Abstract

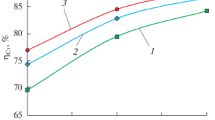

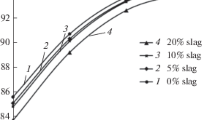

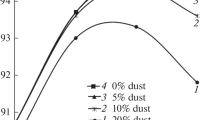

The results of a thermodynamic simulation of the reduction of the elements of the oxide system corresponding to the chromium ore composition (%) 40 Cr2O3, 21 FeO, 15 Al2O3, 6 SiO2, 16 MgO, 2 CaO, and 0.006 P2O5 by the silicon of ferrosiliconickel (28 Fe, 65 Si, 7 Ni) are presented. The HSC Chemistry 6.12 software (Outokumpu Research Oy, Finland) is used for the simulation. The thermodynamic simulation is performed for seven compositions of an ore–lime mixture differed in the CaO content (17–55%). The calculations are performed using the Equilibrium Compositions module at 1700°C, the reducer consumption 1.05mred (mred is the reducer weight stoichiometrically necessary for the reduction of chrome and iron), and the gas phase pressure 0.1 MPa (1 atm). The main results of the calculations performed are given in graphical dependences of the change in the degree of reduction of chromium (ηCr), the amount of silicon used in reduction (φSi), and the chemical compositions of the metal and slag on the slag basicity (CaO)/(SiO2) and the reducer consumption. The degree of reduction of chromium increases by 32.7% (from 64 to 95.1%) in the range of an increase in the slag basicity from 0.07 to 1.86 at φSi = 94.5%. The rational basicity of slag is shown to be 1.86–1.9. The metal of the following chemical composition is formed: 50.4 Cr, 1.97 Si, 3.3 Ni, 0.21 Al, 0.0050 P, and Fe for balance. The influence of the amount of reducer on the degree of reduction of chromium and the chemical compositions of the metal and slag at 1700°C and a slag basicity of 1.86 is studied. An increase in the reducer consumption from 0.5mred to 1.05mred makes it possible to increase the reduction of chromium by 52.4% and to reach ηCr = 95.1%, which is close to the industrial parameters of low-carbon ferrochrome manufacturing. 100% degree of reduction of chromium is achieved at the reducer consumption 2.5mred. The results of the thermodynamic simulation can be used for technological calculations of the reduction of chromium ore elements by ferrosiliconickel.

Similar content being viewed by others

REFERENCES

M. I. Gasik and N. P. Lyakishev, Theory and Technology of Electrometallurgical Ferroalloys (Intermet Inzhiniring, Moscow, 1999).

M. A. Ryss, Production of Ferroalloys (Metallurgiya, Moscow, 1985).

A. F. Kablukovskii, Production of Ferroalloys (Akademkniga, Moscow, 2003).

I. D. Storozhenko and E. V. Kovriga, “Thermodynamics of alloying elements and solutions of oxygen in the Fe–Cr–Si system,” Sovremennye Naukoemkie Tekhnologii, No. 9, 65–66 (2013).

Z. Tsikaridze, I. Janelidze, R. Razmadze, and J. Bagdavadze, “Thermodynamic analysis of carbothermal reduction of the mixture of Cr2O3 and MnO oxides,” Bul. Georg. Nat. Acad. Sci. 5 (3), 77–78 (2011).

T. R. Curr, L. R. Nelson, and L. B. McRae, “The selective carbothermic reduction of chromite” in Proceedings of the 8th International Ferroalloys Congress INFACON-98 (Beijing, 1998), pp. 158–170.

E. N. Akimov, A. V. Senin, and V. E. Roshchin, “Thermodynamic analysis of production of low-carbon ferrochrome using the model of associated solutions,” Vestn. YuUrGU. Ser. Met. 13 (1), 182–184 (2013).

N. M. Tanklevskaya and G. G. Mikhailov, “Thermodynamic analysis of the possibility of production of low-carbon ferrochrome from local ores,” in Proceedings of the XII Russian Seminar on Computer Simulation of Physicochemical Properties of Glasses and Melts (Kurgan Gos. Univ., Kurgan, 2014), pp. 42–44.

Y.-L. Zhang, L. Yang, and W.-J. Wei, “Carbothermal reduction process of the Fe–Cr–O system,” Int. J. Mineral. Met. Mater. 20 (10), 931–940 (2013).

J. Gutierrez-Paredes, A. Romero-Serrano, G. Plascencia-Barrera, M. Vargas-Ramirez, B. Zeifert, and V. Arredondo-Torres, “Chromium oxide reduction from slag by silicon and magnesium,” Steel Res. Int. 76 (11), 764–768 (2005).

M.-A. Van Ende, M. Guo, P. T. Jones, B. Blanpain, and P. Wollants, “Manganese and chromium distribution between CaO–SiO2–MgOsat–CrO1.5–MnO slags and Fe–Cr–Mn stainless steel,” ISIJ Int. 48 (10), 1331–1338 (2008).

O. V. Zayakin and V. I. Zhuchkov, “Preparation and properties of new nickel alloys,” in Proceedings of the IV International Scientific Technical Conference on Modern Technologies of Mastering Mineral Resources (GUTsMIZ, Krasnoyarsk, 2006), pp. 379–381.

V. I. Zhuchkov, L. I. Leont’ev, E. N. Selivanov, O. V. Zayakin, and A. A. Babenko, “Prospects of production of stainless steel using domestic chromium and nickel ferroalloys,” in Proceedings of the International Scientific Practical Conference on Modern Tendencies in the Area of Theory and Practice of Mining and Processing of Mineral and Man-Caused Raw Materials (UMTs UPI, Yekaterinburg, 2014), Vol. II, pp. 210–215.

O. V. Zayakin, “Development of the rational composition of the technology of production of nickel-containing ferroalloys from depleted oxidized nickel ores,” Cand. Sci. (Eng.) Dissertation (Yekaterinburg, 2002).

L. L. Gal’perin, O. V. Zayakin, Ya. I. Ostrovskij, N. F. Kirichenko, and V. I. Zhuchkov, “Particularities in production of high-carbon ferrochrome,” Stahl., No. 11, 47–49 (2003).

A. Roine, Outokumpu HSC Chemistry for Windows. Chemical Reactions and Equilibrium Software with Extensive Thermochemical Database (Outokumpu Res. OY, Pori, 2002).

A. V. Sychev, V. A. Salina, A. A. Babenko, and V. I. Zhuchkov, “Distribution of boron between oxide slag and steel,” Steel Trans. 47 (2), 105–107 (2017).

V. A. Salina, A. V. Sychev, V. I. Zhuchkov, and A. A. Babenko, “Thermodynamic modeling of metal desulfurization with boron-containing slags of the CaO–SiO2–MgO–Al2O3–B2O3 system,” Steel Trans. 47 (12), 768–771 (2017).

V. A. Salina, O. V. Zayakin, and V. I. Zhuchkov, “Thermodynamic simulation of the preparation of a complex alloy of the Fe–Cr–Ni system for melting stainless steel,” in Proceedings of the IX Toraigyrov International Scientific Practical Conference (Pavlodar Gos. Univ., Pavlodar, 2017), pp. 102–107.

V. A. Salina, O. V. Zayakin, and V. I. Zhuchkov, “Study of the silicothermic method for the production of complex nickel- and chromium-containing ferroalloys by thermodynamic simulation,” Nauka Tekhn. Kazakhstana, Nos. 3–4, 85–90 (2017).

Funding

This work was supported by the Russian Foundation for Basic Research, project no. 16-03-00092.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by E. Yablonskaya

Hereafter, the component contents are given in wt %.

Rights and permissions

About this article

Cite this article

Salina, V.A., Zayakin, O.V. & Zhuchkov, V.I. Thermodynamic Simulation of the Silicothermic Reduction of Chromium Ore Elements. Russ. Metall. 2020, 11–16 (2020). https://doi.org/10.1134/S0036029520010127

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0036029520010127