Abstract

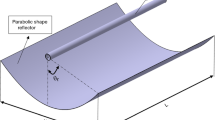

In the present work, a parabolic trough solar collector with inner helical axial fins as a swirl generator is considered and analyzed. All the numerical outcomes are obtained by utilizing the finite volume method's commercial code, ANSYS Fluent 18.2. The discretization of turbulence kinetic energy, turbulence dissipation rate, and energy equations as well as the spatial momentum equation have been done by a second-order upwind scheme. Hybrid nanofluid is utilized as a working fluid. This work consists of two sectors. In the first one, the influence of hybrid nanofluid types and, in the next sector, the impact of the volume concentration of selected hybrid nanofluid on the turbulence thermal efficiency are appraised numerically. The two considered hybrid nanofluids here contain multi-wall carbon nanotubes–iron oxide/water and silver and graphene nanoparticles/water. Obtained results showed that utilizing hybrid nanofluids causes more heat exchange rate than pure water. Also, among the evaluated hybrid nanofluids, multi-wall carbon nanotubes/iron oxide indicated the highest thermal performance. At the lowest studied Re number (Re = 5000), multi-wall carbon nanotubes/iron oxide presented higher thermal performance than silver–graphene/pure water by about 9.66 and 13.68%, respectively. Moreover, the peak thermal performance belongs to the case with volume concentration equal to 4% (φnf,1 = φnf,2) by an 18.5% growth in thermal performance.

Graphic abstract

Similar content being viewed by others

Data availability

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

Abbreviations

- A :

-

Area (m2)

- C P :

-

Specific heat capacity [kJ/(kg K)]

- D 1 :

-

Diameter of the inner tube (m)

- D 2 :

-

Appendix diameter (m)

- D 3 :

-

Diameter of the outer tube (m)

- d :

-

Diameter as length scale (m)

- f :

-

Darcy friction factor (nd)

- G b :

-

Generation of turbulence kinetic energy due to buoyancy (J/kg)

- G k :

-

Generation of turbulence kinetic energy due to the mean velocity gradients (J/kg)

- g :

-

Gravity (m/s2])

- h :

-

Heat transfer coefficient [W/(m2 K)]

- k :

-

Thermal conductivity [W/(m K)]

- L :

-

Length of the tube (m)

- M t :

-

Turbulent Mach number (nd)

- P :

-

Pressure (Pa)

- S m :

-

Mass generation (kg/m3)

- S h :

-

Heat generation (J/m3)

- th:

-

Thickness (m)

- t :

-

Time (second)

- T :

-

Temperature (℃)

- u :

-

Velocity (m s−1)

- Ag:

-

Silver

- Fe3O4 :

-

Iron oxide

- HEG:

-

Graphene

- HTF:

-

Heat transfer fluid

- MWCNT:

-

Multi-wall carbon nanotubes

- PTSCs:

-

Parabolic trough solar collectors

- VG:

-

Vortex generators

- μ :

-

Viscosity (kg/m s)

- ρ :

-

Density (kg/m3)

- \(\overline{\overline{\tau }}\) :

-

Stress tensor (Pa)

- σ :

-

Turbulent Prandtl number (nd)

- \(\eta\) :

-

Thermal performance (nd)

- α :

-

Helical angle (degree)

- k :

-

Turbulent kinetic energy per unit mass (J/kg)

- ε :

-

Energy dissipation rate per unit mass (W/kg)

- \(\varphi\) :

-

Solid volume fraction (%)

- Re:

-

Reynolds number, \({\text{Re}} = \frac{{{\mathcal{P}}ud}}{{\upmu }}\) (nd)

- Pe:

-

Péclet number, \({\text{Pe}} = {\text{ Re*Pr}}\) (nd)

- Pr:

-

Prandtl number, \({\text{Pr}} = \frac{{c_{p} {\upmu }}}{k}\) (nd)

- Nu:

-

Nusselt number, \({\text{Nu}} = \frac{hd}{k}\) (nd)

- 0:

-

Reference

- eff:

-

Effective

- h:

-

Hydraulic

- nf:

-

Nanofluids

- m:

-

Average

- ref:

-

Reference

References

S.A. Berger, L. Talbot, L.S. Yao, Flow in curved pipes. Ann. Rev. Fluid Mech. 15(1), 461–512 (1983)

S. Rashidi, N. Karimi, B. Sundén, O. Mahian, S. Harmand, Passive techniques to enhance heat transfer in various thermal systems. J. Therm. Anal. Calorim. 11, 1–4 (2020). https://doi.org/10.1007/s10973-020-09424-1

H. Olfian, S.S.M. Ajarostaghi, M. Ebrahimnataj, Development on evacuated tube solar collectors: a review of the last decade results of using nanofluids. Sol. Energy 211, 265–282 (2020). https://doi.org/10.1016/j.solener.2020.09.056

S. Rashidi, N.M. Zade, J.A. Esfahani, Thermo-fluid performance and entropy generation analysis for a new eccentric helical screw tape insert in a 3D tube. Chem. Eng. Process. 1(117), 27–37 (2017). https://doi.org/10.1016/j.cep.2017.03.013

K. Kim, K.S. Lee, Frosting and defrosting characteristics of surface-treated louvered-fin heat exchangers: effects of fin pitch and experimental conditions. Int. J. Heat Mass Transf. 60, 505–511 (2013). https://doi.org/10.1016/j.ijheatmasstransfer.2013.01.036

A. Hobbi, K. Siddiqui, Experimental study on the effect of heat transfer enhancement devices in flat-plate solar collectors. Int. J. Heat Mass Transf. 52(19–20), 4650–4658 (2009). https://doi.org/10.1016/j.ijheatmasstransfer.2009.03.018

Y. Yan, Q. Li, C. Liu, A. Pierce, F. Lu, P. Lu, Numerical discovery and experimental confirmation of vortex ring generation by microramp vortex generator. Appl. Math. Model. 36(11), 5700–5708 (2012). https://doi.org/10.1016/j.apm.2012.01.015

K.W. Tsai, K. Sivashanmugan, C.H. Lin, P.J. Tsai, S.C. Cheng, Y.C. Lan, T.Y. Chen, T.C. Wen, The size effect of silver nanocubes on gap-mode surface enhanced Raman scattering substrate. J. Taiwan Inst. Chem. Eng. 69, 146–150 (2016). https://doi.org/10.1016/j.jtice.2016.10.005

H.S. Dizaji, S. Jafarmadar, S. Asaadi, Experimental exergy analysis for shell and tube heat exchanger made of corrugated shell and corrugated tube. Exp. Thermal Fluid Sci. 81, 475–481 (2017). https://doi.org/10.1016/j.expthermflusci.2016.09.007

X. Tang, X. Dai, D. Zhu, Experimental and numerical investigation of convective heat transfer and fluid flow in twisted spiral tube. Int. J. Heat Mass Transf. 90, 523–541 (2015). https://doi.org/10.1016/j.ijheatmasstransfer.2015.06.068

M. Awais, A.A. Bhuiyan, Heat transfer enhancement using different types of vortex generators (VGs): A review on experimental and numerical activities. Thermal Science and Engineering Progress. 5, 524–545 (2018). https://doi.org/10.1016/j.tsep.2018.02.007

Z.J. Jin, F.Q. Chen, Z.X. Gao, X.F. Gao, J.Y. Qian, Effects of pitch and corrugation depth on heat transfer characteristics in six-start spirally corrugated tube. Int. J. Heat Mass Transf. 108, 1011–1025 (2017). https://doi.org/10.1016/j.ijheatmasstransfer.2016.12.091

K. Aroonrat, S. Wongwises, Condensation heat transfer and pressure drop characteristics of R-134a flowing through dimpled tubes with different helical and dimpled pitches. Int. J. Heat Mass Transf. 121, 620–631 (2018). https://doi.org/10.1016/j.ijheatmasstransfer.2018.01.001

M. Noorbakhsh, M. Zaboli, S.S. Ajarostaghi, Numerical evaluation of the effect of using twisted tapes as turbulator with various geometries in both sides of a double-pipe heat exchanger. J. Therm. Anal. Calorim. 140(3), 1341–1353 (2020). https://doi.org/10.1007/s10973-019-08509-w

C. Zhai, M.D. Islam, R. Simmons, I. Barsoum, Heat transfer augmentation in a circular tube with delta Winglet vortex generator pairs. Int. J. Therm. Sci. 140, 480–490 (2019). https://doi.org/10.1016/j.ijthermalsci.2019.03.020

S. Saedodin, M. Zaboli, S.H. Rostamian, Effect of twisted turbulator and various metal oxide nanofluids on the thermal performance of a straight tube: Numerical study based on experimental data. Chemical Engineering and Processing-Process Intensification. 158, 108106 (2020). https://doi.org/10.1016/j.cep.2020.108106

F. Keramat, A. Azari, H. Rahideh, M. Abbasi, A CFD parametric analysis of natural convection in an H-shaped cavity with two-sided inclined porous fins. J. Taiwan Inst. Chem. Eng. 114, 142–152 (2020). https://doi.org/10.1016/j.jtice.2020.09.011

X. Dong, X. Jin, P. Li, Q. Bi, M. Gui, T. Wang, Experimental research on heat transfer and flow resistance properties in spiral twisted tube heat exchanger. Appl. Therm. Eng. 176, 115397 (2020). https://doi.org/10.1016/j.applthermaleng.2020.115397

T.P. Otanicar, P.E. Phelan, R.S. Prasher, G. Rosengarten, R.A. Taylor, Nanofluid-based direct absorption solar collector. Journal of renewable and sustainable energy. 2(3), 033102 (2010). https://doi.org/10.1063/1.3429737

M. Sheikholeslami, R. Ellahi, Three dimensional mesoscopic simulation of magnetic field effect on natural convection of nanofluid. Int. J. Heat Mass Transf. 89, 799–808 (2015). https://doi.org/10.1016/j.ijheatmasstransfer.2015.05.110

R.B. Ganvir, P.V. Walke, V.M. Kriplani, Heat transfer characteristics in nanofluid—a review. Renew. Sustain. Energy Rev. 75, 451–460 (2017). https://doi.org/10.1016/j.rser.2016.11.010

U. Choi, J.A. Eastman, Enhancing thermal conductivity of fluids with nanoparticles. Argonne National Lab., IL (United States); 1995

M. Turkyilmazoglu, Nanofluid flow and heat transfer due to a rotating disk. Comput. Fluids 94, 139–146 (2014). https://doi.org/10.1016/j.compfluid.2014.02.009

M. Ghanbarpour, N. Nikkam, R. Khodabandeh, M.S. Toprak, Improvement of heat transfer characteristics of cylindrical heat pipe by using SiC nanofluids. Appl. Therm. Eng. 90, 127–135 (2015). https://doi.org/10.1016/j.applthermaleng.2015.07.004

X. Wang, Y. He, G. Cheng, L. Shi, X. Liu, J. Zhu, Direct vapor generation through localized solar heating via carbon-nanotube nanofluid. Energy Convers. Manage. 130, 176–183 (2016). https://doi.org/10.1016/j.enconman.2016.10.049

C. Qi, Y.L. Wan, C.Y. Li, D.T. Han, Z.H. Rao, Experimental and numerical research on the flow and heat transfer characteristics of TiO2-water nanofluids in a corrugated tube. Int. J. Heat Mass Transf. 115, 1072–1084 (2017). https://doi.org/10.1016/j.ijheatmasstransfer.2017.08.098

W. Guo, G. Li, Y. Zheng, C. Dong, Laminar convection heat transfer and flow performance of Al2O3–water nanofluids in a multichannel-flat aluminum tube. Chem. Eng. Res. Des. 133, 255–263 (2018). https://doi.org/10.1016/j.cherd.2018.03.009

H. Maddah, M. Ghazvini, M.H. Ahmadi, Predicting the efficiency of CuO/water nanofluid in heat pipe heat exchanger using neural network. Int. Commun. Heat Mass Transfer 104, 33–40 (2019). https://doi.org/10.1016/j.icheatmasstransfer.2019.02.002

Y. Tong, H. Lee, W. Kang, H. Cho, Energy and exergy comparison of a flat-plate solar collector using water, Al2O3 nanofluid, and CuO nanofluid. Appl. Therm. Eng. 159, 113959 (2019). https://doi.org/10.1016/j.applthermaleng.2019.113959

R.C. Al-Zuhairy, Z.S. Kareem, A.A. Abdulhadi, Al2O3-water nanofluid heat transfer enhancement of a twin impingement jet. Case Studies in Thermal Engineering. 20, 100626 (2020). https://doi.org/10.1016/j.csite.2020.100626

S. Mukherjee, S. Chakrabarty, P.C. Mishra, P. Chaudhuri, Transient heat transfer characteristics and process intensification with Al2O3-water and TiO2-water nanofluids: An experimental investigation. Chemical Engineering and Processing-Process Intensification. 3, 107887 (2020). https://doi.org/10.1016/j.cep.2020.107887

R. Shamsoddini, M. Mofidi, ISPH modeling and investigation of the effect of viscosity variations on the fluids mixing in a micro-channel due to oscillation of a circular cylinder. J. Taiwan Inst. Chem. Eng. 1, 1 (2021). https://doi.org/10.1016/j.jtice.2020.12.028

M. Sheikholeslami, S. A. Farshad, Nanofluid flow inside a solar collector utilizing twisted tape considering exergy and entropy analysis. Renew. Energy. 141, 246–258 (2019). https://doi.org/10.1016/j.renene.2019.04.007

E. Ghasemi Seiyed, A. Ranjbar, Effect of nanoparticles in working fluid on thermal performance of solar parabolic trough collector. J. Mol. Liq. 1, 1 (2016). https://doi.org/10.1016/j.molliq.2016.06.091

K.S. Reddy, K.R. Kumar, G.V. Satyanarayana, Numerical investigation of energy-efficient receiver for solar parabolic trough concentrator. Heat Transfer Eng. 29(11), 961–972 (2008). https://doi.org/10.1080/01457630802125757

A. Benabderrahmane, A. Benazza, A.K. Hussein, Heat transfer enhancement analysis of tube receiver for parabolic trough solar collector with central corrugated insert. J. Heat Transf. 142(6) (2020). https://doi.org/10.1115/1.4046440

O. Chakraborty, B. Das, R. Gupta, S. Debbarma, Heat transfer enhancement analysis of parabolic trough collector with straight and helical absorber tube. Thermal Science and Engineering Progress. 20, 100718 (2020). https://doi.org/10.1016/j.tsep.2020.100718

S. Akbarzadeh, M.S. Valipour, Experimental study on the heat transfer enhancement in helically corrugated tubes under the non-uniform heat flux. J. Therm. Anal. Calorim. 7, 1–3 (2020). https://doi.org/10.1007/s10973-020-09385-5

M.S. Khan, M. Yan, H.M. Ali, K.P. Amber, M.A. Bashir, B. Akbar, S. Javed, Comparative performance assessment of different absorber tube geometries for parabolic trough solar collector using nanofluid. J. Therm. Anal. Calorim. 142(6), 2227–2241 (2020). https://doi.org/10.1007/s10973-020-09590-2

K. Amani, M. Ebrahimpour, S. Akbarzadeh, M.S. Valipour, The utilization of conical strip inserts in a parabolic trough collector. J. Therm. Anal. Calorim. 11, 1–7 (2020). https://doi.org/10.1007/s10973-019-09233-1

S. Saedodin, M. Zaboli, S.S. Ajarostaghi, Hydrothermal analysis of heat transfer and thermal performance characteristics in a parabolic trough solar collector with Turbulence-Inducing elements. Sustainable Energy Technol. Assess. 46, 101266 (2021). https://doi.org/10.1016/j.seta.2021.101266

M.S. Nazir, A. Shahsavar, M. Afrand, M. Arıcı, S. Nižetić, Z. Ma, H.F. Öztop, A comprehensive review of parabolic trough solar collectors equipped with turbulators and numerical evaluation of hydrothermal performance of a novel model. Sustainable Energy Technol. Assess. 45, 101103 (2021). https://doi.org/10.1016/j.seta.2021.101103

P.R. Vasanthi, P.G.J. Chandra Reddy, Experimental investigations on heat transfer and friction factor of hybrid nanofliud equiped with angular twisted strip inserts in a parabolic trough solar collector under turbulent flow. Int. J. Innov. Sci. Eng. Technol. 8(4), 1

H. Peng, M. Li, F. Hu, S. Feng, Performance analysis of absorber tube in parabolic trough solar collector inserted with semi-annular and fin shape metal foam hybrid structure. Case Stud. Therm. Eng. 1, 101112. https://doi.org/10.1016/j.csite.2021.101112

O. Chakraborty, S. Roy, B. Das, R. Gupta, Effects of helical absorber tube on the energy and exergy analysis of parabolic solar trough collector–A computational analysis. Sustainable Energy Technol. Assess. 44, 101083 (2021). https://doi.org/10.1016/j.seta.2021.101083

H. Khakrah, A. Shamloo, S.K. Hannani, Exergy analysis of parabolic trough solar collectors using Al2O3/synthetic oil nanofluid. Sol. Energy 173, 1236–1247 (2018). https://doi.org/10.1016/j.solener.2018.08.064

M. Mirzaei, Experimental investigation of CuO nanofluid in the thermal characteristics of a flat plate solar collector. Environ. Prog. Sustainable Energy 38(1), 260–267 (2019). https://doi.org/10.1002/ep.12902

M.A. Sharafeldin, G. Gróf, Efficiency of evacuated tube solar collector using WO3/Water nanofluid. Renewable Energy 134, 453–460 (2019). https://doi.org/10.1016/j.renene.2018.11.010

N. Singh, V. Khullar, On-sun testing of volumetric absorption based concentrating solar collector employing carbon soot nanoparticles laden fluid. Sustainable Energy Technol. Assess. 42, 100868 (2020). https://doi.org/10.1016/j.seta.2020.100868

M.R. Saffarian, M. Moravej, M.H. Doranehgard, Heat transfer enhancement in a flat plate solar collector with different flow path shapes using nanofluid. Renewable Energy 146, 2316–2329 (2020). https://doi.org/10.1016/j.renene.2019.08.081

Y. Peng, A. Zahedidastjerdi, A. Abdollahi, A. Amindoust, M. Bahrami, A. Karimipour, M. Goodarzi, Investigation of energy performance in a U-shaped evacuated solar tube collector using oxide added nanoparticles through the emitter, absorber and transmittal environments via discrete ordinates radiation method. J. Therm. Anal. Calorim. 139(4), 2623–2631 (2020). https://doi.org/10.1007/s10973-019-08684-w

Q. Xiong, T. Tayebi, M. Izadi, A.A. Siddiqui, T. Ambreen, L.K. Li, Numerical analysis of porous flat plate solar collector under thermal radiation and hybrid nanoparticles using two-phase model. Sustainable Energy Technol. Assess. 47, 101404 (2021). https://doi.org/10.1016/j.seta.2021.101404

J. Subramani, P. Sevvel, S.A. Srinivasan, Influence of CNT coating on the efficiency of solar parabolic trough collector using AL2O3 nanofluids-a multiple regression approach. Materials Today: Proceedings. 45, 1857–1861 (2021). https://doi.org/10.1016/j.matpr.2020.09.047

S.M. Hosseini, M.S. Dehaj, An experimental study on energetic performance evaluation of a parabolic trough solar collector operating with Al2O3/water and GO/water nanofluids. Energy 24, 121317 (2021). https://doi.org/10.1016/j.energy.2021.121317

A.C. Yunus, Fluid Mechanics: Fundamentals and Applications (Si Units). Tata McGraw Hill Education Private Limited (2010)

O. Adibi, S. Rashidi, J.A. Esfahani, Effects of perforated anchors on heat transfer intensification of turbulence nanofluid flow in a pipe. J. Therm. Anal. Calorim. 141(5), 2047–2059 (2020). https://doi.org/10.1007/s10973-020-09705-9

W. He, D. Toghraie, A. Lotfipour, F. Pourfattah, A. Karimipour, M. Afrand, Effect of twisted-tape inserts and nanofluid on flow field and heat transfer characteristics in a tube. Int. Commun. Heat Mass Transfer 110, 104440 (2020). https://doi.org/10.1016/j.icheatmasstransfer.2019.104440

A. Bejan, Convection heat transfer. (2013)

M. Zaboli, S. Saedodin, S.S. Mousavi Ajarostaghi, M. Nourbakhsh, Numerical evaluation of the heat transfer in a shell and corrugated coil tube heat exchanger with three various water‐based nanofluids. Heat Transf. https://doi.org/10.1002/htj.22161

T.H. Shih, W.W. Liou, A. Shabbir, Z. Yang, J. Zhu, A new k-ϵ eddy viscosity model for high reynolds number turbulent flows. Comput. Fluids 24(3), 227–38

S. Saedodin, S.H. Rostamian, M. Zaboli, Hydrothermal analysis and optimization of heat transfer and pressure drop characteristics of different nanofluids in a circular tube with turbulator. The European Physical Journal Plus. 136(7), 1–23 (2021). https://doi.org/10.1140/epjp/s13360-021-01678-4

M. Zaboli, M. Nourbakhsh, S.S. Ajarostaghi, Numerical evaluation of the heat transfer and fluid flow in a corrugated coil tube with lobe-shaped cross-sector and two types of spiral twisted tape as swirl generator. J. Therm. Anal. Calorim. 15, 1–7 (2020). https://doi.org/10.1007/s10973-020-10219-7

S. Rashidi, N.M. Zade, J.A. Esfahani, Thermo-fluid performance and entropy generation analysis for a new eccentric helical screw tape insert in a 3D tube. Chem. Eng. Process. 117, 27–37 (2017). https://doi.org/10.1016/j.cep.2017.03.013

H. Olfian, A. Zabihi Sheshpoli, S.S. Mousavi Ajarostaghi, Numerical evaluation of the thermal performance of a solar air heater equipped with two different types of baffles. Heat Transfer 49(3), 1149–1169 (2020). https://doi.org/10.1002/htj.21656

S.S. Mousavi Ajarostaghi, M. Shirzad, S. Rashidi, L.K. Li, Heat transfer performance of a nanofluid-filled tube with wall corrugations and center-cleared twisted-tape inserts. Energy Sources, Part A: Recovery, Utilization, and Environmental Effects 1, 1–21 (2020). https://doi.org/10.1080/15567036.2020.1841860

H.K. Moghadam, S.S.M. Ajarostaghi, S. Poncet, Extensive numerical analysis of the thermal performance of a corrugated tube with coiled wire. J. Therm. Anal. Calorim. 1, 1–13 (2019). https://doi.org/10.1007/s10973-019-08876-4

S.S. Mousavi Ajarostaghi, M. Aghanezhad, H. Davudi, M. Mohammadzadeh Amiri, Numerical Evaluation the Heat Transfer Enhancement in a Tube with Curved Conical Turbulator Insert. Int. J. Ambient Energy 1, 1–23 (2021). https://doi.org/10.1080/01430750.2021.1945490

M. Abbaspour, S.S. Mousavi Ajarostaghi, S.A. Hejazi Ra, M. Nimafar, Heat transfer improvement in a tube by inserting perforated conical ring and wire coil as turbulators. Heat Transf. https://doi.org/10.1002/htj.22167

B.C. Pak, Y.I. Cho, Hydrodynamic and heat transfer study of dispersed fluids with submicron metallic oxide particles. Experimental Heat Transfer an International Journal. 11(2), 151–170 (1998). https://doi.org/10.1080/08916159808946559

B. Takabi, S. Salehi, Augmentation of the heat transfer performance of a sinusoidal corrugated enclosure by employing hybrid nanofluid. Adv. Mech. Eng. 6, 147059 (2014). https://doi.org/10.1155/2014/147059

L.S. Sundar, M.K. Singh, A.C. Sousa, Enhanced heat transfer and friction factor of MWCNT–Fe3O4/water hybrid nanofluids. Int. Commun. Heat Mass Transfer 52, 73–83 (2014). https://doi.org/10.1016/j.icheatmasstransfer.2014.01.012

L.S. Sundar, E.V. Ramana, M.P. Graça, M.K. Singh, A.C. Sousa, Nanodiamond-Fe3O4 nanofluids: preparation and measurement of viscosity, electrical and thermal conductivities. Int. Commun. Heat Mass Transfer 73, 62–74 (2016). https://doi.org/10.1016/j.icheatmasstransfer.2016.02.013

S.S. Ajarostaghi, M. Zaboli, M. Nourbakhsh, Numerical evaluation of turbulence heat transfer and fluid flow of hybrid nanofluids in a pipe with innovative vortex generator. J. Therm. Anal. Calorim. 4, 1–5 (2020). https://doi.org/10.1007/s10973-020-10205-z

C.J. Ho, J.B. Huang, P.S. Tsai, Y.M. Yang, Preparation and properties of hybrid water-based suspension of Al2O3 nanoparticles and MEPCM particles as functional forced convection fluid. Int. Commun. Heat Mass Transfer 37(5), 490–494 (2010). https://doi.org/10.1016/j.icheatmasstransfer.2009.12.007

S.H. Hashemi Karouei, S.S.M. Ajarostaghi, M. Gorji-Bandpy, S.R. Hosseini Fard, Laminar heat transfer and fluid flow of two various hybrid nanofluids in a helical double-pipe heat exchanger equipped with an innovative curved conical turbulator. J. Therm. Anal. Calorim. 143(2), 1 (2021). https://doi.org/10.1007/s10973-020-09425-0

F.A. Hamedani, S.S.M. Ajarostaghi, S.A. Hosseini, Numerical evaluation of the effect of geometrical and operational parameters on thermal performance of nanofluid flow in convergent–divergent tube. J. Therm. Anal. Calorim. 1, 1–23 (2019). https://doi.org/10.1007/s10973-019-08765-w

H. Javadi, J.F. Urchueguia, S.S. Mousavi Ajarostaghi, B. Badenes, Impact of Employing Hybrid Nanofluids as Heat Carrier Fluid on the Thermal Performance of a Borehole Heat Exchanger. Energies 14(10), 2892 (2021). https://doi.org/10.3390/en14102892

P. Frank, Incropera, D.P. DeWitt, Introduction to Heat Transfer. Wiley (1990)

B. Zou, J. Dong, Y. Yao, Y. Jiang, An experimental investigation on a small-sized parabolic trough solar collector for water heating in cold areas. Appl. Energy 163, 396–407 (2016). https://doi.org/10.1016/j.apenergy.2015.10.186

H.E. Woei, C.K. Sinz, M.N. Khalis, S.A. Abbas, Numerical study on turbulent force convective heat transfer of hybrid nanofluid, Ag/HEG in a circular channel with constant heat flux. J. Adv. Res. Fluid Mech. Therm. Sci. 24(1), 1–1 (2016)

M. Izadi, R. Mohebbi, D. Karimi, M.A. Sheremet, Numerical simulation of natural convection heat transfer inside a┴ shaped cavity filled by a MWCNT-Fe3O4/water hybrid nanofluids using LBM. Chem. Eng. Process.-Process Intensif. 125, 56–66 (2018). https://doi.org/10.1016/j.cep.2018.01.004

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that there is no conflict of interests regarding the publication of this paper.

Rights and permissions

About this article

Cite this article

Zaboli, M., Mousavi Ajarostaghi, S.S., Saedodin, S. et al. Hybrid nanofluid flow and heat transfer in a parabolic trough solar collector with inner helical axial fins as turbulator. Eur. Phys. J. Plus 136, 841 (2021). https://doi.org/10.1140/epjp/s13360-021-01807-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1140/epjp/s13360-021-01807-z