Abstract

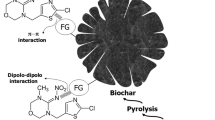

A new biochar was produced from pea peel residues by the dehydration process. The effect of the obtained new biochar on the ability to remove Cr6+ ions from the aqueous solution was investigated. Biochar-SO was obtained from pea peel by dehydration of biochar with 50% sulfuric acid. The obtained biochars were characterized by Fourier transform infrared (FT-IR); Brunauer, Emmett and Teller (BET); Barrett-Joyner-Halenda (BJH); thermogravimetric analysis (TGA); differential scanning calorimetry (DSC); scanning electron microscope (SEM); and energy-dispersive X-ray (EDAX) analyses. The optimum pH value for Cr6+ ion removal was determined as 1.48. The maximum removal percentage of Cr6+ ions was 90.74% for Biochar-SO of 100 mg·L−1 Cr6+ ions initial concentration and 1.0 g L−1 adsorbent dosage. The maximum adsorption capacity (Qm) of biochar-SO was 158.73 mg·g−1. The data obtained were analyzed with Langmuir, Freundlich, Temkin, and Dubinin-Radushkevich (D-R) isotherm models. In addition, the data obtained from these isotherm models were tested using different error functions (hybrid error function (HYBRID), average percent errors (APE), the sum of the absolute errors (EABS), chi-square error (X2), and Marquardt’s percent standard deviation (MPSD and the root mean square errors (RMS)) equations. It was the Freundlich isotherm model that best fits the experimental data of biochar-SO. Kinetic data were evaluated by pseudo–first-order (PFO), pseudo–second-order (PSO), Elovich, and intraparticle diffusion models. The adsorption rate was primarily controlled by the PSO rate model with a good correlation (R2 = 1). The adsorption mechanism of biochar-SO to remove Cr6+ ions can be based on electrostatic interaction and ion exchange with exchangeable cations in biochar such as aluminum, silicon, and calcium ions for chromium. The results indicate that biochar-SO is a promising adsorbent for the adsorption of Cr6+ ions that can be employed repeatedly without substantial loss of adsorption effectiveness.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Water is the most basic substance necessary for the life of all living things. Therefore, the call of countries to protect their water resources is increasing day by day [1,2,3]. Organic pollution and heavy metal pollution, which are the main pollutions of water, are constantly increasing with the development of modern agriculture and industry [4,5,6,7]. Metallurgy, electroplate, natural minerals and equipment, etc. are the main cause of heavy metal pollution [1, 8, 9]. Chromium (Cr) is an element in the heavy metal group and is widely used in textile industries, electroplating, steel production, pigment and dye synthesis, leather tanning, wood protection, etc. industries [10,11,12]. Therefore, since the wastes from such industries contain high levels of Cr ions, their direct discharge to soil or water causes serious environmental problems. Chromium ions are usually found in aqueous media in either a relatively harmless trivalent form or, even in low concentration, a toxic, carcinogenic, and mutagenic hexavalent state [11, 13,14,15]. For this reason, heavy metal–containing wastewater and sewage treatment are of great importance. Scientists have proposed different methods such as membrane separation, chemical precipitation, adsorption, biological treatment, redox, and ion exchange to remove heavy metal ions from wastewaters [16,17,18,19,20,21,22,23]. Among these techniques, the adsorption technique has been the preferred method since it eliminates some disadvantages such as high equipment cost, toxic sludge, and other waste production seen in other methods [24,25,26,27,28,29]. Zeolite, activated carbon, chitosan, graphene, and agroforestry wastes are widely used in the treatment of Cr6+ ions, a toxic heavy metal, from wastewater [30,31,32,33,34,35,36,37,38]. Activated carbon (AC) is one of the most famous and most efficacious adsorbents known in the world, but its expensiveness limits its widespread use [39,40,41]. For this reason, biochar, which is offered as an alternative to AC, is also widely used in the adsorption process [26,27,28]. Comparing studies using biochar [42, 43] and activated carbon [44,45,46], both reported higher removal efficiency with less cost and modification. In environments where agriculture and forestry production is limited, activated carbon and biochar are obtained from the pyrolysis of waste biomass residues. Compared to activated carbon, biochar is produced at relatively lower temperatures and has more functional groups on its surface, although it has a lower surface area and less porosity after the activation process [47, 48]. Since biochars have a non-carbonized fraction with carboxyl, hydroxyl, and phenolic surface functional groups on their surfaces, they are easier to bind effectively to water pollutants compared to activated carbons [49]. Adsorption capacities of biochars can be increased by using modification methods such as mineral impregnation, biochar surface reduction, nanoscale formation, or oxidation [26,27,28, 46]. The activation process is essential for the biochar, which will be obtained from raw material with relatively low porosity, to have a highly porous structure and to increase its adsorption capacity. This process is carried out into two ways, chemical and physical activation. While chemical activation takes place by reacting chemicals such as ZnCl2, KOH, H2SO4, HNO3, and H3PO4 with the raw material in an inert environment at high temperature, no chemicals are used in physical activation, and it is the process of carbonization under an atmosphere of high-temperature carbon dioxide (CO2) or water vapor. Most studies report that adsorbents obtained by chemical activation are more effective than adsorbents obtained by physical activation [50,51,52,53,54,55]. For the removal of chromium ions, scientists have worked with the following adsorbents in the last two decades: tea factory waste [56], moss (Hylocomium splendens) [57], rice straw [58,59,60], pomegranate husk [61, 62], lichen (Parmelina tiliaceae) [63], red algae (Pterocladia capillacea) [64, 65], chemically modified seaweed (Cystoseira indica) [66], sawdust, wool, almond shells, olive cake, charcoal, pine needles, and cactus leaves [67].

In this study, pea peels based biochar is used due to their easy preparation, surface functional groups, easy supply, and efficient treatment. Research on adsorption applications with pea peels based biochar for Cr6 + ion removal is limited. Biochar-SO produced from pea Pisum sativum peels, which is a low-cost agricultural waste material, by dehydration using H2SO4 was tested for its efficiency in Cr6+ ion removal from wastewaters. The effects of pH, initial adsorbent concentration, biochar-SO dose, and contact time between biochar-SO and Cr6+ ions as the removal conditions of Cr6+ ions from aqueous solution were investigated. Adsorption isotherms of chromium ions on Cr6+ ion as adsorbent were also investigated to determine the structure of adsorption and its maximum adsorption capacity.

2 Materials and methods

2.1 Materials

Pea peel (Pisum sativum) obtained from a local market was used for the production of biochar-SO. Sulfuric acid (H2SO4, M.W. = 98.07 g, assay (acid-metric) 99%) and potassium dichromate (K2Cr2O7, M.W = 294.19 g, assay (99%)) were supplied from Sigma-Aldrich. Potassium dichromate standard stock solution was prepared from potassium dichromate. BDHZ chemicals LTD Poole-England provided 1,5-diphenylcarbazide as a reagent for Cr6+ ions. In the experiments, a digital spectrophotometer (Analytic Jena (SPEKOL1300 UV/Visible spectrophotometer)) with matching glass cells with a 1-cm optical path, a shaker (JSOS-500), and a pH meter JENCO (6173) were used.

2.2 Preparation of biochar-SO

Pea peels were properly washed many times with faucet water to eliminate dust and then dried for 48 h at 105 °C. The dried pea peels were ground and crushed. The crushed pea peels (200 g) were cooked for 2 h in a 1.0 L solution of 50% H2SO4 in a refluxed system, then filtered, and washed with pure water until the filtrate became neutral, followed by washing with ethanol. The finished output of biochar was dried overnight at 105 °C and then weighed. Carbonization and sulfonation processes happened with this way of preparation [26,27,28]. The biochar produced in this process was designated biochar-SO.

2.3 Batch adsorption experimental

A stock solution of Cr6+ ions (1000 mg L−1) was obtained by dissolving 2.8289 g of K2Cr2O7 in 1 L of pure water, and this solution was diluted to the desired concentrations for the calibration standard curve and adsorption tests. The adsorption capabilities, thermodynamic, and kinetic characteristics of biochar-SO were determined using batch adsorption studies. A series of Erlenmeyer flasks (300 mL) was shaken at 200 rpm (selected depending on our previous study) for a specified duration with 100 mL of various concentrations of Cr6+ ion solution and varying volumes of biochar-SO. With 0.1-M HCl or 0.1-M NaOH, the pH of the sample was changed to the appropriate levels. Concentration measurement of Cr6+ ions was performed by taking 0.1 mL sample from the solution in the Erlenmeyer flask and separating from the adsorbent, at various intervals and equilibrium. The concentration of Cr6+ ions was measured using spectrophotometry and the chromogenic agent 1,5-diphenylcarbazide (λmax = 540 nm) [68, 69]. The equilibrium adsorption capacities (qe) were estimated using Eq. (1):

where the adsorption capacity (qt) (mg adsorbate/g adsorbent) is the adsorbent’s ability to remove Cr6+ ions from a solution at a certain time. C0 (mg/L) is the initial concentration of Cr6+ ions; Ct (mg/L) is the residual concentration of the Cr6+ ions after the adsorption process had been completed for a given time. The following equation can be used to calculate the elimination % of Cr6+ ions from an aqueous solution (2).

The influence of pH on Cr6+ ion adsorption was examined by mixing 0.1 g of the adsorbent with 100 mL of Cr6+ ion solution of a concentration of 100 mg/L for biochar-SO (0.1 g) with initial pH values varying between 1.48 and 9.41. A total of 0.1-M HCl and 0.1-M NaOH solutions were used to modify the pH levels. At 25 °C, the suspensions were agitated at 200 rpm for 180 min before being sampled for Cr6+ ion measurement.

For the isotherm investigation, 100 mL of Cr6+ ion solutions were mixed at 200 rpm for 3 h at 25 °C with varying initial concentrations of Cr6+ ion solutions (50–300 mg/L) and various amounts of biochar-SO (0.2 to 0.6 g).

At 25 °C, the effect of adsorbent dosage and contact time on Cr6+ ion removal was investigated by shaking 100 mL of initial Cr6+ ion concentration for biochar-SO with varied adsorbent dosages of (0.2, 0.3, 0.4, 0.5, and 0.6 g) at different interval times at 25 °C.

2.4 Biochar-SO characterization

The adsorption–desorption isotherm of N2 on biochar-SO was calculated at the boiling point of nitrogen gas. The surface area and pore analyzer (BELSORP – Mini II, BEL Japan, Inc.) was used to assess the BET surface area (SBET) of the biochar using nitrogen adsorption at 77 K [70, 71]. The BET plot was used to calculate surface area (SBET) (m2/g), monolayer volume (Vm) (cm3 (STP) g−1), total pore volume (p/p0) (cm3/g), mean pore diameter (nm), and energy constant (C) for the isotherm. The following equation was used to compute the average pore radius (3).

To determine the mesopore surface area (Smes), micropore surface area (Smi), mesopore volume (Vmes), and micropore volume (Vmi) of biochar-SO, Barrett-Joyner-Halenda (BJH) method was used by using BELSORP analysis program software.

The BJH method [72] is used to compute the pore size distribution from the desorption isotherm.

The surface morphology of the biochar-SO sample was investigated using a scanning electron microscope (SEM) (QUANTA 250) in conjunction with an energy dispersive X-ray spectrometer (EDX) for elemental analysis.

The functional groups on the biochar-SO surface were investigated using Fourier transform infrared (FT-IR) spectroscopy (VERTEX70) and ATR unit model V-100.

Thermal analyses were carried out using the SDT650-simultaneous thermal analyzer device at a temperature range of 25 °C to 1000 °C, at a temperature increase rate of 5 °C/min.

2.5 Theoretical background

It is assumed in the Langmuir model [73] that adsorption takes place in monolayers on a surface and that there is no transmigration of adsorbate along the plane of the surface [74]. In the Langmuir linear equation, qe (mg/g) represents the equilibrium adsorption capacities; Ce (mg/L) represents the equilibrium concentration; Qm (mg/g) represents the maximum adsorption capacity of a monolayer; and Ka (L/mg) represents a constant that represents the adsorption equilibrium sorption energy; the equation can be written as Eq. (2) [60, 75, 76].

Figure 1 shows the Freundlich model [77] in its linear version, as indicated in Eq. (4). In this equation, KF and 1/n express the relative adsorption capacity constant and the intensity of the adsorption or the degree of surface heterogeneity, respectively. When the value of 1/n approaches zero, it becomes more heterogeneous. The linear version of the Temkin isotherm equation is given by Eq. (5) [60, 78,79,80,81,82], which is the linear form of the equation. It is calculated with BT = (RT)/b in this equation, b is proportional to the heat of adsorption, with the equilibrium binding constant AT (L/mg) equal to the maximum binding energy, with the absolute temperature T (K), and the universal gas constant R (8.314 J/mol K) [83, 84].

A model developed by Dubinin and Radushkevich [85,86,87] is used to evaluate the apparent free energy of porosity and the characteristic of adsorption. The Dubinin-Radushkevich isotherm does not make any assumptions about the surface homogeneity or the continuous sorption potential. The Dubinin-Radushkevich (D-R) model has been widely used to solve the linear Eqs. (6) and (7), which are shown in Table 1.

Pseudo–first-order (PFO) adsorption is represented by the linear Eq. (8) [88], where qt (mg/g) is the adsorption capacity at time t (min); and k1 (L/min) is the rate constant of PFO adsorption. It should be possible to estimate the slope and intercept of the plot by plotting log(qe–qt) with time. This should result in a linear relationship from which the value of k1 and the projected value of qe can be calculated. Using Eq. (9), Ho et al. [89] derive the linear PSO model, in which k2 (g mg−1·min−1) is the adsorption second-order rate constant, which is utilized to compute the initial sorption rate, h, h = k2qe2.

The intercept and slope of the plots of t/qt vs. t, as well as the values of k2 and qe, may be evaluated from the values of k2 and qe, respectively. As a general rule, the linear Elovich kinetic model is represented by Eq. (10), in which α (mg/g min) and β (g/mg) are the initial adsorption rate and desorption constant, respectively. It should be possible to plot the data to see that qt is related to ln(t) in a linear fashion with slope (1/β) and intercept (1/β) ln(αβ) [90,91,92]. With the help of Eq. (11) [93, 94], we may investigate the potential of intraparticle diffusion. As the value of the intercept C grows, the barrier to external mass transfer increases proportionally. When plotting qt against t1/2, the intraparticle diffusion rate constant (mg g−1·min−1/2) can be calculated directly from the slope of the regression line of the regression line of the plot of qt versus t1/2 (Table 2).

Using Eq. (12), which displays the fit between experimental and anticipated data acquired from isotherm model curves [95], the average percentage error (APE) can be calculated (Table 3). Equation (13) [96, 97] expresses the fractional error function for hybrid fractional error. It is given as Eq. (14) the chi-square error, X2, as determined by Ho et al. [97]. Marquart’s percentage standard deviation (MPSD) [60, 95] can be evaluated using Eq. (15). Equation (16) calculates the absolute error sum (EABS) between points [60, 95]. According to Eq. (17), the root means square errors (RMSE) can be calculated [60, 95].

3 Results and discussion

3.1 The characteristics of biochar-SO

The FT-IR method was used to detect the functional groups in the biochar-SO sample that had been manufactured [26,27,28]. Figure 1 illustrates the FT-IR spectra of raw pea peel and biochar-SO, as well as the spectrum of the biochar-SO. Specifically, the strong band at 3224–3378 cm−1 indicates the O–H stretching oscillation, and it was found in both raw pea peel and biochar-SO. The band at 2919–2929 cm−1 is attributed to the –CH stretching oscillation and was found in raw pea peel and biochar-SO, among other things. The adsorption peak at 1701 cm–1 can be attributed to C = O stretching of the carboxyl group, which was present in biochar-SO but was not present in the raw pea peel, demonstrating the synthesis of a new carboxylic group in biochar-SO (Fig. 1). The band at 1620 cm−1 indicates the presence of the C = O stretching oscillation, which was nearly completely absent in the raw pea peel and biochar-SO. Because the C–O functional group was weak, the peak at 1414–1436 cm−1 indicates that the raw pea peel and biochar-SO both included the C–O functional group. Pea peel contains oxygenated carbon chains, with the presence of oxygenated carbon chains peaking at 1239, 1064, and 1002 cm−1. This reflects the C–O–C asymmetric stretching functional group for the raw pea peel. The dehydration with H2SO4 led to the formation of new peaks that appeared at 1151.5, 1037, 879, and 576.6 cm−1, which are due to the formation of sulfonic acid and sulfoxide groups in biochar-SO. These new peaks prove the formation of the biochar-SO due to the treatment of pea peels with 50% H2SO4.

The BET and BJH methods were used to evaluate the textural parameters of the biochar-SO. The BET-specific surface area, mesopore area, total pore volume, mesopore volume, monolayer volume, mean pore diameter, and mesopore distribution peak for the biochar-SO is shown in Fig. 2 [26,27,28]. Figure 2 shows that the BET-specific surface area of biochar-SO was 19.132 m2/g and the monolayer volume value of biochar-SO was 4.94 cm3/g. The total volume value of biochar-SO was 0.022 cm3/g and the mean pore diameters of biochar-SO was 4.45 nm (mesopores). The meso surface area of biochar-SO was 15.94 m2/g and the mesopore distribution peak values of biochar-SO was 1.66 nm.

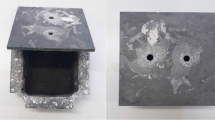

Raw pea peel and biochar-SO micrographs were analyzed by a scanning electron microscope (Fig. 3). The porous structure of prepared biochar with varied sizes, as shown in Fig. 3b of biochar-SO, indicates that the surface area is rather high.

Chemical compositions of the biochar-SO sample were analyzed with EDX (Table 1). Table 4 shows the absence of nitrogen and the presence of 34.24% oxygen and 11.68% of sulfur besides 50.57% of carbon.

The thermogravimetric profile of the raw materials pea peels and biochar-SO samples as a function of temperature is shown in Fig. 4a [26,27,28]. In accordance with Fig. 4a, the degradation of the raw material pea peels and a biochar-SO sample takes place in three stages. When the sample is heated to temperatures varying from 50 to 150 °C, the first step results in the loss of surface-bound water and moisture present in the sample, with weight losses of approximately 4.04 and 8.78% for the raw material pea peels and biochar-SO sample, respectively, in the first step. The second weight loss phase resulted in approximately 63.68% weight loss at 150–350 °C and 20.53% weight loss at 150–275 °C for the raw material pea peels and biochar-SO sample, respectively, in the second weight loss step. The third weight loss phase resulted in approximately 5.014% weight loss at 350–1000 °C and 25.70% weight loss at 275–1000 °C for the raw materials pea peels and biochar-SO sample, respectively, in the third weight loss step. The weight stayed in the same order as the raw material pea peels and biochar-SO, and the percentages of 27.27 and 45.10% were achieved, indicating that biochar-SO is more stable than the raw materials.

Differential thermal analysis (DTA) can only be utilized as a fingerprint for identifying purposes; however, the majority of the time, this method is employed for phase diagram determination, heat change measurements, and decomposition in diverse environments (Fig. 4b). Comparing the DTA curves of raw pea peel and biochar-SO samples, the raw pea peel sample showed two peaks at flow Tf temperature (76.67 and 342.45 °C), while biochar-SO sample showed two peaks at a lower flow Tf temperature (75.95 and 213.84 °C). According to this analysis result, the pea peel sample shows more stability than biochar-SO. However, the pyrolysis of both the raw pea-peel and biochar-SO samples reveals two distinct degradation peaks that can be distinguished from one another. After being treated with sulfuric acid, the degradation peaks are reduced to two peaks. Following acid treatment and dehydration, these findings suggest that the degree of degradation of the pea peel has been lowered.

It is possible to compare materials by using differential scanning calorimetry, which measures thermal transitions. Figure 5 depicted the DSC of the raw pea peel and biochar-SO in comparison to each other. Crystallization temperature (TC) values for all samples were below 100 °C, indicating that the crystallization of water molecules was responsible for their formation. It was determined by DSC that the TC of the pea peel raw material was between 348.29 and 758.59 °C. The DSC analysis of biochar-SO revealed a crystallization temperature (TC) of 219.84 degrees Celsius [26, 27].

3.2 Adsorption of Cr 6+ ions on biochar-SO

3.2.1 Effect of initial pH

Solution pH is among the most significant parameters affecting adsorption. The solution pH affects the amino, carboxyl, and hydroxyl groups on the biochar surface and creates a repulsive/attractive force between the adsorbent and the adsorbate. By using 1 g·L−1 of biochar-SO, the amount of Cr6+ ions adsorbed at equilibrium (qe) and the percentage of effacement of these ions were determined in the experimental studies carried out in a solution containing 100 mg·L−1 of Cr6+ ions and at room temperature (25 ± 2 °C). Figure 6 shows how the adsorption of Cr6+ ions changes with pH over 24 h after contact time in the pH range of 1.48 to 9.41. For the removal of Cr6+ ions using biochar-SO, it is seen in Fig. 6a that the highest Cr6+ ion removal (90.74%) occurred at pH 1.48. Figure 6b shows the amount of Cr6+ ions at equilibrium (qe, mg·g−1) attached to the biochar-SO surface in the pH range of 1.48 to 9.41. According to Fig. 6b, when the adsorption of Cr6+ ions to biochar-SO is examined, the amount of Cr6+ ions adsorbed at equilibrium (qe) slightly decreased (from 90.74 to 82.63 mg·g−1) with the increase in pH value from 1.48 to 3.52, and then we see that it remains constant up to 9.41 pH (81.80 mg·g−1). Therefore, it was concluded that the optimum working pH value for the removal of Cr6+ ions on biochar-SO is 1.48. The percentages of Cr6+ ion removal obtained at all pH values studied ranged between 81.80 and 90.74%. There are two proposed mechanisms in the adsorption process of Cr6+ ions on biochar-SO: (1) There is an attraction between the positively charged biochar-SO and the negatively charged Cr6+ ions and (2) Cr6+ ions are reduced to Cr3+ ions and form complexes with carboxyl and hydroxyl groups on biochar-SO. Between pH 1 and 4, electrostatic attraction forces occur between HCrO4− and Cr2O72−, which are the dominant types of Cr6+ ions, and biochar-SO proving that biochar-SO is an effective adsorbent in adsorbing Cr6+ ions.

3.2.2 Effect of contact time

The effect of contact time on Cr6+ ions, which is different beginning concentrations (50–300 mg·L−1), adsorption by biochar-SO was examined and the results are illustrated in Fig. 7. The removal rate of the Cr6+ ions of the biochar-SO had reached 86–97% in the initial 15–30 min (Fig. 7). The reason for this high removal in the first 30 min can be shown that there is sufficient active adsorption site on biochar-SO at the initial stage of adsorption. As these regions are filled with Cr6+ ions in time, there is not enough active site left, so the removal % has followed a stable course. After 60 min, the adsorption of Cr6+ ions is nearly invariable. At the end of 3 h, it was observed that there were no significant changes in Cr6+ ion concentrations, and the values were measured as 99% for all biochar-SO doses. If all the initial Cr6+ ion concentrations studied are compared, although they show similar removal %, the reason why the beginning concentration of 50 mg·g−1 is slightly more than the initial concentration of 300 mg·g−1 removal % is the limited number of active substances on biochar-SO. This is because the regions hold as many ions as they can and the excess ions remain in the solution.

3.2.3 Effect of initial Cr 6+ ion concentration

Another significant parameter in the adsorption process is the initial concentration of the adsorbed substance. Figure 8 shows the effect of solutions with different initial Cr6+ ion concentrations on the adsorption capacity at equilibrium (qe). To find the effect of biochar-SO dosage on adsorption capacity at equilibrium (qe), the adsorbent concentration (2.0–6.0 g·L−1) and the beginning Cr6+ ion concentration (50–300 mg·L−1) was studied at 25 °C at a pH of 1.48. It can be seen in Fig. 8 that the amount of Cr6+ ions adsorbed at equilibrium (qe) decreases regularly as the biochar-SO dosage increases from 2.0 to 6.0 g·L−1 at the same initial Cr6+ ion concentration. If the equilibrium (qe) adsorption capacities are examined in the elimination of chromium ions by using biochar-SO adsorbent at different doses (2.0–6.0 g·L−1) for beginning Cr6+ ion concentrations (50–300 mg·L−1), these values range from 24.69 to 135.32, 16.56 to 91.42, 12.44 to 70.52, 9.97 to 56.69, and 8.31 to 49.53 mg·g−1 for biochar-SO dosages (2.0, 3.0, 4.0, 5.0, and 6.0 g·L−1), respectively. Therefore, it is seen in Fig. 8 that increasing the beginning Cr6+ ion concentration in all biochar-SO dosages leads to an increase in the amount of Cr6+ ions adsorbed at equilibrium (qe).

3.2.4 Effect of adsorbent dosage on Cr 6+ ion adsorption

The effect of adsorbent dosage on the adsorption process of Cr6+ ions by biochar-SO was examined by varying the adsorbent dosage (2–6 g·L−1), the beginning concentration of Cr6+ ions (50–300 mg·L−1), adsorption time (3 h), and solution temperature (25 ± 2 °C) at an initial pH of 1.48. As shown in Fig. 9a, with an increase in the quantity of biochar-SO adsorbent, the removal efficiency of Cr6+ ions by biochar-SO increased continuously. However, while this increase is negligible in 50 mg·L−1 and 75 mg·L−1 dosages, it reaches from 90 to 100% in 100, 150, 200, and 300 mg·L−1 dosages. Cr6+ ion removal was between 90 and 100% at all adsorbent dosages (2–6 g·L−1) and all beginning Cr6+ ion concentrations (50–300 mg·L−1) studied. The quantity of Cr6+ ions adsorbed at equilibrium (qe) decreases with the increase of biochar-SO adsorbent dosage for all initial Cr6+ ion concentrations. Besides, the quantity of chromium ions adsorbed at equilibrium (qe) decreases from 24.69 to 8.31, 36.75 to 12.47, 45.97 to 16.61, 69.87 to 24.95, 92.12 to 33.13, and 135.32 to 49.53 mg·g−1 with increasing of the amount of biochar-SO adsorbent from 2.0 to 6.0 g·L−1 for initial Cr6+ ion concentrations 50, 75, 100, 150, 200, and 300 mg·L−1, respectively. It is seen in Fig. 9 that the lowest quantity of removal process at equilibrium (qe) and maximum (%) of removal was carried out using 6.0 g·L−1 of biochar-SO dosage.

3.3 Adsorption isotherms

The relationship curve between the adsorption process amount of the adsorbent and the equilibrium concentration of the adsorbent with the adsorption process at a certain adsorption temperature is expressed by the adsorption isotherm. In this study, the correlation between experimental data with different initial Cr6+ ion concentrations and Langmuir, Freundlich, Temkin, and Dubinin-Radushkevich (D-R) isotherm models were investigated. To evaluate the isotherm parameters, linear method was tested. While Fig. 11 shows the graphs of four different isotherm models, the isotherm parameters obtained from these graphs are summarized in Table 5.

The linear form of the Langmuir model showed a high correlation coefficient (R2) ≥ 0.981 when the biochar-SO dose was 4 g·L−1. The maximum monolayer capacity (Qm) of the biochar-SO adsorbent was calculated as 158.73 mg·g−1 when the biochar-SO dosage was 2.0 g·L−1. To calculate the values of 1/QmKL and 1/Qm from the parameters of the Langmuir model, Ce/qe vs. Ce is plotted as illustrated in Fig. 10a, and the intercept and slope of this graph give these values, respectively. As seen in Table 5, the equilibrium adsorption coefficient KL value varies between 0.1 and 1.34 in different adsorbent dosages and the R2 value is as high as 0.981 in biochar-SO with 4 g·L−1 dosage, which is evidence that Cr6+ ions hold on biochar-SO. The high R2 coefficient in the Langmuir isotherm model indicates that Cr6+ ions are adsorbed in a single layer on the biochar-SO surface.

The Freundlich isotherm model, which correctly establishes the adsorption process as a heterogeneous phenomenon, was also used to determine the effectiveness of biochar-SO adsorbent in the removal of Cr6+ ions. To calculate the values of logKF and 1/nF from the parameters of the Freundlich model, log(qe) vs. log(Ce) is plotted as illustrated in Fig. 10b, and the intercept and slope of this graph give these values, respectively. The coefficient KF, which symbolizes the relative adsorption capacity of the biochar-SO, decreased with improving adsorbent dosage (from 2.0 to 5.0 g·L−1). KF value increases when the dosage is improved from 5.0 to 6.0 g·L−1. Generally, the improvement in the adsorption capacity of the adsorbent is directly proportional to the increase in the KF value. The immensity of the Freundlich isotherm exponent 1/n is an index of the degree of the favorability of an adsorption process. In Table 5, since all 1/n values are less than 1, all the n values are above 1, varying between 1.93 and 3.18, an indicator that adsorption of Cr6+ ions on biochar-SO was favorable. The fact that the adsorption process of Cr6+ ions on biochar-SO is a suitable physical process depends on the value of nF greater than 1. Table 5 shows that the Freundlich Qm value for biochar-SO is 159 mg·g−1 at 2 g·L−1 adsorbent dosage. A high Qm value indicates that Cr6+ ions are adsorbed so well on the biochar-SO surface. Freundlich isotherm correlation coefficient also showed a high value (R2 = 0.975) similar to that of Langmuir isotherm.

The Temkin isotherm model, which takes into account the interaction between adsorbate and adsorbent, determines a factor for this. The Temkin model assumes that with the accumulation of adsorbed molecules or ions on the adsorbent surface, the heat of adsorption of all molecules in the layer will decrease over time. This assumption is made due to these interactions and neglecting very low and very high concentration values. The lowest and highest values obtained at five different adsorbent dosages (2.0–6.0 g·L−1) from the Temkin isotherm were AT = 2.72–23.34 L·g−1 and BT = 8.69–24.52 kJ·mol−1, indicating that the adsorption of Cr6+ ions onto biochar-SO occurred via ion exchange, except for the 6.0 g·L−1. The value for the bonding energy was between 8 and 16 kJ·mol−1 and thus the process implied is ion exchange. Considering the correlation coefficients of the Temkin isotherm model, it was observed that it was in the range of 0.912–0.975 in all samples, except for the 2.0 g·L−1 adsorbent (R2 = 0.770) dosed sample, and it can be said to agree with the experimental data.

Equilibrium data were performed to the D-R isotherm model to understand whether the adsorption of Cr6+ ions to Biochar-SO is physical or chemical, and the results are illustrated in Table 5. The D-R isotherm model is attributed to the Polanyi potential theory, which is applied where the adsorption process continues until the pores are filled. The apparent energy (E) value is used to predict the type of adsorption process. If the E value is < 8 kJ mol–1, it refers to physical adsorption, 8–16 kJ·mol−1 refers to ion exchange, and > 16 kJ·mol−1 refers to chemical adsorption takes place.

The estimated values of bonding energy (E) for the present study were found to be > 16 kJ/mol for all adsorbent dosage as (1581–2886 kJ·mol−1), which implies that adsorption of chromium ions onto biochar-SO adsorbent is by chemical adsorption. They are chemical species that develop on the adsorbent surface, which are effective in bond formation during a chemical reaction. In the Dubinin-Radushkevich model, the R2 values ranged from 0.610 to 0.924 for Cr6+ by the biochar-SO adsorbent (Table 5).

3.4 Statistical error function analysis of isothermal models

After obtaining the empirical equilibrium data of chromium ions on biochar-SO using Langmuir, Freundlich, Temkin, and D-R isotherm models, several different error functions (hybrid error function) (HYBRID), the root mean square errors (RMS), average percent errors (APE), the sum of the absolute errors (EABS), chi-square error (X2), and Marquardt’s percent standard deviation (MPSD) were used [60]. The smaller the six error function values expressing the similarity between the experimental data of pea-biochar and the values calculated using theoretical isotherms, this indicates that the model better represents the experimental data (Table 6). The Freundlich model, which has smaller error function values compared to the other models according to the values in Table 6, was determined as the most suitable model for this study.

3.5 Adsorption kinetic studies

For the resulting biochar-SO adsorbents to be considered as candidates for wastewater treatment, a high equilibrium adsorption capacity for a given system must be achieved along with appropriate kinetic parameters. In this study, four kinetic models (pseudo–first-order (PFO) kinetic model, pseudo–second-order (PSO) kinetic model, Elovich kinetic model, and intraparticle diffusion) were used to analyze the data obtained on the adsorption of Cr6+ ions to biochar-SO as shown in Fig. 11. Values for these models are also summarized in Tables 7–8.

The equilibrium adsorption capacity (qe) and the rate constant, k1, were determined using straight-line plots of lg(qe − qt) versus t (Fig. 11a). The R2 correlation values (changing between 0.738 and 0.990) of the PFO kinetic model are also illustrated in Table 7 for all adsorbent dosages (2–6 g·L−1) and beginning Cr6+ ion concentrations (50–300 mg·L−1). Since the R2 values obtained from Fig. 11a of the PFO kinetic model are relatively low (compared with the PSO kinetic model), this indicates that the evaluated qe values deviate greatly from the experimental values. When the R2 correlation coefficients of the adsorption of Cr6+ ions on biochar-SO in Table 7 were examined, no regular increase or decrease in R2 values was observed with the increase of the adsorbent dosage from 2 to 6 g·L−1 or the initial Cr6+ ion concentration from 50 to 300 mg·L−1.

The equilibrium adsorption capacity (qe) and the rate constant, k2 (g·mg−1·min−1), are calculated by plotting t/qe versus t as illustrated in Fig. 11b. The R2 correlation values of the PSO kinetic model are also illustrated in Table 7 for all adsorbent dosages (2–6 g·L−1) and beginning chromium ion concentrations (50–300 mg·L−1). Since the R2 values obtained from Fig. 11b of the PSO kinetic model are 1, this implies that the calculated qe values do not deviate from the experimental values. Therefore, the most suitable kinetic model is the PSO kinetic model.

The third model examined, the Elovich model, makes assumptions about the diffusion of gases to heterogeneous surfaces. α (mg·g−1·min−1) and β (g·mg−1) in the model refer to the adsorption and desorption rates, respectively. Elovich constant α was calculated from the intercept of Fig. 11c and Elovich constant β was calculated from its slope and is illustrated in Table 5. The R2 correlation coefficients of the Elovich model are similar to the values of the PFO kinetic model. However, neither model is as suitable for experimental data as the PSO kinetic model (Tables 7–8). The results show that the chemical adsorption during the adsorption of Cr6+ ions on the biochar-SO adsorbent can be rate-limiting in some cases. However, the fact that the R2 values are not very high makes it possible to have physical adsorption in the process.

In addition to the models described above, it is useful to consider the intraparticle diffusion model as it gives an idea about the diffusion mechanism of the system. Adsorption of an adsorbate to an adsorbent takes place in 3 steps: (i) First, the ions and molecules in the solution adhere to the surface of the adsorbent particles through the liquid film. (ii) The ions and molecules attached to the surface are then diffused into the adsorbent. (iii) A chemical reaction takes place very quickly in the active groups of the adsorbent particles. In determining the adsorption rate, the step with the slowest speed from these three steps is taken as a basis. If the lines obtained according to Fig. 11d pass through the origin, this shows that the adsorption process is controlled by the intraparticle diffusion step by Weber and Morris [93]. As seen in Fig. 11d, in cases where the lines do not pass through the origin, that is, the C values are large, the rate of the adsorption process is determined by the film diffusion. This can be explained by the decrease in Biochar-SO pore volume and surface area overtime during the adsorption process. The C and Kdif values shown in Table 8 were evaluated from the intercept point and slope of the plot of qt versus t0.5, respectively. When the C values of the adsorption of Cr6+ ions on biochar-SO in Table 8 were examined, a regular increase in C values was observed with the increase of the adsorbent dose from 2.0 to 6.0 g·L−1 or the initial Cr6+ ion concentration from 50 to 300 mg·L−1.

3.6 Comparison with results reported in the literature

In the literature review summarized in Table 9, the effectiveness of the elimination of chromium ions using alternative adsorbents was compared with the biochar-SO and showed that biochar-SO was potent in removing chromium ions.

3.7 Regeneration of biochars

It is a widely used method for the removal of pollutants from wastewater that relies heavily on the reuse of adsorbent materials, and the economics of this technology is highly dependent on the reuse of these adsorbent materials as well. For the regeneration of depleted biochar-SO, a chemical regeneration process is employed. The biochar-SO was regenerated by washing it with 0.1-N NaOH solution, 0.1-M HCl solution, and then hot pure water, followed by drying it. It was discovered that the highest removal of Cr6+ ions by biochar-SO was 90% after six regeneration cycles, respectively (Fig. 12), demonstrating that biochar-SO can regenerate.

4 Conclusion

This study showed that pea peels, which are agricultural waste, can be used as inexpensive and effective biochar. Biochar-SO produced from pea peels was used for the elimination of Cr6+ ions from wastewater. It has been understood that solution pH, adsorbent dosage, initial concentration of Cr6+ ions, and adsorption time are effective parameters in the adsorption process of chromium ions onto prepared biochar-SO. For the elimination of chromium ions using biochar-SO, it was determined that the highest Cr6+ removal (90.74%) occurred at pH 1.48. Biochar adsorbent with 6 g·L−1 concentration had minimum adsorption amount (qe) at equilibrium and maximum removal percentage in removing Cr6+ ions. It has been determined that the Freundlich isotherm model in the elimination of chromium ions on biochar-SO is in perfect agreement with the experimental data (R2 = 1). Although the sorption of Cr6+ ions onto biochar-SO adsorbent was better described by the Freundlich model, the maximum adsorption capacity calculated by using the Langmuir isotherm as 158.73 mg·g−1. Estimated binding energy (E) values (1581–2886 kJ·mol−1) obtained from Dubinin-Radushkevich isotherm models for this study show the chemical adsorption structure as it is considerably larger than 16 kJ·mol−1. In conclusion, we believe that biochar-SO obtained from pea peels may be successfully used to purify wastewaters containing toxic Cr6+ ions.

Data availability

Data sharing is not applicable to this article.

References

Gao JXQ, Bu X-H (2019) Recent advances about metal-organic frameworks in the removal of pollutants from wastewater. Coord Chem Rev 378:17–31

Maleki BHA, Naghizadeh M, Joo SW (2015) Adsorption of hexavalent chromium by metal organic frameworks from aqueous solution. J Indust Eng Chem 28:211–216

Yi F-Y, Li J-P, Wu D (2015) Sun Z-M (2015) A series of multifunctional metal–organic frameworks showing excellent luminescent sensing, sensitization, and adsorbent abilities. Chem Eur J 21:11475–11482

El Nemr A (2011) Impact, monitoring and management of environmental pollution. Nova Science Publishers, Inc. Hauppauge New York. [ISBN-10: 1608764877, ISBN-13: 9781608764877], 638 pages.

El Nemr A (2012) Environmental pollution and its relation to climate change. Nova Science Publishers, Inc. Hauppauge New York. [ISBN-13: 978–1–61761–794–2] 694 pages.

El Nemr A (2015) Heavy metals, algae and microbial activities in marine system. Nova Science Publishers, Inc. Hauppauge New York. [Hard cover ISBN: 978–1–63482–314–2, e-Book. ISBN: 978–1–63482–315–9]. 663 pages.

El Nemr A (2016) Pollution status, environmental protection, and renewable energy production in marine systems. Nova Science Publishers, Inc. Hauppauge New York. [Hard cover ISBN: 978–1–63484–047–7, e-Book. ISBN: 978–1–63484–282–2].

Kobielska PA, Howarth AJ, Farha OK, Nayak S (2018) Metal–organic frameworks for heavy metal removal from water. Coord Chem Rev 358:92–107

Peng Y, Huang H, Zhang Y, Kang C, Chen S, Song L, Liu D, Zhong C (2018) A versatile MOF-based trap for heavy metal ion capture and dispersion. Nature Commun 9:187–196

Sarkara YXB, Megharaj M, Krishnamurti GSR, Rajarathnam D, Naidu R (2010) Remediation of hexavalent chromium through adsorption by bentonite based Arquad® 2HT-75 organoclays. J Hazard Mater 183:87–97

Zhang YLY, Li J, Sheng G, Zhang Y, Zheng X (2012) Enhanced Cr(VI) removal by using the mixture of pillared bentonite and zero-valent iron. Chem Eng J 185:243–249

Fida SGH, Zhang G (2015) Preparation and characterization of bifunctional Ti–Fe kaolinite composite for Cr(VI) removal. J Coll Interf Sci 442:30–38

Myers CR, Myers JM, Carstens BP, Antholine WE (2000) Reduction of Chromium (VI) to chromium(V) by human microsomal enzymes: effects of iron and quinones. Toxic Substance Mechanisms 51:19–25

Dupont L, Guillon E (2003) Removal of hexavalent chromium with a lignocellulosic substrate extracted from wheat bran. Environ Sci Technol 37:4235–4241

Abdel Wanees S, Ahmed AMM, Adam MS, Mohamed MA (2013) Adsorption studies on the removal of hexavalent chromium- contaminated wastewater using activated carbon and bentonite. Asian J Chem 25:8245–8252

Baıley SE, Olin TJ, Mark Bricka R, Dean D (1999) Adrian, A review of potentially low-cost sorbents for heavy metals. Water Res 33:2469–2479

Reddad Z, Gerente C, Andres Y, Cloirec PL (2002) Adsorption of several metal ions onto a low-cost biosorbent: kinetic and equilibrium studies. Environ Sci Technol 36:2067–2073

Abdelwahab O, El Sikaily A, Khaled A, El Nemr A (2007) Mass transfer processes of chromium (VI) adsorption onto guava seeds. Chem Ecol 23(1):73–85

Hassaan MA, El Nemr A, Madkour FF (2017) Testing the advanced oxidation processes on the degradation of direct blue 86 dye in wastewater. Egypt J Aquat Res 43:11–19. https://doi.org/10.1016/j.ejar.2016.09.006

Hassaan MA, El Nemr A, Madkour FF (2017) Advanced oxidation processes of mordant violet 40 dye in freshwater and seawater. Egypt J Aquat Res 43:1–9. https://doi.org/10.1016/j.ejar.2016.09.004

Alghamdi MM, El-Zahhar AA, Idris AM, Sadi TO, Sahlabji T, El Nemr A (2019) Synthesis, characterization and application of a new polymeric-clay-magnetite composite resin for water softening. Sep Purif Tech 224:356–365. https://doi.org/10.1016/j.seppur.2019.05.037

Ismail MNM, El Nemr A, El Ashry ESH, Abdel Hamid H, Novel simple modification of chitosan as adsorptive agent for removal of Cr6+ from aqueous solution. Egypt J Chem 63(4):219–1240. https://doi.org/10.21608/ejchem.2019.11157.1716

El Nemr A, Shoaib AGM, El Sikaily A, Mohamed AE-DA, Hassan AF (2021) Evaluation of cationic methylene blue dye removal by high surface area mesoporous nano activated carbon derived from Ulva lactuca. Environ Process 8(1):311–332. https://doi.org/10.1007/s40710-020-00487-8

Baran A, Bıçak E, Baysal SH, Onal S (2006) Comparative studies on the adsorption of Cr(VI) ions on to various sorbents. Bioresour Technol 98:661–665

Liu W, Zhang J, Zhang C, Wang Y, Li Y (2010) Adsorptive removal of Cr (VI) by Fe-modified activated carbon prepared from Trapa natans husk. Chem Eng J 162:677–684

El-Nemr MA, Ismail IMA, Abdelmonem NM, Ragab S, El Nemr A (2020) Ozone and ammonium hydroxide modification of biochar prepared from Pisum sativum peels improves the adsorption of copper (II) from an aqueous medium. Environ Process 7:973–1007. https://doi.org/10.1007/s40710-020-00455-2

El-Nemr MA, Abdelmonem NM, Ismail IMA, Ragab S, El Nemr A (2020) The efficient removal of the hazardous Azo Dye Acid Orange 7 from water using modified biochar from Pea peels. Desal Water Treat 203:327–355

El-Nemr MA, Abdelmonem NM, Ismail IMA, Ragab S, El Nemr A (2020) Removal of Acid Yellow 11 dye using novel modified biochar derived from Watermelon Peels. Desal Water Treat 203:403–431

El-Nemr MA, Ismail IMA, Abdelmonem NM, El Nemr A, Ragab S (2021) Amination of biochar derived from watermelon peel by triethylenetetramine and ammonium hydroxide for toxic chromium removal enhancement. Chinese J Chem Eng 36:199–222. S1004–9541(20)30464-X

Ali IO, Thabet MS, El-Nasser KS, Hassan AM, Salama TM (2012) Synthesis of nanosized ZSM-5 zeolite from rice straw using lignin as a template: surface-modified zeolite with quaternary ammonium cation for removal of chromium from aqueous solution. Microporous Mesoporous Mater 160:97–105

Shen Y-S, Wang S-L, Tzou Y-M, Yan Y-Y, Kuan W-H (2012) Removal of hexavalent Cr by coconut coir and derived chars – the effect of surface functionality. Bioresour Technol 104:165–172

Zibaei Z, Ghasemi-Fasaei R, Ronaghi A, Zarei M, Zeinali S (2020) Improvement of biochar capability in Cr immobilization via modification with chitosan and hematite and inoculation with Pseudomonas putida. Commun Soil Sci Plant Anal 51:963–975

El Nemr A, Aboughaly RM, El Sikaily A, Ragab S, Masoud MS, Ramadan MS (2021) Microporous nano activated carbon type I derived from orange peel and its application for Cr(VI) removal from aquatic environment. In press, Biom Conv Bioref. https://doi.org/10.1007/s13399-020-00995-5

El Nemr A, Aboughaly RM, El Sikaily A, Ragab S, Masoud MS, Ramadan MS (2021) Utilization of sugarcane bagasse/ZnCl2 for sustainable production of microporous nano activated carbons of type I for toxic Cr(VI) removal from aqueous environment. In press, Biom Conv Bioref

Eldeeb TM, El Nemr A, Khedr MH, El-Dek SI, Imam NG (2020) Novel three-dimensional chitosan-carbon nanotube–PVA nanocomposite hydrogel for removal of Cr6+ from wastewater. Desal Water Treat 184:163–177. https://doi.org/10.5004/dwt.2020.25366

Eldeeb TM, El Nemr A, Khedr MH, El-Dek SI (2021) Novel bio-nanocomposite for efficient copper removal. Egypt J Aquat Res 47(3):261–267. https://doi.org/10.1016/j.ejar.2021.07.002

Eldeeb TM, El Nemr A, Khedr MH, El-Dek SI (2021) Imam NG (2021) Efficient removal of Cu(II) from water solution using magnetic chitosan nanocomposite. Nanotechnol Environ Eng 6:34. https://doi.org/10.1007/s41204-021-00129-w

Hosain ANA, El Nemr A, El Sikaily A, Mahmoud ME, Amira MF (2020) Surface modifications of nanochitosan coated magnetic nanoparticles and their applications in Pb(II), Cu(II) and Cd(II) removal. J Environ Chem Eng 8(5):104316. https://doi.org/10.1016/j.jece.2020.104316

Li Y, Gao B, Wu T, Sun D, Li X, Wang B, Fengjuan Lu (2009) Hexavalent chromium removal from aqueous solution by adsorption on aluminum magnesium mixed hydroxide. Water Res 43:3067–3075

Shoaib AGM, El-Sikaily A, El Nemr A, Mohamed AE-DA, Hassan AA (2021) Preparation and characterization of highly surface area activated carbons followed Type IV from marine red alga (Pterocladia capillacea) by zinc chloride activation. Biom Conv Bioref In press. https://doi.org/10.1007/s13399-020-00760-8

Shoaib AGM, El-Sikaily A, El Nemr A, Mohamed AE-DA, Hassan AA (2021) Testing the carbonization condition for high surface area preparation of activated carbon followed Type IV from green alga Ulva lactuca. In press, Biom Conv Bioref. https://doi.org/10.1007/s13399-020-00823-w

Shen Z, Hou D, Jin F, Shi J, Fan X, Tsang DCW, Alessi DS (2019) Effect of production temperature on lead removal mechanisms by rice straw biochars. Sci Total Environ 655:751–758

Tan X, Liu Y, Zeng G, Wang X, Hua X, Gu Y, Yang Z (2015) Application of biochar for the removal of pollutants from aqueous solutions. Chemosphere 125:70–85

Chen D, Zheng Z, Fu K, Zeng Z, Wang J, Lu M (2015) Torrefaction of biomass stalk and its effect on the yield and quality of pyrolysis products. Fuel 159:27–32

Shen Y (2015) Chars as carbonaceous adsorbents/catalysts for tar elimination during biomass pyrolysis or gasification. Renew Sustain Energy Rev 43:281–295

Li Wang Y, Ma F, Tankpa V, Bai S, Guo X, Wang X (2019) Mechanisms and reutilization of modified biochar used for removal of heavy metals from wastewater: a review. Sci Total Environ 668:1298–1309

Huggins TM, Haeger A, Biffinger JC, Ren ZJ (2016) Granular biochar compared with activated carbon for wastewater treatment and resource recovery. Water Res 94:225–232

Sahlabji T, El-Nemr MA, El Nemr A, Ragab S, Alghamdi MM, El-Zahhar AA, Idris AM, Said TO (2021) High surface area microporous activated carbon from Pisum sativum peels for hexavalent chromium removal from aquatic environment. Toxin Rev In Press. https://doi.org/10.1080/15569543.2021.1908361

Uchimiya M, Wartelle LH, Klasson KT, Fortier CA, Lima IM (2011) Influence of pyrolysis temperature on biochar property and function as a heavy metal sorbent in soil. J Agric Food Chem 59:2501–2510

Borah D, Satokawa S, Kato S, Kojima T (2009) Sorption of As(V) from aqueous solution using acid modified carbon black. J Hazard Mater 162:1269–1277

Budinova T, Petrov N, Parra J, Baloutzov V (2008) Use of an activated carbon from antibiotic waste for the removal of Hg(II) from aqueous solution. J Environ Manag 88:165–172

Kobya M, Demirbas E, Senturk E, Ince M (2005) Adsorption of heavy metal ions from aqueous solutions by activated carbon prepared from apricot stone. Bioresour Technol 96:1518–1521

Kula I, Uğurlu M, Karaoglu H, Celik A (2008) Adsorption of Cd(II) ions from aqueous solutions using activated carbon prepared from olive stone by ZnCl2 activation. Bioresour Technol 99:492–501

Sudaryanto Y, Hartono SB, Irawaty W, Hindarso H, Ismadji S (2006) High surface area activated carbon prepared from cassava peel by chemical activation. Bioresour Technol 97:734–739

Reffas A, B V, David B, Reinert L, Lehocine MB, Dubois M, Batisse N, Duclaux L (2010) Carbons prepared from coffee grounds by H3PO4 activation: characterization and adsorption of methylene blue and Nylosan Red N-2RBL. J Hazard Mater 175:779–788

Malkoc E, Nuhoglu Y (2007) Potential of tea factory waste for chromium(VI) removal from aqueous solutions: thermodynamic and kinetic studies. Sep Purif Technol 54:291–298

Sari A, Mendi D (2008) Mustafa Tuzen, Mustafa Soylak, Biosorption of Cd(II) and Cr(III) from aqueous solution by moss (Hylocomium splendens) biomass: equilibrium, kinetic and thermodynamic studies. Chem Eng J 144:1–9

Gao H, Liu Y, Zeng G, Xu W, Li T, Xia W (2008) Characterization of Cr(VI) removal from aqueous solutions by a surplus agricultural waste—rice straw. J Hazard Mater 150:446–452

Abdelwahab O, El Nemr A, El-Sikaily A, Khaled A (2005) Use of rice husk for adsorption of direct dyes from aqueous solution: a case study of Direct F Scarlet. Egypt J Aquat Res 31(1):1–12

El Nemr A, El-Sikaily A, Khaled A (2010) Modeling of adsorption isotherms of methylene blue onto rice husk activated carbon. Egypt J Aquat Res 36(3):403–425

El Nemr A (2007) Pomegranate husk as an adsorbent in the removal of toxic chromium from wastewater. Chem Ecol 23(5):409–425

El Nemr A (2009) Potential of pomegranate husk carbon for Cr(VI) removal from wastewater: kinetic and isotherm studies. J Hazard Mater 161:132–141

Uluozlu OD, Sari A, Tuzen M, Soylak M (2008) Biosorption of Pb(II) and Cr(III) from aqueous solution by lichen (Parmelina tiliaceae) biomass. Bioresour Technol 99:2972–2980

El Sikaily A, El Nemr A, Khaled A (2011) Copper sorption onto dried red alga Pterocladia capillacea and its activated carbon. Chem Eng J 168:707–714

El Nemr A, El Sikaily A, Khaled A, Abdelwahab O (2015) Removal of toxic chromium from aqueous solution, wastewater and saline water by marine red alga Pterocladia capillacea and its activated carbon. Arab J Chem 8:105–117. https://doi.org/10.1016/j.arabjc.2011.01.016

Basha S, Murthy ZVP, Jha B (2008) Biosorption of hexavalent chromium by chemically modified seaweed, Cystoseira indica. Chem Eng J 137:480–488

Dakiky M, Khamis M, Manassra A, Mereb M (2002) Selective adsorption of chromium(VI) in industrial wastewater using low-cost abundantly available adsorbents. Adv Environ Res 6:533–540

El Nemr A, El Sikaily A, Khaled A (2007) Abdelwahab O (2007) Removal of toxic chromium (VI) from aqueous solution by activated carbon using Casuarina equisetifolia. Chem Ecol 23(2):119–129

Eleryan A, El Nemr A, Mashaly M, Khaled A (2019) 6-Triethylenetetramine 6-deoxycellulose grafted with crotonaldehyde as adsorbent for Cr(VI) removal from wastewater. Inter J Scient Eng Res 10(7):1199–1211

Gregg SJ, Sing KSW (1982) Adsorption surface area and porosity, 2nd edn. Academic Press INC., London

Rouquerol F, Rouquerol J, Sing KSW (1999) Adsorption by powders and porous solids. Academic Press INC., London

Barrett EP, Joyner LG, Halenda PP (1951) The determination of pore volume and area distributions in porous substances I Computations from Nitrogen Isotherms. J Amer Chem Soc 73(1):373–380

Langmuir I (1916) The constitution and fundamental properties of solids and liquids. J Amer Chem Soc 38:2221–2295

Doğan M, Alkan M, Onganer Y (2000) Adsorption of methylene blue from aqueous solution onto perlite. Water Air Soil Pollut 120:229–249

Kinniburgh DG (1986) General purpose adsorption isotherms. Environ Sci Technol 20:895–904

Longhinotti E, Pozza F, Furlan L, Sanchez MDND, Klug M, Laranjeira MCM, Favere VT (1998) Adsorption of anionic dyes on the biopolymer chitin. J Braz Chem Soc 9:435–440

Freundlich HMF (1906) Über die adsorption inlösungen. Z Phys Chem (Leipzig) 57A:385–470

Tempkin MJ, Pyzhev V (1940) Kinetics of ammonia synthesis on promoted iron catalysts. Acta Physiochim, URSS 12:217–222

Kavitha D, Namasivayam C (2007) Experimental and kinetic studies on methylene blue adsorption by coirpith carbon. Bioresour Technol 98:14–21

Aharoni C, Ungarish M (1977) Kinetics of activated chemisorption. Part 2. Theoreticalmodels J Chem Soc Faraday Trans 73:456–464

Aharoni C, Sparks DL (1991) Kinetics of soil chemical reactions—a theoretical treatment, in: D.L. Sparks, D.L. Suarez (Eds.), Rate of Soil Chemical Processes, Soil Sci Soc America, Madison, WI 1–18.

Wang XS, Qin Y (2005) Equilibrium sorption isotherms for of Cu2+ on rice bran. Process Biochem 40:677–680

Pearce CI, Lioyd JR, Guthrie JT (2003) The removal of color from textile wastewater using whole bacterial cells: a review. Dyes Pigm 58:179–196

Akkaya G, Ozer A (2005) Adsorption of acid red 274(AR 274) on Dicranella varia: determination of equilibrium and kinetic model parameters. Process Biochem 40(11):3559–3568

Radushkevich LV (1949) Potential theory of sorption and structure of carbons. Zh Fiz Khim 23:1410–1420

Dubinin MM (1960) The potential theory of adsorption of gases and vapors for adsorbents with energetically non-uniform surface. Chem Rev 60:235–266

Dubinin MM (1965) Modern state of the theory of volume filling of micropore adsorbents during adsorption of gases and steams on carbon adsorbents. Zh Fiz Khim 39:1305–1317

Lagergren S (1898) Zurtheorie der sogenannten adsorption gelosterstoffe, Kungliga Svenska Vetenskapsakademiens. Handlingar 24:1–39

Ho YS, McKay G, Wase DAJ, Foster CF (2000) Study of the sorption of divalent metal ions on to peat. Adsorpt Sci Technol 18:639–650

Zeldowitsch J (1934) Über den mechanismus derkatalytischen oxidation von CO and MnO2, Acta Physicochim. URSS 1:364–449

Chien SH, Clayton WR (1980) Application of Elovich equation to the kinetics of phosphate release and sorption on soils. Soil Sci Soc Amer J 44:265–268

Sparks DL (1986) Kinetics of reaction in pure and mixed systems, in Soil Physical Chemistry. CRC Press, Boca Raton

Weber WJ, Morris JC (1963) Kinetics of adsorption on carbon from solution, Journal Sanit. Eng Division Amer Soc Civil Eng 89:31–60

Srinivasan K, Balasubramanian N, Ramakrishan TV (1988) Studies on chromium removal by rice husk carbon. Ind, J Environ Health 30:376–387

Porter JF, McKay G, Choy KH (1999) The prediction of sorption from a binary mixture of acidic des using single-and mixed-isotherm variants of the ideal adsorbed solute theory. Chem Eng Sci 54:5863–5885

Allen SJ, Gan Q, Matthews R, Johnson PA (2003) Comparison of optimized isotherm models for basic dye adsorption by kudzu. Bioresour Technol 88:143–152

Ho YS, Chiu WT, Wang CC (2005) Regression analysis for the sorption isotherms of basic dyes on sugarcane dust. Bioresour Technol 96:1285–1291

Sarin V, P KK (2006) Removal of chromium from industrial waste by using eucalyptus bark. Bioresour Technol 97:15–20

Fan LQ, Li Q, Wan Y, Wang XD, Mıao JX, Caı J, Chen W, Chen FH, Cheng L, Jı L, Luo HB (2019) Hexavalent chromium adsorption removal from aqueous solution by Fe-modified biochar derived from rice straw. Appl Ecol Environ Res 17:15311–15327

Janiszewska D, Olchowski R, Nowicka A, Zborowska M, Marszałkiewicz K, Shams M, Giannakoudakis DA, Anastopoulos I, Barczak M (2021) Activated biochars derived from wood biomass liquefaction residues for effective removal of hazardous hexavalent chromium from aquatic environments. GCB Bioenergy 13:1247–1259

Golestanıfar H, Haibati B, Amını H, Dehghanı MH, Asadı A (2005) Removal of hexavalent chromium from aqueous solution by adsorption on Y-alumina nanoparticles. Environ Protect Eng 41:133–146

Vasudevan M, Ajithkumar PS, Singh RP, Natarajan N (2016) Mass transfer kinetics using two-site interface model for removal of Cr(VI) from aqueous solution with cassava peel and rubber tree bark as adsorbents. Environ Eng Res 21:152–163

Junior ACG, Strey L, Lindino CA, Nacke H, Schwantes D, Seidel EP (2012) Applicability of the Pinus bark (Pinus elliottii) for the adsorption of toxic heavy metals from aqueous solutions. Acta Scientiarum Technol 34:79–87

Kumar MPS, Phanikumar BR (2013) Response surface modelling of Cr6+ adsorption from aqueous solution by neem bark powder: Box-Behnken experimental approach. Environ Sci Pollut Res 20:1327–1343

Çelebi H (2020) Recovery of detox tea wastes: usage as a lignocellulosic adsorbent in Cr6+ adsorption. J Environ Chem Eng 8(5):104310. https://doi.org/10.1016/j.jece.2020.104310

Funding

Open access funding provided by The Science, Technology & Innovation Funding Authority (STDF) in cooperation with The Egyptian Knowledge Bank (EKB). This work was partially funded by the Science and Technology Development Fund (STDF) of Egypt (Projects No. CB-4874 and CB-22816).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Consent to participate

Not applicable.

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

El-Nemr, M.A., Yılmaz, M., Ragab, S. et al. Biochar-SO prepared from pea peels by dehydration with sulfuric acid improves the adsorption of Cr6+ from water. Biomass Conv. Bioref. 14, 2601–2619 (2024). https://doi.org/10.1007/s13399-022-02378-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-022-02378-4