Abstract

LUX-ZEPLIN (LZ) is a second-generation direct dark matter experiment with spin-independent WIMP-nucleon scattering sensitivity above \({1.4 \times 10^{-48}}\, {\hbox {cm}}^{2}\) for a WIMP mass of \({40}\, \hbox {GeV}/{\hbox {c}}^{2}\) and a \({1000}\, \hbox {days}\) exposure. LZ achieves this sensitivity through a combination of a large \({5.6}\, \hbox {t}\) fiducial volume, active inner and outer veto systems, and radio-pure construction using materials with inherently low radioactivity content. The LZ collaboration performed an extensive radioassay campaign over a period of six years to inform material selection for construction and provide an input to the experimental background model against which any possible signal excess may be evaluated. The campaign and its results are described in this paper. We present assays of dust and radon daughters depositing on the surface of components as well as cleanliness controls necessary to maintain background expectations through detector construction and assembly. Finally, examples from the campaign to highlight fixed contaminant radioassays for the LZ photomultiplier tubes, quality control and quality assurance procedures through fabrication, radon emanation measurements of major sub-systems, and bespoke detector systems to assay scintillator are presented.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

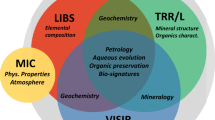

The LUX-ZEPLIN (LZ) experiment operates a \({7}\, \hbox {t}\) purified liquid-xenon target in a time projection chamber (TPC) and has a design sensitivity capable of excluding at \({90}\%\) confidence level spin-independent WIMP-nucleon cross sections above \({1.4 \times 10^{-48}}\, {\hbox {cm}}^{2}\) for a \({40}\, \hbox {GeV}/{\hbox {c}}^{2}\) mass WIMP, providing excellent discovery potential for WIMPs through nucleon elastic scattering and subsequent detection of light and charge from the collisions [1]. The detector is currently being installed in the Davis Cavern of the Sanford Underground Research Facility (SURF) at a depth of approximately 4850 ft which is equivalent to approximately 4300 m of water (henceforth referred to as meters of water equivalent – m w.e.). The detector is described in detail in [2, 3]. The expected sensitivity of the experiment is achieved through a combination of very low background rates, a large fiducial mass of \({5.6}\, \hbox {t}\), and a \({1000}\, \hbox {days}\) WIMP search exposure. The detector backgrounds are predominantly of two kinds: electron recoils (ER) which occur through interaction with the atomic electrons of the target xenon material; and nuclear recoils (NR) which occur through interaction with the nucleus of the xenon. The coincident background levels in LZ are suppressed, tagged and characterized by employing two veto detectors: an instrumented layer of liquid-xenon known as the xenon skin veto, and an outer detector (OD) that uses a Gd-loaded liquid scintillator (GdLS) detection medium. The inner \({5.6}\, \hbox {t}\) fiducial volume further benefits from attenuation of background radioactivity penetrating the TPC.

The construction of LZ requires materials very low in radio-contamination to limit their background contribution in the target, thus maximizing the rare-event search sensitivity. Furthermore, an accurate knowledge of the expected low levels of background from remaining radioactivity and irreducible sources is necessary to ascribe confidence to any possible observation of signal excess. This article presents the results from the radioassay and screening campaign performed to inform the selection of LZ construction materials and to develop the experiment’s comprehensive background model.

Section 2 describes the gamma-ray spectroscopy and mass spectrometry techniques and the facilities used to determine levels of radioactivity in the bulk of the materials, including efforts to cross-calibrate the various detectors deployed. Section 3 presents the radon emanation facilities available to LZ which were used to inform selection of materials in contact with liquid xenon and to characterize components used for the construction of the LZ experiment. Section 4 describes our techniques to limit surface depositions of environmental dust and atmospheric radon decay-progeny, with particular emphasis on the period of detector assembly at SURF. Section 5 presents a selection of highlights from the assay program that illustrates our fixed-contaminant radioassays for the LZ PMTs; demonstrates the importance of our quality control (QC) and quality assurance (QA) procedures for construction of the cryostat; revisits a dedicated detector constructed to survey the scintillator for the OD first discussed in [4]; and presents radon emanation measurements from key components, including in-situ assays of the cryostat with the complete detector within.

Upon completion of any assay, results are uploaded to a dedicated database. This database links assay results to individual components of the LZ detector, greatly simplifying the process of building the expected background model which, in turn, helps to define the expected sensitivity of the detector. The results from the assays performed are tabulated in the Appendix to this article.

2 Fixed contamination

2.1 Origin of fixed contamination

Fixed contaminants are embedded in materials and typically consist of naturally occurring radioactive materials (NORM), the most prevalent being \({}^{238} \hbox {U}\), \({}^{235}\hbox {U}\), \({}^{232} \hbox {Th}\), and their progenies which emit various radioactive species through their decay eventually to stable isotopes of lead; and gamma-ray emitting isotopes, \({}^{40} \hbox {K}\), \({}^{60} \hbox {Co}\) and \({}^{137}\hbox {Cs}\). Neutrons are produced through (\(\alpha \),n) reactions and through spontaneous fission in the uranium and thorium decay chains. The \({}^{238} \hbox {U}\) and \({}^{232} \hbox {Th}\) chains are divided into ‘early’ and ‘late’; for \({}^{238} \hbox {U}\), the early part of the chain (\({}^{238} {\hbox {U}}_{\mathrm {e}}\)) contains the isotopes above \({}^{226}\hbox {Ra}\) since chemical processes may induce a break of secular equilibrium at this point, and it will take thousands of years (\(\tau _{1/2}\) = 1600 years) to be restored. The late part of the chain (\({}^{238} {\hbox {U}}_{\mathrm {l}}\)) is counted from \({}^{226}\hbox {Ra}\) and below. Typical p-type high-purity germanium (HPGe) detectors are not sensitive to the low-energy gamma-ray lines from \({}^{210}\hbox {Pb}\) at the bottom of the chain but broad energy germanium (BEGe), n-type and well-type detectors available to LZ are.

Secular equilibrium breaking is observed by differences in long-lived isotope concentrations in early and late chain values. However, it should be noted that the \({}^{232} \hbox {Th}\) chain, as defined, includes \({}^{228}\hbox {Ra}\) which has a relatively long half-life of \({5.7}\, \hbox {years}\). If \({}^{232} \hbox {Th}\) and \({}^{228}\hbox {Th}\) are depleted in production of a material, it is possible for \({}^{228}\hbox {Th}\) to grow back in from \({}^{228}\hbox {Ra}\) on a time scale of several years, such that assays may underestimate the ultimate activity. It can be difficult to measure \({}^{228}\hbox {Ra}\) with the same sensitivity as \({}^{232} \hbox {Th}\) because HPGe counting used for the former is generally less sensitive than ICP-MS analysis used for the latter, particularly for samples where only small masses are available, but the risk is generally mitigated by using materials where batches of different ages have been measured over the course of a long material selection campaign [5].

The collaboration also performs assays with in-house inductively-coupled plasma mass spectrometry (ICP-MS) (Sect. 2.4) and some limited use of glow discharge mass spectromety (GDMS).

2.2 High-purity germanium screening

Gamma-ray spectroscopy was used to identify the bulk of the radio-isotopes contributing to neutron and gamma-ray emission. In order to achieve sensitivity to the required low levels, these measurements were typically of 1–2 week duration. Assays were made using 12 HPGe detectors, or variants of HPGe detectors, available to the LZ collaboration across four sites, described in the following subsections and with key parameters summarized in Table 1 and performance characteristics summarized in Table 2. In the early stages of the LZ screening program, a campaign of blind cross-calibration across all detectors was undertaken to verify the consistency of analysis and interpretation across the different sites. The cross-calibration campaign is described in Sect. 2.3. HPGe assay sensitivity to both early and late chain activities was critical to the comprehensive modeling of backgrounds.

2.2.1 BHUC

The Black Hills Underground Campus (BHUC) [6] is a facility located at the 4850 ft level of SURF which hosts a class 2000 cleanroom containing six low- and ultra-low background HPGe detectors: Maeve, Morgan, Mordred, SOLO, and the TWINS. Maeve, an Ortec \({85}\%\) relative efficiency p-type detector (where the efficiency is defined as relative to that of a 3-inch \(\times \) 3-inch NaI detector exposed to 1332 keV \({}^{60} \hbox {Co}\) gamma-rays with a source-detector distance of \({25}\, \hbox {cm}\)) was previously situated in the Davis campus at SURF and, before that, at LBNL’s Oroville site for 15 years. Morgan, an Ortec \({85}\%\) relative efficiency p-type detector, is effectively identical to Maeve in performance. Mordred, an Ortec \({60}\%\) relative efficiency n-type detector, was retrofitted with ultra-low background electronics to improve its performance for low-background assay. Mordred has good sensitivity to low-energy gamma rays and is therefore particularly well-suited for U early chain assays. SOLO, a \({30}\%\) relative efficiency p-type detector, was previously sited in the Soudan Underground Laboratory and played an important role in the LUX experiment’s material assay campaign [7,8,9]. While the crystal is small, it has exceptionally low backgrounds. The newest detectors in the BHUC are referred to as the TWINS, a pair of Ortec \({90}\%\) relative efficiency p-type detectors in a common shield. The TWINS can operate in coincidence or anti-coincidence and in combined singles data acquisition mode where spectra from each detector are combined without any regard for events which are detected in coincidence.

In the BHUC, Maeve, Morgan, Mordred, and SOLO are situated in separate graded shields. The TWINS are installed in a common shield. Each shield provides at least \({20}\, \hbox {cm}\) of low-activity lead shielding with \({2.5}\, \hbox {cm}\) of oxygen-free, low conductivity copper within the lead. The shield surrounding Maeve has an inner layer of \({2.5}\, \hbox {cm}\) of ultra-low activity lead and the shield surrounding SOLO has an inner layer of \({5}\, \hbox {cm}\) of ancient lead. The study of low-background lead for detector shielding is discussed in detail in [10]. All HPGe detectors are constructed using low-background designs and include remote preamplifiers. All detectors are cooled using liquid nitrogen from a fully automated filling system. The background radon in the BHUC counting room varies between 500 and 1000 Bq/kg. In order to suppress the background in the detectors caused by radon, a dedicated gas generator was installed which produces low activity nitrogen gas from a liquid nitrogen dewar at a rate of approximately 1.4 L/min. The gas purge flushes the detector counting cavities as well as the lead and copper shields. An additional detector, Ge-IV, operated by the University of Alabama, is installed outside the cleanroom, although this has not been used for assays discussed in this paper.

2.2.2 BUGS

The Boulby Underground Germanium Suite (BUGS) hosts seven gamma spectroscopy detectors \({1.1}\, \hbox {km}\) underground at the Boulby Underground Laboratory in a class 1000 cleanroom. Since 2013, the majority of screening efforts for the LZ experiment were performed using the Chaloner, Lunehead, and Lumpsey detectors. These detectors are, respectively, a Mirion (formerly Canberra) BE5030 broad-energy ultra-low background (ULB) HPGe detector,Footnote 1 a Mirion ULB SAGe well-detector, and a refurbished \({100}\%\) relative efficiency Ortec p-type detector used previously for the ZEPLIN–II and ZEPLIN–III experiment’s low background counting [11,12,13]. The BUGS detectors are housed in custom shields designed and built by Lead Shield Engineering Ltd. The shields comprise \({9}\, \hbox {cm}\) thickness of lead and an inner layer of \({9}\, \hbox {cm}\) thickness of copper with interlocking retractable roofs to simplify sample loading. The lead used in these shields has mostly been recycled from lead used to shield previous low-background experiments hosted at the Boulby Underground Laboratory. The characterizations and sensitivities of these detectors are discussed in [5].

In addition to these detectors, BUGS has installed additional Mirion “specialty ultra-low background” (S-ULB) detectors which have been used to screen later LZ samples since 2017. These comprise two p-type detectors, Belmont and Merrybent, with relative efficiencies of \({160}\%\) and \({100}\%\), respectively, and Roseberry, a BE6530 BEGe type detector. For uniformity, these detectors are housed in similar shields to those used for the ULB standard Mirion detectors with the exception of the shield used for the Belmont detector which includes an inner liner of very low-background copper. These three detectors display substantially lower backgrounds than those of the ULB standard to significantly enhance the throughput rate of assays for LZ. The Belmont detector in particular, was used to further lower the \({}^{238} {\hbox {U}}_{\mathrm {l}}\) upper limits for titanium reported in [14].

The shields used for all detectors are purged using nitrogen from a Wirac NG6 gas generator. The Boulby Underground Laboratory benefits from a low baseline radon level (averaging \({\sim } 2.5\, \hbox {Bq}/ {\hbox {m}}^{3}\)). To remove residual radon in the nitrogen purge gas, charcoal traps containing approximately \({6}\, \hbox {kg}\) of Carboact activated charcoal are deployed in a Labcold ULTF416 \(-80~^{\circ } \hbox {C}\) chest freezer. This radon reduction system is based on the design of a radon emanation detector developed at the Centre de Physique des Particules de Marseille (CPPM) [15]. As an example, the use of this purge system reduces the count rate in the \({609}\, \hbox {keV}\) line by at least a factor of 40 (from 16.4 counts/kg/day to less than 0.4 counts/kg/day at \({90}\%\) confidence level).

2.2.3 LBNL

Lawrence Berkeley National Laboratory (LBNL) has two HPGe detectors devoted to assay [16]. These are housed in a near-surface room shielded with over \({1.5}\, \hbox {m}\) of low radioactivity concrete. The Merlin detector is an Ortec \({115}\%\) n-type detector. Merlin is shielded by \({20}\, \hbox {cm}\) of lead with an inner layer of \({2.5}\, \hbox {cm}\) of copper and is equipped with a plastic scintillator cosmic-ray veto. The BIG-8 detector is an \({85}\%\) p-type detector shielded with \({10}\, \hbox {cm}\) of lead and \({1.2}\, \hbox {cm}\) of copper. It is equipped with a NaI veto that encloses the Ge crystal. Both detectors are flushed with nitrogen boil-off gas. The cosmic-ray vetos and local shielding result in detector performance equivalent to being sited at a depth of approximately 500 m w.e.

2.2.4 Alabama

The University of Alabama operates two above-ground Canberra p-type low-background HPGe detectors [17]. These are Ge-II and Ge-III which have relative efficiencies of \({60}\%\) and \({105}\%\), respectively. Each of these detectors is housed in shielding comprising \({20}\, \hbox {cm}\) of lead with an inner layer of \({5}\, \hbox {cm}\) of copper, instrumented with \({5}\, \hbox {cm}\) thick plastic scintillator cosmic-ray veto detectors. The sample chambers are continuously flushed with nitrogen boil-off gas to displace radon. Despite their above-ground location, the background rates achieved this way are comparable to some of the underground devices, as reported in Table 2. Ge-II and Ge-III have been used for items assayed using Neutron Activation Analysis (NAA), described in Sect. 2.5. Ge-III was further utilized extensively for studies of \(^{210}\hbox {Pb}\) surface activities, their deposition through radon exposure, and their removal.

2.3 HPGe cross-calibration

Early in the LZ assay efforts, it was recognized that samples would be distributed amongst a large variety of detectors with different backgrounds, shielding arrangements, and histories. To cross-calibrate and evaluate the systematic uncertainties in assays performed with a number of the detectors listed in Table 2, a sample of latite with well-characterized uranium, thorium and potassium content was prepared. This material has been used by LBNL for more than 30 years to characterize its detectors. The uniformity of the radioactivity has been studied and is confirmed to be flat across a variety of sample sizes from \({\sim } 1\, \hbox {mm}\) up to several cm. An S5 Marinelli beaker of this mineral was prepared and sealed. The content and activity was not known by the rest of the collaboration and the same beaker was subsequently analyzed by all groups on all their detectors. The analyses were sent to a central site, amassed and compared by one individual who had knowledge of the true contamination of the calibration source material.

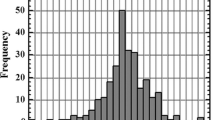

This comparison uncovered some issues with several analyses, mostly due to problems with the Monte Carlo simulations of the detectors. After discrepancies were highlighted by the individual who amassed the results, these issues were identified and corrected. The results were again compared across all the detectors. Table 3 lists reference values for each isotope; compares results from each detector; and gives their combined average and standard deviation. A visual comparison between detectors used in the calibration program for potassium is shown in Fig. 1. It is important to note at this point that when a concentration is reported, in parts per value e.g. ppm, ppb, ppt (\(\hbox {g}\) of U/Th per \(\hbox {g}\) of material), it is no longer pertinent to refer to late chain or early chain values as the concentration defines the concentration of the progenitor isotope (\({}^{238} \hbox {U}\) , \({}^{235}\hbox {U}\), \({}^{232} \hbox {Th}\)) assuming secular equilibrium [18]. There is some residual disagreement between Ge-II, Ge-III and the other detectors. These two surface detectors were used primarily for neutron activation analysis and pre-screening of samples before sending them for assay on an underground detector. We noted the discrepancies but because of their limited use, we chose to accept this in a larger systematic for these two detectors. The vast majority of the assays performed as part of the LZ campaign were carried out on the detectors shown in Fig. 1. The cross-calibration effort confirmed that the modeling of detector geometries and efficiencies were correctly handled and provides a reasonable estimate on the systematic variation among the assays of \({\sim }\, 10\%\) thus giving the collaboration confidence that each individual facility is able to produce consistent and accurate assay results. This being the case, newer detectors that were used later in the campaign (such as the S-ULB detectors added to BUGS) were not required to be characterized using the latite sample. Each facility was able to implement their own calibration and characterization methods and the subsequent assay results were accepted to be accurate within statistical errors and within the systematic errors of the detector used. Agreement between the detectors used in the cross-calibration campaign and newer detectors was also informally verified by assaying identical samples on different detectors.

For some materials, such as the titanium, additional steps were taken to increase our confidence in the assay precision. These included assaying the same sample in multiple locations and at different times (to allow for the decay of cosmogenically activated isotopes of scandium) and assaying samples using mass spectrometry. This cross-calibration also verified that all counters had effective Rn-reducing purge systems. Periodically, the LZ assay campaign screening of selected samples was repeated on different detectors to monitor for stability of assays. These ongoing comparisons spanned a variety of source materials and a wide range of contamination levels, while also probing for Th in-growth in particular LZ components. For many materials we complemented the HPGe assays with inductively-coupled plasma mass spectrometry (ICP-MS) and, after their installation at Boulby, with the new S-ULB detectors to further verify our measured concentrations of \({}^{238} {\hbox {U}}_{\mathrm {e}}\) and \({}^{232} {\hbox {Th}}_{\mathrm {e}}\).

Results from the assays deploying gamma spectroscopy are presented in Table 10.

Cross-calibration results for potassium concentration for the detectors used in the LZ HPGe radioassay campaign. The reference value for potassium concentration in this sample is \({(2.82 \pm 0.01)}\%\). Excluding this, an error-weighted mean of \({(2.84 \pm 0.02)}\%\) was derived from the measurements of \({}^{40} \hbox {K}\). In this figure, the gray band represents the standard deviation of the measurements with a value of \({0.25}\%\)

2.4 Mass spectrometry

Inductively-coupled plasma mass spectrometry (ICP-MS) allows very precise direct measurement of the elemental abundances of uranium and thorium in small samples. The assays can be very quick, taking hours to days depending on requisite sensitivity down to sub-ppt levels and depending on related sample preparation protocols. ICP-MS has been used extensively in LZ to quickly measure \({}^{238} \hbox {U}\) and \({}^{232} \hbox {Th}\) in small samples to either reject or clear materials for use, or to pre-screen materials prior to assay with gamma spectroscopy which can determine the complete activity through the \({}^{238} \hbox {U}\) and \({}^{232} \hbox {Th}\) decay chains. The speed of ICP-MS allowed rapid analysis of test pieces provided by manufacturers at specified points in the production processes to detect potential issues and to ensure radioactivity and cleanliness compliance. The manufacture of the Ti cryostat is one such example, highlighted in Sect. 5.2.

The majority of ICP-MS assays for LZ were performed using a dedicated mass spectrometry laboratory at UCL, housed in a class 1000 cleanroom facility and operating an Agilent 7900 spectrometer installed in 2015 exclusively for LZ [19]. Sample preparation and analysis procedures have been developed for materials with U/Th concentrations in the \(\hbox {ppt}\) to \({1}\, \hbox {ppb}\) range: Samples are microwave-digested in pre-cleaned modified-PTFE vessels using ultra-high purity acids. They are then diluted, without further chemical treatment, into disposable \({50}\, \hbox {mL}\) polypropylene (PP) vessels ready for ICP-MS analysis. Fractional recoveries of \({}^{230}\hbox {Th}\) and \({}^{233}\hbox {U}\) spikes added prior to digestion are used to correct for \({}^{232} \hbox {Th}\) and \({}^{238} \hbox {U}\) signal loss from a range of sources. In particular, this enables accurate analysis of samples with high total dissolved solids (TDS) where the instrument response degrades throughout the run. A full assay including digestion, ICP-MS measurement and analysis can be completed in a single day. The UCL facility was upgraded in 2019 with an Agilent 8900 ICP-MS.

In addition to the ICP-MS system at UCL, some material samples were assayed using facilities at the University of Alabama, the Centre for Underground Physics in Korea, and the Black Hills State University. At the University of Alabama, the LZ group set up a sample preparation laboratory in a class 500 cleanroom equipped with a cryogenic mill, microwave digestion system, and digestion bomb. Further processing of samples, including spiking and resin-based extraction of U/Th isotopes was carried out in a separate cleanroom. The samples were then given to the Department of Geological Sciences which processed the samples using a Perkin-Elmer SCIEX-ELAN 6000 system. In Korea and at Black Hills State University, samples were measured using Agilent 7900 spectrometer, as was used at UCL. Results from ICP-MS assays for LZ are presented in Table 11.

Finally, in the early days of the LZ assay program, a small number of items were assayed using glow discharge mass spectrometry (GDMS). These assays were performed using a Thermo-Fisher VG 9000 GDMS instrument operated by the National Research Council of Canada (NRC). GDMS can achieve sensitivities of around \({10}\, \hbox {ppt}\) for conductive materials. For this reason, GDMS was used for some assays of titanium. Results from the GDMS assays for LZ are presented in Table 12.

2.5 Neutron activation analysis (NAA)

As with ICP-MS, NAA allows sensitive analysis of small concentrations of Th and U in small samples. It only constrains the early decay series. It can be utilized for materials where the matrix does not form long-lived radioactivity after neutron capture. As such, it is well-suited for plastics.

For NAA assay in LZ, the University of Alabama group utilizes the \({6}\, {\hbox {MW}}_{\mathrm{th}}\) tank-type MIT Reactor II (MITR-II, located at the Massachusetts Institute of Technology) to activate samples. This technique is typically used for small size samples of a few mm in diameter and several cm in length. LZ samples were prepared at the University of Alabama in a cleanroom prior to their shipping to the reactor for activation. Surfaces were leached extensively in high-grade acids to distinguish bulk from surface activities. The polyethylene vials used for irradiation are cleaned, welded shut, and leak tested. Samples are typically irradiated for \({10}\, \hbox {h}\) in the high-flux sample insertion facility of MITR-II before being returned for counting analysis. Storage within sealed polyethylene vials serves to protect the samples from cross-contamination during transport and activation. There is a typical delay of around \({24}\, \hbox {h}\) between activation being completed and samples being assayed using Ge-II or Ge-III, but this is acceptable when compared to the half-lives of the activation products used for NAA (e.g. \({}^{42}\hbox {K}{} \hbox {-} \tau _{1/2} = {22.3}\, \hbox {h}\), \({}^{233}\hbox {Pa}{} \hbox {-} \tau _{1/2} = {26.97}\, \hbox {days}\), and \({}^{239}\hbox {Np}{}\hbox {-}\tau _{1/2} = {2.36} \, \hbox {days}\)). Assays typically lasted 2–4 weeks and a double-differential time-energy analysis is used to determine elemental concentrations of samples. Neutron capture cross sections, averaged over the energy distributions of the three reactor neutron flux components, taken from the JENDL4.0 database are utilized in the data analysis. For each of the LZ activation campaigns the neutron fluxes were determined by activating the NIST reference material, fly ash, immediately following the sample. This allows to reference the elements of interest directly to a standard. This method is discussed in depth in [20].

The techniques employed by the University of Alabama group routinely achieve a sensitivity of \(10^{-12}~ \hbox {g U/Th}\) per g of material and, indeed, sensitivities as good as \(10^{-14}~ \hbox {g}\) of U/Th per g of material have been reported by the same group for assays related to the EXO-200 experiment [20, 21]. Such sensitivity has been key for assays and selection of raw materials not readily amenable to direct HPGe due to sample mass or minimal detectable activity requirements, or to ICP-MS due to difficulties in sample digestion and preparation. Selection of PTFE to manufacture the LZ TPC reflectors are one such example where NAA has been deployed, with results presented in Table 13.

3 Radon emanation

3.1 Origin of radon emanation

All isotopes of radon are radioactive and only five are naturally found in minute quantities in nature. Those of interest for the LZ background model and often other experiments in search for WIMP dark matter are \({}^{222}\hbox {Rn}\) (\(\tau _{1/2}= {3.82}\, \hbox {days}\)) from the \({}^{238} \hbox {U}\) decay chain and \({}^{220}\hbox {Rn}\) (\(\tau _{1/2}= 55.8 \, \hbox {s}\)) from the \({}^{232} \hbox {Th}\) decay chain; hereafter called radon and thoron, respectively. Due to the long lifetime of their progenitor isotopes, radon and thoron are produced at a near-constant rate within detector material over the lifetime of an experiment. The emanation rate of a material can be broken down into two parts: emanation due to recoiling radon atoms and emanation due to diffusion. Emanation due to diffusion can vary drastically depending on chemical and lattice structures of a material, density, surface roughness, and temperature. The diffusion length, L(m), of radon for a given material can be represented as \(L(m) = \sqrt{D/\lambda }\), where D is the diffusion coefficient and \(\lambda {}\) the decay constant.

The background from radon emanation in LZ is dominated by the ground-state to ground-state or “naked” \(\beta \)-emission from the \({}^{214}\hbox {Pb}\) progeny of the \({}^{222}\hbox {Rn}\) sub-chain as it decays to \({}^{214}\hbox {Bi}\). The relatively long half-life of \({}^{222}\hbox {Rn}\) leads to a homogeneous mixing within the target volume, resulting in a uniform ER background with a \(\beta \)-spectrum up to 1019 keV. The background from \({}^{220}\hbox {Rn}\) is expected to be significantly suppressed due a much smaller diffusion length as a result of its shorter half-life, hence most of it is expected to decay within the material volume in comparison to \({}^{222}\hbox {Rn}\) before diffusing out, or before maximally mixing with the active xenon volume.

Radon emanation accounts for \({\approx 66}\%\) of the projected ER background in the WIMP search region of interest in LZ [1], predominantly from a projected \({}^{222}\hbox {Rn}\) specific activity of \({2}\,\upmu \hbox {Bq/kg}\) that corresponds to approximately \({20}\, \hbox {mBq}\) in the 10 tonnes of xenon, from which \({11}\, \hbox {mBq}\) is in the fiducial volume. As demonstrated by previous LXe-based rare-event search experiments, including LUX and ZEPLIN–III, the amount of radon in the target can be deduced through analysis of the \({}^{214}\hbox {Pb}\) \(\beta \)-spectrum and from coincidence tagging of decaying radon daughter \(^{214} \hbox {Bi}\) and \(^{214} \hbox {Po}\) [7, 12]. While such in-situ techniques are powerful in constraining the observed radon emanation background once the detector is closed and operational, a screening campaign akin to that for fixed contaminants is required to inform material selection for detector and sub-system construction, and for the experiment background prediction.

3.2 Radon emanation screening

3.2.1 Screening techniques

Radon screening typically involves reconstructing the radon emanation rate by measuring the radon sub-chain daughter isotopes. An approximate way of achieving this uses gamma spectroscopy to measure the \({}^{214}\hbox {Bi}\) (\(\tau _{1/2}= {19.9}\, \hbox {min}\)) and \({}^{214}\hbox {Pb}\) (\(\tau _{1/2}= {26.8}\, \hbox {min}\)) decay rates, from which the radon activity is inferred. Although this method provides useful limits for emanation rates, it is extremely difficult to distinguish radon daughters decaying in the bulk of the material to those that decay outside. Thus, a precise emanation rate cannot be deduced without a material-specific diffusion model.

A more direct and precise approach, one that has been utilised in four of the LZ facilities, is to directly measure the activity of radon that has emanated out from the material. The sample material is initially enclosed in an air-tight chamber that is filled with a low-radon carrier gas, typically helium or nitrogen. This carrier gas prevents recoiling radon atoms from embedding into the chamber walls.After an emanation period that allows the radon concentration in the chamber to approach equilibrium (\({\sim } 1 \, \hbox {week}\)), the emanated radon atoms are transferred into a detector that measures the rate of \({}^{218}\hbox {Po}\) (\(\tau _{1/2}= {3.1} \, \hbox {m}\)) and \({}^{214}\hbox {Po}\) (\(\tau _{1/2}= {164}\, \upmu \hbox {s}\)), with a mean decay time of \(\sim \, {71}\, \hbox {min}\) after the initial \({}^{222}\hbox {Rn}\) decay. A second approach of measuring the emanation rate is by identifying the delayed \({}^{214}\hbox {Bi}\)Po coincidence. In both cases, the radon emanation rate is reconstructed by correcting for the detection and transfer efficiencies, measured during dedicated calibration runs with radon sources of known activity.

The first of these reconstruction techniques determines the radon emanation rate by detecting the \(\alpha \)-particles emitted from the \({}^{218}\hbox {Po}\) and \({}^{214}\hbox {Po}\) isotopes. These systems use electrostatic silicon PIN-diodes to attract and capture the predominantly positively charged ions \({(87.3\pm 1.6)}\%\) of radon daughter nuclei by using an electric field that is generated from the negative voltage applied on the PIN-diode [22]. The \(\alpha \)-particles emitted from the \({}^{218}\hbox {Po}\) and \({}^{214}\hbox {Po}\) ions are detected by a PIN-diode as they undergo \(\alpha \)-decay and are distinguished by the energies they deposit; \({6.1}\, \hbox {meV}\) and \({7.9}\, \hbox {meV}\), respectively. Of the four radon-emanation screening facilities used by LZ, three use electrostatic PIN-diode detectors for radon emanation. The fourth facility collects the harvested radon by dissolving it in organic liquid scintillator by means of a carrier gas. The delayed \({}^{214}\hbox {Bi}\)-\({}^{214}\hbox {Po}\) coincidences are then counted to infer the corresponding \({}^{222}\hbox {Rn}\) decay rate. All facilities operate at room temperature such that the expected suppression of diffusion-dominated radon emanation at low temperature is not probed.

The LZ collaboration performed cross-calibrations for the four radon facilities deployed as part of our assay program. A rubber sample previously screened by the EXO collaboration [23, 24] was assayed at each of the radon emanation facilities. Prior to the emanation period, the sample was prepared under the same conditions to reduce the chances of environmental contamination. The surface of the sample was scrubbed with isopropyl alcohol-soaked lint-free wipes and inspected with UV-light to ensure no presence of surface contamination. The activity of the sample was \({\mathcal {O}}{({10}\, \text {mBq})}\) and was thus well above the minimal detectable activities of the radon systems. Table 4 presents the results of the cross-calibration and a summary of key details of the LZ radon screening facilities.

LZ makes use of two portable radon collection systems for equipment that is too large or delicate to move to the radon emanation facilities or for assays of systems under construction in the SURF Surface Assembly Laboratory (SAL). Emanated radon is transferred to a cold trap consisting of copper beads or wool that is double-sealed and then transported by car or overnight shipping to the radon facility at South Dakota School of Mines and Technology (SDSM&T) or University of Maryland. The collected radon would then be transferred over into the respective radon detector with transfer efficiencies taken into account from portable-system specific calibrations. The activity is then reconstructed by correcting for the transportation time and detector efficiency. These portable systems were critical for measurements of radon emanation from the assembled LZ detector and from large instrumentation used in the circulation path. Results from the radon emanation assay campaign are presented in Table 14. For majority of the measurements, smaller samples are sent to the facilities detailed below and radon is often collected in emanation chambers and measured with their respective detectors.

3.2.2 SDSM&T

The SDSM&T system uses two electropolished stainless steel chambers as the radon collection media: a \({13}\, \hbox {L}\) vessel for smaller components and a \({300}\, \hbox {L}\) vessel for larger components. Emanation samples are placed in the chambers with care taken not to introduce dust into the chambers or onto the samples. The chambers are then filled with nitrogen gas that has been scrubbed of radon by an activated charcoal trap cooled to \({196}\, \hbox {K}\) by a mixture of dry ice and isopropyl alcohol.

After the sample has emanated, the radon is concentrated and transferred to the \({1.7}\, \hbox {L}\) detection chamber in a multi-stage process. In the first stage, the radon is transferred from the emanation chamber to a large brass wool trap cooled to \({77}\, \hbox {K}\) by liquid nitrogen (\({\hbox {LN}}_{2}\)). A high transfer efficiency is achieved even for the \({300}\, \hbox {L}\) vessel by repeatedly pumping the chamber out through the trap and refilling. The radon is then transferred to a small brass wool trap by warming the large trap and cooling the small trap and flowing clean nitrogen through first the large trap and then the small trap. Due to the volume of gas allowed to flow, the transfer efficiency from the large trap to the small trap is \({\approx 100}\%\). Then with the small trap and detection chamber at low pressure, the small trap is warmed and nitrogen is allowed to flow through the small trap into the detection chamber to raise the pressure in the detection chamber to \({100}\, \hbox {Torr}\). This process transfers \({\sim } 95\%\) of the radon to the detection chamber, for overall transfer efficiencies of \({80}\%\) (\({94}\%\)) for the \({300}\, \hbox {L}\) (\({13}\, \hbox {L}\)) chamber. The detector is an electrostatic silicon PIN-diode detector as described above. The detector efficiency was determined to be \(23 \pm 2 \%\) for \({}^{218}\hbox {Po}\) and \(25 \pm 2 \%\) for \({}^{214}\hbox {Po}\) under standard operating conditions. A system for performing emanations at LN temperatures is under construction.

3.2.3 University of Maryland

The Maryland system’s primary focus was to measure emanation rates from volumes that act as their own emanation chambers, such as the LZ compressor system. The Maryland system also contains a \({4.6}\, \hbox {L}\) stainless steel vessel, used to calibrate the system and to perform measurements on smaller samples. The system uses an activated charcoal trap operated at \({\hbox {LN}}_{2}\) temperature to initially scrub the radon from the helium carrier gas. The radon from the emanation volume is captured by a copper pellet trap also cooled to \({\hbox {LN}}_{2}\) temperature. The copper trap is a 0.5” electropolished stainless steel tube bent into a U-shape and containing 180 g of copper pellets (Atlantic Equipment Engineers CU-131). The pellets range in size from 1/16” to 3/32”. The radon is released from the copper at room temperature and transferred to a \({1.7}\, \hbox {L}\) chamber containing an electrostatic PIN diode detector. The efficiency of the copper pellet trap was determined to be near 100% by repeated trapping and counting of a radon sample. The absolute efficiency of the detector was determined to be 24% by measuring a calibrated natural rock source purchased from Durridge. Ion drift simulations were carried out to study the performance of the detector. The predicted efficiency agrees with the measurements within the systematic uncertainty for both the Maryland and the SDSM&T detection chambers, which have a near-identical design.

A second electrostatic PIN diode radon counting system is operated at Maryland in flow-through mode to measure the elution curves of charcoal samples in helium carrier gas. A piece of uranium ore acts as an uncalibrated radon source for these measurements. Once the elution curve is determined, an appropriate radon harvesting time can be chosen for each charcoal sample during its subsequent radon emanation measurement.

3.2.4 UCL

The UCL system’s custom-made electrostatic detector was originally developed for high sensitivity radon measurements for the ELEGANT V and Super-Kamiokande experiments [25]. The detector consists of a \({70}\, \hbox {L}\) electropolished steel chamber with a silicon PIN-diode located at the top, operating under the same principles as described above. By the use of a calibration source of known activity (a \({1.32}\, \hbox {kBq}\) “flow-through” \({}^{226}\hbox {Ra}\) source by Pylon Electronics, RN-1025), the detection efficiencies for \({}^{214}\hbox {Po}\) and \({}^{218}\hbox {Po}\) are determined to be \({(31.6\pm 1.6)}\%\) and \({(27.1\pm 1.4)}\%\), respectively, with helium as the transfer gas. The system operates two \({2.7}\, \hbox {L}\) stainless steel chambers as the emanation media. The larger detector volume and the small emanation volumes allow a single step transfer process, where helium gas is flushed through the emanation chambers, directly into the detector. To eliminate the contamination of background radon from the carrier gas, the gas is initially allowed to flow through an activated carbon trap stored in an ultra-low temperate freezer (\({193}\, \hbox {K}\)) and the entire system is purged to remove accumulated radon emanating out of the transfer lines.

A second mode of operation for the system uses \({57}\, \hbox {g}\) of activated carbon (a synthetic charcoal sourced from Carbo-Act International [26]) as a radon collection trap. In larger emanation volumes, the radon is initially absorbed into the cooled trap while the carrier gas passes through. The trap is then heated to release the radon and the carrier gas is then used to transfer the concentrated radon into the detector volume. The trapping efficiency for this setup has been measured to be \({\approx 93}\%\) at \({248}\, \hbox {K}\). The cold trap was not generally necessary for the results reported in Table 14.

A second facility with sensitivity to low-temperature emanation is under construction and will be operated at the Rutherford Appleton Laboratory.

3.2.5 University of Alabama

The radon emanation facility at Alabama operates in a similar principle to those of the other three detectors, with the exception of their detection technique. Two \({2.6}\, \hbox {L}\) electropolished emanation chambers, of the same design as those utilized by the UCL group, are used to accumulate the radon outgassed from samples of interest. Boil-off nitrogen, selected for its low intrinsic radon content, serves as a carrier to transfer the radon into about \({150}\, \hbox {mL}\) of organic liquid scintillator. The carrier gas is flowed for \({48}\, \hbox {min}\) at a rate of \({20}\, \hbox {mL/min}\). Experiments with a calibrated Pylon RN-1025 radon source showed that longer purge times and higher flow rates result in more effective radon removal from the collection vessel but, on the other hand, lead to radon loss in the liquid scintillator due to the dissolved radon being washed out. The chosen parameters constitute the optimal compromise between these two mechanisms. Measurements with cascaded scintillator collectors showed that under these conditions about \({70}\%\) of the radon arriving at the scintillator-gas interface dissolves in the scintillator. Use of the calibrated radon source yields an overall radon transfer efficiency of \({34.3}\%\). The radon-loaded scintillator is transferred into a small acrylic counting cell, equipped with one low-activity 76mm (3 inch) Hamamatsu R-1307 PMT. The measurement of delayed \({}^{214}\hbox {Bi}\)-\({}^{214}\hbox {Po}\) coincidences allows the determination of the decay rate with low background. The analysis of the delayed-coincidence data sets uses cuts on the \(\beta \)- and \(\alpha \)-like energy deposits. The distribution of time differences between \(\beta \)- and \(\alpha \)-like events is fit to an exponential plus a constant, with the correlation time frozen to the known \({}^{214}\hbox {Po}\) mean lifetime. The exponential component of the fit determines the decay rate; the constant term unfolds the random background. The efficiency of these cuts has been determined, by means of loading radon derived from the calibrated source, to be \({35.9}\%\). However, because of the need to transfer both the carrier gas and the scintillator, the limiting factor is not the detector background but the blank (radon introduced during transfer and handling). Repeated measures of the handling blank allowed for estimation of the blank subtraction uncertainty. A further source of background is steady state leakage of radon into the sealed counting cells. Counting continued after allowing the radon to decay, thus, quantifying this background directly. This leakage varied between counting cells.

4 Surface contamination

4.1 Origins of surface contamination

Radio-pure detector materials and components selected through the LZ screening campaign may be contaminated during the assembly process. Indeed, exposure to airborne radon at any stage of the assembly process results in the contamination of detector materials by radon daughters (mainly the long-lived \({}^{210}\hbox {Pb}\), \(\tau _{1/2} = {22.3}\, \hbox {years}\)) that plate-out onto surfaces [27]. Environmental dust also deposits on detector material surfaces, and later, radon emanates from these surfaces and could yield daughter decays in the LXe volume during the LZ data-taking period.

Of particular concern is \({}^{214}\hbox {Pb}\), which will emit naked betas leading to a continuous ER background down to the WIMP energy window as described in Sect. 3.1. Also, \({}^{210}\hbox {Pb}\) will subsequently decay, with its granddaughter \({^{210}} \hbox {Po}\) releasing \({5.3}\, \hbox {meV}\) alphas. This induces neutrons via (\(\alpha ,n\)) reactions on low-Z nuclei in various detector materials, leading to NR backgrounds. Stable \({}^{206}\hbox {Pb}\) from the decay of \({^{210}} \hbox {Po}\) on material surfaces may recoil into the LXe volume producing a complicated wall background (0–\({103}\, \hbox {keV}\) in energy), which, despite fiducialization, could yield leakage nuclear recoil events in the region of interest due to poor position reconstruction because of their high radius (near wall) and low energy [28]. Surface contamination by radon daughters and dust thus contributes to LZ internal ER and NR backgrounds (at the expected level of about \({3}\%\) and \({38}\%\), respectively) and should therefore be carefully controlled to meet the low level background requirements of the LZ experiment [1]. To this effect, a stringent cleanliness campaign was developed to monitor and mitigate this contamination during sub-systems assemblies, mainly the TPC detector assembly in the SAL.

Left: dust particulate size distribution from fluorescent image analysis of a witness plate. Particulates of size \({>50}\, \upmu \hbox {m}\) are rarely recorded. Right: dust particulate mass distribution of the same witness coupon showing contribution of particulate size to mass. Although most particulates are small, most of the mass on the coupon is from a small number of larger particulates

This section discusses the estimation of the TPC surface contamination from both Rn and dust accumulated during the different phases of the TPC construction, along with the cleanliness measures and procedures undertaken to ensure the contamination levels remain below LZ requirements, and to minimize the internal backgrounds.

4.2 Dust deposition

The ambient dust in the SAL class 1000 cleanroom comes from two main sources: dust from outdoor air flowing through the air filtration system, and dust carried in and generated by personnel and material. The air filtration system consists of a series of six high-efficiency particulate air (HEPA) filters with fiber glass membranes that remove dust particulates from outdoor air fed into the cleanroom with an efficiency \({\ge 99.97}\%\) for particulates \(\ge 0.3 \, \upmu \hbox {m}\) [29]. Recorded dust level (from two Met One GT-526S particle counters installed at different locations) within the cleanroom with and without personnel demonstrates that outdoor dust passing through the air filtration system has a negligible contribution to the dust level within the cleanroom.

The main contribution to dust therefore comes from personnel who bring in dust from their bodies, cleanroom garbs, or equipment they bring into the cleanroom, as well as the dust they generate while working in the cleanroom. While continuous air recirculation within the cleanroom takes part of this dust back out, a portion of it does deposit onto open surfaces within the room, including those of the TPC, and should therefore be carefully quantified and controlled. Two technical probes were developed to estimate dust deposition on the TPC detector components surfaces, and a dust fallout model was developed for the same purpose.

4.2.1 Technical probes: witness coupons

Witness coupons are small samples ideally made of the same materials as the detector component that is being assembled. Since dust deposits are expected to accumulate at the same rate on the detector material, the coupons are then used to infer the dust deposition on the component. For the LZ detector, the coupons are mostly PTFE and glass, since these make up a vast majority of the most background-sensitive surfaces of the TPC.

Although coupon surfaces should preferably be flat, PMT cable coupons with curved surfaces were also deployed in an effort to thoroughly probe dust deposition. All coupons are carefully cleaned with isopropyl alcohol (IPA) soaked non-shedding wipes and then deployed in pairs, as close as possible to the detector, to collect dust under similar conditions as the detector surfaces. They are typically harvested after a couple of weeks, which, based on the cleanroom level and the sensitivity of the assay technique, is enough time to collect the required amount of dust to make an assay possible. The coupons are then assayed via optical or fluorescence microscopy depending on material type in order to enable a contrast between the dust particulates and the rest of the coupon surface. For the PTFE coupons, since PTFE does not fluoresce but many dust particulates do, ultraviolet light is shone on the exposed side of the samples. Glass coupons, on the other hand, may be imaged under visible light. Both fluorescent or optical images are then processed via software written in for ImageJ [30] for further contrast to reveal smaller dust particulates down to \({0.5}\, \upmu \hbox {m}\), and accurately determine the size distribution of these particulates and their contribution to the dust density accumulated on the coupons’ surfaces. Some dust from the optics, which shows up in the same place on each image (of a clean or dirty coupon as seen on Fig. 2), needs to be removed from the analysis and provides some minor calibration which ensures a consistent imageJ threshold is set for all images.

The number of particulates on the coupons decreases with increasing particulate size [31], such that large particles (\({\ge 50}\, \upmu \hbox {m}\)) are relatively uncommon but they may dominate the total mass, as seen in Fig. 3. Once the dust particulates size distribution is determined, the dust density accumulated on the coupon surface (in \({\hbox {ng/cm}}^{2}\)) is calculated by dividing the accumulated mass (assuming particulates are spherical in shape with density of \({\hbox {1\,g/cm}}{^3}\) by the surface area of the coupons.

To obtain the dust fallout rate, witness coupons are assayed both before and after their exposure. The pre-exposure dust concentration is subtracted from the post-exposure dust concentration before dividing by the coupon exposure time to determine the dust fallout rate. Occasionally, mishandling of coupons led to their results being discarded.

4.2.2 Technical probes: tape lifts

Since rough, fluorescing materials cannot be imaged accurately, and because witness coupons never have exactly the history of the material itself, another, more direct, probe of dust deposition was conducted. These so-called tape lifts are simple pieces of acetate or carbon tapes that are stuck to an assembly piece, and are lifted to remove dust for assay. Each tape lift can only be utilized on one spot and only lifted once. To get better statistics more tape lifts on different spots had to be taken. The choice of tape material depends on the surface texture/roughness of the component: acetate tape works better on smooth surfaces, like PTFE, while, for rougher surfaces like titanium, carbon tapes were found to perform better. The tape lifts are assayed using the same fluorescence microscopy technique utilized for the witness coupons. Unlike the coupons that collect dust throughout the assembly process, the tape lift assessment is conducted at the end of a main assembly. In addition to providing a more direct probe, tape lifts also mitigate against improper use or mishandling of coupons. For example, while the witness coupons are supposed to be wiped each time an assembly, sub-assembly or parts are being wiped, this step can be overlooked, in which case the coupons will collect more dust than the actual assembly. The tape lifts instead give confirmation of the dust level on a final assembly. However, tape lifts cannot be taken on particularly sensitive parts of the TPC, and therefore, they do not negate the need for coupons, but rather complement them. Both tape lifts and coupons are necessary for a full history of the dust deposition on every component during the assembly process. In addition, having two probes for dust deposition provided additional opportunities for the calibration and validation of the dust deposition models used by the LZ collaboration.

4.2.3 Dust deposition modeling

As discussed above, the dust density inside the assembly cleanroom depends on the influx and outflux of dust particulates in the room. Its value per unit particulate size D could be described by Eq. (1) originally developed by the SNO collaboration [32, 33]:

where \({R_{AE}}\) is the cleanroom air exchange rate defined as the volumetric air circulation rate in the cleanroom divided by the volume V of the cleanroom, v(D) is the Stokes settling velocity which is dependent on the particulate size [34], \({R_{in}(D)}\) is the volume-normalized dust-particulate carry-in rate mostly from personnel, and S is the area of the projection of the cleanroom volume onto the horizontal plane.

The fallout rate per particulate size in mass per unit area and time could then be deduced using the continuity equation as shown in Eq. (2)

where \({\frac{\pi }{6}D^3}\) is the particulate volume assuming they are spherical in shape and \({\rho }\) is their mass density (\({\equiv } \, {\hbox {1\,g/cm}}{^3}\)). The total fallout rate is then obtained by integrating over all particulate sizes (\({m =\int m(D)~dD}\)); which for LZ ranges between \(0.5 \, \upmu \hbox {m}\) to \(100 \, \upmu \hbox {m}\) as determined by the witness coupons assay results.

However, the carry-in rate per particulate size \({R_{in}(D)}\) was not measured by LZ. Only the air class within the cleanroom was measured using particulate counters. Consequently, a model of air particulate-size distribution from dust carry-in was assumed based on ISO-14644-1 and the measured air class (which generally averages less than 10 particles \({\ge 0.5}\, \upmu \hbox {m}\) per cubic foot due to our developed cleanliness protocols) was used to constrain the model. Also, a scaling factor \({\eta }\) was added to the fallout rate in Eq. (2) and was then calibrated using results of fallout rate measurements from witness coupon assays. Its average value was estimated to be \(\eta =26.86\pm 5.09\). This modified fallout rate, written in Eq. (3) will be referred to as the modified SNO model.

The new modified SNO model was then compared with independent tape lift measurements to ensure agreement within uncertainty between the model and the measurements. Table 5 shows the agreement, hence validating the modified model. The \(\eta \) factor may be influenced by several factors but the clearest observed correlation for an increase in particle fallout rate was with a decrease in the relative humidity in the cleanroom. It was observed that at the lowest relative humidity level of 25%, the fallout rate was the highest (\({1.18 ^{+0.25}_{-0.19}} \, {\hbox {ng/cm}}^{2}/\hbox {h}\)) while in normal relative humidity levels (35–45%), the fallout rate was as low as \({0.03^{+0.02}_{-0.01}} \, {\hbox {ng/cm}}^{2}\)/h. This is expected as, when the cleanroom air is drier, some surfaces like that of PTFE accumulate more static charges and attract more dust particulates.

It is important to note that, while Table 5 shows the validation of the modified SNO model, dust densities recorded there are indicative of accumulated dust on some detector components at a particular period in time. These densities therefore cannot be used to infer the final dust density on the TPC surface since accumulated dust reduced to \({\sim }~{20}\%\) of its value every time cleaning was performed on an assembly. Indeed, tape lift results taken before and after cleaning have verified that cleaning protocols developed by LZ (e.g. wiping surfaces under UV light with IPA soaked non-shedding wipes) consistently reduce dust to the stated level, and serve as stringent mitigation procedures against surface dust contamination. This is discussed in more detail in Sect. 4.4.

4.2.4 Dust fallout calculation for the TPC

The dust deposition rate in mass per unit area per unit time on the various TPC components was estimated using the modified SNO model. Once individual estimates are obtained for different components for each daily work shift, the overall deposited dust density for the ith surface (\(M_{i}\)) is obtained by taking into account the exposure time T of that given surface and the mass of dust deposited per unit area and time (m), and is then given by Eq. (4):

Since different areas of the detector are exposed for different times during the assembly process, one must also take into account the exposed area versus total detector area. Therefore, the overall dust density (\(M_O\)) in \({\hbox {ng/cm}}^{2}\) for the entire TPC is:

The surface areas, \({A_{exposed}^{i}}\) and \({A_{total}^{i}}\) are obtained from a sophisticated information repository developed by LZ to smoothly manage and track detector parts, their surface areas, and their exposure to ambient cleanroom air during TPC construction. In addition, every instance of detector surface cleaning is recorded and taken into account, as described above, which allows for an accurate estimation of the dust contamination on TPC surfaces. The final estimation amounts to a total of \({(0.64 \pm 0.05)}\, \hbox {g}\) of dust accumulated on the entire TPC for a dust density of \({(214 \pm 22)}\, \hbox {ng}/{\hbox {cm}}^2\), below LZ requirement of \({500}\, \hbox {ng}/{\hbox {cm}}^2\).

4.3 Rn progeny plate-out

In addition to dust, another source of background in the experiment comes from the environmental radon-laden air itself, with radon daughters plating out onto the surfaces of materials [35] during assembly. To limit plate-out, most assemblies are done in a radon-reduced cleanroom (RCR) at the SAL. The radon-reduced system used in the RCR was built by ATEKO, and is a continuous filtration system constantly circulating air through a cold carbon column to filter out the radon at an overall reduction factor of 2200 leading to an ambient radon level averaging \({<}0.5\, {\hbox {Bq/m}}^{3}\) as measured by LZ. The RCR high recirculation rate of 8500 cubic feet per minute is enough to mostly sweep out radon daughters (particularly \({}^{218}\hbox {Po}\)) before they plate-out onto detector surfaces. Absolute plate-out prevention is however not possible, and the remaining \({}^{218}\hbox {Po}\) that plates out is problematic due to its long-lived \({}^{210}\hbox {Pb}\) daughter which will decay over time in the detector. Therefore, the plate-out rates on assemblies must be calculated.

Plate-out rates onto materials are often estimated using the Jacobi model [27, 36] , which, similar to the original SNO model, describes particle deposition from a balance of influx and outflux of particles in the room assuming that the room contents are well-mixed. This Jacobi model can also be modified to reflect a cleanroom setting, as is the case here [37]. In its original version, the Jacobi model assumes that all surfaces within a given enclosure or a room are equivalent, with radon daughters ending up on all of them in equal concentrations. Under that assumption, the area-normalized plate-out rate (surface activity) depends on the conditions of the enclosure (air circulation rate, Rn concentration, volume, and surface area) within which the material surfaces are exposed. The \({}^{210}\hbox {Pb}\) plate-out rate expressed as the decay rate per unit area and unit time, \(R_p({\hbox {Bq/m}}{^2}/\hbox {s})\), is thus described by Eq. (6):

where \({C_{Rn}}\) is the Rn concentration in the cleanroom (obtained from Durridge Rad7 radon monitors with the monitors’ blank rates subtracted off), \({\lambda _{Pb_{210}}}\) is the \({}^{210}\hbox {Pb}\) decay rate, V is the volume of the cleanroom, A is the surface area within the cleanroom, \({{\Lambda _d =v\frac{A}{V}}}\) is the deposition rate that depends on the diffusion velocity v of radon daughters measured to be between 5 and 15 m/h [36], \({{\Lambda _v = \frac{R}{V}}}\) is the air ventilation rate obtained by dividing the recirculation rate R of the cleanroom HEPA filters by its volume. The ratio \({\frac{\Lambda _d}{\Lambda _d +\Lambda _v}}\) corresponds to the probability that a Rn daughter will plate-out before being carried out by the ventilation; which, for the RCR, was around 0.17.

It is worth noting that the Jacobi model in Eq. (6) is a direct analog of the SNO dust deposition model, as seen by expanding n(D) from Eq. (1) into Eq. (2) and making a number of associations of variables. While the SNO model describes deposition of dust onto horizontal surfaces, the Jacobi model describes deposition of Rn daughters on all surfaces, both controlled by a characteristic velocity in a similar filtration environment. In particular we can identify the particle deposition rate per unit area per unit time in Eq. (6) as \({R_p/\lambda _{Pb_{210}}}\), whereas in Eq. (2) it is expressed as \({6m/\pi \rho D^3}\). The volume-normalized influx \({R_{in}}\) of dust particulates in Eq. (1) is analogous to the volume-normalized rate of production of Rn daughters in Eq. (6), that is, the Rn activity per unit volume, \({C_{Rn}}\). The volume-normalized filtration rate \({R_{AE}}\) from Eq. (1) is directly associated with \({\lambda _v}\) from Eq. (6). The fallout area S from Eq. (1) is associated with the available Rn daughter plate-out area A from Eq. (6). Finally, the stokes velocity v(D) from Eq. (1) is physically similar and mathematically analogous to the Rn daughter diffusion velocity v in Eq. (6).

However, the assumption in the Jacobi model that plate-out does not depend on material type has been shown to be incorrect, particularly for materials at the bottom of the triboelectric series, such as PTFE [38], which could have a plate-out rate M times higher than for neutral metallic materials. An experiment conducted by the SDSM&T measured the M factor to be between 50 and 100 [37]. So for LZ, plate-out rate estimations using the Jacobi model are thus corrected with a multiplicative factor M which has a value of \({M=1}\) for plate-out onto metals, and its highest value \({M=100}\) for plate-out rate on PTFE material surfaces which are naturally charged.

Pictures of some PTFE components (used on the PMT arrays) under UV light before (left and center) and after (right) cleaning with IPA saturated non-shedding mono-filament wipes. Fluorescent specks are dust particulates which are removed after cleaning the pieces in an IPA bath as seen in the right picture

Much of the inner TPC is made from PTFE such that it is essential to mitigate against this high Rn plate-out. This is achieved by neutralizing the PTFE by using air deionizing fan units. These units are ISO 10 cleanroom compatible Simco 4008630-3 Fan Cleanroom Overhead Air Ionizer units which produce continuous ionized air through corona discharge, thus neutralizing the otherwise negatively charged PTFE material. Usage of the fans was taken into account in the plate-out estimations by reducing the correction factor M to the value of 1 for PTFE surfaces, after the fans’ deployment. Indeed, electrostatic field measurements taken at regular time intervals between metallic surfaces and PTFE surfaces placed under air deionizing fan units showed a consistent reading of \({0}\, \hbox {kV}/\hbox {cm}\) within the uncertainty of the measurement device, while similar measurement for PTFE material not placed under these fans read \({\sim }\, {0.6}\, \hbox {kV}/\hbox {cm}\), thus demonstrating the successful neutralization of PTFE under these deionizer units.

The weighted plate-out rate \(R_w\) on a given TPC assembly for a single work shift time period (exposure time T) is thus given by Eq. (7) where M is the plate-out rate multiplicative factor described above, A is the surface area of the individual parts making up the assembly, and \({R_p}\) is the Jacobi plate-out rate per unit area and time obtained from Eq. (6):

The overall plate-out accumulated for all the work shift time periods for that assembly is obtained by combining all the weighted rates as was done previously for the dust estimation.

Plate-out rate estimations are drastically different during and outside working hours (overnight and during weekends). As expected, the plate-out rates outside working hours were found to be negligible, of the order of less than \({1}\%\). Overall, the average plate-out for the inner TPC PTFE surfaces in contact with the LXe is \(R_{avg}= {(158\pm 13)} \, \upmu {\hbox {Bq/m}}^{2}\), which is below the LZ requirement for the TPC of \({500} \, \, \upmu {\hbox {Bq/m}}^{2}\). After construction at the SAL, the TPC was sealed in the ICV before being transported underground where it was kept under N\(_2\) purge making its underground surface contamination negligible.

4.4 Cleanliness protocols to mitigate against dust and Rn-progeny contamination

Following manufacture, most detector components were sent to be cleaned at AstroPak Inc, a certified professional precision cleaning company. After cleaning, detector components were sealed in multiple Rn barrier bags under \({\hbox {N}}_{2}\) purge. The redundancy in the bags also provided layers to shed, thereby helping to reduce carry-in dust when components were brought into the cleanroom after transportation.

Both aluminized mylar and nylon bags have been shown to be very efficient against Rn penetration, with reduction factors of \({2500 \pm 1042}\) and \({130 \pm 3}\) respectively [39]. Once properly bagged, the detector components were shipped to the SAL facility where they were assembled in the RCR to mitigate, as previously mentioned, against surface contamination during assembly. The cleanliness protocols implemented within the cleanroom allowed its air class to always be measured at a significantly lower level (on average less than 10 particles with a size \({\ge 0.5} \, \upmu \hbox {m}\) per cubic foot) than its class 1000 classification.

Upon arrival at the SAL, the outer layer of the shipping bags was removed before sealed components were brought inside the RCR. Inside the cleanroom, each component was un-bagged under deionizing fans to remove static charges on polymer-like materials such as PTFE. They were then inspected under UV light to check for dust particulates, which were cleaned off using Abgenics Essence Gold non-shedding mono-filament wipes saturated with \({99}\%\) pure IPA as a basic cleaning method. Other cleaning methods involved IPA spray or bath followed by blow drying with filtered \({\hbox {N}}_{2}\), ultra-sonic or high-pressure cleaning using deionized water or IPA, and \({\hbox {CO}}_{2}\) blasting depending on the material type and the amount and type of particulates to be removed. In general, small hardware like screws and bolts were ultrasonically cleaned in deionized water and IPA bath. Smooth surface components, like PTFE parts, were wiped down using IPA saturated non-shedding wipes, but this cleaning method could not be used on rough surfaces, like titanium, because of shedding residues. Those were instead cleaned with high pressure deionized water. \({\hbox {CO}}_{2}\) blasting was also used to clean the titanium surfaces to remove chemical residues from Astropak Inc cleaning. As for the PMT cables, wiping them with IPA saturated wipes was inefficient at removing dust. Instead, they were first sprayed with IPA within the droplets of which the dust accumulated. The cable was then gently blow-dried with \({\hbox {N}}_{2}\) thus removing the IPA droplets and the dust contained within.

All these methods have been visually investigated for efficiency before usage, but only the IPA cleaning was quantified, since it was the most used. Figure 4 shows images before and after cleaning of PTFE pieces under UV light, and visually and qualitatively demonstrates the effectiveness of the cleaning. The quantitative estimates of the IPA cleaning protocol were done using tape lifts, as described in Sect. 4.2.2. The tape lifts were taken on sample coupons before and after cleaning for the various cleaning methods. The average dust removal efficiency was found to be about \({80}\%\). For instance, tape lift on sample PTFE before cleaning was of \({700^{+700}_{-100}} \, {\hbox {ng/cm}}^{2}\) and after cleaning was \({100^{+20}_{-9}} \, {\hbox {ng/cm}}^{2}\) yielding \({\sim } ~ {90}\%\) efficiency.

During assembly, several deionizing fans were used to surround the assembly area, and ensured complete neutralization of materials, thereby reducing plate-out as discussed in Sect. 4.3. Usage of these deionizing fans during assembly was particularly important as the assembly process involved extensive manipulation and rubbing which would have otherwise cause charging, increasing the dust and radon-daughter plate-out, particularly on PTFE surfaces.

In addition to the deionizing fans, UV light inspections were conducted at regular time intervals to evaluate dust accumulation on assembly surfaces, and their cleaning was done every day at the beginning of the work shift. When judged necessary, or at the end of a sub-assembly, remedial cleaning of the surfaces was conducted (IPA wiping, IPA bath, vacuuming) with the appropriate cleaning methods, thus removing most of the accumulated dust. Note that, as mentioned previously, remedial cleanings did not remove all the dust, which is why the witness coupons and tape lifts mentioned in Sect. 4.2.1 were still invaluable in assessing the actual amount of dust collected on the assemblies.

Finally, cleanroom garbs worn by personnel working on the assembly were changed after every work shift to reduce carry-in dust, and wiped off with a lint roller multiple times during work to remove particulates that could deposit onto detector surfaces.

At the end of all daily shifts, smaller detector components were sealed in double nylon bags which prevented plate-out since the components were then no longer in contact with the cleanroom air. Larger components like the PMT arrays, on the other hand, had bespoke airtight enclosures, allowing them to be kept under filtered and ventilated air from an extra HEPA filter unit or under \({\hbox {N}}_{2}\) purge, allowing further mitigation against Rn plate-out.

All of the described procedures have ensured that exposure to Rn and dust during the assembly process was minimal, surpassing LZ requirements, as stated, for both dust and plate-out of radon progeny.

5 Selected highlights from the Assay Program

The LZ design sensitivity imposes limits to radioactivity from particular components, principally items such as PMTs which are close to or in contact with the fiducial volume, thus demanding dedicated fixed contamination screening campaigns to meet requirements. The assay program also included dedicated QC and QA elements to ensure radioactivity and cleanliness compliance throughout all manufacturing processes, such as through the construction of the Ti cryostat. Dedicated radon emanation measurement campaigns were performed on complete purification and recirculation sub-systems that may contribute to radon, as well as in-situ measurements of the inner cryostat with the TPC sealed within. The assay program also included construction and deployment of a dedicated detector system to determine radioactivity in the GdLS for the LZ OD system. In the following sub-sections, we present these dedicated campaigns in order to illustrate through specific examples the deployment of fixed contaminant assays, QA, radon assays, and detector construction and deployment.

5.1 Hamamatsu R11410 PMT HPGe Assay Program

LZ employs three different models of PMT. The main active volume will be viewed by 494 76 mm (3-inch) Hamamatsu R11410 PMTs. Other regions containing xenon are instrumented using a combination of 30mm Hamamatsu R8520 and 56mm Hamamatsu R8778 PMTs with the latter having been repurposed having been used in the LUX dark matter experiment [40]. Additionally, the LZ OD system is instrumented using 202mm (8-inch) Hamamatsu R5912 PMTs.

The radioactive background of the R11410 PMTs is of particular importance as these sit adjacent to the main active volume of LZ. In order to ensure that these met the intrinsic radioactivity requirements of 3.0/3.0/30/2.5 mBq/PMT for \({}^{238} \hbox {U}\)/\({}^{232} \hbox {Th}\)/\({}^{40} \hbox {K}\)/\({}^{60} \hbox {Co}\), respectively, a comprehensive screening program was conducted. Initially, a subset of the raw material used for the construction of the tubes was screened across detectors both at SURF and at Boulby, and from these measurements, a bottom-up prediction of the intrinsic radioactivity of the final tubes was calculated. This calculation is discussed in detail in [3].

Following the raw material screening program, the collaboration was satisfied that PMTs of the required radiopurity could be produced. However, even with knowledge of the radiopurity of the raw materials, it was important to repeat the screening process for the final tubes. This required substantial gamma-ray spectroscopy detector time both at SURF and at Boulby. The program began with an initial batch of tubes being screened at Boulby between August 2016 and February 2017. Over 32 weeks, 102 PMTs were screened and a substantial amount of background data was acquired. Figure 5 shows comparisons between a combination of all PMT runs on the detectors used in this campaign. For protection and cleanliness purposes, the R11410 PMTs assayed at Boulby were screened with PTFE tape wrapped around their body and with protective foam on the pins at the base of the PMT. Subsequently, the tape and foam were screened and their contribution (along with the contribution from the holder and detector setup backgrounds) subtracted to give final contamination levels for the tubes presented here. Screening of tubes at SURF was performed following performance testing at Brown University for which the foam and PTFE tape needed to be removed. No additional correction was required for this data. The full PMT screening program assayed 229 of the 494 R11410 tubes used in the LZ detector.

The tests of individual components showed that the radioactive contaminants were not uniformly distributed. Not only is this the case, but the relative levels of \({}^{238} \hbox {U}\), \({}^{232} \hbox {Th}\) and \({}^{40} \hbox {K}\) were different in each component. Ordinarily, when calculating a geometric efficiency for an assayed material or component (using GEANT4 [41] in this case), gamma-rays are fired uniformly from the component being studied. In order to allow for non-uniform distribution of radioactivity when determining specific activities for the assayed PMTs, geometric efficiency curves had to be calculated for individual isotopes. The distribution of simulated gamma-rays was determined using the expected contamination distribution. This is detailed in Table 6 where the three largest components (both by mass and, in the case of the ceramic stem, by radioactive content) are used to represent the whole PMT. In the case of all other isotopes (detailed in Tables 7 and 8), the contamination was assumed to be distributed uniformly.

The expected distributions of contamination detailed in Table 6 do not take into account one important unknown factor: the distribution of \({}^{40} \hbox {K}\) as the process of forming a PMT photocathode requires the evaporation of potassium onto the inside of the quartz window face of the PMT. This adds a substantial systematic uncertainty to the final measured values of \({}^{40} \hbox {K}\) in this study. As an approximation, the distribution of \({}^{40} \hbox {K}\) in the PMTs was modified in order to give a reasonable systematic error on each setup. The systematic error is set assuming a distribution of 0.1, 0.45 and 0.45 for the ceramic, the Kovar and the quartz face, respectively. In the case of the Chaloner detector, where PMTs are placed so that the pins are the closest part to the front face of the detector and the quartz window the furthest, a systematic error of \({125}\%\) is calculated. In the case of SOLO, where PMTs uniformly surround the detector, there is no substantial systematic error as the geometric efficiency has a very weak dependence on the distribution of \({}^{40} \hbox {K}\) in the PMTs. The systematic errors for \({}^{40} \hbox {K}\) are captured in Table 6. In all other isotopes, it was assumed that the distribution of radiocontaminants follows expectation so only statistical errors are presented.