Abstract

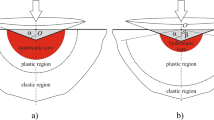

The structure formation in the production of capillary copper tubes is studied using the computational methods of deformable medium mechanics and structural and texture analyses. It is found that intense deformation develops in the real process at a percent reduction up to 99.998%, and the strain tensor components are shown to be nonuniformly distributed. The predominance of the tangential component of the strain tensor leads to the formation of grains with long axes located along the longitudinal and radial coordinate axes near the inner surface of a capillary tube. Texture analysis supports these conclusions.

Similar content being viewed by others

References

A. I. Eideyus and V. L. Koshelev, “Determination of the characteristics of capillary tubes,” Vestn. Mezhd. Akedemii Kholoda, No. 1, 25–27 (2009).

V. S. Parshin, V. I. Boyarkin, and A. M. Antimonov, “Calculation of the tool for the drawing of thick-walled tubes on a self-holding mandrel,” Tsvetn. Met., No. 4, 55–57 (1977).

N. I. Mukhin and Yu. F. Shevyakin, “Bull-block drawing of small-diameter thick-walled tubes,” Tsvetn. Met., No. 12, 44–46 (1974).

Yu. N. Loginov, M. S. Shalaeva, and A. S. Ovchinnikov, “On the hypothesis of fracture of the inner surface of capillary copper tubes in drawing,” Kuzn. Shtamp. Proizv. Obrab. Metallov Davleniem, No. 12, 3–9 (2011).

N. I. Mukhin, M. I. Temkin, V. M. Poyarkov, and V. V. Klyukvin, “Production of capillary tubes from copper by bull-block drawing,” Tsvetn. Met., No. 2, 57–60 (1975).

G. L. Kolmogorov, V. I. Boyarkin, and I. M. Mishutin, “Drawing of capillary tubes under hydrodynamic friction conditions,” Tsvetn. Met., No. 9, 51–53 (1974).

V. M. Segal, V. I. Reznikov, A. E. Drobyshevskii, and V. I. Kopylov, “Simple shear plastic treatment of metals,” Metals, No. 1, 115–123 (1981).

R. Z. Valiev and R. K. Islamgaliev, “Structure and mechanical behavior of ultrafine-grained metals and alloys subjected to severe plastic deformation,” Fiz. Met. Metalloved. 85, 161–177 (1998).

R. Arruffat-Massion, L. S. Toth, and J.-P. Mathieu, “Modeling of deformation and texture development of copper in a 120° ECAE die,” Scripta Materialia 54, 1667–1672 (2006).

V. N. Chuvil’deev and V. I. Kopylov, “Recrystallization in nano- and microcrystalline metals produced by ECAP,” Mikrosistemnaya Tekhnika, No. 8, 25–31 (2002).

I. J. Beyerlein and L. S. Tóth, “Texture evolution in equal-channel angular extrusion,” Prog. Mater. Sci. 54, 427–510 (2009).

M. Haouaoui, K. Ted Hartwig, and E. Andrew Payzant, “Effect of strain path on texture and annealing micro-structure development in bulk pure copper processed by simple shear,” Acta Materialia 53, 801–810 (2005).

Yu. N. Loginov, A. G. Illarionov, S. Yu. Klyueva, and M. A. Ivanova, “Deformations and structure of metal during cold butt-seam welding of copper blanks,” J. Non-Ferrous Metals 53(1), 45–53 (2012).

Yu. N. Loginov, S. L. Demakov, A. G. Illarionov, and A. A. Popov, “Effect of the strain rate on the properties of electrical copper,” Russ. Metall. (Metally), No. 3, 194–201 (2011).

S. Ivanova, B. Stanoevich, and D. Markovich, “Effect of high strains on the texture of copper wire,” Tsvetn. Met., No. 3, 71–73 (2002).

T. Baudin, A. L. Etter, and R. Penelle, “Annealing twin formation and recrystallization study of cold-drawn copper wires from EBSD measurements,” Mater. Characterization 58, 947–952 (2007).

M. M. Borodkina and E. N. Spektor, X-ray Diffraction Analysis of the Texture of Metrals and Alloys, (Metallurgiya, Moscow, 1981).

Yu. N. Loginov, S. L. Demakov, A. G. Illarionov, and M. S. Karabanalov, “Deformation calculation and experimental investigation of the texture in a cold-worked copper wire,” Def. Razr. Mater., No. 5, 38–44 (2011).

S. L. Demakov, Yu. N. Loginov, A. G. Illarionov, M. A. Ivanova, and M. S. Karabanalov, “Effect of annealing temperature on the texture of copper wire,” Phys. Metals and Metallography 113(7), 681–686 (2012).

Author information

Authors and Affiliations

Corresponding author

Additional information

Original Russian Text © Yu.N. Loginov, M.S. Shalaeva, S.L. Demakov, M.A. Ivanova, A.G. Illarionov, 2014, published in Metally, 2014, No. 3, pp. 28–33.

Rights and permissions

About this article

Cite this article

Loginov, Y.N., Shalaeva, M.S., Demakov, S.L. et al. Severe deformation, structure, and texture of the metal in the production of capillary copper tubes. Russ. Metall. 2014, 372–376 (2014). https://doi.org/10.1134/S0036029514050061

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0036029514050061