Abstract

Environmental pollution is a major issue today due to the release of dyestuff waste into the environment through industrial wastewater. There is a need for affordable and effective adsorbents to remove harmful dyes from industrial waste. In this study, Mandarin biochar-CO-TETA (MBCOT) adsorbent was prepared and used to remove Acid Red 73 (AR73) dye from aqueous solutions. The efficiency of dye removal was influenced by various factors such as solution pH, contact time, initial AR73 dye concentration, and MBCOT dosage. All experiments were conducted at 25 ± 2 °C, and the optimal pH was determined to be 1.5. The optimal conditions for dye removal were found to be an AR73 dye concentration of 100 mg/L, an MBCOT dosage of 1.5 g/L, and a contact time of 150 min, resulting in a 98.08% removal rate. Various models such as pseudo-first-order (PFO), pseudo-second-order (PSO), film diffusion (FD), and intraparticle diffusion (IPD) were used to determine the adsorption kinetics of AR73 dye onto MBCOT. The results showed that the PSO model best explains the AR73 dye adsorption. Furthermore, Langmuir and Freundlich's isotherm models were studied to explain the adsorption mechanism using experimental data. The adsorption capacities at equilibrium (qe) in eliminating AR73 dye varied from 92.05 to 32.15, 128.9 to 65.39, 129.25 to 91.69, 123.73 to 111.77, and 130.54 to 125.01 mg/g. The maximum adsorption capacity (Qm) was found to be 140.85 mg/g. In conclusion, this study demonstrates that biochar produced from mandarin peels has the potential to be an effective and promising adsorbent for removing AR73 dye from water.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Introduction

The rapid depletion of water resources is a growing concern due to urbanization, population growth, industrial expansion, and unregulated resource usage. Many industries, including textile1, cosmetics2, plastics3, pharmaceuticals4, food processing5, and paint6, use dyes, heavy metals and other waste materials that pose a threat to the environment, particularly water resources7. This pollution can cause harm to people's eyes, skin, neurological, cardiovascular, and gastrointestinal systems, due to the presence of toxic compounds in water8.

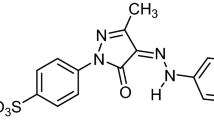

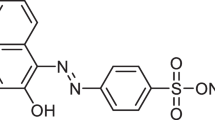

Acid Red 73 (AR73) dye is a commonly used organic azo dye with a diazo and di-sulfonic structure. It is popular due to its affordability, good dyeing performance, and minimal fading. However, it is also a persistent organic pollutant that can cause harm to aquatic ecosystems and humans. It is known to be toxic, carcinogenic, and mutagenic. Due to these concerns, society is becoming increasingly worried about its use9. AR73 dye is bio-resistant because it has stable chromophore structures that contain –N=N– units, benzene rings, and naphthalene rings10.

The primary objective of wastewater treatment is to remove all pollutants to a satisfactory level by utilizing effective and cost-efficient techniques that provide recoverable water. The methods utilized to eliminate these pollutants from wastewater essentially comprise physical adsorption11,12, membrane filtration13, ion exchange14, settling ponds15, oxidation16, chemical coagulation-flocculation17, photocatalytic18, ozone and Fenton19, chemical oxidation processes20, electrochemical21, irradiation22, and biological enzyme-assisted23, bacteria-assisted24, fungal-assisted25 treatment methods.

Adsorption technology has gained significant attention among the existing purification techniques due to its simplicity, availability, and high efficiency26,27,28. However, the commonly used adsorbents have certain drawbacks, such as their high cost, poor adsorption, and sluggish response rates29. Adsorbents with a wide surface area and sufficient active sites often exhibit strong adsorption and a high ability to remove contaminants, as demonstrated by activated carbon30.

In general, activated carbon (AC) is preferable in adsorption procedures31,32,33. However, the cost of activated carbon is high, and there is a desire to obtain AC from cheaper sources. Therefore, using biomass-based adsorbents in the removal of dyestuffs from wastewater has become popular as it reduces some limitations such as operational efficiency, cost, energy, and harmful consequences34. For this reason, activated biomass-based treatments have recently gained popularity, demonstrating the potential to eliminate dyes and wastewater35.

The application of biochars in water purification for colorant removal can be improved by increasing the quantity and diversity of functional groups on their surfaces36. This can be achieved by modifying their surfaces chemically. There are several ways to improve the adsorption capacity of biochar, including metal impregnation, oxidation, carbon surface activation, and nanoscale formation37. The addition of amino groups to the surface of biochar can enhance its adsorption capacity. Applying different acids (HNO3, H2SO4, or H3PO4), bases (KOH, NaOH), or oxidizing reagents (O3, H2O2, NH3.H2O, KMnO4, or (NH4)2S2O8) to biochar can enhance the number of functional groups present in it38,39,40. Biochars that incorporate nanometals have been shown in several studies to have excellent thermal stability, enhanced oxidation resistance, increased surface area, and expanded adsorption sites. The most often used reducing agents are FeSO4, H2, NH3H2O, Na2SO3, and aniline35,41. Nowadays, active substances for adsorption studies are obtained from agricultural wastes. The reasons for obtaining carbon from agricultural waste are the high price of commercial activated carbons, their organic nature, easy availability, non-threatening nature to health, and cost-effectiveness. Since agricultural wastes used as activated carbon give excellent results in purifying water resources, these studies have gained significant momentum. These include the peels or seeds of many agricultural materials such as oranges42,43, mandarin44,45, lemons46, grapefruits47, pomegranates48, bananas49, apricots50, eggs51, walnuts52, peanuts53, hazelnuts54, rice55, olives56 and Palm shell57.

Mandarin is a popular citrus fruit that belongs to the Citrus reticulata species in the Rutaceae family. It grows in temperate climates and is known for its seedless structure, sweetness, and ease of hand peeling. Mandarin is a rich source of different chemical components such as antioxidants, dietary fibre, essential oils, flavonoids, carotenoids, and vitamin C. Due to these components, it has various medicinal properties such as reducing oxidative stress, promoting digestive health and immunity, lowering blood pressure, and even anti-cancer properties58.

The Food and Agriculture Organisation of the United Nations issued figures in 2021 that predicted the annual citrus output to be 80 million tonnes. China is the top producer, followed by Turkey in second place, Brazil in third place, Egypt, Japan, Spain, South Korea, and Italy59. After being utilized, peels from mandarin fruits are discarded into the environment, accounting for 8–14% of the fruit used to make fruit juice. The fertilizer, solid fuel, animal feed, and cosmetic sectors are the main companies that use them60,61. Due to mandarin being used so widely, a large volume of fruit peel ends up as biomass waste. Because mandarin peels include elements of organic carbon (hemicellulose, cellulose, lignin, and pectin) in their structure, they can be pyrolyzed to produce ecologically benign biochars62,63. High adsorption capacity materials may be produced using this method.

The study aimed to investigate the effectiveness of MBCOT produced from mandarin peel waste as an adsorbent for removing AR73 dye from water. The process involved dehydrating the mandarin peel waste with 85% H2SO4, oxidizing it with H2O2, and aminating it with triethylenetetramine. The resulting product, known as Mandarin biochar-CO-TETA (MBCOT), was tested under different conditions such as starting dye concentration, pH level, duration of interaction between MBCOT and AR73 dye, and MBCOT dose. To determine the maximum adsorption capacity (Qm) and the adsorption process for the AR73 dye adsorption by MBCOT, the kinetic and isotherm models were used. This study offers a promising solution for utilizing agricultural waste, such as mandarin peel, to produce an effective and inexpensive adsorbent for removing harmful dyes from water. To the authors' knowledge, this is the first time to use MBCOT for AR73 dye removal.

Materials and methods

Materials

For MBCOT production, Mandarin (Citrus reticulata) peels were obtained from a local market (Alexandria, Egypt). Sigma Aldrich provided the Sulfuric acid (H2SO4, M.W. = 98.07 g, 99%), Triethylenetetramine (TETA) and AR73 dye (Fig. 1). One liter of distilled water was used to dissolve one gram of dye to prepare the AR73 dye standard stock solution.

Fabrication of MBCOT

Mandarin orange peels (Citrus reticulata) were thoroughly cleaned with water multiple times to remove any dust and then dried at 115 °C for 72 h. The dried peels were pulverized and crushed for this recipe. The experiment involved boiling 250 g of crushed mandarin peels in 2L of 85% H2SO4 for 5 h at ~ 240 °C in a reflux system. The peels were then diluted with deionized water, filtered, and repeatedly rinsed with water until the resulting filtrate reached a neutral consistency. After that, they were washed with ethanol, dried at 120 °C for the entire night, and weighed to produce 105 g of biomass-based biosorbent biochar made of mandarin. This biosorbent was transferred to 400 mL of 50% H2O2 and then heated at 70 °C for 60 min, producing 70 g of mandarin biochar-COH biosorbent after filtration, cleaning, and drying at 115 °C overnight. The mandarin biochar-COH biosorbent (50 g) was refluxed (280 °C) in 120 mL of TETA solution for two hours, resulting in 62 g of the product after filtration, and washing twice with ethanol and distilled water. The synthesis procedures of MBCOT are illustrated in Fig. S1. The product was labelled MBCOT and the characterization was found to be similart to that previously reported by us61,64, and all the characterizations data were reported in the supplementary data as Figs. S2–S15.

Batch adsorption procedure

A stock solution of AR73 dye was created by dissolving 1.0 g of the dye in one litre of distilled water, resulting in a concentration of 1000 mg/L. The standard solution used for calibration and absorption experiments was produced by diluting the stock solution to the required concentrations. The absorption potential, isotherm and kinetic properties of MBCOT were determined through bulk adsorption studies. A series of 300 mL Erlenmeyer flasks were filled with 100 mL of AR73 dye solution at concentrations of 50, 100, 150, 200, and 250 mg/L, along with various doses of MBCOT at 0.50, 0.75, 1.0, 1.25, and 1.5 g/L at 25 °C. The flasks were shaken at 200 rpm for a predetermined amount of time, with the pH of the solution adjusted using 0.1 M HCl or 0.1 M NaOH, as required. Using spectrophotometry at λmax = 518 nm, the concentration of the AR73 dye was determined after a 0.5 mL sample of the solution was taken out at different times until equilibrium was established. All experiments were repeated three times and the mean values were reported and the standard deviation was ≤ 2.5. The average data for kinetic and isotherm investigations was used to conduct the adsorption experiments three times. Using Eq. (1), the adsorption capacity at equilibrium (qe) was obtained.

where the adsorbent's ability to adsorb AR73 dye from a solution at a specific time is known as its capacity for adsorption (qt, mg/g). C0 (mg/L) is the initial AR73 dye concentration; Ct (mg/L) is the residual AR73 dye concentration after a certain period. Equation (2) may be used to calculate the percentage of AR73 dye removed from water.

To assess how pH affects the adsorption of AR73 dye by MBCOT, 0.15 g of MBCOT was mixed with 100 mL of 100 mg/L initial AR73 dye concentration. Different initial pH values ranging from 1.5 to 12.2 were studied, and to modify the pH values, 0.1 M HCl or NaOH solutions were used. Before the mixture was analyzed for AR73 dye concentration, it was stirred at 200 rpm for 2.5 h at 25 °C. Isotherm studies were conducted by shaking 100 mL of solutions with varying starting concentrations of AR73 dye (50, 100, 150, 200, and 250 mg/L) at 200 rpm for three hours at 25 °C with different quantities of MBCOT (0.5 to 1.5 g/L). To examine the effects of MBCOT dose and contact duration on AR73 dye adsorption, 100 mL of AR73 dye was shaken with different doses of MBCOT (0.50, 0.75, 1.0, 1.25, and 1.5 g/L) at 25 °C.

Author statement for the use of plants. In this work, experimental research and field studies were conducted on the waste of mandarin orange peels (Citrus reticulata). The collection of plant peel waste was carried out in compliance with relevant institutional, national, and international guidelines and legislation.

Results and discussion

Adsorption of AR73 Dye on MBCOT

Effect of pH

The adsorption of biochar is significantly influenced by the pH of a solution. This is because it has an impact on the surface's carboxyl, hydroxyl, and amino groups. Using 1.5 g/L MBCOT adsorbent and 100 mg/L starting dye concentration at room temperature, the adsorption of AR73 dye was tested at various pH values ranging from 1.5 to 12.2 for two hours to study this impact. According to the results, which are displayed in Fig. 2a, the highest removal of AR73 dye (98.8%) happened at pH 1.5 while employing MBCOT. The adsorption rate dropped from 98.8% to 12.5% when the pH value progressively rose from 1.5 to 12.2. Between pH 1.5 and pH 7.12, the fraction of adsorption removal decreased dramatically; between pH 7.12 and pH 12.2, it decreased marginally. The best dye adsorption at pH 1.5 (protonation of sorbent sites–H+) was caused by the electrostatic interaction between the negatively charged anionic dye molecules and the positively charged MBCOT surface sites. Nevertheless, as the system's pH rose, the proportion of AR73 dye molecules adsorbed to the adsorbent dropped because the MBCOT (–OH) sites were deprotonated. The negatively charged anionic AR73 dye molecules and the negatively charged areas on the MBCOT surface were repelled by electrostatic forces as a result. Because of the adsorbent (MBCOT) surface properties and the ionisation or dissociation of the sorbate (AR73 dye) molecule, the pH of the system also affects the sorptive adsorption of sorbate molecules. It is possible to ascertain the pH at which the adsorbent surface demonstrates net electrical neutrality using the point of zero charge (pHPZC). The pHPZC was discovered to be 10.7, as seen in Fig. 2b. The sites on the sorbent surface were positively charged if the pH was less than the pHPZC; otherwise, they were negatively charged. These results are in line with our previous study61.

Effect of contact time

Equilibrium time is one of the most important properties of inexpensive adsorption systems. The brief equilibrium duration demonstrates that adsorption was effective right away. When the pH was 1.5, the initial AR73 dye concentrations varied from 50 to 250 mg/L, and the MBCOT adsorbent concentration was 1.5 g/L, Fig. 3 shows the time-dependent elimination of the dye. After the first 15 min, the adsorption process picks up speed and increases steadily. Figure 3 demonstrates that the first 15–30 min account for roughly 79.44–92.19% of the adsorption of AR73 dye.

As the contact duration increased, the quantity of AR73 dye that was removed grew steadily. After 2.5 h, the removal was 96.44, 98.08, 91.69, 83.83, and 75%, respectively, depending on the starting concentration (50–250 mg/L). Most of these ions will be able to cling to the adsorbent because of the low dye concentration of the empty active sites in the removal of AR73 dye with a low beginning concentration of the MBCOT adsorbent. However, the removal percentage of AR73 dye will stay low when a high initial MBCOT adsorbent concentration is employed because the empty active sites are limited in their ability to adsorb further dye after being loaded with a certain amount of AR73 dye. The adsorption process occurs quickly and proves to be cost-effective in industrial applications.

Impact of initial AR73 dye concentration

To investigate the effect of the initial concentration of AR73 dye on the adsorption capacity at equilibrium (qe), it is essential to determine the initial concentration of the adsorbed material. The effects of MBCOT dose on equilibrium adsorption capacity (qe), 0.5–1.5 g/L MBCOT concentration and 50–250 mg/L initial AR73 dye concentration were studied at 25 °C and solution pH 1.5. The qe quantity of AR73 dye adsorbed at the same starting concentration of AR73 dye was found to rise at equilibrium as MBCOT doses dropped, as shown in Fig. 4. Using MBCOT adsorbents at several dosages (0.5–1.5 g/L), the adsorption capacities at equilibrium (qe) in eliminating AR73 dye were established 50, 100, 150, 200, and 250 mg/L initial AR73 dye concentrations, the qe values vary from 92.05 to 32.15, 128.9 to 65.39, 129.25 to 91.69, 123.73 to 111.77, and 130.54 to 125.01 mg/g, respectively.

The adsorption capacity (qe) of AR73 dye on MBCOT is influenced by the starting concentration of the dye in the equilibrium state, as shown in Fig. 4. It was discovered that qe dropped as the adsorbent dose rose. Thus, the initial concentration of AR73 dye dictated how well it adsorbs from its aqueous solution. This conclusion is supported by similar research in the literature33,44. The boundary layer effect is the first thing that AR73 dye molecules experience when they adsorb on MBCOT adsorbent. The molecules then diffuse from the boundary layer film to the surface of the adsorbent, where their porous nature finally causes them to adhere.

Impact of MBCOT dosage on AR73 dye adsorption

The adsorbent dosage is a significant aspect in determining the total cost, as well as the recycling and reuse costs, of the adsorption process. As shown in Fig. 5, the effect of MBCOT dosage on AR73 dye removal was investigated by adjusting the initial AR73 dye concentration (50–250 mg/L), MBCOT dosages (0.5–1.5 g/L), solution pH to 1.5, temperature (25 ± 2 °C), and contact time (150 min). While AR73 dye removal reached over 74% removal within 15 min, it gradually increased with advancing contact time. The maximum AR73 dye removal percentage and the lowest adsorption quantity at equilibrium (qe) were discovered using a 1.5 g/L MBCOT dosage.

Adsorption ısotherms

In this step of the study, the MBCOT adsorbent was used to adsorb AR73 solutions with different initial concentrations ranging from 50 to 250 mg/L. Equilibrium studies were conducted using 0.15 g of MBCOT dosage, a solution initial pH of 1.5, and a temperature of 25 ± 2 °C. The Langmuir and Freundlich isotherms were employed to determine the equilibrium quantities for AR73 adsorption, as shown in Fig. 6. The Langmuir isotherm model is the most well-known model for monolayer adsorption. Its equation is given in Eq. 365:

qe (mg/g) adsorption capacity at equilibrium; Ce (mg/L) solution concentration at equilibrium; Qm (mg/g) is the amount of substance adsorbed in the monolayer per unit adsorbent and Ka (L mg–1) is the Langmuir constant. By drawing the graph of Ce/qe against Ce from the adsorption equilibrium data, Qm is calculated from the slope and Ka is calculated from the shift (Fig. 6a).

Heterogeneous, reversible, and multilayer adsorption is specified by the Freundlich isotherm model. Equation 4 provides the adsorption equation for the Freundlich adsorption isotherm model66:

KF (mg1–(1/n) L1/n g–1 ) and n are Freundlich constants. By plotting the diagram of log qe versus log Ce, the n value is calculated from the slope and the KF value is calculated from the drift (Fig. 6b).

With the help of equations for each isotherm model, AR73 adsorption isotherm constants and regression coefficients of the isotherms were established and are provided in Table 1. The regression coefficients in Table 1 show that the AR73 adsorption equilibrium data is compatible with the Langmuir isotherm model. For the Langmuir isotherm model, the adsorption capacity (Qm) in the monolayer was calculated as 140.85 mg/g. The Langmuir isotherm is consistent with the adsorption equilibrium results, which demonstrate the homogenous structure and similar active regions of the MBCOT surface.

Adsorption Kinetic Studies

Using data on AR73 adsorption, the kinetic behaviour of the adsorption process was tried to be elucidated. Kinetic studies were conducted using the pseudo-first-order (PFO), pseudo-second-order (PSO), film diffusion (FD), and intraparticle diffusion (IPD) models. The equations of the PFO kinetic model developed by Lagergren67 and the PSO kinetic model developed by Ho and Mckay68 are given in Eqs. 5 and 6.

qe and qt (mg/g) are the adsorption capacity at equilibrium and at time t, respectively, and k1 (min-1) and k2 (g mg–1 min–1) are constants belonging to PFO and PSO kinetic models, respectively. For the PFO kinetic model, the graph of ln (qe–qt) against t is drawn to find the constant qe from the slip value and k1 from the slope value (Fig. 7a). In the PSO kinetic model, the graph of t/qt against t is drawn and the constant qm is calculated from the slope and k2 is calculated from the shift (Fig. 7b).

Kinetic constants calculated using the data in Fig. 7 are as given in Table 2. As seen in Table 2, it was found more appropriate to represent the adsorption data with a PSO kinetic model. Equation 7 determines the diffusion coefficient in the IPD model69.

where C is the intercept and Kdif is the IPD rate constant (mg g–1 min1/2) and the constant related to the boundary layer thickness (mg/g), respectively (Fig. 7c). The intercept C values give information regarding the thickness of the boundary layer; as the intercept increases, so does the resistance to external mass transfer70. The liquid FD model71 can be used (Eq. 8) when the solute molecules' passage from the liquid phase to the solid phase boundary is the most important factor in adsorption72,73.

where F and KFD are the fractional attainments of equilibrium (F = qt/qe), and the FD rate constant, respectively (Fig. 7d). Due to the parameters calculated in Tables 2 and 3, the PSO model best suited the experimental data because of the final value of the linear regression coefficient (R2) achieved (> 0.990).

The PSO model demonstrated that the calculated and experimentally determined qe values were remarkably close, indicating that the model could accurately describe the absorption process of AR73 dye into MBCOT. Redefining steps and diffusion did not have an impact on the IPD and FD linear plots via the liquid layer surrounding the sorbent since the linear plots did not continue through the origin of their respective plots. In addition, the IPD and FD models' R2 values were less than the PSO model's. Thus, the absorption of AR73 dye to MBCOT sorbent was supported by the notion of chemisorption involving valency force via electron sharing or exchange between MBCOT and AR73 dye molecules.

Regeneration of MBCOT

The viability and reusability of MBCOT for AR73 dye absorption were investigated by performing desorption studies of the dye using 0.1 M NaOH and HCl as an extraction environment. As may be shown in Fig. 8, the study's percentage of AR73 dye desorption rose and then decreased with regeneration cycles. Six cycles of absorption and desorption were examined using regeneration MBCOT. Throughout the cycles, the change in adsorption and desorption was generally consistent. But after six cycles, it dropped by around 10%. It means that it can be used to remove AR73 dye from water.

Comparison of MBCOT with other adsorbents in AR73 dye removal

There are few studies using mandarin peel biochar as dye removal or adsorbent, and there is no research on AR73 dye adsorption using mandarin peel biochar. As a result, comparable research from the literature is included in Table 4, where it is presented that MBCOT adsorbent is successful in removing AR73 dye molecules from its water solution.

Adsorption mechanism of AR73 Dye by MBCOT

Figure 9 explains the likely adsorption mechanism via which MBCOT adsorbed the AR73 dye ions. According to FTIR analysis, a variety of functional groups, including C=O, –NH, hydroxyl O–H, C=N–, C–O–H and NH2 groups, developed on the surface of the MBCOT. Because of the electrostatic interaction between the nitrogen and oxygen lone pair on the MBCOT surface and the negative charge on the AR73 dye, the adsorption mechanism of the AR73 dye ions in an acidic medium (pH 1.5) can be accomplished through physical interaction. In an acidic environment, the surface of MBCOT picks up a positive charge, which attracts negatively charged dye molecules26,83. Furthermore, there is interaction between the functional groups of the positive ions on the MBCOT's surface and the negative ions in the solution. The dye molecules are more soluble at an acidic pH, which makes it easier for them to adhere to the adsorption sites and diffuse through the MBCOT's pores. Since the acidic pH of MBCOT is necessary to promote the adsorption of AR73 dye molecule onto the material surface, it is a great way to remove colour from industrial effluent. The most important mechanism is the electrostatic interaction-mediated adsorption of ionizable organic molecules to the positively charged surface of the adsorbents84. An aqueous solution's pH and ionic strength determine how well it draws or repels contaminants84,85.

Moreover, the capacity of organic contaminants in industrial effluent to be adsorbed is influenced by the pH of the solution86. Parshetti et al.'s study87 examined the use of food waste-derived biochar in the adsorption of cationic dyes from wastewater. They found that an alkaline pH enhanced the adsorption of cationic dyes. It was explained by the strong interaction between the positively charged cationic dyes and the negatively charged sites of the adsorbent surface87. It was less successful in adsorbing cationic dyes, though, because there was an excess of H+ at pH 1.5, which competed with the positive charges of the cationic dye87. The capacity of organic and inorganic pollutants from industrial effluent to be adsorbed on biochar is hence influenced by the pH of the solution, which also affects the charged sites88,89,90,91,92,93,94,95,96,97. Tsai and Chen98 and Xu et al.99 have noted that pH has an impact on biochar's capacity to absorb materials.

Conclusion

In this study, we developed an adsorbent material using biochar obtained from mandarin peels. We tested the biochar (MBCOT) from mandarin peels for its ability to adsorb AR73. We examined various operating parameters such as pH, initial concentration of AR73 dye, MBCOT adsorbent dosage, and contact time in the adsorption process. The main findings are listed below:

-

The maximum removal of 98.08% was achieved at 25 ± 2 °C, pH of 1.5, 100 mg/L AR73 dye concentration, 1.5 g/L MBCOT adsorbent dose, and 150 min contact time.

-

The PSO kinetic model matched the adsorption kinetics, and the most suitable Langmuir isotherm was the adsorption isotherm.

-

The MBCOT adsorbent has a maximum adsorption capacity of 140.85 mg/g. Therefore, biochar obtained from mandarin peels (MBCOT) can be used as an effective adsorbent for the removal of AR73 dye in aqueous solutions.

-

The derived thermodynamic parameters and isotherm model can be useful for the commercial removal of AR73 dye.

Data availability

The corresponding author can provide access to the datasets used in this investigation upon request.

References

Chen, W. et al. A capacitive deionization and electro-oxidation hybrid system for simultaneous removal of heavy metals and organics from wastewater. Chem. Eng. J. 451, 139071 (2023).

Ribeiro, M. R. et al. Synthesis of value-added materials from the sewage sludge of cosmetics industry effluent treatment plant. J. Environ. Chem. Eng. 9(4), 105367 (2021).

Li, Z. et al. Removal of malachite green dye from aqueous solution by adsorbents derived from polyurethane plastic waste. J. Environ. Chem. Eng. 9(1), 104704 (2021).

Gupta, K. & Khatri, O. P. Fast and efficient adsorptive removal of organic dyes and active pharmaceutical ingredient by microporous carbon: effect of molecular size and charge. Chem. Eng. J. 378, 122218 (2019).

El-Sayed, H. E. & El-Sayed, M. M. Assessment of food processing and pharmaceutical industrial wastes as potential biosorbents: a review. BioMed Res. Int. https://doi.org/10.1155/2014/146769 (2014).

Nair, S., Manu, B. & Azhoni, A. Sustainable treatment of paint industry wastewater: Current techniques and challenges. J. Environ. Manag. 296, 113105 (2021).

Şenol, Z. M., Elma, E., El Messaoudi, N. & Mehmeti, V. Performance of cross-linked chitosan-zeolite composite adsorbent for removal of Pb2+ ions from aqueous solutions: experimental and Monte Carlo simulations studies. J. Mol. Liquids 391, 123310 (2023).

Cigeroglu, Z. et al. Clay-based nanomaterials and their adsorptive removal efficiency for dyes and antibiotics: a review. Mater. Today Sustain. 26, 100735 (2024).

Lin, Y. et al. Synergistic and efficient degradation of acid red 73 by using UV, H2O2, and PDS under neutral conditions: water matrix effects and transformation pathways. Res. Chem. Intermediates 49(1), 23–42 (2023).

Xu, L., Guo, Z. & Du, L. Anodic oxidation of azo dye CI Acid Red 73 by the yttrium-doped Ti/SnO 2-Sb electrodes. Front. Chem. Sci. Eng. 7, 338–346 (2013).

El-Nemr, M. A. et al. Fabrication of Pea pods biochar-NH2 (PBN) for the adsorption of toxic Cr6+ ion from aqueous solution. Appl. Water Sci. 13(10), 194 (2023).

Mohamed, S. M. I., Güner, E. K., Yılmaz, M. & El Nemr, A. Removal of Cr6+ ions and mordant violet 40 dye from liquid media using Pterocladia capillacea red algae derived activated carbon-iron oxides. Sci. Rep. 13(1), 18306 (2023).

Cevallos-Mendoza, J., Amorim, C. G., Rodríguez-Díaz, J. M. & Montenegro, M. D. C. B. Removal of contaminants from water by membrane filtration: a review. Membranes 12(6), 570 (2022).

Lahiri, S. K., Zhang, C., Sillanpää, M. & Liu, L. Nanoporous NiO@ SiO2 photo-catalyst prepared by ion-exchange method for fast elimination of reactive dyes from wastewater. Mater. Today Chem. 23, 100677 (2022).

Liu, X. et al. Adsorption-reduction of Cr (VI) with magnetic Fe-CN composites. Water 15(12), 2290 (2023).

Martínez-Sánchez, C., Robles, I. & Godínez, L. A. Review of recent developments in electrochemical advanced oxidation processes: application to remove dyes, pharmaceuticals, and pesticides. Int. J. Environ. Sci. Technol. 19(12), 12611–12678 (2022).

Ihaddaden, S., Aberkane, D., Boukerroui, A. & Robert, D. Removal of methylene blue (basic dye) by coagulation-flocculation with biomaterials (bentonite and Opuntia ficus indica). J. Water Process Eng. 49, 102952 (2022).

Keles Guner, E. Structural, optical, magnetic and photocatalytic properties of Zn doped CoFe2O4 decorated bentonite nanocomposites. ChemistrySelect 8(10), e202204568 (2023).

Mohammed, S., Prathish, K. P., Jeeva, A. & Shukla, S. Integrated Fenton-like and ozonation based advanced oxidation processes for treatment of real-time textile effluent containing azo reactive dyes. Chemosphere 349, 140766 (2023).

Collivignarelli, M. C., Abbà, A., Miino, M. C. & Damiani, S. Treatments for color removal from wastewater: State of the art. J. Environ. Manag. 236, 727–745 (2019).

Anantha, M. S. et al. Comparison of the photocatalytic, adsorption and electrochemical methods for the removal of cationic dyes from aqueous solutions. Environ. Technol. Innov. 17, 100612 (2020).

Nur, A. S. et al. A review on the development of elemental and codoped TiO2 photocatalysts for enhanced dye degradation under UV–vis irradiation. J. Water Process Eng. 47, 102728 (2022).

Ahsan, Z. et al. Enzyme-assisted bioremediation approach for synthetic dyes and polycyclic aromatic hydrocarbons degradation. J. Basic Microbiol. 61(11), 960–981 (2021).

Al-Tohamy, R. et al. A critical review on the treatment of dye-containing wastewater: Ecotoxicological and health concerns of textile dyes and possible remediation approaches for environmental safety. Ecotoxicol. Environ. Safety 231, 113160 (2022).

Chaurasia, P. K., Sharma, N., Rudakiya, D. M., Singh, S. & Bharati, S. L. Fungal-assisted bioremediation of agricultural organic pollutants (Pesticides and Herbicides). Current Green Chem. 9(1), 14–25 (2022).

El-Nemr, M. A., Abdelmonem, N. M., Ismail, I. M., Ragab, S. & El Nemr, A. Ozone and ammonium hydroxide modification of biochar prepared from Pisum sativum peels improves the adsorption of copper (II) from an aqueous medium. Environ. Process. 7, 973–1007 (2020).

El-Nemr, M. A. et al. Adsorption of Cr6+ ion using activated Pisum sativum peels-triethylenetetramine. Environ. Sci. Pollut. Res. 29(60), 91036–91060 (2022).

Hussain, N. B., Akgül, E. T., Yılmaz, M., Parlayıcı, Ş & Hadibarata, T. Preparation and characterization of low-cost activated carbon from Moringa oleifera chemically activated using ZnCl2 for the adsorption of bisphenol A. Int. J. Phytoremed. 25(9), 1199–1214 (2023).

Chakraborty, R., Asthana, A., Singh, A. K., Jain, B. & Susan, A. B. H. Adsorption of heavy metal ions by various low-cost adsorbents: a review. Int. J. Environ. Anal. Chem. 102(2), 342–379 (2022).

Wang, X. et al. Key factors and primary modification methods of activated carbon and their application in adsorption of carbon-based gases: A review. Chemosphere 287, 131995 (2022).

Shoaib, A. G., El-Sikaily, A., El Nemr, A., Mohamed, A. E. D. A. & Hassan, A. A. Preparation and characterization of highly surface area activated carbons followed type IV from marine red alga (Pterocladia capillacea) by zinc chloride activation. Biomass Convers. Biorefinery 12, 1–13 (2020).

El-Nemr, M. A. et al. Microporous activated carbon from Pisum sativum pods using various activation methods and tested for adsorption of acid orange 7 dye from water. Molecules 27(15), 4840 (2022).

Khaled, A., El Nemr, A., El-Sikaily, A. & Abdelwahab, O. Removal of Direct N Blue-106 from artificial textile dye effluent using activated carbon from orange peel: Adsorption isotherm and kinetic studies. J. Hazardous Mater. 165(1–3), 100–110 (2009).

Eldeeb, T. M. et al. Biosorption of acid brown 14 dye to mandarin-CO-TETA derived from mandarin peels. Biomass Convers. Biorefinery 14(4), 5053–5073 (2022).

Hassaan, M. A. et al. Isotherm and kinetic investigations of sawdust-based biochar modified by ammonia to remove methylene blue from water. Sci. Rep. 13(1), 12724 (2023).

Wang, Z., Fernández-Blanco, C., Chen, J., Veiga, M. C. & Kennes, C. Effect of electron acceptors on product selectivity and carbon flux in carbon chain elongation with Megasphaera hexanoica. Sci. Total Environ. 912, 169509. https://doi.org/10.1016/j.scitotenv.2023.169509 (2024).

Wang, L. et al. Mechanisms and reutilization of modified biochar used for removal of heavy metals from wastewater: A review. Sci. Total Environ. 668, 1298–1309 (2019).

Chang, Z. et al. Molecular markers of benzene polycarboxylic acids in describing biochar physiochemical properties and sorption characteristics. Environ. Pollut.. 237, 541–548 (2018).

Hassaan, M. A. et al. Enhancement of biogas production from macroalgae ulva latuca via ozonation pretreatment. Energies 14(6), 1703 (2021).

El-Nemr, M. A., Yılmaz, M., Ragab, S. & El Nemr, A. Biochar-SO prepared from pea peels by dehydration with sulfuric acid improves the adsorption of Cr6+ from water. Biomass Convers. Biorefinery 14(2), 2601–2619 (2022).

Ma, Y. et al. Polyethylenimine modified biochar adsorbent for hexavalent chromium removal from the aqueous solution. Bioresour. Technol. 169, 403–408 (2014).

Khalil, A., Salem, M., Ragab, S., Sillanpää, M. & El Nemr, A. Orange peels magnetic activate carbon (MG-OPAC) composite formation for toxic chromium absorption from wastewater. Sci. Rep. 13(1), 3402 (2023).

Balji, G. B., Surya, A., Govindaraj, P. & Ponsakthi, G. M. Utilization of fly ash for the effective removal of hazardous dyes from textile effluent. Inorganic Chem. Commun. 143, 109708 (2022).

Yılmaz, M. et al. The use of mandarin-biochar-O3-TETA (MBT) produced from mandarin peels as a natural adsorbent for the removal of acid red 35 (AR35) dye from water. Environ. Process. 9(3), 44 (2022).

Eleryan, A. et al. Kinetic and isotherm studies of Acid Orange 7 dye absorption using sulphonated mandarin biochar treated with TETA. Biomass Convers. Biorefinery 14, 10599–10610 (2023).

Bukhari, A. et al. Removal of Eosin dye from simulated media onto lemon peel-based low cost biosorbent. Arab. J. Chem. 15(7), 103873 (2022).

Deng, S. et al. Efficient rhodamine B dye degradation by red mud-grapefruit peel biochar catalysts activated persulfate in water. Environ. Sci. Pollut. Res. 30(56), 119034–119049 (2023).

Gündüz, F. & Bayrak, B. Synthesis and performance of pomegranate peel-supported zero-valent iron nanoparticles for adsorption of malachite green. Desalin. Water Treat. 110, 180–192 (2018).

Kapoor, R. T., Rafatullah, M., Siddiqui, M. R., Khan, M. A. & Sillanpää, M. Removal of reactive black 5 dye by banana peel biochar and evaluation of its phytotoxicity on tomato. Sustainability 14(7), 4176 (2022).

Kavci, E., Erkmen, J. & Bingöl, M. S. Removal of methylene blue dye from aqueous solution using citric acid modified apricot stone. Chem. Eng. Commun. 210(2), 165–180 (2023).

Mittal, A., Teotia, M., Soni, R. K. & Mittal, J. Applications of egg shell and egg shell membrane as adsorbents: A review. J. Mol. Liquids 223, 376–387 (2016).

Shao, Q. et al. Preparation of copper doped walnut shell-based biochar for efficiently removal of organic dyes from aqueous solutions. J. Mol. Liquids 336, 116314 (2021).

Acemioğlu, B. Removal of a reactive dye using NaOH-activated biochar prepared from peanut shell by pyrolysis process. Int. J. Coal Prep. Util. 42(3), 671–693 (2022).

Guo, F. et al. Efficient removal of methylene blue via two-step modification hazelnut shell biochar: Process intensification, kinetics and thermodynamics. J. Indus. Eng. Chem. 125, 105–116 (2023).

Saravanan, P., Josephraj, J., Thillainayagam, B. P. & Ravindiran, G. Evaluation of the adsorptive removal of cationic dyes by greening biochar derived from agricultural bio-waste of rice husk. Biomass Convers. Biorefinery 13, 4047–4060 (2021).

Haris, M., Khan, M. W., Paz-Ferreiro, J., Mahmood, N. & Eshtiaghi, N. Synthesis of functional hydrochar from olive waste for simultaneous removal of azo and non-azo dyes from water. Chem. Eng. J. Adv. 9, 100233 (2022).

Muniyandi, M. & Govindaraj, P. Potential removal of Methylene Blue dye from synthetic textile effluent using activated carbon derived from Palmyra (Palm) shell. Mater. Today: Proc. 47, 299–311 (2021).

Richa, R. et al. Citrus fruit: Classification value addition, nutritional and medicinal values, and relation with pandemic and hidden hunger. J. Agric. Food Res. 14, 100718 (2023).

Yılmaz, M., Eldeeb, T. M., Hassaan, M. A., El-Nemr, M. A., Ragab, S., & El Nemr, A. (2022). Adsorption of Acid Red 35 (AR35) dye onto Mandarin Biochar-TETA (MBT) derived from Mandarin peels.

Koyuncu, F., Güzel, F. & Sayğılı, H. Role of optimization parameters in the production of nanoporous carbon from mandarin shells by microwave-assisted chemical activation and utilization as dye adsorbent. Adv. Powder Technol. 29(9), 2108–2118 (2018).

Eleryan, A. et al. Biochar-C-TETA as a superior adsorbent to acid yellow 17 dye from water: isothermal and kinetic studies. J. Chem. Technol. Biotechnol. 98(10), 2415–2428 (2023).

Yalvaç, G. & Bayrak, B. Use of natural and effective mandarin peel in elimination of malachite green from the aqueous media: adsorption properties, kinetics and thermodynamics. Desalin. Water Treat. 177, 176 (2020).

Eleryan, A. et al. Mandarin Biochar-TETA (MBT) prepared from Citrus reticulata peels for adsorption of Acid Yellow 11 dye from water. Sci. Rep. 12(1), 17797 (2022).

El Nemr, A. et al. Enhancement of biogas production from individually or co-digested green algae Cheatomorpha linum using ultrasound and ozonation treated biochar. Ultrason. Sonochem. 90, 106197. https://doi.org/10.1016/j.ultsonch.2022.106197 (2022).

Langmuir, I. The adsorption of gases on plane surfaces of glass, mica and platinum. J. Am. Chem. Soc. 40, 1361–1368 (1918).

Freundlich, H. M. F. Über die adsorption in lösungen. Zeitschrift für Physikalische Chemie (Leipzig) 57A, 385–470 (1906).

Lagergren, S. Zur theorie der sogenannten adsorption geloster stoffe Kungliga Svenska Vetenskapsakademiens. Handlingar 24, 1–39 (1898).

Ho, Y. S., McKay, G., Wase, D. A. J. & Foster, C. F. Study of the sorption of divalent metal ions on to peat. Adsorpt. Sci. Technol. 18, 639–650 (2000).

Weber, W. J. & Morris, J. C. Kinetics of adsorption on carbon from solution. J. Sanit Eng. Div. Am. Soc. Civ. Eng. 89, 31–60 (1963).

El Nemr, A., El-Sikaily, A. & Khaled, A. EJAR. Egypt. J. Aquat. Res. 36(2), 403–425 (2010).

Boyd, G. E., Adamson, A. M. & Myers, L. S. The exchange adsorption of ions from aqueous solutions by organic zeolites. J. Am. Chem. Soc. 69, 2836 (1949).

Abdelwahab, O., El Sikaily, A., Khaled, A. & El Nemr, A. Mass-transfer processes of Chromium (VI) adsorption onto Guava seeds. Chem. Ecol. 23(1), 73–85. https://doi.org/10.1080/02757540601083922 (2007).

El Nemr, A., El Sikaily, A., Khaled, A. & Abdelwahab, O. Removal of toxic chromium (VI) from aqueous solution by activated carbon using Casuarina Equisetifolia. Chem. Ecol. 23(2), 119–129. https://doi.org/10.1080/02757540701197754 (2007).

El-Shafie, A. S., Rahman, E., GadelHak, Y., Mahmoud, R. & El-Azazy, M. Techno-economic assessment of waste mandarin biochar as a green adsorbent for binary dye wastewater effluents of methylene blue and basic fuchsin: Lab-and large-scale investigations. Spectrochimica Acta Part A: Mol. Biomol. Spectrosc. 306, 123621 (2024).

Park, H., Kim, J., Lee, Y. G. & Chon, K. Enhanced adsorptive removal of dyes using Mandarin peel biochars via chemical activation with NH4Cl and ZnCl2. Water 13(11), 1495 (2021).

Rehman, R., Salman, M., Mahmud, T. & Kanwal, F. Utilization of chemically modified Citrus reticulata peels for biosorptive removal of Acid Yellow-73 dye from water. J. Chem. Soc. Pak 35(3), 611–617 (2013).

Fu, F., Xiong, Y., Xie, B. & Chen, R. Adsorption of Acid Red 73 on copper dithiocarbamate precipitate-type solid wastes. Chemosphere 66(1), 1–7 (2007).

Zine A.M., Thore S.N., Pawar R.P., Pardeshi S.D., Lıgde N.M., Sonar J.P., Adsorption Studies of Acid Red 73 on Parthenium hysterophorus L.

Wang, Q. et al. Adsorption of Azo Dye Acid Red 73 onto rice wine lees: Adsorption kinetics and isotherms. Adv. Mater. Sci. Eng. 2020, 1–8 (2020).

El-Adawy, H. A. Kinetics and thermodynamic study of acid red 73 dye removal on HCl-water hyacinth stems biomass. Egypt. J. Chem. 63(4), 1555–1566 (2020).

Arslan-Şenol, D., Ertap, H., Şenol, Z. M., El Messaoudi, N. & Mehmeti, V. Preparation of polyacrylamide titanium dioxide hybrid nanocomposite by direct polymerization and its applicability in removing crystal violet from aqueous solution. J. Polym. Environ. https://doi.org/10.1007/s10924-023-03004-8 (2024).

El Kaim Billah, R. et al. Methyl orange adsorption studies on glutaraldehyde cross-linking chitosan/fluorapatite-based natural phosphate composite. Int. J. Environ. Anal. Chem. https://doi.org/10.1080/03067319.2022.2130690 (2022).

El-Sikaily, A., El Nemr, A., Khaled, A. & Abdelwehab, O. Removal of toxic Chromium from wastewater using green alga Ulva lactuca and its activated Carbon. J. Hazard. Mater. 148(1–2), 216–228 (2007).

El Nemr, A. Potential of pomegranate husk carbon for Cr(VI) removal from wastewater: Kinetic and isotherm studies. J. Hazard. Mater. 161, 132–141 (2009).

Eleryan, A. et al. Mandarin Biochar-TETA (MBT) prepared from Citrus reticulata peels for adsorption of Acid Yellow 11 dye from water. Sci Rep. https://doi.org/10.1038/s41598-022-22359-x (2022).

El Nemr, A., Abdelwahab, O., Khaled, A. & El Sikaily, A. Removal of direct blue-86 from aqueous solution by new activated carbon developed from orange peel. J. Hazard. Mater. 161, 102–110 (2009).

Parshetti, G. K., Hoekman, S. K. & Balasubramanian, R. Chemical, structural and combustion characteristics of carbonaceous products obtained by hydrothermal carbonization of palm empty fruit bunches. Bioresour. Technol. 135, 683–689 (2013).

Hassaan, M. A. et al. Advanced oxidation of acid yellow 11 dye; detoxification and degradation mechanism. Toxin Rev. 40(4), 1472–1480 (2021).

Eleryan, A. et al. Adsorption of direct blue 106 dye using zinc oxide nanoparticles prepared via green synthesis technique. Environ. Sci. Pollut. Res. 30(26), 69666–69682 (2023).

El-Nemr, M. A. et al. The use of biochar-NH2 produced from watermelon peels as a natural adsorbent for the removal of Cu (II) ion from water. Biomass Convers. Biorefinery https://doi.org/10.1007/s13399-022-02327-1 (2022).

Hassaan, M. A. & El Nemr, A. Classification and identification of different minerals in the Mediterranean sediments using PSA, FTIR, and XRD techniques. Marine Pollut. Bull. 173, 113070 (2021).

Elkatory, M. R. et al. Mitigation and remediation technologies of waxy crude oils’ deposition within transportation pipelines: A review. Polymers 14(16), 3231 (2022).

Eldeeb, T. M. et al. Adsorption of methylene blue (MB) dye on ozone, purified and sonicated sawdust biochars. Biomass Convers. Biorefinery 14(8), 9361–9383 (2024).

Hassaan, M. A. et al. Principles of photocatalysts and their different applications: a review. Top. Current Chem. 381(6), 31 (2023).

Eleryan, A. et al. Copper (II) ion removal by chemically and physically modified sawdust biochar. Biomass Convers Biorefin https://doi.org/10.1007/s13399-022-02918-y (2022).

Ali, R.M., Hassaan, M.A. and Elkatory, M.R., 2020. Towards potential removal of malachite green from wastewater: Adsorption process optimization and prediction. In Materials Science Forum (Vol. 1008, pp. 213–221). Trans Tech Publications Ltd.

El-Nemr, M. A., Yılmaz, M., Ragab, S., Hassaan, M. A. & El Nemr, A. Isotherm and kinetic studies of acid yellow 11 dye adsorption from wastewater using Pisum Sativum peels microporous activated carbon. Scientific Reports 13(1), 4268 (2023).

Tsai, W. T. & Chen, H. R. Adsorption kinetics of herbicide paraquat in aqueous solution onto a low-cost adsorbent, swine-manure-derived biochar. Int. J. Environ. Sci. Technol. 10, 1349–1356 (2013).

Xu, R. K., Xiao, S. C., Yuan, J. H. & Zhao, A. Z. Adsorption of methyl violet from aqueous solutions by the biochars derived from crop residues. Bioresour. Technol. 102, 10293–10298. https://doi.org/10.1016/j.biortech.2011.08.089 (2011).

Funding

Open access funding provided by The Science, Technology & Innovation Funding Authority (STDF) in cooperation with The Egyptian Knowledge Bank (EKB). This work was partially supported by project number SCSE-31235 funded by The Science, Technology & Innovation Funding Authority (STDF) of Egypt.

Author information

Authors and Affiliations

Contributions

During the project, the practical part of the work was overseen by Dr. A. E., Dr. M.A. E.N. and M.A. H., who were also responsible for the calculations. The original manuscript was written by Dr. E.K. G. Dr. S. R. supervised the experimental work. The project was organized and managed by Professor A. E.N., who edited the final draft and submitted it to the journal.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Eleryan, A., Güner, E.K., Hassaan, M. et al. Mandarin biochar-CO-TETA was utilized for Acid Red 73 dye adsorption from water, and its isotherm and kinetic studies were investigated. Sci Rep 14, 13021 (2024). https://doi.org/10.1038/s41598-024-62870-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-024-62870-x

- Springer Nature Limited