Abstract

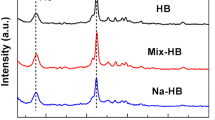

The catalytic properties of a number of FAU (Y) zeolite samples (microporous zeolite H-Y, granular hierarchical zeolite H-Yh, zeolite H-USYh dealuminated by high-temperature steam treatment (HTST), and zeolite H-USYh a.t. dealuminated by HTST with subsequent acid treatment) in the oligomerization of 1-pentene. The samples were characterized by X-ray fluorescence analysis, X-ray powder diffraction analysis, low-temperature nitrogen adsorption–desorption, scanning electron microscopy, and temperature-programmed desorption of ammonia. It was determined that the total yield of pentene oligomers under the studied conditions (150°С, 10 wt % catalyst, 5 h) decreases in the order H-USYh a.t. (93%) ≈ H-Yh (93%) > H-Y (74%) > H-USYh (70%). The dealuminated sample H-USYh a.t., which has the largest mesopore volume, showed high stability in 1-pentene oligomerization at 180°C. The conversion of the monomer in its presence remained unchanged during 5 cycles of operation without catalyst regeneration, and the yield of pentene oligomers after 5 cycles decreased by 39%. Microporous zeolite H-Y lost activity already after the second cycle.

Similar content being viewed by others

REFERENCES

Cejka, J., Corma, A., and Zones, S. Zeolites and Catalysis: Synthesis, Reactions and Applications, Weinheim: Wiley, 2010.

Kerstens, D., Smeyers, B., Van Waeyenberg, J., Qiang Zhang, Q., Yu, J., and Sels, B.S., Adv. Mater., 2020, vol. 32, no. 44., 2004 690.

Chen, L.-H., Sun, M.-H., Wang, Zh., Yang, W., Xie, Z., and Su, B.-L., Chem. Rev., 2020, vol. 120, vol., 20, p. 11194.

Corma, A., Martínez, C., and Doskocil, E., J. Catal., 2013, vol. 300, p. 183.

Zhang, L., Ke, M., Song, Z., Liu, Ya., Shan, W., Wang, Q., Xia, Ch., Li, Ch., and He, Ch., Catalysts, 2018, vol. 8, no. 8, p. 298.

Moon, S., Chae, H.J., and Park, M.B., Appl. Catal., A, 2018, vol. 553, p. 15.

Monama, W., Mohiuddin, E., Thangaraj, B., Mdleleni, M.M., and Key, D., Catal. Today, 2020, vol. 342, p. 167.

Chal, R., Gérardin, C., Bulut, M., and van Donk, S., Chem. Cat. Chem., 2011, vol. 3, p. 67.

Wei, Y., Parmentier, T.E., de Jong, P.K., and Zečević, J., Chem. Soc. Rev., 2015, vol. 44, p. 7234

Feliczak-Guzik, A., Microporous Mesoporous Mater., 2017, vol. 259, p. 33.

Jia, X., Khan, W., Wu, Z., Choi, J., and Yip, A.C.K., Adv. Powder Technol., 2019, vol. 30, p. 467.

Patent RF No. 2456238, 2012.

Patent RF No. 2739350, 2020.

Kutepov, B.I., Travkina, O.S., Agliullin, M.R., Khazipova, A.N., Pavlova, I.N., Bubennov, S.V., Kostyleva, S.A., and Grigor’eva, N.G., Pet. Chem., 2019, vol. 59, p. 297.

Travkina, O.S., Agliullin, M.R., Filippova, N.A., Khazipova, A.N., Danilova, I.G., Grigor’eva, N.G., Narender, N., Pavlov, M.L., and Kutepov, B.I., RSC Adv., 2017, vol. 7. P. 32581.

Breck, D.W., Zeolite Molecular Sieves: Structure, Chemistry, and Use, New York: Wiley, 1973.

Silaghi, M.-Ch., Chizallet, C., and Raybaud, P., Microporous Mesoporous Mater, 2014, vol. 191, p. 82.

van Donk, S., Broersma, A., Gijzeman, O.L.J., van Bokhoven, J.A., Bitter, J.H., and de Jong, K.P., J. Catal., 2001, vol. 204, p. 272.

Verboekend, D., Chabaneix, A.M., Thomas, K., Gilson, J.-P., and Pérez-Ramírez, J., CrystEngComm, 2011, vol. 13, p. 3408.

Funding

This work was performed under state assignment for the Institute of Petrochemistry and Catalysis, Ufa Federal Research Center, Russian Academy of Sciences, Ufa, Russia (subject no. FMRS-2022-0080). The study of the synthesis of pentene oligomers was supported by the Russian Foundation for Basic Research (project no. 20-33-90120). The structural studies were carried out at the Agidel’ Regional Center for Shared Equipment Use, Ufa Federal Research Center, Russian Academy of Sciences, under state assignment for the Institute of Petrochemistry and Catalysis (subject no. FMRS-2022-0081).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

The authors declare that they have no conflicts of interest.

Additional information

Translated by V. Glyanchenko

Abbreviations and notation: HTST, high-temperature heat treatment; DC, degree of crystallinity; XRD, X-ray powder diffraction analysis.

Rights and permissions

About this article

Cite this article

Serebrennikov, D.V., Grigor’eva, N.G., Khazipova, A.N. et al. Granulated Hierarchical Zeolite Y and Dealuminated Samples Based on It in Pentene Oligomerization. Kinet Catal 63, 577–584 (2022). https://doi.org/10.1134/S0023158422050093

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0023158422050093