Abstract

Background

Xylanases have been successfully used in food, paper, and pulp industries and are considered to be a key player in the biodegradation of xylan to valuable end products. However, most of the natural xylanases present poor activity in high-temperature and high-alkali environment. Therefore, it is necessary to modify the enzymes to meet the increasing demands of industries.

Results

Directed evolution was used to improve the specific activity and pH stability of the xylanase (XynHBN188A) that originated from Bacillus pumilus HBP8. The xylanase XynHBN188A was mutated by error-prone PCR. The mutant, XynHBN188A217, was screened from the mutant library by functional screening. The specific activity of XynHBN188A217 was 3986.7 U/mg, which was 2.8-fold higher than that of wild type. The optimum temperature of XynHBN188A and XynHBN188A217 was 50 °C and 55 °C, respectively. The optimum pH of XynHBN188A and XynHBN188A217 was pH 8.0 and pH 7.5, respectively. The half-life at 60 °C of XynHBN188A217 was 20 min. Moreover, the pH stability of XynHBN188A217 was significantly better than that of XynHBN188A. Finally, homology models and molecular docking were used to identify the location of mutation sites and to explore the mechanism of the improved properties.

Conclusion

The xylanase XynHBN188A has been improved in the specific activity and pH stability by directed evolution. Also, the enlarged catalytic channel of mutant is beneficial for the substrates access and products release. It may contribute to the improved activity. The mutant XynHBN188A217 will be a potential candidate to be used for industrial application.

Similar content being viewed by others

Background

Xylanases catalyze the hydrolysis of xylan, which is the second most abundant polysaccharide after cellulose in nature. Xylanases are the key enzymes of the microbial hemicellulolytic system, can randomly cleave the β-1,4-backbone of xylan. Based on amino acid sequence homologies and hydrophobic cluster analysis, most xylanases are classified into glycoside hydrolase families (GH) 10 and 11, and other minorities belong to GH families 5, 7, 8, 16, 26, 43, 52 and 62 (Collins et al. 2005; Motta et al. 2013). In recent years, xylanases have been successfully used for animal food manufacturing and pulp bleaching and are considered to be a key player in the biodegradation of renewable resources to useful end products (Juturu and Wu 2014; Walia et al. 2017).

However, most of the natural enzymes showed poor activity in high-temperature and high-alkali environment which was required in some industrial processes (Beg et al. 2001; Berrin et al. 2007). In order to meet the increasing demands of industries, many efforts have been made to improve the properties of xylanases (Wijma et al. 2013; Zhang et al. 2010). Directed evolution is a technique that can overcome the limitations of natural enzymes. Compared with rational design methods, the significant advantage of directed evolution is that detailed understanding of the relationship between enzyme structure and function are not required to guide the evolution of enzymes (Sen et al. 2007). The error-prone PCR based on the inaccurate amplification of genes is frequently used due to its high efficiency and simplicity (Acevedo et al. 2017; Stephens et al. 2009).

In our previous work, a xylanase gene (xynHB) from Bacillus pumilus HBP8 was cloned and expressed in Pichia pastoris (Zhang et al. 2006). And the mutant XynHBN188A with the increased thermostability was obtained (Lu et al. 2016). The recombinant XynHBN188A from P. pastoris can remain stable at 60 °C for 30 min and present over 50% relative activity from 40 to 60 °C and pH 6–9, respectively, which is suitable for the paper industry (Zhang et al. 2010). However, no further study was made to enhance its activity. In this study, the gene xynHBN188A, encoding the XynHBN188A, was cloned and expressed in E. coli for use as a platform for random mutants. Error-prone PCR was used to introduce random mutagenesis to xynHBN188A gene. And the mutant with the improved specific activity was screened using the functional screening. The mutant was subjected to biochemical characterization in detail. And two crucial amino acid sites, which affect the enzyme activity, were found by sequencing. Furthermore, homology modeling and molecular docking were performed to explore the mechanism of the improved properties.

Materials and methods

Materials

Primers were purchased from GenScript Co. Ltd (Nanjing, China) in PAGE-purified grade. Beechwood xylan was purchased from Sigma-Aldrich (St. Louis, USA). Restriction enzymes, rTaq DNA polymerase, Ex Taq DNA polymerase, LA DNA polymerase, PrimeSTAR Max DNA polymerase and T4 DNA ligase were purchased from TakaRa (Dalian, China). All chemicals were of analytical grade and obtained from commercial suppliers.

Construction of error-prone PCR libraries and screening of mutant

The recombinant plasmid pET28a-xynHBN188A was constructed by using the primers HB1 and HB2 in Table 1. Then, the xylanase gene xynHBN188A was amplified using error-prone PCR varying the concentration of dNTPs, Mg2+ and Mn2+, from the recombinant plasmid pET28a-xynHBN188A. The two PCR systems with different mutation rates were designed (Yi et al. 2013) (Table 2). The PCR was performed under the following conditions: initial denaturation at 94 °C for 5 min, followed by 25 consecutive cycles of denaturation at 91 °C for 1 min, anneal at 55 °C for 1 min, extension at 72 °C for 45 s, and a final extension at 72 °C for 10 min. The primers 18N188AF and18N188AR were used for error-prone PCR (Table 1), which contain BamHI and SalI restriction sites, respectively. The PCR products were purified using a gel extraction kit. After digestion with BamHI and SalI, the purified products were ligated with pET28a vector digested with same enzymes. The ligation products were then transformed into E. coli BL21 (DE3) using Electroporator (Bio-Rad). The positive clones were firstly screened on Luria–Bertani (LB) agar plates containing 50 μg/ml kanamycin, 0.5% RBB-xylan, and 0.5 mM IPTG through observing the hydrolysis circle. Then, the 96-well cell culture plates were used for further screening by determining the enzyme activity in the cell lysis. Finally, the positive clones were rescreened by shaking flask culture.

Expression and purification of wild-type and mutant enzymes

Single colonies were grown in LB medium containing 50 μg/ml kanamycin at 37 °C and induced by adding 0.5 mM IPTG when the OD600 reached 0.6–0.8, and the culture was incubated at 18 °C for 16 h. Cells were harvested by centrifugation and disrupted by sonication, and the supernatant was purified by Ni2+-NTA resin affinity chromatography. Purified XynHBN188A and variants were analyzed by SDS-PAGE and used for enzymatic assay. The concentration of protein was determined with BCA Protein Assay Kit.

Xylanases activity assays

Enzymatic activity was assayed by measuring the reducing sugar released from beechwood xylan by dinitrosalicylic acid method (Miller 1959). Xylanase activity was assayed by incubating 1 ml enzyme solution with appropriate dilution and 1 ml 1% beechwood xylan solution. The mixture was incubated at the certain temperature for 10 min, followed by boiling for 5 min immediately. One unit of enzyme activity was defined as the amount of enzyme capable of releasing 1 μmol reducing sugar from xylan per minute under the assay conditions. The optimal temperatures for enzymatic activity were performed in 50 mM Tris–HCl buffer pH 7.5, over the temperature range from 30 to 70 °C. The thermostability was assessed by pre-incubation of the enzyme at 60 °C for 30 min. Residual xylanase activity was determined at regular time intervals of 5 min in optimal temperatures of XynHBN188A and XynHBN188A217, respectively.

The optimal pH and pH stability of enzymes were determined by assays in a wide pH range, using 50 mM of four different buffers (HAc-NaAc pH 4.0–6.2, phosphate buffer pH 5.8–8.0, Tris–HCl 7.5–9.0, and Gly-NaOH pH 8.6–9.8). The optimal pH was determined at 50 °C. The pH stability was tested by diluting the purified enzyme with the different pH and incubating at 4 °C for 12 h in order to avoid the effect of temperature on enzyme. The xylanase activity under optimal conditions was taken as 100% in pH stability assays. The residual activity was measured as described above. All measurements were performed in triplicate.

Homology modeling and substrate docking

To obtain the theoretical structure of native and mutant xylanases, the 3D structure models of XynHBN188A and XynHBN188A217 were generated by I-TASSER online Server (Yang et al. 2015; Zhang 2008) (https://zhanglab.ccmb.med.umich.edu/I-TASSER/). The 3D structural comparison between XynHBN188A and XynHBN188A217 was revealed using PyMOL 2.2 (https://pymol.org/2/). The co-crystallized ligand (XS2) from 1XNK (Janis et al. 2005) was docked into the pocket of xylanase using YASARA program to get the complex structure. The docked conformations were selected manually.

Results and discussion

Construction and evaluation of error-prone PCR libraries

In this study, directed evolution was employed in an attempt to enhance the specific activity of the xylanase XynHBN188A. Random mutations were introduced into the gene by error-prone PCR. More than 20,000 transformants were obtained. In each library, 15 clones were randomly picked and sequenced (Additional file 1: Figure S1) to evaluate the quality of the library. And the mutation rates of the two libraries were 2.05% and 3%, respectively.

Screening of xylanase mutant libraries

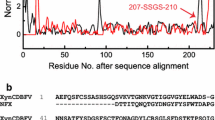

The transformants in the library were spread on the RBB-xylan substrate plates with IPTG induction for preliminary functional screening (Fig. 1), then by 96-well cell culture plate. By several rounds of screening, 46 transformants were isolated. Then, the 46 mutants were rescreened through shaking flask to expand culture. The purified enzymes were obtained to quantify the enzyme activity. Finally, the mutant with the highest activity was obtained and named as XynHBN188A217. Sequencing analysis revealed that four bases were mutated in XynHBN188A217, 105th adenosine (A) was mutated to guanine (G), 124th adenosine (A) was mutated to guanine (G), 153rd adenosine (A) was mutated to guanine (G), and 445th adenosine (A) was mutated to thymine (T), which led to two amino acid mutations (N42D, T149S) within the open-reading frame.

The RBB-xylan substrate plate to screening the mutant library. The mutants in the library were spread on the RBB-xylan substrate plate method with IPTG induction for preliminary functional screening (a, b). The mutants with obvious bigger hydrolysis circle compared with the wide type were rescreened on the RBB-xylan substrate plate (c)

Optimum temperature and thermostability of XynHBN188A217

The optimum activity of XynHBN188A217 occurred at 55 °C, which was 5 °C higher than the wild-type XynHBN188A (Fig. 2a). In addition, XynHBN188A217 showed above 60% activity from 30 to 60 °C. The activity of XynHBN188A217 retained over 50% at 60 °C pre-incubation for 20 min, which was 33% lower than that of XynHBN188A (Fig. 2b).

Effects of temperature and pH on activity (a, c) and stability (b, d) of XynHBN188A217. Beechwood xylan (1%) was used as substrate for xylanases activity assay. The highest activity was taken as 100% in assay of optimum temperature and pH. The xylanase activity under optimal conditions was taken as 100% in thermostability and pH stability assays. The thermostability was tested by pre-incubation the enzyme at 60 °C. The pH stability was tested by diluting the purified enzyme with the different pH buffer and incubating at 4 °C for 12 h. Then the residual activity was measured at the optimal condition

Optimum pH and pH stability of XynHBN188A217

The optimal pH of XynHBN188A217 was pH 7.5, whereas that of wild-type XynHBN188A was pH 8.0 (Fig. 2c). Both XynHBN188A217 and XynHBN188A exhibited higher activity in both acidic and alkaline conditionss, and it retained over 50% activity from pH 5.5 to 9.0. In addition, the pH stability of XynHBN188A217 was significantly better than that of wild-type XynHBN188A (Fig. 2d). More than 60% residual activity of XynHBN188A217 was retained from pH 5.0 to 8.5, showing good resistance to acid and alkali conditions. However, XynHBN188A only retained over 40% activity in the narrow pH range, from pH 7.5 to 8.5, showing poor pH stability.

Several previous studies have shown that the substitution of amino acids on the surface of the protein had different effects on its activity depending on the environment of the mutation sites (Bhardwaj et al. 2010; Perl et al. 2000; Wang et al. 2013). Since asparagine was a neutral amino acid and aspartic acid was an acidic amino acid, the substitution of aspartic acid for asparagine might contribute to the variation in the content of the acidic amino acid on the surface of the protein. Therefore, N42D is likely to help the protein to maintain its activity at acidic pH. This could lead to the optimal pH of XynHBN188A217 decreased by 0.5 compared to that of XynHBN188A. However, few cases have been reported to improve the pH stability of xylanases. In 2008, the mutant enzyme 3SlxB6 with increased stability at pH 9.0 was obtained by directed evolution (Xia and Wang 2008). In 2008, Qin Wang et al. screened a mutant 2TfxA98 with pH stability significantly increased in the alkaline pH by directed evolution (Wang and Xia 2008). In this study, the pH stability of XynHBN188A217 was obviously enhanced from pH 5.0 to 8.5. This is the first report that the pH stability of xylanase was obviously enhanced in both acid and alkali conditions by directed evolution.

Specific activity of XynHBN188A217

The enzyme activity of the purified XynHBN188A217 was 3986.7 U/mg in 55 °C, pH 7.5 against beechwood xylan, whereas that of XynHBN188A was 1423.8 U/mg in 50 °C, pH 8.0 against beechwood xylan. The specific activity of XynHBN188A217 was 2.8-fold higher than that of the wild type. Directed evolution in vitro is a highly effective strategy in protein engineering which provides the possibility to improve the specific activity without knowing the structure–function relationships of the proteins (Stephens et al. 2007; Zheng et al. 2014). Many cases have been reported that the properties of xylanases were improved by directed evolution. In 2016, Xin Xu et al. obtained the xylanase reBaxA50 by error-prone PCR, and the specific activity of reBaxA50 was 3.5 times higher than of its parent (Xu et al. 2016). The mutant Xylst with enhanced thermostability was obtained by directed evolution. The wild-type enzyme was inactivated within 5 min, while Xylst retained full activity for 2 h (Miyazaki et al. 2006).

Although the specific activity of XynHBN188A217 was increased, the thermostability of XynHBN188A217 was slightly decreased. While it might be that with the increased activity, the structure of the protein became more flexible, which led to decreased thermostability (Yu and Huang 2014). Similar results were observed in several studies. Compared to the wild-type GKL, the double mutant E101 N/R230I had an increase in catalytic efficiency, while its thermostability was decreased (Chow et al. 2010). The activity of the laccase α-PM1 P393H mutation was improved to 3000 U/L, but the thermostability was significantly decreased (Mate et al. 2010).

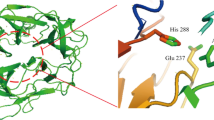

3D structure models of XynHBN188A and XynHBN188A217

The 3D structures of XynHBN188A and XynHBN188A217 were simulated based on 10 proteins structure templates through Web site I-TASSER Suite. The highest homology template (xylanase Xyn11X, PDB: 1IGO_A) showed 84% amino acid identity to XynHBN188A. The structures of XynHBN188A and XynHBN188A217 were mainly composed of one α-helix and several β-strands, which curves around to create a large cleft where the catalytic pair E94 and E183 were located. Compared with that of XynHBN188A, the structure of XynHBN188A217 remained almost unchanged. However, the distances between the catalytic pair E94 and E183 in XynHBN188A217 became larger. It was 9.0 Å, while 7.7 Å in XynHBN188A (Fig. 3).

Through homology modeling analysis, the two mutant sites, N42D and T149S, were located on the surface of XynHBN188A217. Each hydrogen bond was observed between N42 with N41 and S187 in XynHBN188A, respectively (Fig. 4a). While, in XynHBN188A217, D42 formed a hydrogen bond with N25, a new hydrogen bond, which was absent in XynHBN188A, was formed between S149 and K150 (Fig. 4b). In XynHBN188A, the catalytic site E94 formed the hydrogen bonds network with Y85, K141, Q142, and Y143, and E183 formed the hydrogen bonds network with S80, Y81, and Y96 (Fig. 4a). Comparably, in XynHBN188A217, besides forming hydrogen bonds with Y85, K141, Q142, and Y143, E94 also formed a hydrogen bond with Y96 that could form a hydrogen bond with E183 in XynHBN188A. Moreover, in addition to forming hydrogen bonds except with S80 and Y81, E183 also form an additional hydrogen bond with N45 in XynHBN188A217 (Fig. 4b). It was noticed that two new hydrogen bonds were formed between E183 and N45, as well as E94 and Y96, which possibly drove away the catalytic pair E94 from E183 (Fig. 4b). Furthermore, electrostatic interactions were also identified between E94 and R128, E183 and R128, respectively, in XynHBN188A, thus further dragging close the catalytic E94 and E183 residues. Comparably, no electrostatic interactions were identified among E94, R128, and E183 in XynHBN188A217. Instead, a Pi-charge interaction between E183 and Y81 in XynHBN188A217 would further push away the catalytic E94 and E183 residues (Fig. 4b). As a result, the catalytic residues could more easily approach the substrate.

Interactions of the catalytic residues (E94 and E183, marked in red) and the mutated amino acids (marked in blue) with their surroundings (marked in gray) of XynHBN188A (a) and XynHBN188A217 (b). The green dashed lines indicate hydrogen bonds, the yellow dashed lines indicate electrostatic interactions, and the purple dashed lines indicate salt bridges

Furthermore, the catalytic channel in XynHBN188A217 became larger compared to that in XynHBN188A, which would be beneficial for the substrates access and metabolites release (Fig. 5). These factors may contribute to the increase in the specific activity of XynHBN188A217. In some degree, modified the catalytic pocket could improve the specific activity. In 2011, Liang et al. screened a mutation of Cel5A, the mutant I321V could result in the formation of a larger active pocket and displayed an increased specific activity (Liang et al. 2011). And in 2014, Chen et al. got the mutant ep-1 with enlarged the binding pocket, and the specific activity was improved 1.89-fold compared to the wild type (Chen et al. 2014). Although the two mutation sites in the XynHBN188A217 had no direct relationships with the catalytic region, the mutations still somehow changed the structure of the catalytic region.

The molecular docking of XynHBN188A and XynHBN188A217

Also the substrate docking results indicated that the substrate was inserted deeper into the catalytic pocket of XynHBN188A217 compared to that in XynHBN188A (Fig. 6). In XynHBN188A, it was speculated that the side chains of R128 and Q131 swinging toward the catalytic channel, thus impeding the entry of substrate into the catalytic channel. In contrast, the substrate was closer to the catalytic residues in XynHBN188A217, suggesting that the substrate could be hydrolyzed more easily. However, the mechanism that how these mutation residues affect the enzymatic activity remain unclear and further studies should be performed to clarify it.

Conclusions

In summary, the XynHBN188A originated from B. pumilus HBP8 has been improved in the specific activity and pH stability by directed evolution. A mutant xylanase, XynHBN188A217, was obtained from an error-prone PCR mutants library using the functional screening. The specific activity of XynHBN188A217 was 2.8-fold higher than that of XynHBN188A. The pH stability of XynHBN188A217 was significantly better than that of wild-type XynHBN188A. But, the thermostability of XynHBN188A217 was slightly lower than that of XynHBN188A. The enlarged catalytic channel of XynHBN188A to be beneficial for the substrates access and products release may contribute to the improved activity by homology modeling and structure analysis.

Availability of data and materials

All data generated or analyzed during this study are included in this published article and its additional files.

Abbreviations

- RBB:

-

remazol brilliant blue

- IPTG:

-

isopropyl-β-d-thiogalactopyranoside

- OD:

-

optical density

- PCR:

-

polymerase chain reaction

- SDS:

-

sodium dodecyl sulfate

- PAGE:

-

polyacrylamide gel electrophoresis

- XS2:

-

methyl 4,4II,4III,4IV-terathio-beta-d-xylopentoside

References

Acevedo JP, Reetz MT, Asenjo JA, Parra LP (2017) One-step combined focused epPCR and saturation mutagenesis for thermostability evolution of a new cold-active xylanase. Enzyme Microb Technol 100:60–70

Beg QK, Kapoor M, Mahajan L, Hoondal GS (2001) Microbial xylanases and their industrial applications: a review. Appl Microbiol Biotechnol 56:326–338

Berrin JG, el Ajandouz H, Georis J, Arnaut F, Juge N (2007) Substrate and product hydrolysis specificity in family 11 glycoside hydrolases: an analysis of Penicillium funiculosum and Penicillium griseofulvum xylanases. Appl Microbiol Biotechnol 74:1001–1010

Bhardwaj A, Leelavathi S, Mazumdar-Leighton S, Ghosh A, Ramakumar S, Reddy VS (2010) The critical role of N- and C-terminal contact in protein stability and folding of a family 10 xylanase under extreme conditions. PLoS ONE 5:e11347

Chen X, Ma Y, Shao J, Lai D, Wang Z, Chen Z (2014) Increasing activity of a monoamine oxidase by random mutation. Chinese J Biotechnol 30:109–118

Chow JY, Xue B, Lee KH, Tung A, Wu L, Robinson RC, Yew WS (2010) Directed evolution of a thermostable quorum-quenching lactonase from the amidohydrolase superfamily. J Biol Chem 285:40911–40920

Collins T, Gerday C, Feller G (2005) Xylanases, xylanase families and extremophilic xylanases. FEMS Microbiol Rev 29:3–23

Janis J, Hakanpaa J, Hakulinen N, Ibatullin FM, Hoxha A, Derrick PJ, Rouvinen J, Vainiotalo P (2005) Determination of thioxylo-oligosaccharide binding to family 11 xylanases using electrospray ionization Fourier transform ion cyclotron resonance mass spectrometry and X-ray crystallography. FEBS J 272:2317–2333

Juturu V, Wu JC (2014) Microbial exo-xylanases: a mini review. Appl Biochem Biotechnol 174:81–92

Liang C, Fioroni M, Rodriguez-Ropero F, Xue Y, Schwaneberg U, Ma Y (2011) Directed evolution of a thermophilic endoglucanase (Cel5A) into highly active Cel5A variants with an expanded temperature profile. J Biotechnol 154:46–53

Lu Y, Fang C, Wang Q, Zhou Y, Zhang G, Ma Y (2016) High-level expression of improved thermo-stable alkaline xylanase variant in Pichia Pastoris through codon optimization, multiple gene insertion and high-density fermentation. Sci Rep 6:37869

Mate D, Garcia-Burgos C, Garcia-Ruiz E, Ballesteros AO, Camarero S, Alcalde M (2010) Laboratory evolution of high-redox potential laccases. Chem Biol 17:1030–1041

Miller GL (1959) Use of dinitrosalicylic acid reagent for determination of reducing sugar. Anal Chem 31:426–428

Miyazaki K, Takenouchi M, Kondo H, Noro N, Suzuki M, Tsuda S (2006) Thermal stabilization of Bacillus subtilis family-11 xylanase by directed evolution. J Biol Chem 281:10236–10242

Motta F, Andrade C, Santana M (2013) A review of xylanase production by the fermentation of xylan: classification, characterization and applications. IntechOpen, New York

Perl D, Mueller U, Heinemann U, Schmid FX (2000) Two exposed amino acid residues confer thermostability on a cold shock protein. Nat Struct Biol 7:380–383

Sen S, Venkata Dasu V, Mandal B (2007) Developments in directed evolution for improving enzyme functions. Appl Biochem Biotechnol 143:212–223

Stephens DE, Rumbold K, Permaul K, Prior BA, Singh S (2007) Directed evolution of the thermostable xylanase from Thermomyces lanuginosus. J Biotechnol 127:348–354

Stephens DE, Singh S, Permaul K (2009) Error-prone PCR of a fungal xylanase for improvement of its alkaline and thermal stability. FEMS Microbiol Lett 293:42–47

Walia A, Guleria S, Mehta P, Chauhan A, Parkash J (2017) Microbial xylanases and their industrial application in pulp and paper biobleaching: a review. 3 Biotech 7:11

Wang Q, Xia T (2008) Enhancement of the activity and alkaline pH stability of Thermobifida fusca xylanase A by directed evolution. Biotechnol Lett 30:937–944

Wang Y, Feng S, Zhan T, Huang Z, Wu G, Liu Z (2013) Improving catalytic efficiency of endo-beta-1,4-xylanase from Geobacillus stearothermophilus by directed evolution and H179 saturation mutagenesis. J Biotechnol 168:341–347

Wijma HJ, Floor RJ, Janssen DB (2013) Structure- and sequence-analysis inspired engineering of proteins for enhanced thermostability. Curr Opin Struct Biol 23:588–594

Xia T, Wang Q (2008) Directed evolution of Streptomyces lividans xylanase B toward enhanced thermal and alkaline pH stability. J Microbiol Biotechnol 25:93–100

Xu X, Liu MQ, Huo WK, Dai XJ (2016) Obtaining a mutant of Bacillus amyloliquefaciens xylanase A with improved catalytic activity by directed evolution. Enzyme Microb Technol 86:59–66

Yang J, Yan R, Roy A, Xu D, Poisson J, Zhang Y (2015) The I-TASSER Suite: protein structure and function prediction. Nat Methods 12:7–8

Yi L, Gebhard MC, Li Q, Taft JM, Georgiou G, Iverson BL (2013) Engineering of TEV protease variants by yeast ER sequestration screening (YESS) of combinatorial libraries. P Natl Acad Sci USA 110:7229–7234

Yu H, Huang H (2014) Engineering proteins for thermostability through rigidifying flexible sites. Biotechnol Adv 32:308–315

Zhang Y (2008) I-TASSER server for protein 3D structure prediction. BMC Bioinform 9:40

Zhang GM, Hu Y, Zhuang YH, Ma LX, Zhang XE (2006) Molecular cloning and heterologous expression of an alkaline xylanase from Bacillus pumilus HBP8 in Pichia pastoris. Biocatal Biotransform 24:371–379

Zhang ZG, Yi ZL, Pei XQ, Wu ZL (2010) Improving the thermostability of Geobacillus stearothermophilus xylanase XT6 by directed evolution and site-directed mutagenesis. Bioresour Technol 101:9272–9278

Zheng H, Liu Y, Sun M, Han Y, Wang J, Sun J, Lu F (2014) Improvement of alkali stability and thermostability of Paenibacillus campinasensis Family-11 xylanase by directed evolution and site-directed mutagenesis. J Ind Microbiol Biotechnol 41:153–162

Acknowledgements

Not applicable.

Funding

This work was financially sponsored by Technical innovation special fund of Hubei Province (2018ABA113), Technical innovation special fund of Hubei Province (2017ACA171), Natural Science Foundation of Hubei Province (ZRMS2019000843), and 2016 Wuhan Yellow Crane Talent (Science) Program.

Author information

Authors and Affiliations

Contributions

All authors directly participated in the planning, execution, or analysis of this study. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Ethics approval and consent participate

Not applicable.

Consent for publication

All of the authors have read and approved to submit it to bioresources and bioprocessing.

Competing interests

The authors declare that they have no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Additional file

Additional file 1: Figure S1.

DNA sequence alignment and base mutation frequency detection of xylanase mutant library.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Xiang, L., Lu, Y., Wang, H. et al. Improving the specific activity and pH stability of xylanase XynHBN188A by directed evolution. Bioresour. Bioprocess. 6, 25 (2019). https://doi.org/10.1186/s40643-019-0262-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1186/s40643-019-0262-8