Abstract

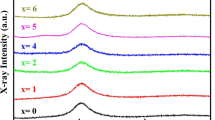

(Cu0.47Zr0.45Al0.08)100-x Dyx (x = 0, 1, 2, 3, 4; at.%) metallic glasses with greatly enhanced glass-forming ability (GFA) and plasticity were synthesized based on microalloying technique. The structure, thermal stability, and elastic properties of the BMG samples were studied by x-ray diffraction (XRD), differential scanning calorimetry (DSC), and ultrasonic measurements, respectively. With addition of minor dysprosium (Dy), fully metallic glassy rods with diameters exceeding 20 mm could be successfully fabricated by copper mold casting. In addition, the Cu-Zr-Al-Dy BMGs exhibit good mechanical properties under a compressive deformation mode, i.e., high yield strength of 1735–1906 MPa, Young’s modulus of 85–100 GPa, and distinct plastic strain up to 4.02%. The strength and plasticity show remarkable correlations with glass transition temperature and Poisson’s ratio, respectively. The role of minor Dy addition in enhancement in GFA and mechanical property of the Cu-rich BMGs is also discussed.

Similar content being viewed by others

References

A. Inoue: Stabilization of metallic supercooled liquid and bulk amorphous alloys. Acta Mater. 48, 279 (2000).

W.H. Wang, C. Dong, and C.H. Shek: Bulk metallic glasses. Mater. Sci. Eng., R 44, 45 (2004).

H.S. Chen: Thermodynamic considerations on the formation and stability of metallic glasses. Acta Metall. 22, e1505 (1974).

W.L. Johnson: Bulk glass-forming metallic alloys: Science and technology. MRS Bull. 24, 42 (1999).

A. Peker and W. Johnson: A highly processable metallic glass: Zr41.2Ti13.8Cu12.5Ni10.0Be22.5. Appl. Phys. Lett. 63, 2342 (1993).

Q. Zhang, W. Zhang, and A. Inoue: Preparation of Cu36Zr48Ag8Al8 bulk metallic glass with a diameter of 25 mm by copper mold casting. Scr. Mater. 55, 711 (2006).

A. Inoue, N. Nishiyama, and H. Kimura: Preparation and thermal stability of bulk amorphous Pd40Cu30Ni10P20 alloy cylinder of 72 mm in diameter. Mater. Trans., JIM 38, 179 (1997).

B.W. Zhou, X.G. Zhang, W. Zhang, H. Kimura, T. Zhang, A. Makino, and A. Inoue: Synthesis and mechanical properties of new Cu-based Cu-Zr-Al glassy alloys with critical diameters up to centimeter order. Mater. Trans. 51, 826 (2010).

W.H. Wang, Z. Bian, P. Wen, M.X. Pan, and D.Q. Zhao: Role of addition in formation and properties of Zr-based bulk metallic glasses. Intermetallics 10, 1249 (2002).

Z.P. Lu and C.T. Liu: Role of minor alloying additions in formation of bulk metallic glasses: A review. J. Mater. Sci. 39, 3965 (2004).

J.F. Wang, R. Li, N.B. Hua, and T. Zhang: Co-based ternary bulk metallic glasses with ultrahigh strength and plasticity. J. Mater. Res. 26, 2072 (2011).

L. Zhang, Y.Q. Cheng, A.J. Cao, J. Xu, and E. Ma: Bulk metallic glasses with large plasticity: Composition design from the structural perspective. Acta Mater. 57, 1154 (2009).

X. Xu, L.Y. Chen, G.Q. Zhang, L.N Wang, and J.Z. Jiang: Formation of bulk metallic glasses in Cu45Zr48−xAl7REx (RE=La, Ce, Nd, Gd and 0≤x≤5at.%). Intermetallics 15, 1066 (2007).

E.S. Park, J.S. Kyeong, and D.H. Kim: Role of minor addition of metallic alloying elements in formation and properties of Cu-Ti-rich bulk metallic glasses. Scr. Mater. 57, 49 (2007).

E.S. Park and D.H. Kim: Phase separation and enhancement of plasticity in Cu–Zr–Al–Y bulk metallic glasses. Acta Mater. 54, 2597 (2005).

D. Turnbull: Under what conditions can a glass be formed?. Contemp. Phys. 10, 473 (1969).

Z. P. Lu and C. T. Liu: A new glass-forming ability criterion for bulk metallic glasses. Acta. Mater. 50, 35013512 (2002).

J.J. Lewandowski, W.H. Wang, and A.L. Greer: Intrinsic plasticity or brittleness of metallic glasses. Philos. Mag. Lett. 85, 77 (2005).

E.P. Papadakis: Ultrasonic phase velocity by the pulse echo overlap method incorporating diffraction phase corrections. J. Acoust. Soc. Am. 42, 1045 (1967).

D. Scheriber: Elastic Constants and their Measurement (McGraw-Hill, NewYork, 1973).

A. Inoue, W. Zhang, T. Zhang, and K. Kurosaka: High-strength Cu-based bulk glassy alloys in Cu–Zr–Ti and Cu–Hf–Ti ternary systems. Acta Mater. 49, 2645 (2001).

W. Zhang and A. Inoue: Formation and mechanical properties of Ni-based Ni–Nb–Ti–Hf bulk glassy alloys. Scr. Mater. 48, 641 (2003).

W.H. Wang: Bulk metallic glasses with functional physical properties. Prog. Mater. Sci. 52, 540 (2007).

Y. Zhang, J. Chen, G. L. Chen, and X. J. Liu: Glass formation mechanism of minor yttrium addition in CuZrAl alloys. Appl. Phys. Lett. 89, 131904 (2006).

J. Schroers and W.L. Johnson: Ductile bulk metallic glass. Phys. Rev. Lett. 93, 255506 (2004).

H.S. Chen, J.T. Krause, and E. Coleman: Elastic constants, hardness and their implications to flow properties of metallic glasses. J. Non-Cryst. Solids 18, 157 (1975).

ACKNOWLEDGMENTS

This research is financially supported by the National Natural Science Foundation of China (Grant No. 51301029 and 51375071).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhou, B.W., Deng, L., Zhang, X.G. et al. Enhancement of glass-forming ability and plasticity of Cu-rich Cu-Zr-Al bulk metallic glasses by minor addition of Dy. Journal of Materials Research 29, 1362–1368 (2014). https://doi.org/10.1557/jmr.2014.132

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1557/jmr.2014.132