Abstract

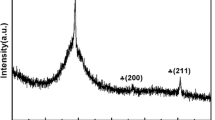

One monolithic Cu-based bulk metallic glass and three composites with tiny crystalline phases embedded in metallic glass matrix are successfully fabricated by solidification technique. Al is selected as an alloying element to be added into a ternary Cu-based bulk metallic glass to regulate microstructure and enhance mechanical property. All quaternary Cu-Zr-Ti-Al alloys have composite structure. The amount of crystalline phases in Cu59Zr32Ti8Al1 and Cu59Zr31Ti8Al2 is more than that in Cu59Zr33Ti7Al1. The compression results show that Cu59Zr32Ti8Al1 and Cu59Zr31Ti8Al2 rods possess large plastic deformation, but the others do not. Cu59Zr31Ti8Al2 has the best mechanical property among the four representative alloys, its compressive strength and plasticity reaches 2304 MPa and 18% respectively. The composition of those crystalline phases and the enhancement reason of plasticity are also investigated. Consequently, the presence of certain crystalline phases in glass matrix benefits enhancement of mechanical properties of the as-cast bulk metallic glass composites.

Access this chapter

Tax calculation will be finalised at checkout

Purchases are for personal use only

Preview

Unable to display preview. Download preview PDF.

Similar content being viewed by others

References

M.M. Trexler, and N.N. Thadhani, “Mechanical properties of bulk metallic glasses,” Progress in Materials Science, 55 (2010), 759–839.

C.L. Qin, W. Zhang, K. Asami, H. Kimura, X.M. Wang, and A. Inoue, “A novel Cu-based BMG composite with high corrosion resistance and excellent mechanical properties,” Acta Materialia, 54 (2006), 3713–3719.

Y.H. Liu, G. Wang, R.J. Wang, D.Q. Zhao, M.X. Pan, and W.H. Wang, “Super plastic bulk metallic glasses at room temperature,” Science, 315 (2007), 1385–1388.

H.J. Chang, W. Yook, E.S. Park, J.S. Kyeong, and D.H. Kim, “Synthesis of metallic glass composites using phase separation phenomena,” Acta Materialia, 58 (2010), 2483–2491.

Y. Wu, H. Wang, H.H. Wu, Z.Y. Zhang, X.D. Hui, G.L. Chen, D. Ma, X.L. Wang, and Z.P. Lu, “Formation of Cu-Zr-Al bulk metallic glass composites with improved tensile properties,” Acta Materialia, 59 (2011), 2928–2936.

Z. Bian, H. Kato, C.L. Qin, W. Zhang, and A. Inoue, “Cu-Hf-Ti-Ag-Ta bulk metallic glass composites and their properties,” Acta Materialia, 53 (2005), 2037–2048.

X. Hu, S.C. Ng, Y.P. Feng, and Y. Li, “Glass forming ability and in-situ composite formation in Pd-based bulk metallic glasses,” Acta Materialia, 51 (2003), 561–572.

S. Pauly, G. Liu, G. Wang, U. Kuhn, N. Mattern, and J. Eckert, “Microstructural heterogeneities governing the deformation of Cu47.5Zr47.5Al5 bulk metallic glass composites,” Acta Materialia, 57 (2009), 5445–5453.

D.C. Hofmann, J.Y. Suh, A. Wiest, G. Duan, M.L. Lind, M.D. Demetriou, and W.L. Johnson, “Designing metallic glass matrix composites with high toughness and tensile ductility,” Nature, 451 (2008), 1085–1089.

J.W. Qiao, S. Wang, Y. Zhang, P.K. Liaw, and G.L. Chen, “Large plasticity and tensile necking of Zr-based bulk-metallic-glass-matrix composites synthesized by the Bridgman solidification,” Applied Physics Letters, 94 (2009), 151905.

N. Chen, D.V. Louzguine-Luzgin, G.Q. Xie, T. Wada, and A. Inoue, “Influence of minor Si addition on the glass-forming ability and mechanical properties of Pd40Ni40P20 alloy,” Acta Materialia, 57 (2009), 2775–2780.

N. Zheng, R.T. Qu, S. Pauly, M. Calin, T. Gemming, Z.F. Zhang, and J. Eckert, “Design of ductile bulk metallic glasses by adding “soft” atoms,” Applied Physics Letters, 100 (2012), 141901.

X.L. Ji, “Study on amorphous forming ability and copper based bulk amorphous alloys,” (Ph.D. thesis, Southeast University, 2008), 67–85.

D. Wang, H. Tan, and Y. Li, “Multiple maxima of GFA in three adjacent eutectics in Zr-Cu-Al alloy system — A metallographic way to pinpoint the best glass forming alloys,” Acta Materialia, 53 (2005), 2969–2979.

W.H. Wang, “Roles of minor additions in formation and properties of bulk metallic glasses,” Progress in Materials Science, 52 (2007), 540–596.

Q. Wang, C. Dong, J.B. Qiang, and Y.M. Wang, “Cluster line criterion and Cu-Zr-Al bulk metallic glass formation,” Materials Science and Engineering a-Structural Materials Properties Microstructure and Processing, 449 (2007), 18–23.

C.C. Hays, C.P. Kim, and W.L. Johnson, “Microstructure controlled shear band pattern formation and enhanced plasticity of bulk metallic glasses containing in situ formed ductile phase dendrite dispersions,” Physical Review Letters, 84 (2000), 2901–2904.

Z.F. Zhang, J. Eckert, and L. Schultz, “Difference in compressive and tensile fracture mechanisms of Zr59Cu20Al10Ni8Ti3 bulk metallic glass,” Acta Materialia, 51 (2003), 1167–1179.

P. Lowhaphandu, L.A. Ludrosky, S.L. Montgomery, and J.J. Lewandowski, “Deformation and fracture toughness of a bulk amorphous Zr-Ti-Ni-Cu-Be alloy,” Intermetallics, 8 (2000), 487–492.

Author information

Authors and Affiliations

Editor information

Editors and Affiliations

Rights and permissions

Copyright information

© 2013 TMS (The Minerals, Metals & Materials Society)

About this paper

Cite this paper

Wu, J., Pan, Y., Pi, J., Wang, L. (2013). Fabrication and Mechanical Properties of Cu-Based Bulk Metallic Glass and Composites. In: Marquis, F. (eds) Proceedings of the 8th Pacific Rim International Congress on Advanced Materials and Processing. Springer, Cham. https://doi.org/10.1007/978-3-319-48764-9_395

Download citation

DOI: https://doi.org/10.1007/978-3-319-48764-9_395

Publisher Name: Springer, Cham

Print ISBN: 978-3-319-48586-7

Online ISBN: 978-3-319-48764-9

eBook Packages: Chemistry and Materials ScienceChemistry and Material Science (R0)