Abstract

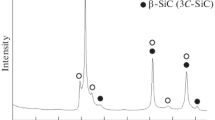

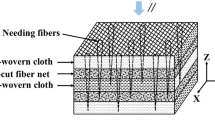

Methods for the production and application of ultrafine β silicon carbide fibers for hardening metal matrix composite materials based on Al and Mg are developed. The fundamental possible application of the fabricated fibrous silicon carbide for creating Al–SiC and Mg–SiC composites by liquid-phase stirring without additional wetting reagents under a layer of protective fluxes at the melting temperature of the matrix alloy is shown. Ultrafine SiC is found to be uniformly distributed over the composite volume. The microhardness of the sample surface increases with the silicon carbide content as compared to the initial materials and composites made from other silicon carbide modifications.

Similar content being viewed by others

REFERENCES

V. N. Gulbin, V. A. Popov, and I. Sevostiyanov, “Metal matrix composites reinforced with the high-strength nanopowders,” Nanoindustriya, No. 1, 16–19 (2007).

E. N. Kablov, “Innovative developments of the FSUE VIAM SSC of RF for the realization of ‘Strategic Directions in Developing Materials and Their Processing Technologies up to 2030,’” Aviats. Mater. Technol. 34 (1), 3–33 (2015).

H. M. Zakaria, “Microstructural and corrosion behavior of Al/SiC metal matrix composites,” Ain Shams Eng. J. 5, 831–838 (2014).

Ch.-P. Li, Zh.-G. Wang, M. Zha, Ch. Wang, H.‑Ch. Yu, H.-Yu. Wang, and Q.-Ch. Jiang, “Effect of preoxidation treatment of nano-sic particulates on microstructure and mechanical properties of SiC/Mg–8Al–1Sn composites fabricated by powder metallurgy combined with hot extrusion,” Materials (Basel) 9 (12), 964 (2016). https://doi.org/10.3390/ma9120964

G. Roewer, U. Herzog, K. Trommer, et al. “Silicon carbide. A survey of synthetic approaches, properties and applications,” Struct. Bonding 101, 59–135 (2002).

V. M. Efremenkova and V. G. Sevast’yanov, “Information support of the silicon carbide research,” Nauchno-Tekh. Inf. Ser. 1. Org. Met. Inform. Rab., No. 9, 16 (2004).

E. Stephen, Advances in Silicon Carbide Processing and Applications, Ed. by Saddow Anant Agarwal (Artech House, Boston, London, 2004).

V. P. Rastegaev, “Production of the semiconductor silicon carbide single crystals in vacuum,” Perspekt. Mater., No. 2, 43–48 (2008).

L. S. Ratkin, “New developments of the Russian Academy of Sciences in the field of nanotechnologies,” Nano Microsyst. Tech., No. 4, 2–4 (2010).

Silicon Carbide: Technology, Properties, and Application, Ed. by A. E. Belyaeva and R. V. Konakova, (ISMA, Kharkov, 2010).

M. Mukherjee, Silicon Carbide—Materials, Processing and Applications in Electronic Devices, Ed. by M. Mukherjee (InTech., 2011).

V. M. Kevorkijan, M. Komak, and D. Kolar, “Low-temperature synthesis of sinterable SiC powders by carboth ermic reduction of colloidal SiO2,” Mater. Sci. 27, 2705–2712 (1992).

H. P. Martin, R. Ecke, and E. Muller, “Synthesis of nanocrystalline silicon carbide powder by carbothermal reduction,” Eur. Ceram. Soc. 18, 1737 (1998).

W. Wesch, “Silicon carbide: synthesis and processing,” Nucl. Instrum. Methods Phys. Res. B. 116, 305 (1996).

V. G. Sevastyanov, E. P. Simonenko, Yu. S. Ezhov, and N. T. Kuznetsov, “Thermodynamic analysis of the production of silicon carbide via silicon dioxide and carbon,” Mater. Sci. Forum 59, 457–460 (2004).

Z. Ju, L. Xu, Q. Pang, Z. Xing, X. Ma, and Y. Qian, “The synthesis of nanostructured SiC from waste plastics and silicon powder,” Nanotechnology, No 2, 20–55 (2009).

S. M. Oh, M. Cappelli, and D. W. Park, “Preparation of nano-sized silicon carbide powder using thermal plasma,” Korean J. Chem. Eng. 19, 903–907 (2002).

V. D. Krstic, “Production of fine, high-purity beta silicon carbide powders,” Am. Ceram. Soc. 75, 170–174 (1992).

V. G. Sevast’yanov, R. G. Pavelko, and N. T. Kuznetsov, “The effect of the nature of the fine carbon precursors on the morphology of the silicon carbide nanoparticles,” Chim. Technol. 1, 12–17 (2007).

S. D. Kurbakov and T. A. Mireev, “Precipitation of the high-density silicon carbide coatings at pyrolysis of the silane chloride derivatives in the fluidized bed,” Khim. Tverd. Topl., No. 2, 60–72 (2009).

B. Babić, D. Bučevac, A. Radosavljević-Mihajlović, A. Došen, et al. “New manufacturing process for nanometric SiC,” J. Eur. Ceram. Soc. 32 (9), 1901–1906 (2012).

L. Wang, S. Dimitrijev, J. Han, F. Iacopi, and J. Zou, “Transition between amorphous and crystalline phases of SiC deposited on Si substrate using H3SiCH3,” J. Cryst. Growth 311 (19), 4442–4446 (2009).

M. P. Orthnerz, L. W. Rieth, and F. Solzbacher, “Design and performance of an LPCVD reactor for the growth of 3C-silicon carbide,” Electrochem. Soc. 92 (6), 1296–1302 (2009).

H. ElGazzar, H. G. Abdel-Rahman Salem, and F. Nassar, “Preparation and characterizations of amorphous nanostructured SiC thin films by low energy pulsed laser deposition,” Appl. Surf. Sci. 256, 2056–2060 (2010).

L. K. Orlov, E. A. Steinman, T. N. Smyslova, N. L. Ivina, and A. N. Tereshchenko, “Peculiarities and mechanisms of the silicon carbide film growth on silicon,” Fiz. Tverd. Tela 54 (4), 666–672 (2012).

I. K. Beisembetov, K. Kh. Nusupov, N. B. Beisenkhanov, S. K. Zharikov, B. K. Kenzhaliev, T. K. Akhmetov, and B. Zh. Seitov, “Synthesis of the SIC thin films on the Sl substrates by the ion-beam spraying method,” Poverkhnost., No. 4, 81 (2015).

E. López-Honorato, P. J. Meadows, J. Tan, and P. Xiao, “Control of stoichiometry, microstructure, and mechanical properties in SiC coatings produced by fluidized bed chemical vapor deposition,” Mater. Res. Soc. Symp. Proc. 23, 1785–1796 (2008).

Y. Hwang, D.-H. Riu, H.-J. Kang, J.-H. An, W. S. Jung, D. Chun, and Y. Kim, “Carbothermal synthesis of β‑SiC powders from silicon and SiO2-coated carbon powders,” Int. J. Mater. Res. 105 (4), 392–396 (2014).

V. I. Gorovenko, V. A. Knyazik, and A. S. Shteinberg, “High-temperature interaction between silicon and carbon,” Ceram. Int. 19 (2), 129–132 (1993).

V. N. Anfilogov, A. S. Lebedev, V. M. Ryzhkov, and I. A. Blinov, “Carbothermal synthesis of nanoparticulate silicon carbide in a self-contained protective atmosphere,” Inorg. Mater. 52 (7), 655–660 (2016).

V. N. Anfilogov, A. S. Lebedev, and V. M. Ryzhkov, “Carbothermal synthesis of nanosized silicon carbide under an autonomous protective atmosphere,” Dokl. Chem. 460 (1), 10–12 (2015).

A. S. Lebedev, V. E. Eremyashev, E. A. Trofimov, and V. N. Anfilogov, “Thermodynamic analysis of the interaction of components in the Si–C–O system in the carbothermic synthesis of silicon carbide,” Dokl. Chem. 484 (2), 41–43 (2019).

V. N. Anfilogov and A.S. Lebedev, “Method of carbothermal synthesis of fine silicon carbide powders,” RF Patent 2537616, Byull. Izobret., No. 1 (2015).

B. Venkatesh and B. Harish, “Mechanical properties of metal matrix composites (Al/SiCp) particles produced by powder metallurgy,” Int. J. Eng. Res. Gen. Sci. 3, 1277–1284 (2015).

E. N. Kablov, B. V. Shchetanov, A. A. Shavnev, A. N. Nyafkin, et al., “Properties and application of the highly filled Al–SiC metal matrix composite material,” Vestn. Novgorod. Gos. Univ. 3 (1), 56–59 (2011).

M. Esmaily, N. Mortazavi, J. E. Svensson, M. Halvarsson, and M. A. Wessen, “New semi-solid casting technique for fabricating SiC-reinforced Mg alloys matrix composites,” Composites B 94, 176–189 (2016).

T. Xiangrong, A. Zhu, J. Wei, and R. Han, “Preparation and forming technology of particle reinforced aluminum matrix composites,” Mater. Sci. Adv. Compos. Mater., 1–9 (2017).

S. Yu. Khripchenko and P. A. Oborin, “Device for stirring the molten aluminium alloy (variants),” RF Patent 2567970, Byull. Izobret., No. 31 (2015).

S. Yu. Khripchenko, S. A. Denisov, V. M. Dolgikh, and A. M. Pavlinov, “Use of a travelling magnetic field “rod” inductor for stirring molten metal in an aluminum bath,” Magnetohydrodynamics 52, 407–416 (2016).

S. Yu. Kripchenko, L. V. Nikulin, V. M. Dolgikh, and S. A. Denisov, “Structure and properties of the ingots made of the aluminum-silicon alloy produced by the magnetohydrodynamic influence,” Tsvetn. Met., No. 6, 82–86 (2014).

P. S. Pershin, A. V. Suzdaltsev, and Yu. P. Zaikov, “Synthesis of silumins in KF–AlF3–SiO2 melts,” Electrochem. Soc. D 163 (5), 167–170 (2016).

Funding

This work was performed within the scope of a state assignment of the Ministry of Education and Science of the Russian Federation (project no. 5–100, state assignment no. 11.9643.2017/8.9) and supported in part by the program of basic research of the Ural Branch of the Russian Academy of Sciences (project no. 18-10-5-16, Creation of ceramic and metal ceramic composites based on ultrafine silicon carbide).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by T. Gapontseva

Rights and permissions

About this article

Cite this article

Lebedev, A.S., Eremyashev, V.E., Suzdal’tsev, A.V. et al. Hardening of Light Metals and Alloys with Ultrafine Fibrous β Silicon Carbide. Russ. Metall. 2020, 682–686 (2020). https://doi.org/10.1134/S0036029520060129

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0036029520060129