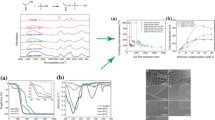

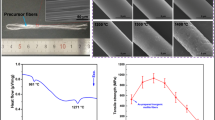

A novel hybrid processing has been developed to achieve dense and crack-free mullite films with large critical thicknesses. The amorphous solid nanoparticles obtained from the mullite sol–gel precursor were mixed with the same liquid precursor to form stable suspensions, which were subsequently used to form mullite coatings with the dip-coating method, followed by drying and firing. The hybrid precursor suspensions resulted in highly close-packed nanoparticles, which reduced shrinkage during sintering. Selecting the solvent with a low evaporation rate and high surface tension can effectively eliminate the surface instability caused by the lateral flow during solvent evaporation. The mullite film density was significantly improved at low sintering temperatures, because of the high packing density and viscous flow at above the glass transition temperature of the amorphous gel nanoparticles before crystallization. Dense and crack-free mullite films with 500–600 nm thickness can be obtained from the novel hybrid approach.

Similar content being viewed by others

References

W.M. Kriven, J.W. Palko, S. Sinogeikin, J.D. Bass, A. Sayir, G. Brunauer, H. Boysen, F. Frey, and J. Schneider: High temperature single crystal properties of mullite. J. Eur. Ceram. Soc. 19, 2529 (1999).

P.C. Dokko, J.A. Pask, and K.S. Mazdiyasni: High-temperature mechanical properties of mullite under compression. J. Am. Ceram. Soc. 60, 150 (1977).

S. Kanzaki, H. Tabata, T. Kumazawa, and S. Ohta: Sintering and mechanical properties of stoichiometric mullite. J. Am. Ceram. Soc. 68, C–6 (1985).

K.N. Lee: Current status of environmental barrier coatings for Si-based ceramics. Surf. Coat. Technol. 133, 1 (2000).

R.A. Miller: Thermal barrier coatings for aircraft engines: History and directions. J. Therm. Spray Technol. 6, 35 (1997).

T. Kulkarni, H.Z. Wang, S.N. Basu, and V.K. Sarin: Compositionally graded mullite-based chemical vapor deposited coatings. J. Mater. Res. 24, 470 (2009).

O.R. Monteiro, Z. Wang, and I.G. Brown: Deposition of mullite and mullite-like coatings on silicon carbide by dual-source metal plasma immersion. J. Mater. Res. 12, 2401 (1997).

P. Hou, S.N. Basu, and V.K. Sarin: Nucleation mechanisms in chemically vapor-deposited mullite coatings on SiC. J. Mater. Res. 14, 2952 (1999).

R.P. Mulpuri and V.K. Sarin: Synthesis of mullite coatings by chemical vapor deposition. J. Mater. Res. 11, 1315 (1996).

C.J. Brinker and G.W. Scherer: Sol–gel Science: The Physics and Chemistry of Sol–gel Processing (Academic press, New York, 2013).

J. Roy, S. Das, and S. Maitra: Sol gel-processed mullite coating—A review. Int. J. Appl. Ceram. Technol. 12, S2 (2014).

Y.Y. Chen and W.C.J. Wei: Formation of mullite thin film via a sol–gel process with polyvinylpyrrolidone additive. J. Eur. Ceram. Soc. 21, 2535 (2001).

N. Wang, X.Z. Yang, J.B. Li, H. Lin, and B. Chi: Fabrication and characterization of porous mullite coating on porous silicon carbide support. Key Eng. Mater. 280, 1301 (2004).

S.A. Ansar, S. Bhattacharya, S. Dutta, S.S. Ghosh, and S. Mukhopadhyay: Development of mullite and spinel coatings on graphite for improved water-wettability and oxidation resistance. Ceram. Int. 36, 1837 (2010).

M. Jayasankar, G.M. Anilkumar, V.S. Smitha, P. Mukundan, C.D. Madhusoodana, and K.G.K. Warrier: Low temperature needle like mullite grain formation in sol–gel precursors coated on SiC porous substrates. Thin Solid Films 519, 7672 (2011).

U. Selvaraj, S. Komarneni, and R. Roy: Structural differences in mullite xerogels from different precursors characterized by 27Al and 29Si MASNMR. J. Solid State Chem. 106, 73 (1993).

D.J. Cassidy, J.L. Woolfrey, J.R. Bartlett, and B. Ben-Nissan: The effect of precursor chemistry on the crystallisation and densification of sol–gel derived mullite gels and powders. J. Sol-Gel Sci. Technol. 10, 19 (1997).

T. Ban, S. Hayashi, A. Yasumori, and K. Okada: Characterization of low temperature mullitization. J. Eur. Ceram. Soc. 16, 127 (1996).

H. Kozuka, S. Takenaka, H. Tokita, T. Hirano, Y. Higashi, and T. Hamatani: Stress and cracks in gel-derived ceramic coatings and thick film formation. J. Sol-Gel Sci. Technol. 26, 681 (2003).

A. Atkinson and R.M. Guppy: Mechanical stability of sol–gel films. J. Mater. Sci. 26, 3869 (1991).

Z. Chen, R. Burtovyy, K. Kornev, I. Luzinov, D. Xu, and F. Peng: The effect of polymer additives on the critical thicknesses of mullite thin films obtained from the monophasic sol–gel precursors. J. Sol-Gel Sci. Technol. 80, 285 (2016).

C.J. Brinker, A.J. Hurd, P.R. Schunk, G.C. Frye, and C.S. Ashley: Review of sol–gel thin film formation. J. Non-Cryst. Solids 147, 424 (1992).

S.Y. Chen and I.W. Chen: Cracking during pyrolysis of oxide thin films-phenomenology, mechanisms, and mechanics. J. Am. Ceram. Soc. 78, 2929 (1995).

H. Kozuka and S. Takenaka: Single-step deposition of gel-derived lead zirconate titanate films: Critical thickness and gel film to ceramic film conversion. J. Am. Ceram. Soc. 85, 2696 (2002).

C. Jing, X. Zhao, and Y. Zhang: Sol–gel fabrication of compact, crack-free alumina film. Mater. Res. Bull. 42, 600 (2007).

T. Kishimoto and H. Kozuka: Sol–gel preparation of TiO2 ceramic coating films from aqueous solutions of titanium sulfate (IV) containing polyvinylpyrrolidone. J. Mater. Res. 18, 466 (2003).

H. Kozuka and M. Kajimura: Single-step dip coating of crack-free BaTiO3 films >1 µm thick: Effect of poly(vinylpyrrolidone) on critical thickness. J. Am. Ceram. Soc. 83, 1056 (2000).

H. Kozuka and S. Takenaka: Single-step deposition of gel-derived lead zirconate titanate films: Critical thickness and gel film to ceramic film conversion. J. Am. Ceram. Soc. 85, 2696 (2002).

Z.H. Du and J. Ma: The effect of PVP on the critical thickness and properties of PLZT ceramic films. J. Electroceram. 16, 565 (2006).

D.A. Barrow, T.E. Petroff, R.P. Tandon, and M. Sayer: Characterization of thick lead zirconate titanate films fabricated using a new sol gel based process. J. Appl. Phys. 81, 876 (1997).

Z. Wang, W. Zhu, C. Zhao, and O.K. Tan: Dense PZT thick films derived from sol–gel based nanocomposite process. Mater. Sci. Eng., B 99, 56 (2003).

B. Lee and J. Zhang: Preparation, structure evolution and dielectric properties of BaTiO3 thin films and powders by an aqueous sol–gel process. Thin Solid Films 388, 107 (2001).

D.L. Corker, Q. Zhang, R.W. Whatmore, and C. Perrin: PZT ‘composite’ ferroelectric thick films. J. Eur. Ceram. Soc. 22, 383 (2002).

K.A. Erk, C. Deschaseaux, and R.W. Trice: Grain-boundary grooving of plasma-sprayed yttria-stabilized zirconia thermal barrier coatings. J. Am. Ceram. Soc. 89, 1673 (2006).

Z. Chen, Z. Zhang, C.C. Tsai, K. Kornev, I. Luzinov, M. Fang, and F. Peng: Electrospun mullite fibers from the sol–gel precursor. J. Sol-Gel Sci. Technol. 74, 208 (2015).

K. Okada, S. Yasohama, S. Hayashi, and A. Yasumori: Sol–gel synthesis of mullite long fibres from water solvent systems. J. Eur. Ceram. Soc. 18, 1879 (1998).

K.C. Song: Preparation of mullite fibers from aluminum isopropoxide–aluminum nitrate–tetraethylorthosilicate solutions by sol–gel method. Mater. Lett. 35, 290 (1998).

J. Vázquez, P.L. López-Alemany, P. Villares, and R. Jiménez-Garay: A study on glass transition and crystallization kinetics in Sb 0.12 as 0.36 Se 0.52 glassy alloy by using non-isothermal techniques. Mater. Chem. Phys. 57, 162 (1998).

W. Xu, J. Ren, and G. Chen: Glass transition kinetics and crystallization mechanism in Ge–Ga–S–CsCl chalcohalide glasses. J. Non-Cryst. Solids 398, 42 (2014).

L. Hu and F. Ye: Liquid fragility calculations from thermal analyses for metallic glasses. J. Non-Cryst. Solids 386, 46 (2014).

D.J. Harris, H. Hu, J.C. Conrad, and J.A. Lewis: Patterning colloidal films via evaporative lithography. Phys. Rev. Lett. 98, 148301 (2007).

S.J. Milne, M. Patel, and E. Dickinson: Experimental studies of particle packing and sintering behaviour of monosize and bimodal spherical silica powders. J. Eur. Ceram. Soc. 11, 1 (1993).

C. Ji, W. Lan, and P. Xiao: Fabrication of yttria-stabilized zirconia coatings using electrophoretic deposition: Packing mechanism during deposition. J. Am. Ceram. Soc. 91, 1102 (2008).

J.A. Lewis: Colloidal processing of ceramics. J. Am. Ceram. Soc. 83, 2341 (2000).

Y. Gu, Z. Chen, N. Borodinov, I. Luzinov, F. Peng, and K.G. Kornev: Kinetics of evaporation and gel formation in thin films of ceramic precursors. Langmuir 30, 14638 (2014).

M.J. Cima, J.A. Lewis, and A.D. Devoe: Binder distribution in ceramic greenware during thermolysis. J. Am. Ceram. Soc. 72, 1192 (1989).

R.C. Chiu and M.J. Cima: Drying of granular ceramic films: II, drying stress and saturation uniformity. J. Am. Ceram. Soc. 76, 2769 (1993).

K. Sefiane, L. Tadrist, and M. Douglas: Experimental study of evaporating water–ethanol mixture sessile drop: Influence of concentration. Int. J. Heat Mass Transfer 46, 4527 (2003).

J.L. Beuth: Cracking of thin bonded films in residual tension. Int. J. Solids Struct. 29, 1657 (1992).

Z.C. Xia and J.W. Hutchinson: Crack patterns in thin films. J. Mech. Phys. Solids 48, 1107 (2000).

P. Xu, A.S. Mujumdar, and B. Yu: Drying-induced cracks in thin film fabricated from colloidal dispersions. Drying Technol. 27, 636 (2009).

H. Kozuka: On ceramic thin film formation from gels: Evolution of stress, cracks and radiative striations. J. Ceram. Soc. Jpn. 111, 624 (2003).

M.S. Tirumkudulu and W.B. Russel: Cracking in drying latex films. Langmuir 21, 4938 (2005).

K.B. Singh and M.S. Tirumkudulu: Cracking in drying colloidal films. Phys. Rev. Lett. 98, 218302 (2007).

R. Baranwal, M.P. Villar, R. Garcia, and R.M. Laine: Flame spray pyrolysis of precursors as a route to nano-mullite powder: Powder characterization and sintering behavior. J. Am. Ceram. Soc. 84, 951 (2001).

I.M. Kalogeras and H.E.H. Lobland: The nature of the glassy state: Structure and transitions. J. Mater. Educ. 34, 69 (2012).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chen, Z., Burtovyy, R., Kornev, K.G. et al. Dense and crack-free mullite films obtained from a hybrid sol–gel/dip-coating approach. Journal of Materials Research 32, 1665–1673 (2017). https://doi.org/10.1557/jmr.2017.122

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2017.122