Abstract

This paper presents a comprehensive review regarding the published work related to the effect of dust on the performance of photovoltaic panels in the Middle East and North Africa region as well as the Far East region. The review thoroughly discusses the problem of dust accumulation on the surface of photovoltaic panels and the severity of the problem. Moreover, a survey of the most advanced cleaning techniques is presented, and their applicability is evaluated. There are plenty of techniques that have been used to remove the dust accumulated on the surface of PV panels, and these include manual and self-cleaning methods. However, it is concluded from the presented review that there is a strong need for developing new cleaning methods especially for the Middle East and North Africa region, which do not consume water and have low capital and operational costs with less human intervention, especially for hot, arid, and dusty regions.

Similar content being viewed by others

Introduction

Renewable energy versus nonrenewable energy

Nowadays, the world energy consumption is soaring, and it is projected to increase further in the upcoming decades. Nonrenewable energy sources such as fossil fuels produce about 80% of the world’s energy, thus leading to the rapid depletion of the natural resources, and the pace of extraction is only set to increase, which may lead to an inevitable energy crisis. Furthermore, environmental concerns are rising, as the extraction and burning of fossil fuels emanates greenhouse gases into the atmosphere, leading to global warming and its disastrous unpredictable effects [1]. Therefore, it is extremely crucial to conserve energy and utilize available energy resources at maximum possible efficiency. For example, the Middle East region possesses more than 50% of the known oil reserves around the world; therefore, economic instabilities around the world arise, which affect the whole geopolitical system. Overexploitation of these fuels is leading to the exhaustion of these resources. Accordingly, the current energy system cannot be maintained for more than two generations [2].

To avert an energy crisis and mitigate the effects of climate change, then it is exceedingly important to steer away from traditional nonrenewable energy resources and shift towards renewable energy on a wide scale [3, 4]. Moreover, in order to establish a sustainable global development, with the global population boom and high living expenses, it is increasingly vital to rapidly adopt renewable and cleaner energy sources, as the main sources of energy and to improve energy efficiency and mechanisms that make it attractive to utilize new technology. Renewable energy is the most promising solution to the aforementioned problems, as the increasing popularity of renewable sources all around the world has led to a remarkable contribution of closing the energy gap to a good extent. A combination of volatile conventional fuel prices, global warming, and pollution is a driving investment in electricity generation plants based on renewable energy, especially in Sunbelt countries. For instance, the oil crisis that occurred in the USA during the 1970s was the main reason to focus on harnessing solar energy as a main source of heat and power in order to be extensively used [5].

Solar energy and PV panels

Nowadays, the solar energy is considered as a promising renewable energy source; it is regarded as one of the leading solutions for the world’s skyrocketing energy demand, where nonrenewable sources of energy are rapidly depleting. It is projected that solar energy is going to be the primary source of energy in the upcoming decades, replacing traditional nonrenewable energy sources, since it is renewable, abundant, relatively inexpensive, clean, and safe, in addition to its longer durability. Solar energy–harvesting devices are becoming increasingly widespread due to their unlimited and infinite energy source, their easy installation, maintenance, and the tremendous increase in the development of the panel energy conversion efficiency [6]. It was found that the total energy consumption on Earth in 1 year is likely equivalent to the incident solar energy on its surface during just 1 hour [7].

Middle East and North Africa (MENA) and Far East

By 2050, the wind power will be the dominant power generation source, after which, comes the solar PV panels as shown in Fig. 1. The solar PV panels could produce 25% of the total electricity demand worldwide, becoming one of the most eminent and leading electricity sources. Accordingly, the electricity sector will be altered and will undergo some rearrangement. Yet, managing the volume of decommissioned PV panels and preventing the PV modules’ deterioration are necessary in order to grow the global PV market share. This could be achieved using new methods to reduce material usage, decay, and module deterioration in addition to introducing new techniques, which are capable of reprocessing and recycling the PV panels at the end of their lifespan [8].

Share of the different sources of energy in the global electricity generation (left) and installed power (right) starting from 2016 up to 2050 [8]

The MENA region is one of the most promising territories for the development of solar energy due to its exceptional solar irradiation potential where most of the tropical countries are taking advantage of this and starting to invest in the renewable energy sector. The solar and wind energies are taking the lion’s share of the contributions to the renewable energy sector [8]. Among the MENA countries are the Gulf Cooperation Countries (GCC). The GCC is a regional political and economic union consisting of all the Arabian countries bordering the Gulf except Iraq, namely: Kuwait, Qatar, Oman, Bahrain, Saudi Arabia, and the United Arab Emirates. The GCC countries started undertaking several efforts in investing in renewable energy sources in the 1970s. The research and the prototype projects first started in Kuwait, followed by Saudi Arabia in the 1980s; United Arab Emirates in the 1990s; Bahrain, Oman and Qatar in the 21st century [9]. The first large solar energy project in the region was the full solar air-conditioned British School in Kuwait using PV and solar thermal applications in the 1970s. This project was under the supervision of Kuwait Institute for Scientific Research. Another project was conducted in Saudi Arabia in the 1980s by the King Abdulaziz City for Science and Technology organization (KACST), which is an independent scientific organization that played a significant role in developing solar energy technologies throughout the Kingdom of Saudi Arabia since 1977. Another project conducted by KACST is the Solar Village PV system 350 kW (2155 MWh) to provide AC/DC electricity for remote areas in the period from 1981 to 1987. Through the same period, KASCT and Energy Research Institute (ERI) conducted multiple projects concerning developing of solar cooling laboratories in Saudi universities [9]. The United Arab Emirates also started investing in renewable energy in the 1990s by Masdar Company. Another project of full PV operated fuel filling station was conducted at Al Hora area in Manama, Bahrain in 1980 (with the aid of Bahrain Petroleum Company and now the Sustainable Energy Unit) [9]. The reason behind the GCC passion for renewable energy extensive use is that these countries are blessed with an exceptionally high solar irradiance and energy. For example, the annual average solar irradiance is equivalent to 1.1 barrel of oil per millimeter squared [10]. Moreover, in the recent years, investment in solar development in some African and Arabian countries such as Egypt, Libya, Algeria, and Morocco, as well as the Far East region has increased, thanks to numerous projects, whether under construction or upcoming projects [11]. The installed capacity of photovoltaics, the growth rate, and the target of installed power in the future in the MENA region and the Far East are shown in Table 1. In the past few years, the PV industry had witnessed dramatic changes, since China became the largest producer for manufacturing of PV cells and solar modules, followed by Japan and India. Furthermore, in 2017, China became the largest market regarding total installed PV power capacity, when it succeeded to surpass the European Union in terms of total installed power [17]. In 2018, about 71% of the new PV electricity generation systems in the world were installed in China [17].

Nowadays, most of the world’s efforts are focused upon improving the performance of PV panels, in order to increase the PV energy production. Nevertheless, these efforts are not quite sufficient. There is an increasing concern towards finding new means to mitigate the factors that can reduce the efficiency of the PV modules. Among these factors is the soiling effect [24], which is caused by the accumulation of dirt and dust on the surface of solar PV modules, especially in the MENA and the Far East regions. The effect of dust accumulation on the surface of the PV panel is being given much scrutiny nowadays, as it can dramatically decrease the energy production of solar modules [25].

The objective of this research is to emphasize the impact of dust on the performance of PV panels installed in the MENA and the Far East regions. A summary of dust effect on the performance of PV panels in some countries of the MENA and the Far East regions is presented. Also, a review of the different cleaning techniques available in the market is presented. Moreover, the feasibility and applicability of each system is examined based on the MENA region environment.

Dust accumulation

Dust accumulation on the PV panels is an area of growing concern for the reliability of solar panels; dust mitigation of solar photovoltaics is a main aspect of maintenance required for enhanced and longer yield performance of PV panels. Wind sweeps dust and dirt onto the solar panel surface, causing the dust to cover the entire panel, which will impair the PV module production level because as the dust accumulates onto the panel’s surface, it decreases its transparency by preventing the sunrays from reaching the panel’s surface. Consequently, the output power and the efficiency of the PV panel decreases resulting in decreasing the performance, as well as shortening the lifetime of the solar panel [26,27,28].

Dust intensity around the world

The pattern of dust distribution and dust intensity around the world is illustrated in Fig. 2, where the darker the region gets, the more significant the dust intensity is. It was noticed that the MENA region countries are most affected when it comes to dust mitigation, leaving regions such as parts of Asia as the next critically affected places [29].

Dust intensity around the world [29]

The MENA region is the dustiest in the world [30]; Iraq, Sudan, the Persian Gulf, and Saudi Arabia experience the greatest number of rampant dust storms around the world [31]. During the summer, most of the dust storms carried by the Shamal winds are mainly reported in Iran, the Persian Gulf, Syria, the southern Arabian Peninsula, and Iraq, while in winter, the Mediterranean parts of northern Egypt experience the dust storms. Besides, the Mediterranean parts of northern Egypt, southern Egypt, Jordan, western Iraq, Lebanon, and northern Arabian Peninsula experience dust storms mainly during the spring season [32].

Dust frequency around the world

The Sahara Desert is famous for being the biggest mineral dust source in the whole world, in the range of 60 to 200 million tons per year. It was found that the emitted dust in the Sahara desert is about a whopping 400% as much as the dust percentage in the Arabian deserts [33]. The MENA, North East Asia, and South West Asia are the regions with the highest dust storm frequencies. The Northern Iraq region between the Tigris and Euphrates rivers and along the Syria–Iraq border experience the highest dust density in the Middle East [33]. The global pattern of dust frequency according to the synoptic weather records for the period from 1974 to 2012 [34] is presented in Fig. 3.

The global pattern of dust frequency according to the synoptic weather records for the period of 1974 to 2012 [34]

Dust and sand storm paths in the MENA region

Dust and sand storm paths and source clusters in the MENA region are demonstrated in [35]; there are six main sand and dust storm paths dominated by the climate in the MENA region [35]. In terms of dust storms paths, it has been reported that frontal dust storms occur across Israel, Jordan, and the northern Arabian Peninsula, while “Shamal” dust storms usually take place in Iraq, Kuwait, and some parts of the Arabian Peninsula [36]. In terms of dust frequency [33], it has been reported that the greatest number of dust storms overall occur in Iraq, Sudan, the Persian Gulf, and Saudi Arabia. There is no doubt that the Sahara desert is the major natural dust source on Earth, from which most of the North African dust storms originate. This dust can be conveyed by excessively high wind speeds for long distances over hot desert areas, reaching very high altitudes. Nevertheless, every year, countless tons of dust are carried away at relatively low altitudes across the Atlantic Ocean to the Caribbean Sea and southeastern United States, as reported by the studies of the satellite images. On the other hand, the Middle East region experiences anthropogenic dust sources in addition to the natural sources, which is 300% as much as the anthropogenic dust sources [33]. Due to the changes in land usage during the previous decades, there has been a remarkable increase in some anthropogenic dust sources such as Southern Sahel, the Mediterranean coast, and the Atlas Mountains sources.

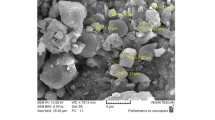

Causes of dust accumulation

The energy production of PV panels is profoundly affected by several factors, such as the wind speed and direction, solar irradiance, shading, temperature, cleanliness, air pollution, etc.. A slight change in the climatic conditions affects the solar irradiance as well as the ambient temperature, thus, leading to differences in the output energy obtained from the PV panels [37,38,39,40]. The dust, which can be measured in micron layers, can accumulate over a certain period on the PV panels based on the environment, dust type, location, and installation of the solar plant [41]. The PV panel’s tilt angle also influences the rate of dust deposition on its surface and it was found that a tilt angle of 26° is the optimum tilt angle for the solar panels located in the city of Hangzhou, China [42]. A detailed view of the causes for dust accumulation is demonstrated in Fig. 4.

A detailed view of the causes for dust accumulation [29]

The solar panel’s efficiency is influenced by the size and the weight of the dust particles deposited on the panel’s surface. The relationship between the power losses from the PV panel and the mass of the dust accumulated on its surface has been deeply investigated by plenty of studies [43]. It was concluded that there is a linear relation between the two variables; as the size of the deposited dust particles gets smaller, the more the radiation on the PV module surface is blocked and, consequently, the more prominent the decrease in the power output is [44]. Some types of deposited pollutants include ash, red soil, sand, silica, etc.. These pollutants are affected by various environmental factors such as air temperature and humidity, along with the wind speed; these factors play a significant role in altering the size, phase, physical and chemical properties of these pollutants, in addition to how it accumulates on the panel’s surface [45]. Air pollution may decrease the panel’s energy yield substantially, even if the PV panels are exposed to the outdoor environment for a short period of time [46]. Several researchers investigated the effect of changing the tilt angle on the soiling effect and the efficiency of the PV panels [39, 47]. It was concluded that there is a relationship between the tilt angle and the soiling effect; the soiling effect increases as the tilt angle of the solar panel decreases, or in other words, the soiling effect increases as the solar PV panel becomes increasingly horizontal, as shown in Fig. 5 [47]. This analysis can be associated with the fact that gravity supports the dust removal process, while as the tilt angle decreases, the effect of the gravitational force on removing the accumulated dust declines. This accumulated dirt, due to soiling, causes shading of the PV modules, and consequently, the obtained output power decreases. However, if the modules are cleaned, the output power rebounds again [48].

Soiling losses at different tilt angles [47]

Intensity of the dust problem in the MENA and the Far East regions

It is shown that most of the studies regarding dust accumulation and the soiling effect on PV panels emerged mainly from Asia, as shown in Fig. 6. Saudi Arabia is reported to be the country with the largest number of researches and studies that are investigating the soiling effect on PV panels, around the whole world [49].

Contribution percentage of different continents to the studies of the impact of dust on PV panels [49]

There are two major reasons that could explain the dominance of Asia in dust accumulation studies on the PV panel surface. First of all, Asia was responsible for a huge chunk of all newly added PV installations, accounting for about a staggering 60% of new PV installations all around the world [50]. Secondly, there are huge arid and semiarid regions in Asia [30, 51]; Asia is considered to be one of the most arid, windy, and dusty environments in the world, where the interaction of dust with the clouds has a great impact on Asia’s regional climate, and Africa is considered to be one of the worst sand and dust accumulation regions on Earth and there are many proposals that support renewable energy collaboration between Africa and the European Union countries [52]. Unfortunately, there is a significant lack of corresponding studies in Africa, as the share of studies conducted in Africa is roughly 12%. On the other hand, Europe is ranked as the second continent in conducting dust accumulation studies, where the share of published studies is around 23%, which is almost twice that of the surveyed studies in Africa. However, this relatively small percentage of studies conducted in Europe, when compared with Asia is considered to be normal and of no surprise, since Europe does not experience huge dust storms as compared with Asia and the MENA region [52]. A summary of the effect of dust accumulation on the PV panel’s performance in different locations in the MENA and the Far East regions is presented in Table 2. The presented values of efficiency deterioration and power degradation are based on actual measurements, and the variation in the presented values is due to the location and time of measurement. The soiling effects are crucial and significant for the Middle East, North Africa, and the Far East regions. It can be concluded, based on the data presented in Table 2, that the problem of dust accumulation over the PV panels is quite severe in the MENA and the Far East regions. The monthly deterioration in efficiency in Egypt can range from 11 [53] to 17% [54, 55], which means that the PV panel efficiency can drop by 50% in a period of 3 to 5 months, which indicates that it is necessary to clean the PV panels, in order to preserve the efficiency and maintain a reliable energy output. This immense deterioration of efficiency in Egypt holds for many other countries in the MENA region as well as in the Far East (e.g., Pakistan). The monthly deterioration in the PV panels’ efficiency in Pakistan due to dust accumulation can vary from 16 [88] up to 57% [86], which is quite large and again indicates that more research should be done to minimize dust accumulation over PV panels. The maximum and minimum values for monthly reduction in the PV efficiency in different countries based on Table 2 are presented in Fig. 7. It is clear that the monthly reduction is high and sometimes can reach 65%. This will significantly affect the output energy obtained and payback period. That is why it is important to clean the PV panels in a periodic manner with less resources and low cost.

Soiling mitigation techniques

The soiling effect is now recognized as a threat that greatly affects the solar PV efficiency, and cleaning of the PV panels should not be ignored, as it leads to a significant reduction in power and efficiency. Dust accumulation is a continuous challenge for solar PV panels, particularly in desert areas. Mega Solar Parks and Ultra Mega Solar Parks are sited mostly in the desert-prone areas for their sheer size, and they are likely to be more vulnerable to dust accumulation, when compared with those in urban areas. Soiling mitigation techniques of PV panels [95, 96] can be classified into two types of cleaning methods, which are manual cleaning and self-cleaning. A schematic diagram of the different soiling mitigation techniques is presented in Fig. 8.

Manual cleaning of PV panels

Manual cleaning is accustomed mostly to water cleaning techniques by labor. The cleaning techniques are chosen according to the location of the plant and the availability of water resources. This method uses manpower in order to remove bird wastes, and cemented dust from the surface of the PV panel. Besides, this method is considered efficient if arranged according to a regular and proper schedule [97]. Nevertheless, this method has several drawbacks. Not only does the manual cleaning of PV panels require qualified, professional, and well-trained labor to remove the hard soiling, which makes this method relatively costly [98], but also the labor safety, health considerations, and government-related regulations, as well as the high cost of water, maintenance, cleaning detergents and systems are several aspects that need to be considered thoroughly [98]. However, using the cleaning tools should be handled in a proper way or else, the PV panel surface might be subjected to severe damage. Moreover, manual cleaning is not adequate, in case the PV modules are located at high altitudes and unreachable areas. Water cleaning is shown in Fig. 9. An example of labor manual cleaning is illustrated in Fig. 9a, which is a water and time-consuming technique that is not always safe, as the operator may damage the delicate material on the surface of the panel with excess pressure of water or abnormal weight during cleaning. Therefore, self-cleaning methods are developed to solve the challenges of labor cost and the difficulty of cleaning unreachable areas. Heliotex technology is shown in Fig. 9b [99], which is also a method of cleaning the PV panel by automatically rinsing and washing the PV surfaces using pressurized water, in addition to being programmed frequently or whenever is necessary according to the surrounding environment. Such techniques are difficult to implement in Mega Solar Parks and Ultra Mega Solar Parks. The severity of the dust problem arises and increases due to the lack of natural cleaning methods like rainfall and shortage of water resources. Cleaning of the PV panels at such huge plants could prove to be cost-effective and effort oriented, since it requires huge amounts of water and workforce; on the other hand, it is difficult to find an abundance of clean water in the MENA region countries and some countries in Asia [100].

Water cleaning of PV panels by a labor and b using the Heliotex technology [99]

Self-cleaning of PV panels

Self-cleaning techniques of the solar panel can be broadly classified into active techniques, passive techniques, and a combination of both techniques, as demonstrated in Fig. 8. An active technique is an active restoration cleaning method, which utilizes external energy, such as water cleaning, mechanical cleaning, and electrodynamics screen. On the other hand, a passive cleaning technique does not make use of external energy. An example of passive cleaning is natural cleaning, which uses rainfalls to wash away the dust accumulated on the surface of PV panels. However, due to the shortage of rainfalls in many regions, two other passive techniques were developed, which make use of changing the morphology of the PV module surface by using super hydrophilic or super hydrophobic coatings. Another type of coating is the antistatic coating, which prevents the dust from sticking to the surface of the PV panel without being repelled from the panel’s surface. A combination of both active and passive techniques has been developed to benefit from the advantages of both techniques such as using an antistatic coating with mechanical vibrations [101]. The antistatic coating prevents the sticking of dust on the PV panel surface, while the mechanical vibrator shakes the panel, allowing the dust to fall off by the gravitational force from the panel’s surface.

Active cleaning methods

Mechanical cleaning

Most of the mechanical cleaning systems use wipers and brushes. They move either vertically or horizontally, based on the dirt location [102, 103]. The mechanical cleaning systems can be activated either manually or automatically (e.g., robotic cleaners by using electrical or electronic systems) [104]. Examples of dry cleaning robots are presented in Fig. 10. The robot demonstrated in Fig. 10a removes the dust from the PV panel’s surface by using brushes analogous to windshield wipers of motor vehicles, while in Fig. 10b, it uses suction bots. The robot shown in Fig. 10c is a self-powered cleaning-type robot that charges its battery using small PV panels. The weight of the robots presented in Fig. 10 is suitable for the surface of the solar panels, and the robots can be remotely operated.

The robotic cleaning of solar panels offers additional more integrated features over the ordinary manual cleaning systems, such as quick response, high stability, and reliability. They may be used whenever robust autonomous and unmanned control is required in addition to solving the labor problems. Nevertheless, the capital cost for purchasing the robot itself is high, especially for large PV plants due to the usage of various mechanical parts and the additional costs required for installing the system. Maintenance costs of the hardware system such as gears and chains need to be taken into account, when calculating the robotic cleaning system’s expenses; the maintenance schedule should be performed according to a timely manner in order for the system to work properly. As previously mentioned, since wipers and brushes are the cleaning tools used in the vast majority of the mechanical cleaning systems, the PV panel might be subjected to severe surface damage during cleaning. Therefore, without proper maintenance, dirt and dust will accumulate on the cleaning tools and the other parts, which contact the PV panel surface directly, and accordingly, the efficiency decreases [105, 106]. Moreover, an important aspect that needs to be considered is that the active cleaning systems are electrically powered either from a frequently replaceable external battery used for charging or from the PV system itself. However, the later condition will decrease the output power of the PV system during the cleaning process leading to high power consumption rates, especially in large PV systems [107].

Electrodynamic cleaning

The dust electrostatic property was the main concept used to develop the electrodynamics screen cleaning technique, which is known as electrodynamic screening (EDS). The electrodynamics screen cleaning technique was further developed using the electric curtain concept by Masuda et.al [108]. This concept is based on the movement of oppositely charged particles due to the dust electrostatic reactions. Therefore, once the dust settles on the panel’s surface, it keeps moving from one edge to a neighboring one and so on until it is removed entirely from the surface of the panel, as illustrated in Fig. 11. It was proved experimentally that during each cleaning cycle, the EDS technique requires low energy consumption rate of less than 1 Wh/m2 in order to remove the dust layer. This amount of energy resembles 0.1% of the energy produced by a 1 m2 PV panel. Moreover, it has been proven that the EDS technique is capable of cleaning the solar panels swiftly; the dust layer can be removed within a couple of minutes, achieving very high efficiencies under dry ambient conditions [110]. Furthermore, this technique shows high flexibility, as it does not need an external power supply or any additional cleaning detergents. The EDS technique consumes a low amount of energy that is capable of restoring the surface of the PV panel back to its default clean conditions achieving high efficiencies, which are greater than 90% [111]. It was found that the EDS technique is less effective for small dust particles ranging from 0 to 5 μm, while it demonstrated more enhanced performance for dust particles that are larger than 20 μm [112].

Schematic diagram of the electrostatic cleaning system that uses a standing wave and gravity to remove sand from a solar panel [109]

Nevertheless, it was found that using the EDS cleaning method as an extra layer on top of the PV panel reduces the intensity of sun radiation through its transparent screen, thus, leading to a reduction in the panel’s efficiency, resulting from uncertain durability consideration on ultraviolet radiations. Accordingly, the output power decreases by 15% [113, 114]. EDS is unreliable in wet conditions or cemented dust; however, it can be integrated with super hydrophobic coatings in order to achieve a better cleaning effect on the panels in rainy conditions [115, 116].

Passive cleaning methods

A hydrophobic surface

A hydrophobic surface is a surface having low wettability. This property helps to repel water droplets and prevents them from sticking on the surface. The ability of water droplets to roll off a surface while picking up the contaminants determines the hydrophobicity of a surface, in addition to measuring the contact angle between the surface and the water droplets [117]. Super hydrophobic surfaces have a high capability of hydrophobic characteristic and high contact angles; therefore, rainfalls or any other cleaning technique can easily remove any dust or dirt accumulation. Besides, a super hydrophobic surface means a low hysteresis of the contact angle, in which a water droplet can easily bounce on the surface of the PV panel while also removing the accumulated dirt [118]. This will enlarge the effective area of the PV module to absorb the maximum solar irradiance, in addition to increasing the probability of the PV module surface cleaning conditions recovery [119]. Midtdal et al. [120] found that the cleaning effect of this method could last for about 3 to 4 years. The hydrophobic surface is made from polymer layers, which exhibit high initial transmittance [121,122,123,124,125]. Unfortunately, some of these layers are characterized by having high surface energy, which might increase the probability of dust accumulation. Moreover, these layers often degrade more rapidly upon frequent exposure to ultraviolet radiations, as compared with glass [116]. Furthermore, this hydrophobic surface might suffer severe corrosion and severe damage upon exposure to certain chemical solvents found in acidic rain and salty air [126].

A hydrophilic surface

Hydrophilicity is the term used to express the complete dispersal of water or liquid on a substrate. A hydrophobic surface repels water droplets, while a hydrophilic surface attracts them strongly. A hydrophilic surface is a surface having high wettability, which is the opposite to hydrophobicity, as it expresses the complete water dispersion on any surface [127]. A hydrophilic surface is similar to a hydrophobic one, as both surfaces obtain their cleaning effect through rainfalls. This means that applying super-hydrophilic coatings, showing high hydrophilic characteristic capability, to solar modules located in arid and dry environments is not sufficient to remove the decomposed dust particles, when compared with wet environments [128]. In contrast to super hydrophobic surfaces, a hydrophilic surface has lower contact angles, and the water droplets on a super-hydrophilic surface forms flattened glob droplets that spread and go below the dirt particles and carry them away [129], as illustrated in Fig. 12.

The self-cleaning mechanism of the hydrophilic (left) and hydrophobic surfaces (right) [129]

Table 3 presents a comparison that offers a broad view regarding the advantages and disadvantages of the aforementioned soiling mitigation techniques. This comparison helps to find out which dust mitigation technique should be used for cleaning the PV systems with respect to the initial cost, the surrounding circumstances and conditions of the site, site location, site installation purpose, and the environmental factors such as atmospheric and ambient conditions. Table 4 compares between the soiling mitigation techniques regarding the efficiency and applicability in the MENA region and the Far East region, in addition to several proposed improvements.

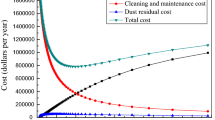

Effect of the cleaning frequency on the efficiency of the panels

Proper estimation of when to start cleaning of solar panels is a compromise between gross costs of cleaning the panels and how much reduction in efficiency of solar panels can be tolerated. Shah et al. [154] studied the optimal time interval for PV cleaning in the UAE climate. This study revealed that the output power of the panels that remain uncleaned for 3 months decreased by 13% compared with the panels that were cleaned daily. On the other hand, leaving the panel in a dusty environment for 10 days caused a 3% drop in the output power obtained. Meanwhile, the PV panels, kept uncleaned for 20 days and 30 days produced 5% and 7% less power, respectively. However, it was found that cleaning the panels after 15 days is the most feasible cleaning frequency; the losses were brought down to 4%. Hammad et al. [155] proposed a calculated cleaning frequency of 12–15 days for PV panels in Jordan. Mohamed et al. [156] also monitored the soiling losses for different time intervals from 3 days to 1 month, and it was found that 8 days is the optimal cleaning frequency according to the cleaning and energy loss cost. In [157], the influence of varying daily soiling rates, due to varying weather conditions in Zimbabwe, was considered in decreasing the number of days between successive cleaning intervals. It was found that 15 days is the optimum cleaning frequency in order to minimize the losses associated with both frequent cleaning and not cleaning.

Results and discussion

Deciding the optimum cleaning technique for the MENA and the Far East regions will depend on several aspects. These aspects are the labor cost, as well as the availability of water at a given region, the quantity of modules requiring cleaning, the PV panel’s ease of reach; whether the modules are ground-mounted, installed on light posts or installed on rooftops along with the needed frequency of cleaning. Many researchers proposed the frequency of cleaning of PV modules, based on their geographical location, energy wasted due to soiling, PV integration scheme, scale of the PV power plant, and cost associated with cleaning which is completely different in the two countries. Moreover, selecting a cleaning method depends on whether the modules are installed in a heavily rainy atmosphere and low dust intensity region or whether it is installed in a dry and highly polluted region. It is strongly recommended based on numerous researches to perform the cleaning cycle for the installed PV systems in the MENA region on a weekly or biweekly basis [26, 37, 57, 61, 154,155,156,157]. On the other hand, the majority of the PV systems in Europe are installed in rainy green regions, and the optimum pattern for cleaning is less frequent than that in the MENA and the Far East regions. Generally speaking, cleaning methods of PV panels using water have not been the focus of attention among the research conducted in Europe and America, due to the low dust intensity and the huge amount of rainfall that facilitate the cleaning of the PV systems, in addition to the accessibility of water resources that can be used in cleaning. However, in regions experiencing low rainfall or having elongated periods of drought, especially in Africa, this natural cleaning effect by rainfalls inevitably decreases and thereby, dirt accumulates faster on the modules [158].

The imbalance between water supply availability and the soaring water demand for the majority of the MENA countries and some countries in the Far East region is constantly recurring on the long term and is expected to deteriorate further in the near future. Nowadays, the current total water demand in the MENA region is almost 50% below the water scarcity limit, which is 1000 m3/capita/year [159], which explains the huge water supply gap. This gap is expected to grow to large extents, which shows the importance of efficient water usage in the MENA region. Water resources per capita in the region account for just one sixth of the global average, and they continue to dwindle. This persistent water imbalance can be attributed to the region’s booming population, robust economic growth, and global changes in the atmosphere, with drought becoming increasingly frequent, unless major strict measures are implemented to increase water supply and manage water demand [159]. Many countries in the MENA region practiced the supply management approach for many years. However, this approach proved its inability to bridge the present water gap due to two reasons. The first reason is that most of conventional water resources in the majority of the MENA countries have been overexploited, and the second one is that the cost of nonconventional water resources, apart from its environmental impact, has become very expensive. Therefore, many experts regarded water demand management as the answer for the water imbalance problem. However, if the current rates of population growth and climatic changes in the MENA region continue to surpass its normal rates as expected, it is projected that by 2050, the water demand will increase by 50%, thereby increasing the water gap [159]. In addition to that, many countries in the MENA region have the lowest renewable water resources in the world. The water scarcity threshold set by the UN-FAO is 1000 m3 of renewable water resources per capita per year. From 2000 to 2009, only 4 out of 21 countries in the MENA region exceeded this threshold (i.e., greater than 1000 m3 per capita per year as shown in [160, 161]). Moreover, 8 out of 21 countries are subjected to severe water stress conditions of having less than 200 m3 per capita per year. The water share per capita in 2020–2030 is expected to get more even worse as have been indicated by [160, 161]. For example, the Gulf countries have surpassed the threshold with an average water availability of less than 300 m3 per capita per year. In addition to that, no country is expected to have renewable water resources above 1000 m3 per capita per year [159]. This clearly indicates that the MENA countries are very poor in water resources; the current total water demand in the MENA region already exceeds the naturally available water supplies. Accordingly, the available water is not sufficient for the sharp population growth and cannot be used for cleaning purposes.

It can be inferred from the above that dust mitigation techniques of PV panels using water are not feasible for the MENA region and some countries in the Far East due to the scarcity of fresh water; water demand management approach will not be able to solve the problem of water scarcity. Cleaning using water and detergents is the safest method for cleaning of the glass surface of the PV panel, but such possibility is not applicable in scarce water regions. Therefore, new cleaning methods should be developed that are not water dependent (i.e., based on dry cleaning), and at the same time, it should not influence the surface texture of the glass surface of the panel (i.e., does not scratch the surface). Cleaning a photovoltaic system is ultimately an economical question. In order for the cleaning system to be feasible, the cleaning costs have to be covered by the improvement in efficiency caused by the cleaning process. In order to calculate the economic viability of a cleaning method, two aspects must be taken into consideration, namely, the amount of kilowatt hours that a PV plant must generate as additional yield to recover the cost of cleaning and the percentage of additional yield for the total production of the plant.

Accordingly, innovative methods for soiling detection and measurements [162, 163] should be developed in order to alarm the PV plant engineers, when and where to clean the panels. For example, not all the PV panels in the same plant are subjected to the same rate of dust accumulation (e.g., the panels at the front rows are subject to more dust than the panels at the rear side). Some recent researches proposed the use of communication and data transfer for efficient cleaning methodologies (i.e., Smart Self-Cleaning systems). These systems require the least human effort such that instructions for cleaning of solar cell photovoltaic surfaces can be activated when required by using Internet of things (IOT) [164, 165]. The innovation of Smart Self-Cleaning systems lies within the implementation of the IOT-based model and autonomous cleaning unit along with cloud-based Man-machine interface in order to make the system even smarter and effective. This smart self-cleaning technique proved to be very effective for a large solar farm located in semiarid areas, where frequent cleaning is required due to sand deposition. Also, artificial intelligence (AI) techniques can play an important role in soiling prediction. These techniques use artificial neural network (ANN) models to predict the daily and the cumulative PV soiling loss based on the current environmental data [166,167,168]. ANN models might also be used to model dust deposition affecting transmittance of PV modules [169], forecasting output power [170], studying the effect of soiling on energy production [171], and estimating the soiling losses based on the density of dust and particle size composition under artificial soiling conditions [172, 173]. Recently, unmanned aerial vehicles (UAVs) are considered one of the key factors that become increasingly used in order to replace the conventional soiling inspection techniques that are time-consuming and expensive to implement. UAVs are used in effective inspection of photovoltaic modules in order to predict accurate losses resulting from dirt and dust accumulation. It also allows the quick collection of data especially for large areas, increases the measurement coverage, inspects hard-to-reach installations in addition to being highly flexible and able to operate in harsh environments [174, 175]. This saves time, lessens human intervention and reduces the workload in power plant operation. UAVs are economical in soiling detection compared with dust sensors because it is a topographic detection rather than spot detection; however, dust sensors are more accurate than UAVs. More research should be performed to improve the accuracy of UAVs such that it can detect the soiling in centimetric or millimetric levels, also, correlating this soiling detection to the loss in panel efficiency, such that accurate decisions of cleaning could be reached.

Conclusions

The current article provided a comprehensive literature and a critical review on the problem of dust deposition, showing its negative effect on the surface of PV panels, as well as the various cleaning techniques, challenges, and proposed improvements. There are several parameters that can affect the percentage reduction in efficiency due to dust accumulation on the PV panels over a certain period, such as the climatic and environmental conditions, which include the wind magnitude and direction; ambient temperature; amount of rain; humidity; seasonal variations; and dust characteristics concerning size, shape, and mass; as well as the location and installation of the solar plant. The deposited dust concentration on the surface of the PV panel affects the PV panel’s performance by decreasing the energy production and therefore, lowering its efficiency. The MENA, North East Asia, and South West Asia are the regions with the highest frequencies of dust storms in the world, such that the efficiency might decline by 70% or more after a couple of months as mentioned earlier. Accordingly, cleaning cycles every week or 2 weeks are deemed to be essential, due to the high density and high frequency of dust as mentioned earlier.

This article offered a detailed review of the different cleaning techniques (i.e., manual and self-cleaning methods). These various cleaning techniques have been investigated and compared with an overall view, regarding their advantages, disadvantages, efficiency, applicability, and several proposed improvements. This comparison helps to find out which dust mitigation technique is the optimum one for cleaning the PV systems, with respect to the initial cost, the surrounding circumstances, conditions of the site, site location, site installation purpose, and the environmental factors such as atmospheric and ambient conditions. Manual cleaning techniques seem to be energy-intensive and time-consuming efforts, while the additional maintenance and energy consumption always remain a point of debate for commercial application of self-cleaning techniques. Recent researches began to introduce more innovative methods for soiling detection and measurements such as the introduction of artificial intelligence techniques, the use of drones, the use of sensors to detect the critical point for cleaning in addition to the use of communication and data transfer (e.g., smart techniques for optimum and efficient cleaning methodologies).

Also, it is concluded that dust mitigation techniques of PV panels using water are not feasible for the MENA region and some countries in the Far East region, due to the persistent challenge of water scarcity and the imbalance between water supply availability and the surging water demand. A combination of water demand management and supply management measures together might be able to bridge the water gap; water demand management should be given the first priority, especially, in the agricultural sector where it has the maximum impact. Nevertheless, if all demand management options are implemented, it will not be able to fill the water gap. It should be accompanied by new water supply options coming from nonconventional water resources such as seawater desalination and treated wastewater. These nonconventional water resources will play a major role in bridging the water gap in the MENA region to some extent. However, there will still be a noticeable water demand gap. Accordingly, there is a heavy burden on researchers to find new effective cleaning techniques, that are not water dependent and have low initial costs, as well as low running costs. Therefore, it is highly recommended to decrease the use of water in dust mitigation and cleaning of PV panels and search for more feasible cleaning techniques.

Cleaning of PV panels has become a defined challenge for researchers in the MENA and the Far East regions. Scientists are trying to find a balance regarding the initial and running costs of the PV system with its performance and durability. Researchers should manage to carry out further comprehensive studies in order to decrease the reliability on the conventional cleaning methods that use water in cleaning of PV panels. Therefore, continuous efforts in this direction seem to be a positive step towards maintaining the efficiency of the PV panels. Developing of artificial intelligence models as well as smart cleaning systems that can determine the best and the most favorable cleaning time and frequency based on the dust pattern is highly recommended, and more research should be performed in this direction especially in the MENA and the Far East regions.

Availability of data and materials

All presented data are available under any request.

Abbreviations

- PV:

-

Photovoltaic panel

- MENA:

-

Middle East and North Africa

- GCC:

-

Gulf Cooperation Countries

- UAE:

-

United Arab Emirates

- KSA:

-

Kingdom of Saudi Arabia

- UV:

-

Ultraviolet

- EDS:

-

Electrodynamic screening

- USA:

-

United States of America

- UN-FAO:

-

United Nations–Food and Agriculture Organization

- PLC:

-

Programmable logic controller

- KACST:

-

King Abdulaziz City for Science and Technology Organization

- ERI:

-

Energy Research Institute

- IOT:

-

Internet of things

- AI:

-

Artificial intelligence

- ANN:

-

Artificial neural network

- UAV:

-

Unmanned aerial vehicles

References

Chaniotakis E (2001) Modelling and analysis of water cooled photovoltaics. University of Strathclyde., Dissertation

Singh BR, Singh O (2012) Global trends of fossil fuel reserves and climate change in the 21st century. In: Shahriar K (ed) Fossil fuel and the environment, InTech, pp 167–192

Zhi J, Zhang LZ (2018) Durable superhydrophobic surface with highly antireflective and self-cleaning properties for the glass covers of solar cells. Appl Surf Sci 454:239–248. https://doi.org/10.1016/j.apsusc.2018.05.139

Virtanen S (2017) Self-Cleaning Technologies on solar modules and their effect on performance. JAMK University of Applied Sciences, Dissertation

Poullikkas A, Hadjipaschalis I, Kourtis GA (2013) Comparative overview of wet and dry cooling systems for Rankine cycle based CSP plants. Trends Heat Mass Momentum Transf. 13:27–50

Ye L, Zhang Y, Zhang X, Hu T, Ji R, Ding B, Jiang B (2013) Sol–gel preparation of SiO2/TiO2/SiO2–TiO2 broadband antireflective coating for solar cell cover glass. Sol Energy Mater Sol Cells 111:160–164. https://doi.org/10.1016/j.solmat.2012.12.037

Styszko K, Jaszczur M, Teneta J, Hassan Q, Burzyńska P, Marcinek E, Łopian N, Samek L (2019) An analysis of the dust deposition on solar photovoltaic modules. Environ Sci Pollut Res 26:8393–8401. https://doi.org/10.1007/s11356-018-1847-z

IRENA (2019) Future of Solar Photovoltaic: Deployment, investment, technology, grid integration and socio-economic aspects. Available via https://irena.org/-/media/Files/IRENA/Agency/Publication/2019/Nov/IRENA_Future_of_Solar_PV_2019.pdf. Accessed 19 Sept 2021

Hepbasli A, Alsuhaibani Z (2011) A key review on present status and future directions of solar energy studies and applications in Saudi Arabia. Renew Sustain Energy Rev 15:5021–5050. https://doi.org/10.1016/j.rser.e2011.07.052

Alnaser WE, Alnaser NW (2011) The status of renewable energy in the GCC countries. Renew Sustain Energy Rev 15:3074–3098. https://doi.org/10.1016/j.rser.2011.03.021

MESIA (2020) Solar outlook report 2020. Available via http://www.mesia.com/wp-content/uploads/2020/01/MESIA-Annual-Solar-Outlook-Report-2020.pdf. Accessed 9 Nov 2021.

IRENA (2020) Renewable capacity statistics 2020. Available via file:///C:/Users/kc/Downloads/IRENA_RE_Capacity_Statistics_2020.pdf. Accessed 9 Nov 2021.

Liu LQ, Wang ZX, Zhang HQ, Xue YC (2010) Solar energy development in China—a review. Renew Sust Energy Rev 14:301–311. https://doi.org/10.1016/j.rser.2009.08.005

Liu J (2019) China's renewable energy law and policy: a critical review. Renew Sust Energy Rev 99:212–219. https://doi.org/10.1016/j.rser.2018.10.007

Esteban M, Portugal-Pereira J, Mclellan BC, Bricker J, Farzaneh H, Djalilova N, Roeber V (2018) 100% renewable energy system in Japan: smoothening and ancillary services. Appl Energy 224:698–707. https://doi.org/10.1016/j.apenergy.2018.04.067

Kumar A, Kumar K, Kaushik N, Sharma S, Mishra S (2010) Renewable energy in India: current status and future potentials. Renew Sust Energy Rev 14:2434–2442. https://doi.org/10.1016/j.rser.2010.04.003

Jäger-Waldau A (2019) PV status report 2019. Accessed 9 Nov 2021. Available via https://ec.europa.eu/jrc/sites/default/files/kjna29938enn_1.pdf Accessed 9 Nov 2021.

IRENA (2014) REmap 2030: a renewable energy roadmap, summary of findings. Available via https://www.irena.org//media/Files/IRENA/Agency/Publication/2014/IRENA_REmap_summary_findings_2014.pdf. Accessed 9 Nov 2021.

IRENA (2018) Renewable energy outlook: Egypt. Available via https://www.irena.org//media/Files/IRENA/Agency/Publication/2018/Oct/IRENA_Outlook_Egypt_2018_En.pdf Accessed 9 Nov 2021.

Kamran M (2018) Current status and future success of renewable energy in Pakistan. Renew Sust Energy Rev 82:609–617. https://doi.org/10.1016/j.rser.2017.09.049

Salam MA, Khan SA (2018) Transition towards sustainable energy production–a review of the progress for solar energy in Saudi Arabia. Energy Explor Exploit 36:3–27. https://doi.org/10.1177/0144598717737442

REN21 (2018) Renewables 2018 global status report. Available via https://www.ren21.net/wp-content/uploads/2019/05/GSR2018_Full Report_English.pdf. Accessed 9 Nov 2021.

Mohamed AM, Al-Habaibeh A, Abdo H (2016) Future prospects of the renewable energy sector in Libya. In: Paper presented in proceedings of SBE16 Dubai Conference, Dubai, United Arab Emirates

Dida M, Boughali S, Bechki D, Bouguettaia H (2020) Output power loss of crystalline silicon photovoltaic modules due to dust accumulation in Saharan environment. Renew Sust Energy Rev 124:109787. https://doi.org/10.1016/j.rser.2020.109787

Costa SC, Diniz ASA, Kazmerski LL (2016) Dust and soiling issues and impacts relating to solar energy systems: literature review update for 2012–2015. Renew Sust Energy Rev 63:33–61. https://doi.org/10.1016/j.rser.2016.04.059

Mani M, Pillai R (2010) Impact of dust on solar photovoltaic (PV) performance: research status, challenges and recommendations. Renew Sust Energy Rev 14:3124–3131. https://doi.org/10.1016/j.rser.2010.07.065

Zaihidee FM, Mekhilef S, Seyedmahmoudian M, Horan B (2016) Dust as an unalterable deteriorative factor affecting PV panel’s efficiency: why and how. Renew Sust Energy Rev 65:1267–1278. https://doi.org/10.1016/j.rser.2016.06.068

Rahman MM, Hasanuzzaman M, Rahim NA (2015) Effects of various parameters on PV-module power and efficiency. Energy Convers Manag 103:348–358. https://doi.org/10.1016/j.enconman.2015.06.067

Maghami MR, Hizam H, Gomes C, Radzi MA, Hajighorbani RMI (2016) Power loss due to soiling on solar panel: a review. Renew Sustain Energy Rev 59:1307–1316. https://doi.org/10.1016/j.rser.2016.01.044

Choobari OA, Zawar-Reza P, Sturman A (2014) The global distribution of mineral dust and its impacts on the climate system: a review. Atmos Res 138:152–165. https://doi.org/10.1016/j.atmosres.2013.11.007

Furman H, Kutiel H (2003) Dust storms in the Middle East: sources of origin and their temporal characteristics. Indoor Built Environ 12:419–426. https://doi.org/10.1177/1420326X03037110

World Meteorological Organization (WMO) (2013) Establishing a WMO sand and dust storm warning advisory and assessment system regional node for West Asia: current capabilities and needs. Available via https://library.wmo.int/doc_num.php?explnum_id=7837 Accessed 19.9.2021.

The World Bank publications (2019) Sand and dust storms in the Middle East and North Africa (MENA) region: sources, costs and solutions. Available via https://documents1.worldbank.org/curated/en/483941576489819272/pdf/SAND-AND-DUST-STORMS-IN-THE-MIDDLE-EAST-AND-NORTH-AFRICA-MENA-REGION-SOURCES-COSTS-AND-SOLUTIONS.pdf. Accessed 9 Nov 2021.

Shao Y, Klose M, Wyrwoll KH (2013) Recent global dust trend and connections to climate forcing. J Geophys Res Atmos 118:107–118. https://doi.org/10.1002/jgrd.50836

Cao H, Amiraslani F, Liu J, Zhou N (2013) Identification of dust storm source areas in West Asia using multiple environmental datasets. Sci Total Environ 502:224–235. https://doi.org/10.1016/j.scitotenv.2014.09.025

Middleton NJ (1986) Dust storms in the Middle East. J Arid Environ 10:83–96. https://doi.org/10.1016/S0140-1963(18)31249-7

Ghazi S, Sayigh A, Ip K (2014) Dust effect on flat surfaces–a review paper. Renew Sustain Energy Rev 33:742–751. https://doi.org/10.1016/j.rser.2014.02.016

Meral ME, Diner F (2011) A review of the factors affecting operation and efficiency of photovoltaic based electricity generation systems. Renew Sustain Energy Rev 15:2176–2184. https://doi.org/10.1016/j.rser.2011.01.010

Babatunde AA, Abbasoglu S, Senol M (2018) Analysis of the impact of dust, tilt angle and orientation on performance of PV plants. Renew Sustain Energy Rev 90:1017–1026. https://doi.org/10.1016/j.rser.2018.03.102

Skoplaki E, Palyvos JA (2009) On the temperature dependence of photovoltaic module electrical performance: a review of efficiency/power correlations. Sol Energy 83:614–624. https://doi.org/10.1016/j.solener.2008.10.008

Alquthami T, Menoufi K (2019) Soiling of photovoltaic modules: comparing between two distinct locations within the framework of developing the photovoltaic soiling index (PVSI). Sustainability 11:4697–4709. https://doi.org/10.3390/su11174697

Xu R, Ni K, Hu Y, Si J, Wen H, Yu D (2017) Analysis of the optimum tilt angle for a soiled PV panel. Energy Convers Manag 148:100–109. https://doi.org/10.1016/j.enconman.2017.05.058

Tanesab J, Parlevliet D, Whale J, Urmee T (2019) The effect of dust with different morphologies on the performance degradation of photovoltaic modules. Sustain Energy Technol 31:347–354. https://doi.org/10.1016/j.seta.2018.12.024

Sayyah A, Horenstein MN, Mazumder MK (2014) Energy yield loss caused by dust deposition on photovoltaic panels. Sol Energy 107:576–604. https://doi.org/10.1016/j.solener.2014.05.030

Darwish ZA, Kazem HA, Sopian K, Alghoul MA, Chaichan MT (2013) Impact of some environmental variables with dust on solar photovoltaic (PV) performance: review and research status. Energy Environ 7:152–159

Chaichan MT, Mohammed BA, Kazem HA (2015) Effect of pollution and cleaning on photovoltaic performance based on experimental study. J Sci Eng Res 6:594–601

Cano J (2011) Photovoltaic modules: effect of tilt angle on soiling. University of Arizona State, Dissertation

Said SA, Hassan G, Walwil HM, Al-Aqeeli N (2018) The effect of environmental factors and dust accumulation on photovoltaic modules and dust-accumulation mitigation strategies. Renew Sustain Energy Rev 82:743–760. https://doi.org/10.1016/j.rser.2017.09.042

Menoufi K (2017) Dust accumulation on the surface of photovoltaic panels: introducing the Photovoltaic Soiling Index (PVSI). Sustainability 9:963. https://doi.org/10.3390/su9060963

REN21 (2016) Renewables 2016 global status report. REN21. 2021. Available via https://www.ren21.net/wp_content/uploads/2019/05/REN21_GSR2016_FullReport_en_11.pdf. Accessed 19 Sept. 2021.

Huang J, Wang T, Wang W, Li Z, Yan H (2014) Climate effects of dust aerosols over East Asian arid and semiarid regions. J Geophys Res Atmos 119:398–416. https://doi.org/10.1002/2014JD021796

Chanchangi YN, Ghosh A, Sundaram S, Mallick TK (2020) Dust and PV performance in Nigeria: a review. Renew Sustain Energy Rev 121:109704. https://doi.org/10.1016/j.rser.2020.109704

Hassan AH, Rahoma UA, Elminir HK, Fathy AM (2005) Effect of airborne dust concentration on the performance of PV modules. J Astron Soc Egypt 13:24–38

Elminir HK, Ghitas AE, Hamid R, El-Hussainy F, Beheary M, Abdel-Moneim KM (2006) Effect of dust on the transparent cover of solar collectors. Energy Convers Manag 47:3192–3203. https://doi.org/10.1016/j.enconman.2006.02.014

Menoufi K, Farghal H, Farghali AA, Khedr MH (2017) Dust accumulation on photovoltaic panels: a case study at the East Bank of the Nile (Beni-Suef, Egypt). Energy Procedia 128:24–31. https://doi.org/10.1016/j.egypro.2017.09.010

Abdeen E, Hasaneen ES, Orabi M (2016) Real study for photovoltaic system performance in desert environment-Upper Egypt-case study. In: IEEE Eighteenth International Middle East Power Systems Conference, Cairo, Egypt. IEEE, Cairo

Hegazy AA (2001) Effect of dust accumulation on solar transmittance through glass covers of plate-type collectors. Renew Energy 22:525–540. https://doi.org/10.1016/S0960-1481(00)00093-8

Mohamed AO, Hasan A (2012) Effect of dust accumulation on performance of photovoltaic solar modules in Sahara environment. J Basic Appl Sci Res 2:11030–11036

Nimmo BR, Said SA (1981) Effects of dust on the performance of thermal and photovoltaic flat plate collectors in Saudi Arabia-preliminary results. Alternative Energy Sources 1:145–152

Al-Hasan AY, Ghoneim AA (2005) A new correlation between photovoltaic panel’s efficiency and amount of sand dust accumulated on their surface. Int J Sustain Energy 24:187–197. https://doi.org/10.1080/14786450500291834

Adinoyi MJ, Said SA (2013) Effect of dust accumulation on the power outputs of solar photovoltaic modules. Renew Energy 60:633–636. https://doi.org/10.1016/j.renene.2013.06.014

Said SAM (1990) Effects of dust accumulation on performances of thermal and photovoltaic flat-plate collectors. Appl Energy 37:73–84. https://doi.org/10.1016/0306-2619(90)90019-A

Benghanem M, Almohammedi A, Khan MT, Al-Masraqi A (2018) Effect of dust accumulation on the performance of photovoltaic panels in desert countries: a case study for Madinah, Saudi Arabia. Int J Power Electron Drive Syst 9:1356–1366. https://doi.org/10.11591/ijpeds.v9n3.pp1356-1366

Wakim F (1981) Introduction of PV power generation to Kuwait. Kuwait Institute for Scientific Researchers, Kuwait City

Sayigh A, Al-Jandal S, Ahmed H (1985) Dust effect on solar flat surfaces devices in Kuwait. In: Proceedings of the workshop on the physics of Non-conventional energy sources and materials science for energy Trieste

Bunyan H, Ali W, Alnaser M (2016) Enhancing the performance of photovoltaic panel by proper washing periods in Kuwait. Smart Grid Renew Energy 7:190–196. https://doi.org/10.11591/ijpeds.v9n3.pp1356-1366

Ben F, Martinez PD, Mirza T (2014) PV Soiling rate variation over long periods. In: Qatar Environment and Energy Research Institute Green Gulf

Touati F, Chowdhury NA, Benhmed K, Gonzales AJRSP, Al-Hitmi MA, Benammar M, Gastli A, Ben-Brahim L (2017) Long-term performance analysis and power prediction of PV technology in the State of Qatar. Renew Energy 113:952–965. https://doi.org/10.1016/j.renene.2017.06.078

Guo B, Javed W, Figgis BW, Mirza T (2015) Effect of dust and weather conditions on photovoltaic performance in Doha, Qatar. In: 2015 First Workshop on Smart Grid and Renewable Energy (SGRE) (pp. 1-6). IEEE

Chaichan MT, Abass KI, Kazem HA (2018) Energy yield loss caused by dust and pollutants. Deposition on concentrated solar power plants in Iraq weathers. Int J Adv Eng Res Sci 3:160–169

Abbas KK, Al-Wattar AJ, Kasim NK (2010) New technique for treatment of the dust accumulation from PV solar panels surface. IJAP 8:54–59

Al-Sudany AHS (2009) Studying the effects of dust and temperature on the solar cell performance. College of Education, University of AlMustansiriyah, Dissertaion

Saidan M, Albaali AG, Alasis E, Kaldellis JK (2016) Experimental study on the effect of dust deposition on solar photovoltaic panels in desert environment. Renew Energy 92:499–505. https://doi.org/10.1016/j.renene.2016.02.031

Al-Ammri AS, Ghazi A, Mustafa F (2013) Dust effects on the performance of PV street light in Baghdad city. In: IEEE International Renewable and Sustainable Energy Conference, Ouarzazate, Morocco

Mohandes BMA, El-Chaar L, Lamont LA (2009) Application study of 500 W photovoltaic (PV) system in the UAE. Appl Sol Energy 45:242–247. https://doi.org/10.3103/S0003701X09040057

EL-Nashar AM (1994) The effect of dust accumulation on the performance of evacuated tube collectors. Sol Energy 53:105–115. https://doi.org/10.1016/S0038-092X(94)90610-6

Kazem HA, Chaichan MT (2016) Experimental analysis of the effect of dust’s physical properties on photovoltaic modules in Northern Oman. Sol Energy 139:68–80. https://doi.org/10.1016/j.solener.2016.09.019

Bouraiou A, Messaoud H, Abdelkader C, Mohammed M, Salah L, Mohammed S, Nadir B, Mourad O, Attoui I (2015) Analysis and evaluation of the impact of climatic conditions on the photovoltaic modules performance in the desert environment. Energy Convers Manag 106:1345–1355. https://doi.org/10.1016/j.enconman.2015.10.073

Dahlioui D, Laarabi B, Sebbar MA, Barhdadi A, Dambrine G, Menard E, Boardman J (2016) Soiling effect on photovoltaic modules performance. In: International renewable and sustainable energy conference, Marrakech, Morocco

Azouzoute A, Merrouni AA, Garoum M (2020) Soiling loss of solar glass and mirror samples in the region with arid climate. Energy Rep 6:693–698. https://doi.org/10.1016/j.egyr.2019.09.051

Boykiw E (2011) The effect of settling dust in the Arava valley on the performance of solar photovoltaic panels. Department of environmental science, Allegheny college Meadville, Pennsylvania, Dissertation. IEEE, Piscataway, NJ

Asl-Soleimani E, Farhangi S, Zabihi MS (2001) The effect of tilt angle, air pollution on performance of photovoltaic systems in Tehran. Renew Energy 24:459–468. https://doi.org/10.1016/S0960-1481(01)00029-5

Gholami A, Khazaee I, Eslami S, Zandi M, Akrami E (2018) Experimental investigation of dust deposition effects on photovoltaic output performance. Sol Energy 159:346–352. https://doi.org/10.1016/j.solener.2017.11.010

Chen J, Pan G, Ouyang J, Ma J, Fu L, Zhang L (2020) Study on impacts of dust accumulation and rainfall on PV power reduction in East China. Energy 194:116915. https://doi.org/10.1016/j.energy.2020.116915

Ramli MA, Prasetyono E, Wicaksana RW, Windarko NA, Sedraoui K, Al-Turki YA (2016) On the investigation of photovoltaic output power reduction due to dust accumulation and weather conditions. Renew Energy 99:836–844. https://doi.org/10.1016/j.renene.2016.07.063

Ramli MA, Prasetyono E, Wicaksana RW, Windarko NA, Sedraoui K, Al-Turki YA (2019) A self-cleaning device for pole mounted solar photovoltaic installations. Therm Sci 23:739–749. https://doi.org/10.2298/TSCI170401065A

Ali HM, Zafar MA, Bashir MA, Nasir MA, Ali M, Siddiqui AM (2017) Effect of dust deposition on the performance of photovoltaic modules in Taxila, Pakistan. Therm Sci 21:915–923. https://doi.org/10.2298/TSCI140515046A

Abbas Z, Harijan K, Hameed P, Bhayo F (2017) Effect of dust on the performance of photovoltaic system. (A case study of Quaid-E-Azam Solar Park Bahawalpur, Pakistan). Int J Sci Res 1:73–79

Afridi MA, Arbab M, Bilal M, Ullah H, Ullah N (2017) Determining the effect of soiling and dirt particles at various tilt angles of photovoltaic modules. Eng J 4:143–146

Sakarapunthip N, Chenvidhya D, Chuangchote S, Kirtikara K, Chenvidhya T, Onreabroy W (2017) Effects of dust accumulation and module cleaning on performance ratio of solar rooftop system and solar power plants. Jpn J Appl Phys 56

Kumar A, Manish S (2018) Analyzing the impact of dust accumulation and different cleaning mechanism on efficiency of solar photovoltaic panel. Therm Sci Eng 1. https://doi.org/10.24294/tse.v1i3.730

Vaishak S, Bhale PV (2019) Effect of dust deposition on performance characteristics of a refrigerant based photovoltaic/thermal system. Sustain Energy Technol 36:100548. https://doi.org/10.1016/j.seta.2019.100548

John JJ (2015) Characterization of soiling loss on photovoltaic modules, and development of a novel cleaning system. Department of Electrical Engineering, Indian Institute of Technology, Dissertation, pp 730–737

Paudyal BR, Shakya SR (2016) Dust accumulation effects on efficiency of solar PV modules for off grid purpose: a case study of Kathmandu. Sol Energy 135:103–110. https://doi.org/10.1016/j.solener.2016.05.046

Al-Sabounchi AM, Yalyali SA, Al-Thani HA (2013) Design and performance evaluation of a photovoltaic grid-connected system in hot weather conditions. Renew Energy 53:71–78. https://doi.org/10.1016/j.renene.2012.10.039

Al-Jawah MJ (2014) A decision aiding framework for investing in cleaning systems for solar photovoltaic (PV) power plants in arid regions. University of George Washington, Dissertation

Heliotex (2009) Automatic solar panel cleaning systems, https://www.solarpanelcleaningsystems.com/ Accessed 15 Sept 2021.

Mondal S, Mondal AK, Sharma A, Devalla V, Rana S, Kumar S, Pandey JK (2018) An overview of cleaning and prevention processes for enhancing efficiency of solar photovoltaic panels. Curr Sci 115:1065–1077. https://doi.org/10.1016/j.renene.2012.10.039

Al-Badra MZ, Abd-Elhady MS, Kandil HA (2020) A novel technique for cleaning PV panels using antistatic coating with a mechanical vibrator. Energy Rep 6:1633–1637. https://doi.org/10.1016/j.egyr.2020.06.020

Mayhoub M (2017) Cleaning innovative daylighting systems: review and suggested methods. Light Res Technol 49:1015–1033. https://doi.org/10.1177/1477153516669969

Salam YA, Green T, Lin YT (2014) Automated self-cleaning solar panel. Eng Technol 1:40–43

Shubbak MH (2019) Advances in solar photovoltaics: technology review and patent trends. Renew Sustain Energy Rev 115:109383. https://doi.org/10.1016/j.rser.2019.109383

Solarfarmer (2017). https://solarfarmer.tistory.com/63. Accessed 9 Nov 2021.

SolarDuster (2018) http://solarduster.memighty.com/. Accessed 9 Nov 2021.

Yuyi Z, Yu Z, Huanxin L, Yunjia L, Liang L (2013) Control system design for a surface cleaning robot. Int J Adv Robot Syst 10:1–5. https://doi.org/10.5772/56200

Al Shehri A, Parrott B, Carrasco P, Al Saiari H, Taie I (2016) Impact of dust deposition and brush-based dry cleaning on glass transmittance for PV modules applications. Sol Energy 135:317–324. https://doi.org/10.1016/j.solener.2016.06.005

Ju F, Fu X (2011) Research on impact of dust on solar photovoltaic (PV) performance. In: IEEE International Conference on Electrical and Control Engineering, Yichang, China

Masuda S, Fujibayashi K, Ishida K, Inaba H (1972) Confinement and transportation of charge aerosol clouds via electric curtain. Trans Inst Electr Eng Jpn 92:9–18. https://doi.org/10.1002/eej.4390920106

Kawamoto H, Shibata T (2015) Electrostatic cleaning system for removal of sand from solar panels. J Electrostat 73:65–70. https://doi.org/10.1016/j.elstat.2014.10.011

Mazumder M, Horenstein M, Stark J, Erickson D, Sayyah A, Jung S, Hao F (2013) Development of self-cleaning solar collectors for minimizing energy yield loss caused by dust deposition. In: Proceedings of the ASME 7th International Energy Sustainability Conference, Minneapolis, Minnesota, USA

Hudelson JN, Stark J, Gibson H, Hao F, Xu Z, Mazumder M, Horenstein MN (2014) Development and evaluation of prototype transparent electrodynamic screen (EDS) integrated solar collectors for automated dust removal. In: Proceedings of the ASME 8th International Energy Sustainability Conference, Boston, Massachusetts, USA. American Society of Mechanical Engineers, New York, N.Y.

Johnson CE, Srirama PK, Sharma R, Pruessner K, Zhang J, Mazumder MK (2005) Effect of particle size distribution on the performance of electrodynamic screens, IEEE 40th Industry Applications Society Annual Meeting Conference, Hong Kong, China. ASME, New York

Sharma R, Wyatt CA, Zhang J, Calle CI, Mardesich N, Mazumder MK (2009) Experimental evaluation and analysis of electrodynamic screen as dust mitigation technology for future Mars missions. IEEE Trans Ind Appl 45(2):591–596

Sharma R, Wyatt C, Zhang J, Mazumder MK, Calle CI, Mardesich N (2007) Performance analysis of electrodynamic self-cleaneing transparent films for its applications to mars and lunar missions. In: IEEE Industry Applications Annual Meeting Conference, New Orleans, LA, USA

Mazumder M, Horenstein MN, Stark JW, Girouard P, Sumner R, Henderson B, Sharma R (2013) Characterization of electrodynamic screen performance for dust removal from solar panels and solar hydrogen generators. In: IEEE Transactions on Industry Applications

Sarver T, Al-Qaraghuli A, Kazmerski LL (2013) A comprehensive review of the impact of dust on the use of solar energy: history, investigations, results, literature, and mitigation approaches. Renew Sustain Energy Rev 22:698–733. https://doi.org/10.1016/j.rser.2012.12.065

Crick CR, Parkin IP (2011) Water droplet bouncing—a definition for superhydrophobic surfaces. Chem Comm 47:12059–12061. https://doi.org/10.1039/C1CC14749H

Zhang X, Shi F, Niu J, Jiang Y, Wang Z (2008) Superhydrophobic surfaces: from structural control to functional application. J Mater Chem 18:621–633. https://doi.org/10.1039/B711226B

Owusu-Brown B (2016) The effect of settling Harmattan dust on photovoltaic modules in Walewale, Northern Ghana. University of Science and Technology, Disseretation

Midtdal K, Jelle BP (2013) Self-cleaning glazing products: a state-of-the-art review and future research pathways. Sol Energy Mater Sol Cells 109:126–141. https://doi.org/10.1016/j.solmat.2012.09.034

Wang SD, Shu YY (2013) Superhydrophobic antireflective coating with high transmittance. J Coat Technol Res 10:527–535. https://doi.org/10.1007/s11998-012-9468-9

Torma M, Loget G, Corn RM (2014) Flexible Teflon nanocone array surfaces with tunable superhydrophobicity for self-cleaning and aqueous droplet patterning. ACS Appl Mater Interfaces 6:11110–11117. https://doi.org/10.1021/am500735v

Hong L, Pan T (2011) Surface microfluidics fabricated by photopatternable superhydrophobic nanocomposite. Microfluid Nanofluidics 10:991–997. https://doi.org/10.1007/s10404-010-0728-7

Maghsoudi K, Vazirinasab E, Momen G, Jafari R (2020) Advances in the fabrication of superhydrophobic polymeric surfaces by polymer molding processes. Ind Eng Chem Res 59:9343–9363. https://doi.org/10.1021/acs.iecr.0c00508

Smitha VS, Jaimy KB, Shajesh P, Jeena JK, Warrier KG (2013) UV curable hydrophobic inorganic–organic hybrid coating on solar cell covers for photocatalytic self cleaning application. J Mater Chem A 1:12641–12649. https://doi.org/10.1039/C3TA12314F

Ishizaki T, Masuda Y, Sakamoto M (2011) Corrosion resistance and durability of superhydrophobic surface formed on magnesium alloy coated with nanostructured cerium oxide film and fluoroalkylsilane molecules in corrosive NaCl aqueous solution. Langmuir 27:4780–4788. https://doi.org/10.1021/la2002783

Drelich J, Chibowski E, Meng DD, Terpilowski K (2011) Hydrophilic and superhydrophilic surfaces and materials. Soft Matter 7:9804–9828. https://doi.org/10.1039/C1SM05849E

He G, Zhou C, Li Z (2011) Review of self-cleaning method for solar cell array. Procedia Eng 16:640–645. https://doi.org/10.1016/j.proeng.2011.08.1135

Nishimoto S, Bhushan B (2013) Bioinspired self-cleaning surfaces with superhydrophobicity, superoleophobicity, and superhydrophilicity. RSC Adv 3:671–690. https://doi.org/10.1039/C2RA21260A

Deb D, Brahmbhatt NL (2018) Review of yield increase of solar panels through soiling prevention, and a proposed water-free automated cleaning solution. Renew Sustain Energy Rev 82:3306–3313. https://doi.org/10.1016/j.rser.2017.10.014

Parrott B, Zanini PC, Shehri A, Kotsovos K, Gereige I (2018) Automated, robotic dry-cleaning of solar panels in Thuwal, Saudi Arabia using a silicone rubber brush. Sol Energy 171:526–533. https://doi.org/10.1016/j.solener.2018.06.104

Ganesh VA, Raut HK, Nair AS, Ramakrishna S (2011) A review on self-cleaning coatings. J Mater Chem 21:16304–16322. https://doi.org/10.1039/C1JM12523K

Bahaidarah H, Subhan A, Gandhidasan P, Rehman S (2013) Performance evaluation of a PV (photovoltaic) module by back surface water cooling for hot climatic conditions. Energy 59:445–453. https://doi.org/10.1016/j.energy.2013.07.050

Smith MK, Selbak H, Wamser CC, Day NU, Krieske M, Sailor DJ, Rosenstiel TN (2014) Water cooling method to improve the performance of field-mounted, insulated, and concentrating photovoltaic modules. J Sol Energy Eng 136:034503. https://doi.org/10.1115/1.4026466

Krauter S (2004) Increased electrical yield via water flow over the front of photovoltaic panels. Sol Energy Mater Sol Cells 82:131–137. https://doi.org/10.1016/j.solmat.2004.01.011

Odeh S, Behnia M (2009) Improving photovoltaic module efficiency using water cooling. Heat Transf Eng 30:499–505. https://doi.org/10.1080/01457630802529214

Kim DJ, Kim DH, Bhattarai S, Oh JH (2011) Simulation and model validation of the surface cooling system for improving the power of a photovoltaic module. J Sol Energy Eng 133:41012–41017. https://doi.org/10.1115/1.4004508

Cazzaniga R, Rosa-Clot M, Rosa-Clot P, Tina GM (2012) Floating tracking cooling concentrating (FTCC) systems. In: IEEE 38th Photovoltaic Specialists Conference, Austin, TX, USA

Moharram KA, Abd-Elhady MS, Kandil HA, El-Sherif H (2013) Influence of cleaning using water and surfactants on the performance of photovoltaic panels. Energy Convers Manag 68:266–272. https://doi.org/10.1016/j.enconman.2013.01.022

Hacke P, Terwilliger K, Glick S, Trudell D, Bosco N, Johnston S, Kurtz S (2010) Test-to-failure of crystalline silicon modules. In: IEEE 35th Photovoltaic Specialists Conference, Honolulu, HI, USA. IEEE, Piscataway, NJ

Lamont LA, El Chaar L (2011) Enhancement of a stand-alone photovoltaic system’s performance: reduction of soft and hard shading. Renew Energy 36:1306–1310. https://doi.org/10.1016/j.renene.2010.09.018

Bernard AR, Eriksen R, Horenstein MN, Mazumder MK (2018) Dust settles, we don’t: the electrodynamic screen—a self-cleaning technology for concentrated solar power mirrors and photovoltaic panels. MRS Energy Sustain 5. https://doi.org/10.1557/mre.2018.12

Polizos G, Schaeffer DA, Smith DB, Lee DF, Datskos PG, Hunter SR (2014) Enhanced durability transparent superhydrophobic anti-soiling coatings for CSP applications. In: Proceedings of the ASME 8th International Energy Sustainability Conference, Boston, Massachusetts, USA

Park YB, Im H, Im M, Choi YK (2011) Self-cleaning effect of highly water-repellent microshell structures for solar cell applications. J Mater Chem 21:633–636. https://doi.org/10.1039/C0JM02463E

Fujishima A, Rao TN, Tryk DA (2000) Titanium dioxide photocatalysis. J Photochem Photobiol C: Photochem Rev 1:1–21. https://doi.org/10.1016/S1389-5567(00)00002-2