Abstract

Sensing devices are key nodes for information detection, processing, and conversion and are widely applied in different fields such as industrial production, environmental monitoring, and defense. However, increasing demand of these devices has complicated the application scenarios and diversified the detection targets thereby promoting the continuous development of sensing materials and detection methods. In recent years, Tin+1CnTx (n = 1, 2, 3) MXenes with outstanding optical, electrical, thermal, and mechanical properties have been developed as ideal candidates of sensing materials to apply in physical, chemical, and biological sensing fields. In this review, depending on optical and electrical sensing signals, we systematically summarize the application of Tin+1CnTx in nine categories of sensors such as strain, gas, and fluorescence sensors. The excellent sensing properties of Tin+1CnTx allow its further development in emerging intelligent and bionic devices, including smart flexible devices, bionic E-skin, neural network coding and learning, bionic soft robot, as well as intelligent artificial eardrum, which are all discussed briefly in this review. Finally, we present a positive outlook on the potential future challenges and perspectives of MXene-based sensors. MXenes have shown a vigorous development momentum in sensing applications and can drive the development of an increasing number of new technologies.

Similar content being viewed by others

Introduction

In the information age, sensing is a key technology for information collection, detection, and analysis that is widely used in defense [1], disaster relief [2], medical diagnosis [3], environmental monitoring [4], ocean exploration [5], industrial production [6], food safety [7], and so on. Conventional sensors can be used to detect certain biological interactions, chemical reactions, or physical variables. These sensors can detect changes in the detection target and convert them into electrical, optical, thermal, or other easily detected signals for transmission, processing, and storage. An ideal sensor should have the following characteristics: high sensitivity, outstanding selectivity, low detection limit, good stability/durability, and fast response time. However, the complexity of the detection environment, the diversity of detection targets, and the requirements for high sensitivity, fast response, and durability have promoted the renewal and development of sensing materials.

In recent years, Tin+1CnTx (n = 1, 2, 3) MXenes have been developed as one of the most ideal candidates for sensing owing to their large specific surface areas, excellent mechanical stability, outstanding electrical conductivity, and good hydrophilicity [8, 9]. MXenes have an octahedral structure composing an ordered combination of transition metal atoms and C/N atoms, where the C/N atoms are located at the center of the octahedron formed by the transition metal atoms [10]. Ti3C2Tx, one of the most representative MXenes, comprises two layers of carbon atoms sandwiched between three layers of titanium atoms, forming a sandwich structure [11,12,13]. Compared with other two-dimensional (2D) materials, MXenes offer the following advantages in sensing applications: 1) the large specific surface area [8, 14] can provide adequate surface area for loading the target. Moreover, etched MXene materials exhibit an accordion-like structure, and intercalation with urea, hydrazine hydrate, or metal ion salts can further expand the interlayer spacing and increase the space for biological and chemical reactions [15]. 2) The abundant surface functional groups endow MXenes with good hydrophilicity, enabling achievement of selective detection of specific targets through modification [16]. 3) Ti3C2Tx has metal-like properties with electrical conductivity as high as 4600 S cm−1 [17]. 4) MXenes have stable structures, and modified MXenes have strong oxidation resistance; they can withstand various conditions, such as strong acidity, strong alkalinity, high humidity, high salinity, and high temperatures [18, 19].

There are numerous MXene-based sensors, which can be divided into two types, optical and electrical, depending on the sensing signal. In this review, we present and discuss the synthesis routes, important properties, sensing applications, and prospects of Tin+1CnTx (n = 1, 2, 3) MXenes. Ti3C2Tx is the earliest MXene material discovered and successfully fabricated, which represents the rise of MXenes. Among all MXene materials, Ti3C2Tx is the most extensively studied, including preparation methods, physical properties, application fields, etc. Therefore, this review only summarizes the sensing applications of Ti3C2Tx MXene and its allotrope Ti2CTx.

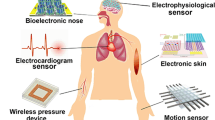

First, several mainstream approaches for synthesizing Tin+1CnTx (n = 1, 2, 3) MXenes are discussed [13, 20], such as hydrofluoric acid (HF) etching, LiF-HCl etching, and alkaline etching. Second, we discuss the excellent physical, chemical, and biological properties of MXenes, such as good chemical stability, outstanding electrical conductivity, and abundant surface functions. Third, nine types of optical and electrical sensors, based on Tin+1CnTx (n = 1, 2, 3) nanosheets (NSs) and quantum dots (QDs), in the fields of biology, chemistry, and physics are presented (Fig. 1) [11, 21,22,23,24,25,26], namely surface plasmon resonance (SPR), gas, fluorescence, surface-enhanced Raman scattering (SERS), colorimetric, electrochemical, temperature, humidity, and pressure/strain sensors. Among these MXene-based sensors, SPR, colorimetric, SERS, and fluorescence sensors use optical signals as detection methods; thus, they are classified as optical sensing technologies. Gas, pressure/strain, temperature, humidity, and electrochemical sensors use electrical analysis signals, and hence, they are classified as electrical sensing technologies. In addition to their applications in conventional fields, MXene-based sensors can also be used in frontier technological fields, such as intelligent sensing, bionic robots, neural network coding, and intelligent artificial eardrum. The discussion presented in this section is a gist of this review, and it is discussed in detail in the subsequent sections. Lastly, this review proposes some potential future applications of MXenes and their modifications such as human–machine interfaces, smart sensing, and sensing applications of high-entropy MXenes. All in all, MXene is currently a new type of sensing material that has attracted extensive attention due to its excellent physical and chemical properties. Here, we provide a comprehensive review of MXene sensors based on optical and electrical principles, and believe that this review can provide guidance for the development of MXene materials in the field of sensing technology.

Schematic diagram of MXene sensing application areas: from biological, chemical, and physical detection to intelligent and bionic devices [11, 21,22,23,24,25,26]. Copyright 2021, American Chemical Society. Copyright 2020, American Chemical Society. Copyright 2016, Wiley–VCH. Copyright 2019, Wiley–VCH. Copyright 2020, Springer Nature. Copyright 2022, Elsevier. Copyright 2019, Elsevier

Fabrication and characterization of 2D Tin+1CnTx

MXene, an emerging type of 2D material, is fabricated using the Mn+1AXn (n = 1, 2, 3) phase as a precursor to selectively remove ‘A’ by etching while retaining the ‘M’ and ‘X’ layers (Fig. 2). Typically, ‘A’ is an element of group IIIA or IVA, which is mainly Al or Si. ‘M’ is usually a transition metal element, and ‘X’ is C or N. The MXene NSs obtained after MAX phase etching exhibit a large number of surface functional groups (–O, –OH, and –F), which are represented by Tx. Ti3C2Tx is the most representative candidate among MXenes, it was successfully fabricated using chemical etching in 2011 [13]. They extracted Al from the MAX phase of Ti3AlC2 and achieved 2D Ti3C2Tx layers. In etching, approximately 10 g of Ti3AlC2 powder is added to a 50% concentrated HF solution (100 mL), followed by etching at room temperature for 2 h. The resulting suspension was washed and centrifuged several times with deionized water. The fabrication process of 2D Ti3C2Tx is presented in Fig. 3(a) [27]. After the Ti3AlC2 powders were etched, exfoliated Ti3C2Tx flakes were obtained through sonication. Figure 3(b) shows the SEM image of Ti3AlC2 powders before HF etching, which is the typical MAX phase [28]. After HF etching, the morphology of the as-prepared Ti3C2Tx with Al removed is shown in Fig. 3(c) [28], which indicates an accordion-like structure of Ti3C2Tx. After sonication, the Ti3C2Tx flakes fall off from the accordion-like structure, forming an independent 2D atomic layer (Fig. 3(d) and (e)) [29]. The etching of Tin+1AlCn by the HF solution is represented using the following chemical reactions [28]:

The chemical elements contained in the Mn+1AXn (n = 1, 2, 3) phases [30]

a Flow chart of etching Ti3AlC2 powders to obtain exfoliated 2D Ti3C2Tx layers [27]. Copyright 2017, Elsevier. b Typical SEM image of Ti3AlC2 powders before HF etching [28]. c The SEM image obtained after the removal of ‘Al’ by HF etching [28]. Copyright 2019, American Chemical Society. d SEM and e TEM images of the exfoliated 2D Ti3C2Tx flakes after sonication [29]. Copyright 2020, American Chemical Society. f HRTEM image of bilayer Ti3C2Tx and its corresponding atomistic model [13]. Copyright 2011, Wiley–VCH. g HRTEM image showing the exfoliated 2D Ti3C2Tx after sonication, and the interlayer spacing is characterized to be 9.82 Å [31]. Copyright 2018, Wiley–VCH. h HRTEM image of Ti3C2Tx with an equiangular lattice spacing of ∼2.54 Å, which matches well with the result obtained by DFT calculation (Table 1) [32]. Copyright 2018, Wiley–VCH

The 2D Tin+1CnTx (n = 1, 2, 3) obtained by HF etching had surface groups (–O, –OH, and –F) attached to the outermost Ti atoms. The HRTEM image showing the atomic arrangement of bilayer Ti3C2Tx and its corresponding atomistic model are presented in Fig. 3(f) [13], which clearly shows the existence of surface groups. The unit cell parameters of Ti3AlC2 and Ti3C2Tx obtained by density functional theory (DFT) calculations are listed in Table 1. The interlayer spacing and equiangular lattice spacing of Ti2CTx were approximately 9.82 Å (Fig. 3(g)) [31] and 2.54 Å (Fig. 3(h)) [32], respectively, which matches well with the results obtained by density functional theory (DFT) calculations (Table 1) [13]. Moreover, there is another form of Ti2CTx (T = –O, –OH, and –F) in Tin+1CnTx, and its fabrication method differs, mainly in terms of the HF concentration and the reaction time. To fabricate Ti2CTx, Al is removed from the Ti2AlC powders using a 10% concentrated HF solution; the reaction lasts 10 h, and the reactant is washed several times.

High-yield production methods of high-quality Tin+1CnTx are influenced by the synthesis routes used. Direct concentrated HF etching is an efficient method for fabricating 2D Tin+1CnTx; however, it causes harm to humans and the environment. Therefore, other alternative low-risk and environmentally friendly etching routes have been developed (Fig. 4(a)) to avoid the direct use of concentrated HF [33], such as in-situ HF etching [34,35,36], alkaline etching [37,38,39], and Lewis acid molten salt etching [40, 41]. These approaches can effectively avoid or reduce the direct use of HF, while successfully yielding Tin+1CnTx. Among these methods, using a mixture of HCl and LiF for in situ HF etching is the most widely used method, which was proposed by Ghidiu et al. [35] Ti3C2Tx was synthesized by immersing Ti3AlC2 in a LiF–HCl solution, with a LiF to Ti3AlC2 molar ratio of 5:1. The preparation of MXenes by HF etching requires an additional step of inserting organic molecules, such as amines [42, 43] and dimethyl sulphoxide (DMSO) [44], while for LiF–HCl etching, Tin+1CnTx can be layered immediately by ultrasonic treatment in water [35, 36]. Lipatov et al. modified the route proposed by Ghidiu and proposed increasing the molar ratio of LiF to Ti3AlC2 to 7.5:1, thus eliminating the ultrasonic layering step (Fig. 4(b)) [36]. Schematics of the LiF–HCl etching method is presented in Table 2. In addition to LiF, other fluoride salts, such as KF, NaF, FeF3, CaF2, and CsF, can also be used for mixing with HCl as the etchant [45, 46]. Xu et al. systematically discussed and summarized the synthesis routes and delamination strategies of MXenes, and prospected a promising large-scale preparation scheme, providing important insights for preparing MXenes [47].

The F-containing acid etching method with strong environmental hazards and low yield are important factors restricting the development of MXenes. How to develop an environmentally friendly etching method and increase the yield of MXenes is a challenge for researchers. Recently, Yang et al. [48] proposed a supercritical exfoliation method to achieve high-yield manufacture of Ti3C2Tx MXene in a short period of time (Fig. 4(c)). They put the MAX materials in a supercritical carbon dioxide (SC-CO2) environment, and the intense thermal motion between supercritical CO2 molecules will promote the in-situ generated HF of NH4HF2 to penetrate into the MAX phase faster and quickly remove the by-products of etching. Finally, they successfully mass-produced 5 kinds of MXene materials.

Properties of Tin+1CnTx MXenes in sensing technology

Tin+1CnTx MXenes possess good electrical conductivity, excellent hydrophilicity, high specific surface area, and abundant surface functional groups, which make them ideal candidates for sensing technologies. Furthermore, modification of MXenes or modifying with other materials can significantly improve or change their properties, making them multifunctional and enabling a wide range of sensing applications.

Computational properties

Generally, the theoretical calculation researches of MXenes are based on the density functional theory (DFT). Using this calculation method, the structural stability and physical properties of MXenes can be predicted, which has important guiding significance for the experimental researches. In 2011, Ti3C2, the first MXene material [13], was successfully experimentally fabricated by Naguib et al. Using the DFT calculation, it was determined that the bandgap structure of a single Ti3C2 layer resembles that of a typical semimetal with a finite density of states. Moreover, the unit cell parameters of Ti3AC2, Ti3C2, Ti3C2(OH)2, and Ti3C2F2 were also calculated in Table 1. The surface of MXene materials obtained by etching usually carries a large number of functional groups. Berdiyorov used DFT to analyze Ti3C2 carrying different functional groups, showing that different functional groups have a great influence on its refractive index, absorption and dielectric function [49]. For several allotropes of Tin+1CnTx, DFT calculation results indicate that they have good mechanical properties, and a smaller value of n results in stronger and stiffer MXenes [50].

For the Ti3C2Tx MXene-based composites, Jiang et al. studied the electronic properties of MXene and graphene heterojunction by DFT calculation, and theoretically demonstrated that Ti3C2(OH)2 has the strongest interaction with graphene [51] and demonstrated that has the strongest interaction with graphene. Electron transfers from Ti3C2(OH)2 to graphene, which leads to a shift in the Dirac point of the graphene bands in the graphene-MXene heterostructures. In addition, the influence of the impurity ions on the structure of Ti3C2 MXene can also be calculated by theoretical method. Shi et al. used the x-ray atomic pair distribution function to analyze the effect of intercalated Na+ and K+ on the structure of Ti3C2 MXene, indicating that Na+ and K+ increase the layer spacing of Ti3C2 MXene, but shrinks the in-plane a and b lattice parameters [10]. In summary, through theoretical calculations, it is found that various properties of Ti3C2 MXene materials can be modulated by changing functional groups, doping ions, and combining other materials, which makes it applicable in a wide range of fields.

Stability of MXenes

Lattice energy is an important basis for evaluating the stability of crystal materials; greater lattice energy implies more unstable crystal structures. Using first-principles calculations, Shein et al. determined that MXenes have negative lattice energy, which indicates that MXenes can exist stably at room temperature [19]. The pH of the colloidal solution of MXenes synthesized by etching was close to neutral after repeated centrifugal cleaning with deionized water. At this time, the zeta potential of MXene NSs was as high as − 80 mV, indicating a strong electrostatic repulsion force between the negatively charged few-layer/single-layer MXene NSs. Therefore, 2D MXene NSs can form a stable colloidal solution in water [52]. However, the antioxidant capacity of MXenes in aqueous solutions is weak [53]. The chemical stability of MXenes is affected by the water and oxygen dissolved in water, and exposure to light can accelerate the oxidation of colloidal MXene solutions, forming metal oxide nanocrystals (such as TiO2) [54, 55]. Li et al. [56] studied the thermal stability of MXenes and found that –F/–OH-terminated MXenes remained stable up to 800 °C in an Ar atmosphere; however, at 200 °C in an oxygen atmosphere, they were partially oxidized. Refrigeration and storage in a low-temperature and oxygen-free dark environment can significantly improve the stability of MXenes [53]. To improve the chemical stability of MXenes, Liu et al. [18] synthesized an aramid nanofiber@MXene coaxial fiber with excellent antioxidant properties that could withstand extreme conditions, such as strong acidity, strong alkalinity, high humidity, high salinity, and high temperature. The electrical resistance and electromagnetic shielding properties of the aramid nanofiber@MXene coaxial fiber remained mostly stable under these extreme environmental conditions, proving their good environmental stability.

Optical properties of MXenes

MXenes have abundant surface functional groups, and different of functional groups change the electronic properties of the material, thereby affecting its optical properties [57, 58]. The optical properties of MXenes can be adjusted by controlling the types and ratios of surface functional groups. The UV–Vis light absorption of MXenes is closely related to their thickness, size, and method used for modification. In the range of 300–500 nm, the light transmittance of 5 nm Ti3C2Tx MXene films reached 91.2%; as the film thickness increased to 70 nm, light transmittance decreased to 43.8% [59, 60]. Related studies have shown that the absorbance decreases as the lateral size of MXene flakes decreases [61]. Interestingly, the transmittance of MXene films can be optimized by changing the inserted ion species [59]. When hydrazine, urea, and DMSO are inserted, the transmittance of Ti3C2Tx films decreases, while it increases when NMe4OH is inserted. Additionally, MXenes are also an excellent nonlinear material with tunable optical nonlinearity, and they are widely used for developing all-optical devices [32, 62,63,64].

Hydrophilicity of MXenes

The abundant functional groups on the surfaces of MXenes endow them good hydrophilicity. Depending on the type of functional groups, the water contact angle ranges from 21.5° to 35° [16, 44]. Wang et al. [65] mixed MXene and polyvinyl alcohol (PVA) to prepare a PVA/MXene nanofiber film (water contact angle = 35.7°–24.5°), which exhibited excellent hydrophilicity compared with the unmodified MXene. Furthermore, the alkaline treatment of MXene increased the oxygen–fluorine ratio ([O]/[F]) in the functional groups, especially hydroxyl groups, which greatly improved the hydrophilicity of MXenes [66, 67].

Conductivity of MXenes

The electrical conductivity of MXenes can be optimized by changing their elemental composition or surface functional groups. Studies have shown that Tin+1Cn MXenes without surface functional groups have metallic conductivity, which decreases with an increase in the value of n [68]. Shahzad et al. investigated the electrical conductivity of functional group-terminated MXenes and reported that Ti3C2Tx MXenes have metal-like properties, with electrical conductivities as high as 4600 S cm−1 [17]. Differences in the preparation process result in different proportions of various functional groups, which leads to differences in the conductivity. Ling et al. [69] demonstrated that the conductivity of pure Ti3C2Tx MXene is 2400 S cm−1 and that for the Ti3C2Tx/PVA composite is 220 S cm−1. Recently, Liu et al. [18] reported an aramid nanofiber@MXene coaxial fiber with a highly oriented and low-defect structure, which exhibited a high conductivity of 3000 S cm−1.

Mechanical properties of MXenes

Both molecular dynamics and DFT calculation results indicate that Tin+1CnTx MXenes have good mechanical properties; a smaller value of n results in stronger and stiffer MXenes [50, 70]. Ling et al. [69] investigated the mechanical properties of MXenes and found that the Ti3C2Tx film (thickness = ~ 3.3 μm) has a tensile strength of 22 ± 2 MPa and Young's modulus of 3.5 ± 0.01 GPa. When the MXene film was rolled into a hollow cylinder, it could support 4000 times its own weight. Mixing MXene with PVA in a composite film increased the tensile strength of the film by 34%, and its hollow cylinder could support approximately 15,000 times its own weight. Furthermore, some composites of MXene exhibit excellent mechanical flexibility (e.g., tensile elongation = ~ 1000%). For example, the composite of MXene and hydrogel can be stretched in knots at high strains and recovered in compression at 90% large strains [71].

Thermal effect of MXenes

MXenes are excellent thermo-sensitive materials, and their heating process generates photo-thermal and electro-thermal effects [72,73,74]. Li et al. [72] fabricated an MXene aerogel fiber via dynamic sol–gel spinning, which exhibited strong electrothermal and photothermal effects. With an increase in input voltage, the temperature of the aerogel fibers gradually increased, and only 0.5 V input voltage was required to generate a thermal effect on the surface. When the input voltage reached 4.5 V, the surface temperature of the aerogel fibers was > 178 °C. Aerogel fibers have a high light absorption capacity, and the absorption rate in the near-infrared region is close to 100%. Under low-temperature conditions, the temperature of MXene aerogel fibers can increase to 40 °C after irradiation in sunlight for 2 min, indicating that the aerogel fibers also have a light-to-heat conversion effect and thermal insulation function at extremely low temperatures.

Tin+1CnTx MXene-based sensing technologies

SPR sensors

SPR sensing is an advanced detection technique that does not require fluorescent or enzymatic labels, and it can offer label-free and rapid real-time detection. Conventional SPR sensors are not sufficiently sensitive to trace small molecules [75], such as explosive materials, insecticides, and hormones. In the past decade, several 2D materials have been developed, and the research on SPR sensors based on enhanced 2D materials has attracted considerable attention [76,77,78]. Graphene is the foremost 2D material used to enhance the sensitivity of SPR sensors; the metasurface of graphene–gold has been reported to greatly enhance the electric field at the sensing interface, thereby improving the sensing sensitivity [79, 80]. Herein, we summarize the application of a graphene-like material, namely Tin+1CnTx MXene, in SPR sensing. At present, the application of Tin+1CnTx MXenes in SPR sensing mainly relies on two platforms, namely prism- [26, 81, 82] and fiber-type sensing structures [83]. Typically, Au thin films are used in both these structures to excite the SPR signal owing to their strong oxidation resistance. The application of MXene in SPR sensing technology utilizes its light absorption properties. Due to light absorption, MXene materials generate a large number of photogenerated carriers, and combining them with SPR sensors can greatly enhance the electric field strength at the sensing interface, thereby improving the sensing sensitivity.

Figure 5(a) shows a prism-type SPR sensor covered with Ti3C2Tx MXene. MXene-Au metasurface greatly improves the sensitivity of the SPR sensor [81]. Although the refractive index (RI) of the analyte changes only slightly, it can be effectively tracked and detected by the SPR signal (Fig. 5(b)) [81]. Theoretical calculations and analyses show that the optimal number of MXene layers is 4, which can improve the sensitivity by 16.8% (Fig. 5(c)) [81]. SPR technology can also be applied in bio-sensing by multiple modifications of Ti3C2Tx MXenes. Wu et al. [26] designed an ultrasensitive MXene-based SPR biosensor to achieve effective detection of carcinoembryonic antigen (CEA) with a low detection limit (0.07 fM). They used the Ti3C2Tx film as the carrier and decorated it with Au nanoparticles (AuNPs) to construct Ti3C2Tx–AuNPs nanocomposites. Then, AuNPs were modified with staphylococcal protein A (SPA) to immobilize monoclonal anti-CEA antibodies (Fig. 5(d)). By using the sensing platform of Ti3C2–MXene/AuNPs/SPA, CEA was selected and effectively sensed, as shown in Fig. 5(e) and (f). Different from the prism-type sensing structure, the optical fiber-type SPR sensor can detect spectral information, and the biological or chemical reaction processes are judged by the detected spectral shift. Using optical fiber as the sensing carrier, Chen et al. [83] uniformly coated Ti3C2Tx MXene NSs on Au-coated optical fibers to design a highly sensitive RI sensor. The structure of the Ti3C2Tx MXene/Au-based fiber SPR sensor is shown in Fig. 5(g), and the microscopic images are shown in Fig. 5(h). The comparison results indicate that coating with Ti3C2Tx MXene can increase the shift of the resonance wavelength, thereby improving the sensitivity (Fig. 5(i)).

a Kretchmann configuration-based SPR sensor covered with Ti3C2Tx MXene [81]. b Sensitive detection of diverse sensing analytes by SPR signals enhanced with Ti3C2Tx MXene [81]. c Sensitivity enhancement by different number of Ti3C2Tx layers [81]. Copyright 2018, Elsevier. d Applications of MXene/AuNPs + MWPAg hybrid structure in SPR bio-sensing for detecting CEA [26]. e Resonance angle shift for different concentration of CEA [26]. f Variation of SPR signal when the concentration of CEA changes from 2 × 10–16 to 2 × 10–8 M [26]. Copyright 2019, Elsevier. g Structure diagram of the MXene/Au-based fiber SPR sensor [83]. h Micrograph images of the fiber SPR sensor before and after Ti3C2Tx MXene self-installation [83]. i Enhancement of the resonance wavelength shift for the fiber SPR sensor by coated Ti3C2Tx MXene [83]. Copyright 2020, American Chemical Society

Gas sensors

Large surface area of 2D materials allows more reactions on their surface, making them important candidates for gas sensing [29, 84, 85]. MXene and its modifications are emerging 2D materials with excellent metallic conductivity, functionalized surfaces, and large surface-to-volume ratios [86], and they are widely used in gas sensors. In this section, we discuss and overview the application of Ti3C2Tx MXenes and their modified materials in gas sensing. Figure 6(a) shows a Ti3C2Tx MXene-based gas sensor designed by Kim et al. [87] The detection limit of the Ti3C2Tx gas sensor for volatile organic compounds was as low as 50–100 ppb at room temperature. It also showed good selective detection of ethanol gas (Fig. 6(b)) [87]. To improve the gas response, Chen et al. proposed a gas sensing material composed of a combination of Ti3C2Tx MXene and WSe2 in a nanohybrid structure [88]. Through electrostatic interactions, WSe2 was compounded on the surface of the Ti3C2Tx MXene, fabricating the Ti3C2Tx/WSe2 nanohybrid (Fig. 6(c)). Compared with Ti3C2Tx, the Ti3C2Tx/WSe2 nanohybrid provided a large number of heterointerfaces, which significantly increased the adsorbed oxygen species, thereby trapping more electrons. When the Ti3C2Tx/WSe2 nanohybrid was exposed to volatile organic compounds, the adsorbed active oxygen species on the surface reacted with ethanol to form carbon dioxide and water (Fig. 6(d)). The Ti3C2Tx/WSe2 nanohybrid possessed more abundant adsorbed oxygen species, and thus, it had a stronger gas response to volatile organic compounds (Fig. 6(e)). The modification of Ti3C2Tx MXene with polyaniline also increased the catalytic sensitivity, enabling the selective detection of ethanol with stronger gas response [89].

a Schematic illustration of the Ti3C2Tx MXene-based gas sensor [87]. b Selective detection of ethanol by Ti3C2Tx gas sensor [87]. Copyright 2018, American Chemical Society. c Fabrication of Ti3C2Tx/WSe2 hybrids [88]. d Mechanism of sensing enhancement for the Ti3C2Tx/WSe2 hybrid [88]. e Comparison of the detection ability of Ti3C2Tx and Ti3C2Tx/WSe2 hybrid for various volatile organic compounds at 40 ppm [88]. Copyright 2020, Springer Nature. f Ti3C2Tx treated by urea-involved solvothermal reactions to obtain the nitrogen-functionalized heterophase TiO2 homojunctions (N-MXene) [90]. g Selectivity detection of NH3 by modified the N-MXene [90]. Copyright 2021, American Chemical Society. h Alkaline MXene to enhance gas response to ammonia NH3 [67]. Copyright 2019, American Chemical Society. i MXene/rGO hybrid structure to selected detection of NH3 [29]. Copyright 2020, American Chemical Society. j Selective detection of the Ti3C2Tx MXene/PANI/BC composite aerogel-based gas sensor with high gas response [91]. Copyright 2021, American Chemical Society

Modified Ti3C2Tx MXenes enable the selective detection of ethanol gas, and they can be modified by other methods to achieve selective gas detection. Zhou et al. reported a gas sensing material of Ti3C2Tx-derived nitrogen-functionalized heterophase TiO2 homojunctions (N-MXenes), which could achieve selective detection of ammonia (NH3) [90]. Figure 6(f) shows the fabrication method of N-MXenes. Ti3C2Tx was subjected to a urea-involved solvothermal reaction at 180 °C for 18 h, and then, the Ti atoms of Ti3C2Tx MXene were oxidized to TiO2. With the increase in oxidation time, the outer surface of MXene was covered by TiO2 nanoparticles, and finally, N–MXene was formed. Thereafter, the as-prepared N–MXene was sprayed onto an interdigital electrode device to fabricate the N–MXene-based gas sensor. The detection results indicated that the N–MXene-based gas sensor had selective detection ability for NH3 (Fig. 6(g)), and the detection limit was 200 ppb. Wang et al. grew ZnO nanorods on the surface of Ti3C2Tx (MXene/ZnO nanorod hybrids) to fabricate a novel light-activated NO2 gas sensor, which has a high sensitivity, and the detection limit was 0.2 ppb [92]. To enhance the gas response of the Ti3C2Tx-based sensor, researchers have proposed many effective schemes in recent years, such as alkalized Ti3C2Tx MXene (Fig. 6(h)) [67], MXene/rGO (reduced graphene oxide) hybrid fiber (Fig. 6(i)) [29], and Ti3C2Tx MXene/PANI/BC composite aerogels (Fig. 6(j)) [91]. Table 3 summarizes the recent applications of MXenes and their modified composites in gas sensing.

Fluorescence sensors

Ti3C2Tx MXenes, including NSs and QDs, are important in fluorescence sensors due to their unique optical properties. MXene NSs exhibit high fluorescence quenching ability, while MXene QDs have a strong fluorescence effect. Ti3C2Tx NSs can be used as a fluorescent sensing platform for biological testing, such as HPV-18 DNA detection (Fig. 7(a)) [106]. The fluorescent probe (P) single-stranded DNA (ssDNA) of HPV-18 exhibits strong fluorescence (Fig. 7(b)); it was mixed with a certain amount of Ti3C2Tx NSs; thereafter, the probe ssDNA was adsorbed on the surface of an MXene; the fluorescence was greatly quenched. Thereafter, the target (T) ssDNA was injected into the Ti3C2Tx MXene solution modified with the probe ssDNA; the target ssDNA was then combined with the probe ssDNA to form double-stranded DNA (dsDNA). At this time, the dsDNA was detached from the MXene surface, and the fluorescence was restored. To improve sensitivity, exonuclease III (Exo III) was used as a sensitizer to amplify changes in the fluorescence signals. By comparison, after adding Exo III, changes in the fluorescence signals were greatly enhanced (Fig. 7(b)). Based on the advantages of the quenching and recovery of fluorescence during DNA adsorption and detachment, a pathway for detection of HPV-18 virus was proposed (Fig. 7(c)). Changes of fluorescence intensity were measured when the concentration of target ssDNA was in the range 0–50 nM. The results showed that layered Ti3C2Tx is a suitable sensing platform for HPV virus detection, with a low detection limit of 100 pM.

a Ti2CTx served as bio-sensing material for detecting HPV-18 type DNA [106]. b Fluorescence spectra of the Ti3C2Tx NSs-based fluorescence sensor under different conditions [106]. c Variation of the fluorescence spectra at different concentrations of target DNA [106]. Copyright 2019, Elsevier. d TEM and AFM images of Ti2CTx MXene quantum dots (QDs) [107]. Copyright 2017, American Chemical Society. e Fluorescence spectra of Ti3C2Tx MXene QDs after adding different metal ions [108]. Copyright 2019, Elsevier. f Fluorescence spectra of the PEI- Ti3C2Tx QDs at different pH buffer solutions [109]. Copyright 2018, Royal Society of Chemistry. g Fluorescence spectra of the N, P-Ti3C2Tx QDs with different concentrations of Cu2+ ranging from 0 to 5000 μM [110]. Copyright 2019, Royal Society of Chemistry

When the lateral dimensions of Ti3C2Tx MXenes were decreased to several nanometers, they transformed into QDs (Fig. 7(d)) [107] with photoluminescent properties [107, 111]. Ti3C2Tx MXene QDs have excellent fluorescence properties, and their fluorescence characteristics vary under different excitation wavelengths, which are suitable for fluorescence sensing of biological macromolecules such as metal ions, small organic molecules, and enzymes [108, 112, 113]. Desai et al. fabricated ultra-small Ti3C2Tx MXene QDs and used them for metal ion detection [108]. The fluorescence signal excited by Ti3C2Tx MXene QDs was highly sensitive and could selectively detect Ag+ and Mn2+ ions (Fig. 7(e)), with the detection limits for Ag+ and Mn2+ ions being 9.7 and 102 nM, respectively. Chen et al. co-hydrothermally synthesized Ti3C2Tx MXene QDs with polyethyleneimine (PEI) to synthesize surface-functionalized Ti3C2Tx QDs [109]. The fluorescence effect of Ti3C2Tx QDs exhibited sensitive pH-responsivity. By linking it with a pH-insensitive dye [Ru(dpp)3]Cl2, a pH-responsive proportional fluorescent probe was constructed, which was used for intracellular pH determination (Fig. 7(f)). Guan et al. functionalized Ti3C2Tx MXene QDs with nitrogen (N) and phosphorus (P) to fabricate the N, P–Ti3C2Tx QDs [110]. The fluorescence of this new material exhibited selective detection of Cu2+ ions, and the detection limit was as low as 2 μM (Fig. 7(g)). Moreover, the effective detection of many analytes has been achieved through special modifications of Ti3C2Tx MXene QDs such as CsPbBr3–Ti3C2Tx MXene QD heterojunction [114], glutathione-functionalized Ti3C2Tx QDs [115], and N-Ti3C2Tx QDs/Fe3+ [116]. Overall, Ti3C2Tx can not only act as quenchers but also as fluorophores in different morphologies. MXene NSs act as quenchers, while MXene QDs act as fluorophores. The applications of Ti3C2Tx NSs and Ti3C2Tx QDs in fluorescence sensors are summarized in Table 4.

SERS sensors

SERS possesses the advantages of photostability, non-destructiveness, fingerprint spectrum, and ultra-sensitivity at the single-molecule level [136, 137], and thus, it has been successfully applied in various fields such as biomedicine [138, 139], environmental monitoring [140, 141], and food safety [142, 143]. In general, SERS requires noble metal nanoparticles as substrates to exert a strong SPR effect [144, 145]. However, the application of noble metal-based SERS sensors is limited by the easy aggregation and oxidation of metal nanoparticles, along with the weak ability to adsorb molecules. To solve the problem of aggregation of metal nanoparticles and further enhance the intensity of Raman signals, researchers have proposed using MXenes as the substrates of SERS sensors. MXenes have the advantages of excellent hydrophilicity, large specific surface areas, and strong electrical conductivity, which make them suitable as substrates for SERS sensors [146]. In SERS sensors, metal nanoparticles can be used as amplifiers for Raman signal changes, and they are uniformly modified on the surfaces of MXenes. Recently, Wu et al. reported a highly sensitive Au nanoparticle dimer/Ti3C2Tx-based SERS sensor for detecting mycotoxin B1 (AFB1) [147]. First, Au nanoparticles were assembled using 1,2-bis(4-pyridyl) ethylene (BPE) to form Au nanoparticle dimers. Second, a nano-gap smaller than 2 nm, called “hot spot,” was formed in the Au nanoparticle dimer, which considerably enhanced the SERS signal. Thereafter, aptamer-modified Au nanoparticle dimers were linked with Ti3C2Tx MXene NSs via hydrogen bonding and chelation. Finally, with the interaction of AFB1 with the structure of Au nanoparticle dimer/Ti3C2Tx MXene, the AFB1 adhered to the aptamer-modified Au nanoparticle dimer, which had detached from the MXene surface (Fig. 8(a)); this strongly enhanced the SERS signal.

a Fabrication of Au nanoparticle dimers/Ti3C2Tx MXenes assemblies-based SERS sensor for the detection of AFB1 [147]. b Raman intensities of Au nanoparticle dimers/Ti3C2Tx MXenes assemblies at different concentrations of Ti3C2Tx NSs [147]. c SERS spectra of the Au nanoparticle dimers/MXenes assemblies-based SERS sensor with different concentrations of mycotoxin B1 [147]. d Selective detection of AFB1 for the Au nanoparticle dimers/Ti3C2Tx MXene-based SERS sensor [147]. Copyright 2022, Elsevier. e Au − Ag Janus nanoparticles/ Ti3C2Tx NSs-based SERS sensor for the detection of ochratoxin A [145]. f SERS signals of Au − Ag Janus nanoparticles at 1278 cm-1 and Ti3C2Tx NSs at 730 cm−1 with different concentrations of ochratoxin A [145]. Copyright 2019, American Chemical Society. g The sandwich SERS sensor [148]. h Selective detection of carcinoembryonic antigen by the sandwich type SERS sensor [148]. i SERS spectra of the sandwich type SERS sensor at different concentrations of carcinoembryonic antigen [148]. Copyright 2020, Elsevier

Figure 8(b) shows the SERS intensity enhanced by the Ti3C2Tx MXene NSs with the Au nanoparticle dimer/Ti3C2Tx MXene structure. Equal volumes of Au NP dimer and Ti3C2Tx MXene NSs were mixed and the intensity of the SERS signal gradually increased with the increase in Ti3C2Tx concentration; it was the strongest at the optimal concentration of 160 µg·mL−1. Using the Au nanoparticle dimer/Ti3C2Tx MXene-based SERS sensor, AFB1 was effectively detected in the concentration range of 0.001–100 ng⋅mL−1, and the detection limit was 0.6 pg⋅mL−1 (Fig. 8(c)). The SERS sensor also exhibited selective detection of AFB1 (Fig. 8(d)). Compared with the ratiometric intensities of Blank, AFG1, AFG2, and AFB2, the detection result of AFB1 was distinctive, indicating its excellent selective detection. Zheng et al. used Ti3C2Tx MXenes as substrates and linked aptamer-modified Au–Ag Janus nanoparticles on it to achieve highly sensitive detection of ochratoxin A (Fig. 8(e)) [145]. The SERS signals of Au–Ag Janus nanoparticles at 1278 cm−1 and Ti3C2Tx NSs at 730 cm−1 with different concentrations of ochratoxin A are presented in Fig. 8(f), indicating that the SERS intensity at 1278 cm−1 was sensitive to the change of ochratoxin A concentration, while the SERS intensity at 730 cm−1 remained almost unchanged. By analyzing the variation in the ratiometric peak intensity (I1278/I730), the concentration change (0.01–50 nM) of ochratoxin A was effectively detected, and the detection limit was 1.28 pM. Medetalibeyoglu et al. presented a sandwich-type SERS sensor using MoS2 nanoflowers@Au nanoparticles and Fe3O4@Au nanoparticle-functionalized Ti3C2Tx NSs as CEASERS tags and SERS substrates, respectively, for the detection of carcinoembryonic antigen (Fig. 8(g)) [148]. The sandwich-type SERS sensor exhibited selective detection of carcinoembryonic antigen (Fig. 8(h)). The SERS signal achieved effective tracking and detection when the concentration of carcinoembryonic antigen changed from 0.0001 to 100.0 ng mL−1; the detection limit was calculated to be 0.033 pg mL−1 (Fig. 8(i)). In addition to the aforementioned sensors, other MXene-based SERS sensors with high performance have been reported in recent years, and the main performance indicators are presented in Table 5.

Colorimetric sensors

Colorimetric sensing technology is an important analysis method that is widely used, due to its advantages of high sensitivity, low cost, short color development time, obvious phenomenon, visualization, convenience and quickness. Ti3C2Tx-based colorimetric sensing technology, a visualized and ultrasensitive assay, has garnered extensive attention in recent years. This sensing technology mainly includes two types of detection methods, namely retouch-free and retouched. The difference between these two methods is that the retouch-free assay enables direct interaction between the sensing material and the analyte, while the retouched assay requires probe or dye modification of the sensing material to detect specific targets. For the retouch-free assay, Wang et al. reported a colorimetric sensing strategy based on Ti3C2Tx MXene NS-mediated in situ reduction for ultrasensitive detection of Ag+ (Fig. 9(a)) [151]. First, the stability of the Ti3C2Tx MXene NS was improved by carboxy-rich poly(acrylic acid) (PAA). Due to the good adsorption capacity and reducibility of Ti3C2Tx MXene for Ag+ ions, no additional stabilizers or reducing agents were required for the selective detection of Ag+. As the Ag+ ions were reduced in situ to nanoparticles by Ti3C2Tx MXene, the color of the solution gradually deepened to tan. The UV–Vis absorption spectra of Ag+ ions, Ti3C2Tx–PAA, and Ag nanoparticle@Ti3C2Tx–PAA are shown in Fig. 9(b). The localized SPR of in situ Ag nanoparticles was excited, which considerably influenced the properties of the sensing material. Moreover, Ti3C2Tx–PAA could realize the retouch-free and visual detections of Ag+ by the in situ reduction method. Figure 9(c) presents the UV–vis absorption spectra of Ti3C2Tx–PAA (12 μg/mL) reacted with different concentrations of Ag+ (0–500 μM). The absorption spectrum at 450 nm of the nanoplasmonic platform based on Ag nanoparticle@Ti3C2Tx–PAA exhibited sensitivity to Ag+, and the detection limit was 0.615 μM.

a Fabrication and modification of Ti3C2Tx NSs for the detection of Ag+ ions [151]. b UV − vis absorption spectra of Ag+ ions, Ti3C2Tx − PAA, and Ag nanoparticles@Ti3C2Tx − PAA [151]. c UV − vis absorption spectra of Ti3C2Tx − PAA reacted with different concentrations of Ag+ [151]. Copyright 2020, American Chemical Society. d Fabrication of the Ti3C2Tx NSs-based colorimetric sensor for hepatitis B virus DNA sensing [152]. e Absorption spectra of the Ti3C2Tx NSs-based colorimetric sensor at different concentrations of target hepatitis B virus DNA [152]. Copyright 2022, Academic Press Inc. f The size of Ti3C2Tx MXene QDs [135]. g Absorbance ratio of the N, P − Ti3C2Tx QDs − based colorimetric sensor at different concentrations of NO2− (4 – 85 μM) [135]. Copyright 2022, Elsevier. h Absorbance ratio of the glutathione (GSH) functionalized Ti3C2TX QDs − based colorimetric sensor for the selective detection of uric acid [115]. Copyright 2020, Elsevier

For the retouched assay, special probes (e.g. DNA) need to be modified on the MXene surface to achieve highly sensitive detection of specific targets. Tao et al. designed a colorimetric sensor based on MXene-probe DNA–Ag/Pt nanohybrids, where MXene was used as the supporting substrate; its surface was modified with the special probe DNA (Fig. 9(d)) [152]. Ti3C2Tx MXene was reported to possess intrinsic peroxidase-like activity [153]; however, its catalytic ability was still weaker than those of other metal or metal oxide nanozymes. Therefore, exploring combinations of MXene with noble metal nanomaterials as enzyme mimics can help improve the catalytic performance. To achieve effective linking between MXene and noble metals, an intermediate medium (i.e., DNA) is required. Controlling changes in the sequence and structure of template DNA enables precise deposition of the specific type of metal nanoparticles to form DNA metallization structures [154,155,156]. Furthermore, single-stranded DNA can be efficiently adsorbed onto Ti3C2Tx MXenes by chelating phosphate groups in the DNA with titanium ions on Ti3C2Tx NSs [119]. DNA metallization on Ti3C2Tx is an ideal strategy for the efficient preparation of MXene–metal nanohybrids, which can serve as effective enzyme mimics for sensitive colorimetric detection. Figure 9(d) shows the manufacturing strategy of MXene-probe DNA-Ag/Pt nanohybrid-based colorimetric sensing platform for hepatitis B virus DNA detection. The MXene-probe DNA–Ag/Pt nanohybrid was sensitive to the target hepatitis B virus DNA; the changes were visible to the naked eye (Fig. 9(e)) [152], and the detection limit was as low as 0.5 pM.

QDs, another form of MXenes with diameters of 2–5 nm (Fig. 9(f)) [135], are also a promising sensing material. Ti3C2Tx MXene QDs can be used in fluorescence sensing technology due to their good fluorescence effect and are ideal candidates for colorimetric sensing with high sensitivity. Bai et al. modified N,P-doped Ti3C2Tx QDs (N,PvTi3C2Tx QDs) with the 1,10-phenanthroline-Fe (II) complex (Phen-Fe2+) to fabricate an orange-colored colorimetric sensing platform. After reacting with nitrite (NO2−), the color of orange suspension gradually lightened and finally became colorless with the increase in NO2− concentration [135]. Suspensions of different colors have different absorption spectra; therefore, changes in NO2− concentration could be clearly visualized by plotting the absorbance ratio curve (Fig. 9(g)) [135]. The detection limit of the N,P-doped Ti3C2Tx MXene QD/Phen-Fe2+-based colorimetric sensing platform toward NO2− was 0.71 μM. Furthermore, changes in the probes of the Ti3C2Tx MXene QDs enabled the detection of other specific analytes. For example, glutathione-functionalized Ti3C2Tx QDs have a highly sensitive and precise selective detection ability for uric acid, with a detection limit of 200 nM (Fig. 9(h)) [115]. MXene-based colorimetric sensors have also received considerable research attention; Table 6 summarizes the related studies conducted so far.

Electrochemical sensors

Electrochemical sensing is a technology that converts chemical signals into electrical signals for sensing detection. It takes the electrode as the conversion element or fixed carrier, and realizes the qualitative or quantitative analysis of the target by transforming the chemical changes at the electrode interface into electrical signal parameters such as potential, conductivity, and current. In a loop circuit where the external voltage is applied, the specific recognition between the probe and the analyte near the electrode leads to charge transfer in the circuit, resulting in an electric current. The current is transmitted through the conductive system of the electrodes to the signal analysis system for amplification, forming an identifiable electrical signal. Finally, changes in the electrical signal are analyzed to track different concentrations of the analyte [161, 162]. Electrochemical sensors usually employ a three-electrode system, comprising a working electrode (WE), a counter electrode (CE), and a reference electrode (RE) (Fig. 10(a)). Modifying special materials on the surface of WE is one of the effective approaches for enhancing the sensitivity and selectivity of an electrochemical sensor. After modification, these electrode modification materials should exhibit high electron mobility, excellent biocompatibility, good hydrophilicity, and selective recognition ability. MXenes [163,164,165] and their modifications (Fig. 10(b)) [166,167,168,169] exhibit these characteristics, which can greatly improve the sensing performance, making them ideal materials for designing high-performance electrochemical sensors. Moreover, the electrochemical signals generated by MXene and its modifications can detect multiple targets simultaneously. For example, the accordion-like alk-Ti3C2 (Fig. 10(c)) modified electrode could detect multiple target heavy metal ions simultaneously with high sensitivity (Fig. 10(d)), with detection limits of 0.041 mM, 0.098 mM, 0.130 mM, and 0.032 mM, for Pb2+, Cd2+, Hg2+, and Cu2+, respectively [170].

a Schematic of the three-electrode system. b SEM image of modified MXene [166]. Copyright 2021, Springer Berlin Heidelberg. c Alkaline treatment of MXene [170]. d Simultaneous detection of multiple targets by the alk- Ti3C2Tx MXene-based electrochemical sensor [170]. Copyright 2017, Elsevier. e Schematic diagram of the detection of hygromycin B in food by the Cu-MOF@MXene-based electrochemical sensor [25]. Copyright 2022, Elsevier. f Schematic illustration of the fabrication of MXene@carbon black and its detection of Cu2+ by electrochemical sensing technology [171]. Copyright 2021, Springer Vienna. g Fabrication of MXene/MWCNTs/ZnO-based glassy carbon electrode for dopamine detection [172]. Copyright 2022, Elsevier. h Preparation of L-cys/AuNPs/ Ti3C2Tx composite-based electrochemical sensors for cortisol detection [173]. Copyright 2022, Elsevier

MXenes are promising candidates for electrochemical sensors and have been extensively investigated in recent years [15, 162, 174]. The application of MXenes in electrochemical sensing technology has been well summarized in relevant reviews [162, 175]. Therefore, herein, we only present a supplementary summary of a few representative recent reports. MXene-based electrochemical sensors are widely used in food safety, water source monitoring, medical diagnosis, and health monitoring due to their high sensitivity and stability. For food safety monitoring, Wang et al. reported a molecularly imprinted electrochemical sensor modified with Cu–MOF and MXene for the detection of hygromycin B (Fig. 10(e)) [25]. Cu–MOF, a material with large specific surface area, was compounded with Ti3C2Tx MXenes, which greatly improved the performance of the molecularly imprinted electrochemical sensor. The sensor exhibited excellent selectivity and high sensitivity to hygromycin B in food, and the detection limit was 1.92 nM. For water source monitoring, Xia et al. combined Ti3C2Tx MXene with carbon black as an electrode material to achieve effective detection of Cu2+ (Fig. 10(f)) [171]. Cu2+ is a relatively common heavy metal ion in water sources, and its excessive intake can damage human body functions. Therefore, the development of reliable Cu2+ detection methods is crucial for risk assessment. In this MXene@carbon black-based electrochemical sensor, carbon black could prevent the aggregation of MXene NSs and enhance the electron transfer rate. The detection limit for Cu2+ was 4.6 nM in a wide linear range of 0.01–15.0 μM. For medical diagnosis, Ni et al. fabricated a composite containing MXene, multi-walled carbon nanotubes (MWCNTs), and ZnO nanospheres, which were modified on a glassy carbon electrode to enable highly sensitive (S = 16 A/M) detection of dopamine (Fig. 10(g)) [172]. Effective monitoring of dopamine concentrations in humans can enable the diagnosis of many diseases, such as Parkinson's disease, schizophrenia, and Alzheimer's disease. The MXene/MWCNT/ZnO-based electrochemical sensor exhibited precise dopamine capture capability with a detection limit of 3.2 nM in the linear range of 0.01–30 μM. For health monitoring, Laochai et al. modified anti-cortisol on a L-cys/AuNP/Ti3C2Tx composite to design an electrochemical sensor for detecting cortisol in sweat (Fig. 10(h)) [173]. Cortisol is a steroid hormone produced by the adrenal glands, and it affects various physiological processes in the human body; thus, detecting cortisol in sweat can enable effective monitoring of human health. Utilizing the L-cys/AuNP/Ti3C2Tx composite-based electrochemical sensor, cortisol in sweat was detected with high sensitivity, and the detection limit was 0.54 ng mL−1. In addition to the aforementioned MXene-based electrochemical sensors, there have been several exciting related reports, some of which are summarized in Table 7.

Temperature sensors

Temperature measurement is crucial for human life and production. Strict temperature control is required for medical diagnosis, scientific research, or industrial production. As an emerging 2D transition metal carbide material, MXenes have attracted attention due to their excellent thermoelectric properties, high electrical conductivity, and good water dispersibility [74, 201]. Tin+1CnTx MXenes and their related composites exhibit excellent electro-thermal and photo-thermal conversion behavior, which is conducive to designing temperature sensors [17, 73, 202]. Xuan et al. irradiated a low-concentration MXene solution with an 808 nm laser and found that the temperature increased from room temperature to > 60° within 300 s, whereas for pure water, the temperature change was negligible [38]. Luo et al. decorated Ti3C2Tx MXene on textile to fabricate a temperature sensor, and tested its photo-thermal behavior using a xenon lamp (Fig. 11(a)) [202]. The MXene exhibited a strong photo-thermal effect. Under the irradiation of the xenon lamp, the temperature increased rapidly and reached a saturation temperature of ~ 59 °C after 300 s. When the xenon lamp was turned on and off, the temperature curve showed periodic changes, and the changing trend was consistent, indicating that the photothermal conversion of MXene exhibited good repeatability (Fig. 11(b)) [202]. During the heating and cooling process, the temperature of MXene changed, and its relative resistance also changed (Fig. 11(c)) [202]. Therefore, changes in temperature can be monitored by measuring the relative resistance of MXene.

a Schematic diagram of photothermal testing of MXene sample under a xenon lamp [202]. b Temperature changes of MXene sample with the xenon lamp on and off (power density = 100 mW/cm2) [202]. c Changes in temperature and relative resistance during heating and cooling of MXene sample [202]. Copyright 2021, Elsevier. d Real-time changes in temperature under different input voltages [203]. e Stable changes in temperature when the input voltage is repeatedly turned on and off [203]. Copyright 2020, American Chemical Society. f The relative resistance of MXene sample changes under different temperature environments [204]. Copyright 2019, Royal Society of Chemistry. g SEM images of the MXene/CCS@CF [205]. h Voltage-current curve of the MXene/CCS@CF [205]. i Real-time temperature changes of MXene/CCS@CF with different input voltages [205]. j Infrared camera images of MXene/CCS@CF after heating and cooling [205]. Copyright 2021, American Chemical Society

MXenes also exhibit an excellent electrothermal conversion effect, which can rapidly increase the temperature by additional input voltage. The joule heating capability of MXenes was evaluated by measuring the change in temperature with time (Fig. 11(d)) [203]. According to Joule's law, the temperature increased gradually with the increase in input voltage, and it was almost proportional to the square of the input voltage. Figure 11(e) shows the durable and reproducible thermal response of the MXene specimen [203]. When a voltage of 3 V was cycled on and off for 20 cycles, the temperature of the MXene samples could be rapidly increased and decreased, and the maximum temperature value could be maintained at 45 °C. The excellent photothermal conversion and electrothermal conversion behaviors of MXenes indicate that they have a good temperature sensing function. Under different temperature environments, the relative resistance of MXenes shows significant responses (Fig. 11(f)) [204]. To improve the temperature resistance and flame resistance of MXenes, Wang et al. coated MXene NSs with carboxymethyl chitosan (CCS) and deposited it on cotton fabric (CF) to prepare a flame-resistant, temperature-sensitive sensing material, labeled as MXene/CCS@CF (Fig. 11(g)) [205]. The linear voltage-current curve (Fig. 11(h)) indicates the stability of the operating voltage and current, confirming the reliability of the MXene/CCS@CF heater. The temperature of the MXene/CCS@CF is controlled by switching the input voltage on and off, demonstrating the controllability of the joule heating performance (Fig. 11(i)) [205]. In a short period of time, the temperature of MXene/CCS@CF increases rapidly under the influence of the input voltage. Rapid heating of the MXene/CCS@CF was achieved in approximately 30 s with excellent repeatability (Fig. 11(j)) [205]. The sensitive photothermal and electrothermal conversion capabilities of MXenes and their modifications indicate that they are promising candidates for the development of temperature sensors.

Humidity sensors

Humidity is an important environmental parameter that is closely related to human production and life. Humidity sensors can rapidly and accurately sense the changes in humidity in the environment and then convert this information into electrical or optical signals that can be easier for humans to observe. To meet the needs of different application scenarios and measure humidity in different environments, different types of humidity sensors are used that can be divided into resistive and capacitive types according to their outputs. As a hydrophilic material, MXene is rich in surface functional groups, which can interact with the moisture in the environment and realize effective humidity detection. Some oxygen groups (epoxy and hydroxyl functional groups) demonstrated by MXene NSs can trap or release water molecules with the aid of H bonds, as shown in Fig. 12(a) [206]. When a multilayer MXene absorbs a certain amount of water molecules, the surface properties are changed and the interlayer spacing is widened (Fig. 12(b)) [207]. These changes greatly affect the electronic properties of the MXene materials. Therefore, by monitoring the changes in the resistance signal of the MXene, the change of the environmental humidity can be intuitively observed (Fig. 12(c)) [207]. Wang et al. deposited MXene on a spring-like helical core-sheath polyester yarn to form a flexible sensing structure (Fig. 12(d)) [206]. This flexible sensor was extremely sensitive to the humidity of the environment and could effectively detect relative humidity (RH) from 30 to 100% with a sensitivity of 0.157 kΩ/RH% (Fig. 12(e)) [206]. The effects of humidification and drying on resistance are shown in Fig. 12(f) [206], which demonstrate the recoverability of the sensing performance and the reusability of the structure.

a Schematic diagram of atomic structure of multilayer MXene before and after water absorption [206]. Copyright 2020, Springer US. b Structural changes of MXene materials in low-humidity and high-humidity environments [207]. c Variation of resistance of MXene materials in different humidity environments [207]. Copyright 2019, American Chemical Society. d Spring-like helical core-sheath polyester yarn-based flexible MXene sensing structure [206]. e Variation of resistance with respect to the RH for the flexible MXene sensor [206]. f The effects of humidification and drying on resistance, which demonstrate the recoverability of the sensing performance and the reusability of the structure [206]. Copyright 2020, Springer US. g Schematic diagram of the synthesis of S- Ti3C2Tx MXene K2Ti4O9 composite [208]. h Variation of resistance with different RH [208]. i Response comparison of different humidity [208]. Copyright 2021, Elsevier. j The synthesis process of Ti3C2Tx/TiO2 composite [209]. k Variation of capacitance of Ti3C2Tx/TiO2 composite at different relative humidity [209]. Copyright 2021, Royal Society of Chemistry. l Dynamic response-recovery curve of resistance for the pristine Ti3C2Tx and alkalized Ti3C2Tx under different RH [67]. m, n Resistance responses (R/R11%) of pristine Ti3C2Tx and alkalized Ti3C2Tx under different RH [67]. Copyright 2019, American Chemical Society

To enhance the sensitivity of the humidity sensor, some other MXene-derived novel materials have been synthesized with stronger absorption ability of water molecules, such as Ti3C2Tx MXene/K2Ti4O9 composites, urchin-like Ti3C2Tx/TiO2 composites, and alkalized Ti3C2Tx. Wu et al. used KOH to treat sheet-like Ti3C2Tx (S–Ti3C2Tx) for 48 h at 30 °C and then fabricated an S–Ti3C2Tx MXene/K2Ti4O9 composite (Fig. 12(g)) [208]. In the composite, K2Ti4O9, a hydrophilic material that enhances water absorption, exhibited filament-like nanostructures with narrow widths of 10–50 nm and was wound on the surface of S–Ti3C2Tx MXene. The enlargement of the interlayer distance of the S–Ti3C2Tx caused by the intercalated K+ increased the intake of water molecules. Owing to these two advantages, the S–Ti3C2Tx MXene/K2Ti4O9 composite-based sensor exhibited stronger humidity sensitivity (Fig. 12(h)) [208]. The RH response of the S–Ti3C2Tx MXene/K2Ti4O9 composite was more than 8 times higher than that of the accordion-like Ti3C2Tx (Fig. 12(i)) [208]. Li et al. used varied reaction conditions of MXene in KOH to develop a novel Ti3C2Tx/TiO2 composite. In the synthesis method, 100 mg of Ti3C2Tx MXene was poured into 60 mL KOH (12 mol/L) and they were allowed at 50 °C for 10 h (Fig. 12(j)) [209]. The as-prepared Ti3C2Tx/TiO2 composite had a strong humidity sensing ability, and it was used to develop a humidity sensor. The Ti3C2Tx/TiO2 composite-based humidity sensor had high sensitivity (280 pF/%RH) in a low-RH environment (Fig. 12(k)) [209]. Instead of KOH, Yang et al. treated MXene with NaOH at room temperature for 2 h, and finally prepared the alkalized Ti3C2Tx MXene [67]. The Na+ insertion and increased surface terminal oxygen–fluorine ratio in Ti3C2Tx MXene effectively enhanced the humidity sensing ability. Compared with the pristine Ti3C2Tx MXene, the alkalized Ti3C2Tx exhibited stronger resistance changes under different ambient humidity conditions (Fig. 12(l)) [67]. Figure 12(m) and (n) show the resistance responses (R/R11%) of pristine Ti3C2Tx and alkalized Ti3C2Tx, respectively, to different humidity conditions [67]. The resistance response showed a trend of enhancement with the increase in RH, and the response value of alkalized Ti3C2Tx was greatly improved. In general, MXene and its derivatives show excellent application potential in humidity sensing, indicating that they may be used in the development of intelligent devices and bionic technologies.

Pressure/strain sensors

Strain sensors are flexible electronic devices that can convert strain into electrical signals for easy collection and transmission, enabling accurate record-keeping of the deformations of the target in real time. High-performance flexible strain sensors should exhibit high sensitivity, stretchability, flexibility, durability, and low power consumption [210,211,212,213]. Tin+1CnTx MXenes possess excellent electrical conductivity, good hydrophilicity, and outstanding mechanical properties, which can be developed as ideal conductive force-sensitive materials for flexible strain sensors [214,215,216]. In strain sensing, there are four main factors that cause strain, namely, pressure, tension, bending, and torsion. These strain modes can change the electrical properties of the force-sensitive material, converting the strain signal into an electrical signal. Therefore, effective detection of various strain forces can be realized by monitoring changes in electrical signals. Herein, we summarize and discuss the sensing detection of four strain forces by MXene materials.

Tin+1CnTx is essentially a ceramic phase material and has some brittleness; therefore, the piezoresistive sensor assembled from pure MXene materials cannot withstand high pressure and thus easily breaks or collapses. Therefore, MXene materials should be compounded with some highly flexible materials to meet the mechanical strength requirements of pressure sensing. The internal structure of MXene-based sensing composites deforms when subjected to pressure, resulting in a fluctuation in carrier mobility, that is, the piezoresistive effect. The composition of piezoresistive sensors with MXenes as the sensitive material is shown in Fig. 13(a) [217]. First, the conductive MXene/CF hybrid material was fabricated using CF as the flexible carrier to support force-sensitive MXene materials. Second, the conductive fabric was covered on a polyimide (PI) substrate plated with interdigital electrodes. Finally, the polydimethylsiloxane (PDM) film was coated on the conductive fabric as an encapsulation layer, thus completing the fabrication of the MXene-based piezoresistive sensor. The resistance of the MXene-based piezoresistive sensor was measured, and the results demonstrated that the resistance decreased significantly from 1946 Ω to 168 Ω when the MXene concentration increased from 0.1 mg/mL to 0.4 mg/mL. With further increase in the concentration, the resistance of the pressure sensor stabilized at 134.2 Ω (Fig. 13(b)) [217]. Therefore, when MXene concentration exceeds a certain threshold, the resistance tends to be stable, avoiding the impact of concentration on the detection function of the sensor.

a Schematic illustrations of the MXene-based piezoresistive sensor [217]. b Variation of the resistance with respect to the concentration of the MXene [217]. Copyright 2021, Elsevier. c Schematic diagram of MXene-based sensing circuit [218]. d The current change of the piezoresistive sensor under different pressure [218]. e The sensitivity of the MXene-based piezoresistive sensor [218]. Copyright 2022, Elsevier. f Schematic illustration of BBP-MX-AG-based piezoresistive sensor [219]. g Pressure sensitivity of the piezoresistive sensor under different pressure stimuli [219]. Copyright 2022, Springer Nature. h Variation of relative resistance with respect to the tensile strain [220]. Copyright 2018, American Association for the Advancement of Science. i Variation of relative current with respect to the torsion angle [221]. j Variation of relative current with respect to the bending angle [221]. Copyright 2021, Elsevier

Figure 13(c) illustrates the strain process of the sensing structure under external pressure [218]. When an external force is applied to the piezoresistive sensor, the sensitive material deforms, increasing the effective contact area between the MXene composite and the electrode, thereby increasing the conductive path, which eventually increases the current (Fig. 13(d)) and decreases the resistance. The MXene-based piezoresistive sensor has a sensitivity of 164.93 k·Pa−1 in the range of 0–10 kPa and 403.46 k·Pa−1 in the range of 10–18 kPa (Fig. 13(e)) [218]. Recently, Shi et al. reported a method for the fabrication of soft polysiloxane crosslinked MXene aerogel, labeled as BBP–MX–AG [219]. The BBP–MX–AG has a retractable nanochannel structure with multi-level cellular walls inside (Fig. 13(f)). The synergistic effect of easily shrinkable nanopores and sensitive materials conferred a pressure-sensitive aerogel an ultra-low Young's modulus (140 Pa), rich conductive network, and mechanical stability. The fabricated BBP–MX–AG is an extremely sensitive piezoresistive sensor with extremely low detection limit (0.0063 Pa), fast response time (millisecond level), and high sensitivity (1929.8 k·Pa−1) (Fig. 13(g)) [219]. This flexible strain sensor also exhibited excellent durability, and it could quickly return to its original shape after being subjected to external force without undergoing physical damage, and the electrical stability was not affected. BBP–MX–AG-based sensor is one of the highly sensitive biosensors reported in contemporary literature, and it can be considered a leading achievement in piezoelectric sensors. In addition to being sensitive to pressure, MXene-based flexible strain sensors are also sensitive to other strain-generating factors, such as tension (Fig. 13(h)) [220], torsion (Fig. 13(i)) [221], and bending (Fig. 13(j)) [221]. Whether tension, torsion, or bending, the morphology of the MXene-based strain sensing film changes, resulting in changes in its electrical properties, and it can ultimately be used to sense various strain forces by monitoring changes in current or resistance. In the past few years, MXene-based strain sensors have been extensively studied, and various high-performance sensing structures have been reported. In Table 8, we list and summarize the main performance indicators of MXene-based strain sensors from the past two years, while earlier related reports have been well summarized in other reviews [222,223,224].

MXene-based sensing technology for wearable smart device

In recent years, with advances in flexible electronics, wearable smart devices have attracted extensive research attention. Wearable smart sensors can convert the strain, temperature, and humidity changes of the human body into electrical signals and output them on various devices. Weaving or assembling the wearable smart sensors on clothing or skin can enable monitoring of human physiological information in real time, such as movement status, skin temperature, humidity, and blood pressure. In the previous section, we summarized and discussed the application of Tin+1CnTx materials in various sensors, which indicates that MXene and its composites are highly sensitive to changes in strain, temperature, and pressure, showing that MXenes are suitable for designing flexible wearable smart devices. However, MXenes are a ceramic phase material, and exhibiting some brittleness and poor self-straining ability; thus, high-performance and high-flexibility wearable devices should combine MXenes with textiles, hydrogels, aerogels, and so on. The fabrication methods include dip coating, spray drying, freeze–drying, electrospinning, wet spinning, and vacuum filtration [23, 201, 280,281,282].

The frequency of breathing is generally proportional to the heart rate. When the heart beats faster, the breathing rate increases. Therefore, by monitoring breathing, the health status of humans in terms of movement, disease, or weakness can be monitored. MXenes are a highly humidity-sensitive material that can be developed into a wearable device for respiratory monitoring [203, 283, 284]. Recently Xing et al. proposed a wearable breathing sensor based on a Ti3C2Tx and MWCNTs (MXene/MWCNT) composite electronic fabric (Fig. 14(a)) [284]. The sensor had a 265% resistance response at 90% RH and a large stable response under deformation conditions. Furthermore, the humidity response change of the MXene/MWCNT fabric-based sensor under stretching is only 7%, which is a substantial improvement in stability compared with the pure MXene fabric sensor (35% humidity response change under stretching). Integrating the MXene/MWCNT fabric-based sensor into a mask leads to the formation of a wearable breathing monitor that can accurately identify different breathing states (Fig. 14(b)) [284]. MXene-based wearable sensors are sensitive to not only humidity but also temperature, and they can be used for smart thermotherapy and wound dressing (Fig. 14(c)) [203]. Zhao et al. deposited 2D Ti3C2Tx NSs onto cellulose fiber nonwovens to fabricate a multifunctional MXene-based smart fabric with reliable flexibility, excellent breathability, and self-controllable electro-thermal effect [203]. Taking advantage of the multifunctional MXene-based smart fabric, they successfully applied it in the field of smart hyperthermia, which could effectively warm the body and relieve muscle spasms and joint damage under a low voltage supply. Furthermore, the smart fabric had a good joule heating effect, such that it was moderately bactericidal and could accelerate healing.

a Schematic diagram of the wireless data transmission and detection of the MXene-based breathing sensor [284]. b The response signals of the MXene-based smart sensor under different breathing states [284]. Copyright 2022, Elsevier. c The application of MXene-based smart sensor in breath monitoring, smart thermotherapy, and wound dressing [203]. Copyright 2020, American Chemical Society. d Model diagram of MXene-based wearable textile for human physiological information detection [202]. Copyright 2021, Elsevier. e–h Electrical responses of MXene-based wearable sensor under different joint movements of the human body [21, 65, 260]. Copyright 2021, American Chemical Society. Copyright 2021, American Association for the Advancement of Science. Copyright 2021, Springer Singapore. i Electrical responses of MXene-based wearable sensor for speaking “hello” and “sensor” [285]. Copyright 2020, Wiley–VCH. j Fabrication of conductive MXene@aramid fiber by the method of wet spinning [286]. k Morphology of MXene@aramid fiber and its fabricated wearable device [286]. Copyright 2021, American Chemical Society

In terms of human motion status monitoring, wearable MXene textiles can be designed as bracelets or patches to obtain real-time motion feedback (Fig. 14 (d)). When people walk and run, the bending degree of the knee varies; hence, MXene textile sensors attached to the knees can be used to monitor the movement state of the human body in real time (Fig. 14 (e)) [65]. In addition, the movements of other human joints, such as fingers, arms, and ankles, can be monitored using MXene textile sensors (Fig. 14 (f–h)) [21, 260]. The wearable MXene sensor also has exciting application potential in physiological signal detection (Fig. 14(i)) [285]. According to the throat vibration, the electrical signal output acquired by the MXene sensor can be used to distinguish the tones of different words, which makes the development of a smart sound generator possible for the benefit of mute people [285]. Moreover, the use of MXene nanofibers is a novel method for fabricating wearable devices [286]. Wang et al. fabricated a conductive MXene@aramid fiber through wet spinning (Fig. 14(j, k)) [286]. The MXene@aramid fiber had a high conductivity (2515 S m−1), which is suitable for designing smart wearable devices for monitoring human movements. In conclusion, both MXene-based textiles and fibers are important candidates for designing wearable smart sensing devices.

MXene-based sensing technology for bionic E-skin

The skin is one of the most important organs of human beings, and touch is the core function of the skin for sensing surroundings, such as the sensing of strain, temperature, and humidity. In recent years, MXenes have been used for developing bionic electronic skins (E-skins) because of their excellent strain, temperature, and humidity sensing capabilities [21, 217, 287, 288]. Figure 15(a) shows the spinous microstructure model of human skin [22]. The spinous microstructure typically provides highly concentrated localized stress in the contact area, improving the sensitivity and accuracy of skin to pressure. The sensing film prepared using microspinous Ti3C2Tx MXene had a structure similar to that of human skin, and it possessed outstanding electrical conductivity, making it an ideal candidate for bionic E-skin. The sections and models of the microstructure of the MXene-based bionic E-skin in pristine, light-loaded, heavy-loaded, and recovered conditions are shown in Fig. 15(b) [22]. When E-skin was subjected to external extrusion, with the increase in pressure, the contact area between microspinous MXene and the interdigital electrodes gradually increased, thereby significantly increasing the conductive path and eventually causing changes in resistance or current. When the external force was withdrawn, the microspinous MXene-based E-skin quickly returned to its original state, resulting in a reduction in the contact surface area. During the pressure application and withdrawal process, the relative current of the MXene-based E-skin showed a strict symmetrical relationship, indicating the good recoverability (Fig. 15(c)) [219]. When MXene materials are fabricated into arrays as bionic E-skins, their excellent electrical sensing properties enable sensitive detection of strain. MXene materials can be fabricated as array units, which are then attached to the robot body as bionic E-skin, such as at the elbow joint. When the elbow joint bends, or when a foreign object extrudes, the electrical properties of bionic E-skin are significantly affected, thereby realizing real-time response to external strain (Fig. 15(d)) [267].

a The spinous microstructure model of human skin [22]. b The sections and models of the microstructure of the Ti3C2Tx MXene-based bionic E-skin in pristine, light-loaded, heavy-loaded, and recovered conditions [22]. Copyright 2020, American Chemical Society. c Variation in relative current at different pressures [219]. Copyright 2022, Springer Nature. d Photographs of the elbow joint with MXene array sensing E-skin under different motion states and the corresponding mapping of the strain-induced capacitance distribution [267]. Copyright 2021, American Chemical Society. e Schematic diagram of thermal response of MXene bionic E-skin [288]. f Temperature sensitivity of Ti3C2Tx MXene-based bionic E-skin [288]. Copyright 2022, Wiley–VCH. g Ti3C2Tx MXene-based array unit, and its response to temperature [204]. Copyright 2019, Royal Society of Chemistry. h Hydrophilic characterization of MXene and its complex [65]. Copyright 2021, Springer Singapore. i Change in relative resistance of the MXene-based bionic E-skin with increasing humidity [203]. Copyright 2020, American Chemical Society. j The humidity response of the MXene-based bionic E-skin during humidification and drying [284]. Copyright 2022, Elsevier

MXene-based E-skin should also be sensitive to temperature (Fig. 15(e)) [288]. Temperature sensitivity is demonstrated in Fig. 15(f), which shows that the voltage exhibits stable and sensitive changes in response to repeated hot and cold stimuli. Even slight thermal changes in the environment can be sensed by the E-skin. As an example, MXene was fabricated into an array unit similar to skin, and a finger was used as the weak heat source close to the top of the temperature sensor array (Fig. 15(g)) [204]. The Ti3C2Tx MXene-based E-skin could accurately sense the position of the finger and respond through resistance changes in the sensor. Finally, MXene-based bionic E-skins are also extremely sensitive to humidity, which can be attributed to the abundant functional groups on the surface that enhance their hydrophilicity (Fig. 15(h)) [65]. Moisture changes in the environment can also be captured by the MXene-based bionic E-skin and converted into electrical signals for further processing (Fig. 15(i)) [203]. The humidity response exhibited good stability and recoverability during humidification and drying, which proves the feasibility for the design of E-skin (Fig. 15(j)) [284].