Abstract

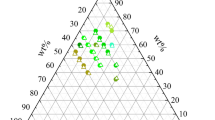

The viscosities of the slags of the CaO–SiO2–Cr2O3–3% Al2O3–8% MgO–6% B2O3 system over a wide range of their chemical compositions are studied using the simplex lattice method of experimental design. For each viscosity, an adequate mathematical model described by a reduced third-degree polynomial is constructed. The results of mathematical modeling are presented graphically in the form of composition–viscosity diagrams. The slags in the composition region with a basicity of 1.5–2.0 are found to have a high fluidity in the temperature range 1600–1700°C: their viscosity does not exceed 0.3 Pa s.

Similar content being viewed by others

Notes

From here on, the contents of the slag components are given in wt %.

REFERENCES

O. K. Tokovoi, Argon–Oxygen Refining of Stainless Steel (Izd. Tsentr YuUrGU, Chelyabinsk, 2015).

V.-V. Visuri, M. Järvinen, J. Savolainen, P. Sulasalmi, E.-P. Heikkinen, and T. A. Fabritius, “Mathematical model for the reduction stage of the AOD process. Part II. Model validation and results,” ISIJ Int. 53 (4), 613–612 (2013).

Z. Kalicka, E. Kawecka-Cebula, and K. Pytel, “Application of the Iida model for estimation of slag viscosity for Al2O3–Cr2O3–CaO–CaF2 systems,” Arch. Metall. Mater. 54 (1), 179–187 (2009).

I. A. Magidson, A. S. Morozov, M. F. Sidorenko, L. K. Kosyrev, and V. P. Kolesnikov, “Viscosity of chromium slags,” Izv. Vyssh. Uchebn. Zaved., Chern. Metall., No. 11, 61–64 (1973).

D. A. Dyudkin and V. V. Kisilenko, Secondary Steel Processing (Teplotekhnik, Moscow, 2010).

X. P. Hong, “Fluorine and acid pollutant within soil around three coal-rich areas in China,” Ph. D. Thesis, China University Mining and Technology, Beijing, China, 2018. http: //cdmd.cnki.com.cn/Article/CDMD-11413-1018096977.htm. Accessed October 18, 2022.

Zh. Zhao, J. Zhao, Z. Tan, B. Qu, L. Lu, and Ya. Cui, “Effect of the heating rate and premelting process on the melting point and volatilization of a fuorine-containing slag,” Sci. Reports. 10 (1), 11254 (2020).

L. Zhang, W. Wang, S. Xie, K. Zhang, and I. Sohn, “Effect of basicity and B2O3 on the viscosity and structure of fluorine-free mold flux,” J. Non-Cryst. Solids 460, 113–118 (2017).

Y. Sun, J. Liao, K. Zheng, X. Wang, and Z. Zhang, “Effect of B2O3 on the structure and viscous behavior of Ti-bearing blast furnace slags,” JOM 66 (10), 2168–2175 (2014).

A. A. Babenko, L. A. Smirnov, A. G. Upolovnikova, A. N. Smetannikov, and A. V. Sychev, “Theoretical bases and technology of steel exhaustive metal desulfurization and direct microalloying with boron beneath basic boron-containing slags,” Metallurgist 63 (11, 12), 1259–1265 (2020).

V. A. Kim, E. I. Nikolai, A. A. Akberdin, et al., Experiment Design in Studying the Physicochemical Properties of Metallurgical Slags: Methodological Guide (Nauka, Alma-Ata, 1989).

A. A. Babenko, V. I. Zhuchkov, A. G. Upolovnikova, and I. N. Kel’, “Studying the viscosity of CaO–SiO2–B2O3–25% Al2O3–8% MgO slags,” Izv. Vyssh. Uchebn. Zaved., Chern. Metall. 60 (10), 820–825 (2017).

V. A. Kim, A. A. Akberdin, I. S. Kulikov, et al., “Use of the simplex lattice method for constructing composition–viscosity diagrams,” Izv. Vyssh. Uchebn. Zaved., Chern. Metall., No. 9, 167 (1980).

Funding

This work was carried out in terms of state assignment no. AAA-A19-119020690017-0 NIOKTR to the Institute of Metallurgy, Ural Branch, Russian Academy of Sciences.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

The authors declare that they have no conflicts of interest.

Additional information

Translated by K. Shakhlevich

Rights and permissions

About this article

Cite this article

Babenko, A.A., Shartdinov, R.R., Smetannikov, A.N. et al. Construction of Viscosity Diagrams for Slags Containing Chromium and Boron Oxides by the Simplex Lattice Method. Russ. Metall. 2023, 602–605 (2023). https://doi.org/10.1134/S0036029523050026

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0036029523050026