Abstract

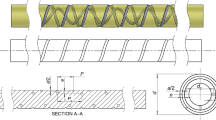

In the present study, heat transfer and fluid flow in a corrugate coil tube with different lobe-shaped cross-sections are evaluated numerically. Also, spiral twisted tape as turbulator with various geometries is placed in the proposed corrugate coil tube. The examined parameters include the geometry of corrugated coil’s cross-section and twisted tape’s geometry in corrugated coil tube. Obtained results show that five-lobe cross-section rises the Nusselt number and pressure drop by 9.1% and 3.7%, respectively, in comparison with three-lobe case. Furthermore, increasing the area of spiral twisted tape in the five-lobe corrugated tube leads to growth in Nusselt number and pressure drop by 30.7% and 37.1%, respectively. Also, among the cases with spiral center cleared twisted tape, at higher investigated Reynolds number (Re = 35,000), the thermal efficiency of the three-, four-, and five-lobe models with center cleared twisted tape is more than the three-, four-, and five-lobe models with simple spiral twisted tape by 16, 18.64, and 19.16%, respectively.

Similar content being viewed by others

Abbreviations

- C p :

-

Specific heat capacity (kJ kg−1 K−1)

- D C :

-

Diameter of coil (m)

- d C :

-

Diameter of tube (m)

- d h :

-

Hydraulic diameter (m)

- f :

-

Darcy friction factor

- g :

-

Gravitational acceleration (m s−2)

- h :

-

Heat transfer coefficient (W m−2 K−1)

- K :

-

Turbulent kinetic energy

- k :

-

Thermal conductivity (W m−1 K−1)

- L :

-

Length of corrugated coil (m)

- L Corrugated :

-

Height of corrugated coil (m)

- P :

-

Pressure (Pa)

- p :

-

Pitch of coil (m)

- S :

-

Source term (kJ m−3)

- T :

-

Temperature (°C)

- t :

-

Time (s)

- u :

-

Fluid velocity (m s−1)

- w :

-

Width of twisted tape (m)

- Pr:

-

Prandtl number [\( \Pr = \frac{{c_{\text{p}} \mu }}{k} \)]

- Pe:

-

Péclet number [\( {\text{Pe}} = \text{Re} \cdot \Pr \)]

- Re:

-

Reynolds number [\( \text{Re} = \frac{{{\mathcal{P}}ud}}{\mu } \)]

- Nu:

-

Nusselt number [\( {\text{Nu}} = \frac{hd}{k} \)]

- \( \rho \) :

-

Density (kg m−3)

- μ :

-

Viscosity (cP)

- ε :

-

Turbulent dissipation

- \( \eta \) :

-

Thermal performance

- 0:

-

Reference

- Corrugated:

-

Corrugated tube

- RNG:

-

Re-normalization group

- SST:

-

Shear stress transport

- TT:

-

Twisted tape

- CCTT:

-

Center cleared twisted tape

References

Rohsenow WM, Hartnett JP, Cho YI. Handbook of heat tansfer. New York: Mc-Graw Hill; 1998. p. 1–11.

Dean WR. XVI, note on the motion of fluid in a curved pipe. London Edinb Dublin Philos Mag J Sci. 1927;4(20):208–23.

Dean WR. LXXII. The stream-line motion of fluid in a curved pipe (second paper). Lond Edinb Dublin Philos Mag J Sci. 1928;5(30):673–95.

McConalogue DJ, Srivastava RS. Motion of a fluid in a curved tube. Proc R Soc Lond Ser A Int J Math Phys Sci. 1968;307:37–53.

Aouabed H, Legentilhomme P, Legrand J. Wall visualization of swirling decaying flow using a dot-paint method. Int J Exp Fluids. 1995;19(1):43–50.

Jamshidi N, Farhadi M, Ganji DD, Sedighi K. Experimental analysis of heat transfer enhancement in shell and helical tube heat exchangers. Int J Appl Therm Eng. 2013;51(1–2):644–52.

Liu S, Sakr M. A comprehensive review on passive heat transfer enhancements in pipe exchangers. Int J Renew Sustain Energy Rev. 2013;19:64–81.

Wang W, Zhang Y, Li B, Han H, Gao X. Influence of geometrical parameters on turbulent flow and heat transfer characteristics in outward helically corrugated tubes. Int J Energy Convers Manag. 2017;136:294–306.

Austen DS, Soliman HM. Laminar flow and heat transfer in helically coiled tubes with substantial pitch. Int J Exp Therm Fluid Sci. 1988;1:183–94.

Steenbergen W, Voskamp J. The rate of decay of swirl in turbulent pipe flow. Int J Flow Meas Instrum. 1998;9(2):67–78.

Dizaji HS, Jafarmadar S, Mobadersani F. Experimental studies on heat transfer and pressure drop characteristics for new arrangements of corrugated tubes in a double pipe heat exchanger. Int J Therm Sci. 2015;96:211–20.

Zachár A. Analysis of coiled-tube heat exchangers to improve heat transfer rate with spirally corrugated wall. Int J Heat Mass Transf. 2010;53(19–20):3928–39.

Rainieri S, Bozzoli F, Cattani L, Pagliarini G. Compound convective heat transfer enhancement in helically coiled wall corrugated tubes. Int J Heat Mass Transf. 2013;59:353–62.

Yarmohammadi S, Farhadi M. Optimization of thermal and flow characteristics of R-404A vapor condensation inside corrugated tubes. Int J Exp Therm Fluid Sci. 2016;79:1–12.

Jafari M, Daribi S, Farhadi M, Sedighi K. Effects of a three-lobe swirl generator on the thermal and flow fields in a heat exchanging tube: an experimental and numerical approach. Int J Energy Convers Manag. 2017;148:1358–71.

Nuntaphan A, Vithayasai S, Vorayos N, Kiatsiriroat T. Use of oscillating heat pipe technique as extended surface in wire-on-tube heat exchanger for heat transfer enhancement. Int Commun Heat Mass Transf. 2010;37(3):287–92.

Rabienataj Darzi AA, Farhadi M, Sedighi K, Aallahyari SH, Delavar MA. Turbulent heat transfer of Al2O3–water nanofluid inside helically corrugated tubes: numerical study. Int Commun Heat Mass Transf. 2013;41:68–75.

Lin ZM, Wang LB, Lin M, Dang W, Zhang YH. Numerical study of the laminar flow and heat transfer characteristics in a tube inserting a twisted tape having parallelogram winglet vortex generators. Int J Appl Therm Eng. 2017;115:644–58.

Promvonge P, Eiamsa-ard S. Heat transfer behaviors in a tube with combined conical-ring and twisted-tape insert. Int Commun Heat Mass Transf. 2007;34(7):849–59.

Eiamsa-ard S, Eiamsa-ard P, Promvonge P. Convective heat transfer in a circular tube with short-length twisted tape insert. Int Commun Heat Mass Transf. 2009;36:365–71.

Eiamsa-ard S, Thianpong C, Eiamsa-ard P. Turbulent heat transfer enhancement by counter/co-swirling flow in a tube fitted with twin twisted tapes. Int J Exp Therma Fluid Sci. 2010;34:53–62.

Man C, Lv X, Hu J, Sun P, Tang Y. Experimental study on effect of heat transfer enhancement for single-phase forced convective flow with twisted tape inserts. Int J Heat Mass Transf. 2017;106:877–83.

Karimi A, Al-Rashed AA, Afrand M, Mahian O, Wongwises S, Shahsavar A. The effects of tape insert material on the flow and heat transfer in a nanofluid-based double tube heat exchanger: two-phase mixture model. Int J Mech Sci. 2019;156:397–409.

Moghaddaszadeh N, Esfahani JA, Mahian O. Performance enhancement of heat exchangers using eccentric tape inserts and nanofluids. Int J Therm Anal Calorim. 2019;137:1–13.

Rashidi S, Hormozi F, Sundén B, Mahian O. Energy saving in thermal energy systems using dimpled surface technology—a review on mechanisms and applications. Int J Appl Energy. 2019;250:1491–547.

Bejan A. Convection heat transfer. 4th ed. New York: Wiley; 2013. p. 62–75.

Fluent AN. 18.2, Theory Guide, ANSYS Inc. Canonsburg, PA (2017).

Baragh S, Shokouhmand H, Ajarostaghi SSM, Nikian M. An experimental investigation on forced convection heat transfer of single-phase flow in a channel with different arrangements of porous media. Int J Therm Sci. 2018;134:370–9.

Shirzad M, Ajarostaghi SSM, Delavar MA, Sedighi K. Improve the thermal performance of the pillow plate heat exchanger by using nanofluid: numerical simulation. Int J Adv Powder Technol. 2019;30(7):1356–65.

Baragh S, Shokouhmand H, Ajarostaghi SSM. Experiments on mist flow and heat transfer in a tube fitted with porous media. Int J Therm Sci. 2019;137:388–98.

Shirzad M, Delavar MA, Ajarostaghi SSM, Sedighi K. Evaluation the effects of geometrical parameters on the performance of pillow plate heat exchanger. Int J Chem Eng Res Des. 2019;150:74–83.

Noorbakhsh M, Zaboli M, Ajarostaghi SSM. Numerical evaluation of the effect of using twisted tapes as turbulator with various geometries in both sides of a double-pipe heat exchanger. J Therm Anal Calorim. 2020;140(3):1341–53.

Hamedani FA, Ajarostaghi SSM, Hosseini SA. Numerical evaluation of the effect of geometrical and operational parameters on thermal performance of nanofluid flow in convergent–divergent tube. Int J Therm Anal Calorim. 2019. https://doi.org/10.1007/s10973-019-08765-w.

Kazemi Moghadam H, Ajarostaghi SSM, Poncet S. Extensive numerical analysis of the thermal performance of a corrugated tube with coiled wire. Int J Therm Anal Calorim. 2019. https://doi.org/10.1007/s10973-019-08876-4.

Zaboli M, Ajarostaghi SSM, Noorbakhsh M. Effects of geometrical and operational parameters on heat transfer and fluid flow of three various water based nanofluids in a shell and coil tube heat exchanger. SN Appl Sci. 2019. https://doi.org/10.1007/s42452-019-1431-2.

Karouei SHH, Ajarostaghi SSM, Gorji-Bandpy M, Fard SRH. Laminar heat transfer and fluid flow of two various hybrid nanofluids in a helical double-pipe heat exchanger equipped with an innovative curved conical turbulator. J Therm Anal Calorim. 2020. https://doi.org/10.1007/s10973-020-09425-0.

Outokesh M, Ajarostaghi SSM, Bozorgzadeh A, Sedighi K. Numerical evaluation of the effect of utilizing twisted tape with curved profile as a turbulator on heat transfer enhancement in a pipe. J Therm Anal Calorim. 2020. https://doi.org/10.1007/s10973-020-09336-0.

Olfian H, Zabihi Sheshpoli A, Mousavi Ajarostaghi SS. Numerical evaluation of the thermal performance of a solar air heater equipped with two different types of baffles. Heat Transf. 2020;49(3):1149–69.

Noorbakhsh M, Pourfallah M, Ajarostaghi SS, Zaboli M. Numerical evaluation and the effects of geometrical and operational parameters on thermal performance of the shell and double coil tube heat exchanger. Heat Transf. 2020. https://doi.org/10.1002/htj.21847.

Incropera FP, DeWitt DP. Introduction to heat transfer. 3rd ed. New York: Wiley; 1996.

Funding

This research received no external funding.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zaboli, M., Nourbakhsh, M. & Ajarostaghi, S.S.M. Numerical evaluation of the heat transfer and fluid flow in a corrugated coil tube with lobe-shaped cross-section and two types of spiral twisted tape as swirl generator. J Therm Anal Calorim 147, 999–1015 (2022). https://doi.org/10.1007/s10973-020-10219-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-020-10219-7