Abstract

In this paper, the properties of CuInSe2 (CISe) films deposited on three transparent substrates (FTO, FTO/NiOx, FTO/MoO3) are studied. These substrates might be used for bifacial solar cells, in place of the conventional glass/Mo substrates. CISe layers are deposited by spray pyrolysis followed by a selenization process. For the same deposition conditions, the CISe layers on FTO show the largest grain size (~ 0.50 µm) and crystallinity, while FTO/MoO3 substrates result in the smallest grains (~ 0.15 µm). The optical bandgap of the CISe films ranged from 1.35 eV for FTO substrate to 1.44 eV for FTO/MoO3 substrate. All films show p-type conductivity, with the carrier densities of 1.6 × 1017 cm−3, 5.4 × 1017 cm−3, and 2.4 × 1019 cm−3 for FTO, FTO/NiOx, and FTO/MoO3 substrates, respectively. The CISe films also show different conduction, and valence levels, based on the substrate. In all cases, an ohmic behavior is observed between the CISe and substrate. The results demonstrate that CISe layer crystallinity, carrier concentration, mobility, and energy levels are strongly dependent on the chemical nature of the substrate. Bare FTO shows the most appropriate performance in terms of device requirements.

Similar content being viewed by others

Introduction

Ternary semiconductors such as thin films of CuInGaSe2 (CIGS), CuInSe2 (CISe), CuInS2 (CIS), and their alloys have been widely used as absorbers for thin-film solar cells with high efficiencies and long-time stability. They have a narrow bandgap, high absorption coefficients, and good carrier-transport properties1,2. Recently these materials have shown successful application in other fields including a hole transporting material in perovskite solar cells3,4, photoelectrochemical water splitting5,6, photodetectors7,8, and photo-catalyst9,10. Although it has been a long time since the introduction of this class of semiconductors, it is still a challenge to make a low-cost film with proper features especially with the application in photovoltaics (PVs).

The deposition of CIGS and CISe thin films can be made using vacuum or solution-based techniques. The usual vacuum methods such as evaporation and/or sputtering are expensive and require high energy input. Therefore, alternative approaches such as solution-based methods have been studied. Solution-based methods include spin coating11, spray pyrolysis12,13, solvothermal14, electrodeposition15,16,17, printing18, successive ionic layer adsorption and reaction (SILAR)19 and colloidal methods6,20. Among all inexpensive techniques, spray pyrolysis is one of the best methods to deposit low-cost, highly scalable, and suitable CISe thin films for roll-to-roll production12,13,21.

However, due to the complex nature of CISe, a wide range of parameters needs to be controlled to get a suitable film in PV applications. Studying CISe films deposited at various conditions on different substrates shows that considerable parameters such as growth methods, thermal annealing, substrate temperature, thickness, composition, and adhesion can affect the grain structure, defect states, orientation texture of the CISe films, and hence the PV device performance22,23,24,25.

Despite a considerably complicated and expensive deposition process, metallic molybdenum (Mo), is considered as the conventional opaque substrate due to thermal and mechanical stability, low resistance, excellent adhesion with the substrate and the absorber, low film stress, and high optical reflectance26,27,28,29. Utilizing a transparent substrate is beneficial in the sense that leads to bifacial photovoltaic devices. Transparent substrates can be used to make PV devices since in this case light can penetrate through the entire device structure both from the front and the back contacts at different times of the day, leading to the creation of more photo-generated charge carriers30,31,32.

The properties of deposited CIGS and/or CISe films by various deposition methods on transparent electrodes have already been reported in the literature, such as pulsed electron deposition of CIGS films on the fluorine-doped tin oxide (FTO) or indium tin oxide (ITO)31, evaporation of CIGS films on the FTO, ITO, and soda-lime glass (SLG)33,34,35,36, ITO/SLG, and tin oxide (SnO2)37, MoO3/Mo/SLG, and MoO3/ITO/SLG38, electrodeposition of CIS films on the flexible ITO/PET substrates25, and FTO39, and chemical bath deposition of CIS films on glass40. There are also limited reports on spray-deposition of CIS films on the polyethylene terephthalate (PET)41, borosilicate glass, molybdenum-coated glass, and CdS42, spray-deposition of aluminum-doped CIS films on glass, In2S3/glass, ZnO/glass, and SnO2/glass43, and spray-deposition of CIS films on top of a single (compact), and a double (compact + porous) ZnO substrates44.

In this research, we have used FTO, FTO/nickel oxide (NiOx) and FTO/molybdenum oxide (MoO3) as substrates to deposit CISe. FTO (Fluorine-doped Tin Oxide) glass is a transparent conductive metal oxide with a work function of −4.9 eV45 which is near to the valence band of CISSe (−5.14 eV)46. In this regard, to reduce the charge recombination, depositing a hole transporting layer (HTL) in substrate structure or an electron transporting layer (ETL) in the superstrate structure with a high band gap on the FTO glass could be an efficient way. Among different inorganic hole transporting materials, MoO3, and NiOx with high hole mobilities, wide bandgaps, and high work functions are the most promising choices to reduce energy barrier for the hole transfer (in the substrate structure) from the valence band of CISe to the FTO35,38,45,46,47,48. Also, MoO3 is a two-dimensional layered structure, chemical activity, easy reproducibility, high transparency (> 80% in the visible and near IR range), wide bandgap (3.0–3.8 eV), and high work function (~ 5.7 eV), and has been utilized in PV and tandem devices38,49,50. In addition, NiOx is a wide bandgap (Eg ~ 3.60 eV) p-type metal oxide by deep valence band around 5.4 eV and suitable work function (WF) over 5.0 eV, and optimal hole mobility of 0.141 cm2 V−1 s−1, which is usually compact nanocrystalline and is known as one of robust hole transport layers (HTL)47,51,52. FTO is one of the most widely used substrates for optoelectronic applications, like liquid crystal displays, organic light-emitting diode displays, touch screens, smart windows, and solar cells53,54,55 due to its wide band gap (> 3 eV), high mechanical hardness, low resistance (< 10–4 Ω cm), high optical transparency (> 80%) in the visible region, reasonably low-cost, good stabilities in the acid atmosphere or atmospheric conditions and at high temperature.

This manuscript aims to potentially substitute the molybdenum (Mo) opaque substrate with a transparent substrate in the bifacial photovoltaic device, by using a low-cost, fast, and more industrial method of spray pyrolysis for CISe films. For this purpose, we have investigated the effect of three different substrates (FTO, FTO/NiOx, and FTO/MoO3) on the optical, structural, morphological, electrochemical, and electrical properties of deposited CISe films by spray pyrolysis.

Experimental

CuInS2 (CIS) and CuInSe2 (CISe) thin films were deposited by the chemical spray pyrolysis (CSP) technique from precursor aqueous solutions. Fluorine-doped tin oxide (FTO) conductive glass (15 Ω/sq, Dyesol), FTO/NiOx, and FTO/MoO3 were used as substrates in this work. Before film deposition, FTO substrates were cleaned for 15 min with detergent, hydrochloric acid (HCl), acetone, and ethanol, respectively in an ultrasonic bath and then heat-cleaned for 30 min at 500 °C.

Material types

The CIS precursor solutions were prepared using a mixture of copper iodide (CuI, Merck, 98%), Indium (III) chloride (InCl3, Strem Chemicals, 99.99%), and thiourea (CH4N2S, Acros, 99%) salts as copper, indium, and sulfur sources, respectively, by dissolving in de-ionized water (DI-water). The concentration of copper, indium and sulfur was 0.08 M, 0.1 M, and 0.4 M, respectively, which was held constant for all experiments. All chemicals were used without further purification. Molybdenum (VI) oxide (MoO3, Sigma-Aldrich, ACS reagent, ≥ 99.5%) was used as a molybdenum (VI) oxide source. Nickel (II) acetate tetrahydrate (98%), methanol (99.8%), and diethanolamine (≥ 98.0%) were purchased from Sigma-Aldrich which were used as nickel and solvent sources.

Deposition method

Molybdenum oxide (MoO3)

We deposited MoO3 thin films in this research. First, the FTO substrates were placed into a DC magnetron sputtering system to deposit a stack of MoO3 films on the rear side. Deposition time is 15 min with a power of 150 W. MoO3 films deposition were done by thermal evaporation method in a chamber with a base pressure of approximately 2 × 10−5 Torr. The resulting MoO3 films were then annealed on a hot plate, in an air environment, at 150 °C temperature for 5 min to generate the oxygen vacancy defects.

Nickel oxide (NiOx)

NiOx was prepared by a sol–gel method. The sol–gel mixture was prepared by dissolving nickel (II) acetate tetrahydrate in methanol at a concentration of 0.3 M. Then an equimolar amount of diethanolamine was added and the mixture was stirred and heated on a hotplate at 70 °C. The NiOx films were deposited by spin coating at 2000 rpm for 30 s on FTO substrates at room temperature. This process was repeated three times. The NiOx films were then annealed at 350 °C for 1 h in ambient air47.

Copper indium selenide (CISe)

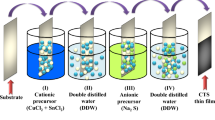

FTO, FTO/NiOx and, FTO/MoO3 were used as substrates. Based on initial studies, some parameters were assumed to be constant in this research such as rate of deposition: 4 ml/min, the distance between hot plate and nozzle: 15 cm, and deposition temperature: 350 °C. These parameters were elected to avoid wet droplet stains on the substrate at low temperature/high deposition rate conditions, also powdery film formation at high temperature/low deposition rate conditions. The desired deposition regime lies between these two extremes. The solution was sprayed by air as carrier gas and using a conventional airbrush. Conditions during selenization have an extreme influence on crystallization and large grain formation. The selenization process was done for ten 1.4 × 1.4 cm2 films in a graphite box with elemental Se pellets. Before starting the selenization process, the furnace tube was first purged with nitrogen gas and then was set at a predetermined pressure of 500 Torr. The heating profile lasted for 40 min, containing ramping up (~ 25°C min−1) to 500 °C for 20 min and was resided for 20 min. For ease of reference, the films formed on different substrates are named as FTO:(FTO/CISe) film, FTO/NiOx: (FTO/NiOx/CISe) film, FTO/MoO3: (FTO/MoO3/CISe) film. A schematic of film deposition by the spray method can be seen in Fig. 1.

Characterization

The morphology, composition and crystal structure of different CIS(e) films before and after selenization were examined by high-resolution field emission scanning electron microscopy (FESEM; HRSEM, XL30SFEG Phillips Co., Holland at 10 kV), energy dispersive spectroscopy (EDS; EDAX Genesis apex, acceleration voltage: 30 kV). To measure the roughness, atomic force microscopy (AFM) (VEECO-CP research) was used with a silicon tip of 10 nm radius in tapping mode. The crystal structure of the as-sprayed thin films was analyzed by X-ray diffraction (XRD) technique (X’Pert Pro MPD, PANalytical) with CuKα (λ = 1.5406 Å) radiation in the 2θ range from 4° to 80°. The scanning mode is continuous with a step size of 0.02°and scan step time of 0.5 s. The optical properties of the deposited layers were evaluated by measuring the transmittance spectra by Ultraviolet–Visible (UV/Vis) spectroscopy (Lamda 25, Perkin Elmer). The Mott-Schottky (MS) analysis was performed in a three-electrode system, in 0.5 M Na2SO4 solution (pH 6.0) as an electrolyte using an EIS-26H system (IRASOL). The working, reference and counter electrodes were (FTO, FTO/NiOx, FTO/MoO3), Ag/AgCl (3 M KCl), and Pt rod, respectively. The frequency of the signal was 1 kHz, and the bias voltage was scanned from − 0.8 V to 0.3 V, with 50 mV s−1 speed (peak-to-peak) at ambient conditions. All experiments proceeded after 5 s electrode stabilization. Charge mobility of CISe films was measured using Keithley 2400 Source meter.

Results and discussion

Morphological and structural properties

The AFM topographical images of different substrates including FTO, FTO/NiOx, and FTO/MoO3 are shown in Fig. 2. According to AFM images, the surface roughness of FTO is 16.5 nm. After deposition of the NiOx and MoO3 layers, the surface roughness decreases to 10.9 and 12.8 nm, respectively. Similar roughness reductions were previously reported for FTO, FTO/SnO2, and FTO/SnO2/CdS surfaces in which the surface roughness decreases by deposition of CdS nanoparticles56.

According to the results of the FESEM cross-sectional images, the thickness of the NiOx and MoO3 layers deposited onto the FTO are 28 and 36 nm, respectively, Fig. S1.

Figure 3 represents the FESEM surface and cross-sectional images of CISe thin films on different substrates. As shown in FESEM surface images (Fig. 3a–c), all deposited films show dense and crack-free surface morphology while the FTO films show larger grains compared to other films (Fig. 3a). The largest grain size was calculated using ImageJ software which was estimated to be ~ 0.50 μm (Table 1). The FESEM surface images of CISe films are also shown in smaller magnifications in Supporting Information, Fig. S2.

Cross-sectional FESEM images of CISe films on various substrates have been shown in Fig. 3d–f. The morphology of deposited CISe films on the FTO substrate looks very similar to the case of CISe growth on FTO/NiOx substrate, hence the thickness of the film appears to be affected by the type of substrate. The deposited CISe films on the FTO substrate have the highest roughness substrate and film thickness is about 2.3 µm (Fig. 3b), while CISe deposition on FTO/NiOx substrate leads to the lowest roughness substrate and thickness of 1.2 µm (Fig. 3e). On the other hand, the CISe films grown on FTO/MoO3 substrate show a bilayer structure in which the small and large grains are placed at the bottom and the top surface, respectively. As shown in Fig. 3f pores in the film can act as pathways for the evaporation of volatile materials (such as Cl2 or In2Se) during the selenization process57. Similar results were previously reported for doctor blade coating of CIS precursor solutions on Mo substrates58, solution-processing of amorphous nanoparticle-based CISe films on the Mo substrate59,60, which selenization of the CIS films with Se vapor at high-temperature results in bi-layered films with an upper layer of chalcopyrite CISe and a small grain-sized bottom layer.

The exact influence of this bilayer on different film properties and the resulting device is not still clear, and contradictory views are present. Generally, the generated bi-layered CISe films have been attributed to the presence of carbon at the bottom58,59,60, formation of CIS on top of the layer and hinder further evaporation of solvent58, the existence of mixed-phases, consisting of the ordered vacancy compound (OVC), Cu–Se phases, CISe and trace of CIS in the top layers59. In this study, the probable cause for creating a bilayer structure for CISe film growth on FTO/MoO3 substrate is the existence of impurity.

The composition of each sample was determined by EDS analysis (see Fig. S3 and Table S1). The compositional ratio of CISe films deposited on FTO, FTO/NiOx, and FTO/MoO3 substrates showed that the S/In ratio was variable from about 0.37 to 0.53. Thus, the films are described as CuIn(SySe1−y)2 because of the presence of ~ 9 to 14% atomic sulfur determined using EDS. The elemental compositions demonstrate that the atomic percentage (48.8 at.%) of selenium is higher for the CISe film on the FTO substrate than those deposited on other substrates, which proposes lower selenium vacancies.

Also, the CISe films have a Cu/In ratio in the range of 0.77–1.04. The atomic ratio of Cu/In in the CISe film on the FTO substrate is larger than that of the initial solution before depositing. These results revealed that the films changed from the In-rich CISe phase, in the FTO/NiOx and FTO/MoO3 films to the stoichiometric CISe phase. This phenomenon can be described by the formation of volatile In2Se during the selenization process and subsequent evaporation due to the high vapor pressure of In2Se61,62. As confirmed by EDS results, there is a minor Cl residue (0.08 at%) in the FTO films and a major chlorine (Cl) residue (0.50 at%) in the FTO/MoO3 films within the EDS resolution. The high chlorine residual content indicates an incomplete reaction between the precursor ingredients in the FTO/MoO3 films and can lead to the formation of a bilayer structure in these films. These results are in good agreement with the results of the FESEM-analysis.

Figure 4 represents the XRD patterns obtained from the CuInSe2 films used for structural and materials identification study. It can be observed that three prominent peaks identified as the planes of (112), (204), and (215) corresponding to CuInSe2 chalcopyrite tetragonal crystal structure and are in good agreement with the standard JCPDS file (standard JCPDS no. 085-1575 and 01-075-0107) for CIS and CISe films, respectively. In addition, no peaks of other impurities such as CuxSe, In2S3, etc. were detected, indicating the high phase purity of CuInSe2 films (Fig. 4a). However, considering the used CISe reference card, a noticeable peak shift towards higher diffraction angles can be observed considering the reflections of the detected chalcopyrite phase. This peak shift can be described by a non-complete substitution of sulfur with selenium. The smaller atomic radius of the remaining sulfur compared to selenium results in the smaller unit cell of the chalcopyrite phase, which causes a peak shift towards higher diffraction angles and forms the CI(S, Se) alloy (Fig. 4b)63.

Figure S4 demonstrates the XRD pattern obtained from the NiOx and MoO3 films compared to standard prominent peaks identified as the planes of (1 1 1), (2 0 0), and (2 2 0) demonstrating a cubic crystal structure for NiOx thin films and planes of (0 2 0), (1 2 1) and (1 5 0) showing an orthorhombic crystal structure for MoO3which is in good agreement with the standard JCPDS file (standard JCPDS no. 00-002-0422 and 01-076-1003) for NiOx and MoO3 films, respectively.

To research, the structural properties of CISe films such as dislocation densities, micro-strain, the number of crystallites per unit area, etc. have been calculated from the major (112) peak of X-ray microbeam studies. The dislocation density (δ) presents information about the crystal structure of CISe films, which can be evaluated using Williamson and Smallman’s equation (Eq. 1)64:

where D is the crystallite size.

The micro-strain (ε) influences the optoelectronic properties of the CISe thin films due to the distorted lattice. The average micro-strain present in the CISe films was calculated by Eq. (2)65:

where β is the full peak width at half maximum (FWHM)and θ is the Bragg angle.

Furthermore, the number of crystallites per unit area (N) was estimated by using the following equation66:

where (t) is the thickness of the film.

As reported in Table 2, the dislocation density of films is found to increase from 4.52 to 44.44 [(lines m−2) × 10−2] with changes in the substrate from FTO to FTO/MoO3. This indicates that the crystallinity of the films impairs for FTO/MoO3 substrate67. Hence, the suitable structural properties in terms of good crystallinity and lowest dislocation density belong to the FTO substrate. On the other hand, values of micro-strain decrease from 5.12% for FTO/MoO3 substrate to 4.52% for FTO substrate. This is ascribed to the decrease of defect level and grain boundaries due to improved crystallinity and increased grain size for FTO substrate.

The minimum amount of dislocation density and the micro-strain of the CISe films were 4.52 × 1014 and 4.45 × 10–2 cm−2, respectively. These values are significantly lower than the spray pyrolyzed CuInGaS2 and CuAlS2 films in literature68,69. The reduction in the dislocation density and micro-strain for FTO substrate was most probably due to the stress relaxation, which occurs during the recrystallization process69.

Also, the number of crystallites per unit area significantly changes with the substrate type. The number of grains increased notably up to about 622 × 108 cm−2 for FTO/MoO3 substrate, (Table 2). According to Table 1, the results show that the type substrate has an important effect on the grain size of the CISe films. The grain size increases to less than 0.47 µm for the FTO substrate and decreases to 0.15 µm for the FTO/MoO3 substrate.

This result is probably due to the highly increased growth rate in FTO/MoO3 substrate, which results in lower grain size and a higher number of crystallites per unit area in the films68,69.

Optical properties

The optical transmittance spectra of CISe films by various substrates within the range of 350–1100 nm are shown in Fig. 5a. UV–Vis transmittance spectra can be used to extract the band gap energy of the films using the Tauc plot formalism70:

where A is a constant, n = 0.5 for allowed direct band transition, h is the Planck constant, α is the absorption coefficient near the absorption edge and Eg is the optical band gap value. The optical bandgap energy of the CISe films has shown in Fig. 5b.

Moreover, the optical transmittance slightly decreased with depositing CISe films on FTO. The transmittance of this film was approximately 40%. Figure 5a shows the absorption edge shifts to shorter wavelengths with the variation of the substrate type from FTO to FTO/NiOx and FTO/MoO3 for films. From the Tauc plot analysis (Fig. 5b), energy band gap values of 1.35, 1.41, and 1.44 eV were found for FTO, FTO/NiOx, and FTO/MoO3 CISe films, respectively (Table 3).

The values of the band gap are slightly larger than the previously reported solution-based CISe thin films, with values of 1.00 eV71, 1.0472, 1.06 eV73, and 1.15 eV74, which may be due to the small amount of residual sulfur in the CISe films71, as shown by the EDS and XRD results. Also, a further decrease in band gap value for FTO films may be due to crystallinity improvement75,76,77. The band gaps are higher for FTO/NiOx and FTO/MoO3 films with smaller crystalline sizes, which may be due to the density of states at the interfaces, grain boundaries, and the defects energy level on the surface78,79.

Electrochemical properties

To further investigate the effect of the substrate on the electrochemical properties of CISe films, we have measured the Mott Schottky (M–S) relationship based on the capacitance versus applied potential. The Mott Schottky equation is given as follows80:

where Csc is the space charge capacitance, εr is the dielectric constant of the CISe film (13.6)81, ε0 is the permittivity of a vacuum, e is the electron charge, A is the film surface area in contact with the electrolyte, NA is the density of acceptor in the semiconductor, V is the externally applied potential, Vfb is the flat band potential, k the Boltzmann constant (1.38 × 10−23 J K−1) and T the operation temperature (300 K). The negative slope in Fig. 6 (M–S plots) indicates that all CISe thin films are p-type semiconductors.

The carrier density (NA) can be also conveniently found by determining the slope of the linear region of the M–S plot by using Eq. (5)77. The semiconductor parameters such as values of the Vfb, the carrier density NA width of the space-charge region (SCR), W, and energy level have been shown (Table 4).

NA is estimated as 1.6 × 1017, 5.4 × 1017, 2.4 × 1019 cm−3 with a variation of the substrate type from FTO to FTO/NiOx and FTO/MoO3 films, respectively. These results indicate that the carrier density concentration in the CISe absorber does not change significantly by the vary of substrate type from FTO to FTO/NiOx films.

Although the carrier density values of FTO and FTO/NiOx films are close to previous data reported by the solution method82,83,84,85,86,87, carrier density values of FTO/MoO3 films are nearly high compared to the vacuum-based deposition method85,88,89. In this work, the high values of carrier density for FTO/MoO3 films could be due to the presence of more grain borders and grain boundaries85, roughness and non-planar interfaces on the surface85,90, impurities like Cl91, as evidenced by the FESEM and EDS analysis.

An important parameter in solar cells or other electronic devices is Vfb, which controls the band alignments and carrier transfer at the interfaces92. The flat-band potential of the semiconductor can be calculated by intersecting the V-axis of the linear region of the M–S plot77. The Vfb value shifts significantly from 0.13 to −0.37 V (vs. Ag/AgCl) with a variation of the substrate type from FTO to FTO/NiOx and FTO/MoO3 films. This shift can be related to the change in the morphology and the composition of elements by changing the substrate type77. The Vfb value for CISe films with FTO substrate is more positive than those obtained by other films, that is indicating the better conductivity of FTO thin films due to an increase in their crystallinity93 which is confirmed by FESEM data.

The width of the SCR, W, is directly related to the capacitance of the CISe films. Equation (6) gives94:

Using this equation, the width of the space-charge layer results in a maximum value of about 34.9 nm for CISe films with FTO substrate. The broader space-charge region in FTO films can increase the accumulation of charge carriers80. Utilizing the other substrate seems quite to reduce the SCR width in the CISe films (to about 4.81 nm), which leads to the limited short-circuit current density (Jsc) values obtained in solar cells95. This would prove that the electrically active region of the CISe films is different for the various substrates.

Electrical properties

To understand more deeply the effect of the substrate type on the hole mobility, conductivity, bulk electrical resistivity, diffusion coefficient, and electrical behavior in the absorber layers, the current density–voltage (J–V) characteristics were recorded in the dark conditions and at ambient temperature. Figure 7 describes the typical curves of current density (J) as a function of the applied potential (V) for FTO, FTO/NiOx, and FTO/MoO3 films. For all films, the dark J-V analysis indicates a linear characteristic that means good ohmic contacts without an intermediate layer of Mo between CISe films and substrate.

The devices were fabricated with the structure of FTO/CISe/Graphite. Then, the following equation is used to calculate the mobility in the ohmic region96:

where J is the current density, NA is the carrier density, e is the electronic charge, μ is the hole mobility, V is the applied voltage and d is the distance between the electrodes, (the thickness of the thin film). The electrical parameters of all corresponding films were summarized in Table 5.

Hole mobility values of 7.37 × 10–2, 2.08 × 10–2, and 1.17 × 10−3cm2 V−1 s−1were obtained for FTO, FTO/NiOx, and FTO/MoO3 films, respectively. The measured hole mobility values for FTO and FTO/NiOx films are about one order of magnitude larger than FTO/MoO3 film, which indicates better crystallinity, uniformity, and grain boundary continuities in these thin films. On the other hand, the larger grain size in FTO and FTO/NiOx films is desirable as it leads to less grain boundary scattering of the charge carriers, i.e., better electrical transport properties97. Although the hole mobility values for FTO and FTO/NiOx films are slightly lower than the previously reported data88,98. The low value of mobility in FTO/MoO3 films may be attributed to impurities (i.e. 0.50 atomic% chlorine), which can act as dopants or cause traps that increase recombination or reduce mobility. Moreover, because FTO/MoO3 films have poor crystallinity and more grain boundary scattering, grain boundary discontinuities and presence of surface states99 specific surface area and a border effect may intensify carrier scattering at the surface and reduce mobility85.

Both the carrier density and the hole mobility contribute to the bulk electrical resistivity and conductivity. The conductivity of the CISe thin films is proportional to the carrier density and hole mobility100:

where σ is conductivity, e is the electronic charge, NA is carrier density and µ is hole mobility. The bulk electrical resistivity values were calculated using the following well-known equation101:

where ρ is bulk electrical resistivity and σ is conductivity.

Table 5 shows the substrate type dependence of the bulk resistivity and conductivity of CISe films. The bulk resistivity of the CISe films was about 5.6 × 102 to 2.2 × 102 Ωcm. These values are similar to the reported values which are in the range 4.3 × 102–5.3 × 102 Ωcm102,103. Also, the conductivity of all films was between 1.78 × 10–3 to 4.49 × 10–3 S cm−1.

The charge carrier diffusion length in a semiconductor is described by the average distance that charge carriers travel in a semiconductor. The diffusion coefficient and mobility of charge carriers are related by Einstein's equation104:

where D is diffusion coefficient, µ is hole mobility, k is the Boltzmann constant (1.38 × 10−23 J K−1), T is the operation temperature (300 K) and e is the electronic charge.

The CISe films prepared using various substrates show hole diffusion coefficients from 10–3 to 10–5 cm2 s−1. The J–V dark measurements results reveal that the hole diffusion coefficient of the FTO films is 1.91 × 10−3 cm2 s−1, which is higher than the FTO/NiOx (5.38 × 10−4 cm2 s−1) and FTO/MoO3 (3.03 × 10−5 cm2 s−1) films. The higher hole diffusion coefficient value is favorable for fast charge transport and results from the effective connection of the grains to create the charge carrier's continuous pathway in the CISe films105. However, the existence of deep levels in the CISe films is unsuitable since they act as recombination centers for charge carriers and therefore reduce carrier diffusion coefficients in FTO/NiOx and FTO/MoO3 films103.

In addition, the diffusion coefficients calculated from the other research have been reported 10−16 cm2 s−1 and 10−7 cm2 s−1 for CuIn(Se,S)2 crystals106,107, 10−14 cm2 s−1 for CuInSe2 quantum dots108, 10−6 cm2 s−1 for Cu(In,Ga)Se2 thin films109, which are notably lower than the estimated values in this work.

Conclusion

In this research, transparent substrates for the replacement of molybdenum (Mo) opaque substrate were studied for use in bifacial photovoltaic devices. Three transparent substrates (FTO, FTO/NiOx, and FTO/MoO3) were used as substrates, and CISe thin films were deposited by spray pyrolysis and selenization. The results of different characterization techniques have a good correlation to each other. The optical transmittance and significant band gap energy of CISe films were changed from 1.35 to 1.44 eV depending on the substrate type. The CISe films deposited on the FTO substrate were more compact, thicker, with larger grains than others. The XRD peaks confirm that all films show a chalcopyrite tetragonal structure without any impurity phase but structural parameters such as micro-strain(ε) of ~ 4.45 × 10–2, number of crystallites per unit area (N) of ~ 22.15 × 108 cm−2 and dislocation density (δ) of ~ 4.52 (lines cm−2) × 108 have the lowest values for CISe films on FTO substrates. All CISe films are p-type semiconductors with a carrier density of ~ 1017 to 1019 cm−3. Flat band potential and space-charge layer values of the CISe films are estimated based on the Mott-Schottky analysis to be 0.13 V (vs. Ag/AgCl) and 34.94 nm for FTO substrates, respectively. Dark J–V measurement exhibited that the CISe films have ohmic behavior with a favorable hole mobility of around 7.37 × 10−2 cm2 V−1 s−1 and diffusion coefficient of 1.91 × 10−3 cm2 s−1 for CISe film deposited on FTO substrate which is notably higher than the other two films. Generally, the optical, physical, and electrical properties of CISe films are influenced by substrate type. It is thought that the properties of CISe thin films deposited on the FTO substrates are considerably close to the properties essential for photovoltaic applications, thus FTO can be an alternative substrate to opaque substrates with deposited CISe films as absorber layer, hole transport layer, and photoanode used in applications such as bifacial and tandem solar cell, supercapacitor and sensor.

Data availability

All data generated or analysed during this study are included in this published article [and its supplementary information files].

References

Sung-MinYoun, M.-J.P., Kim, J. H. & Jeong, C. Performance enhancement of CIGS thin-film solar cells with a functional-window NiO thin layer. Alloys Compds. 836, 154803 (2020).

Singh, J.R.A.U.P. Copper indium gallium selenide based solar cells. Rev. Energy Environ. Sci. 10, 1306–1319 (2017).

Yan Zhang, Z. Z., Liu, Y., Gao, H. & Mao, Y. Short-chain ligands capped CuInSe2 quantum dots as hole transport material for inverted perovskite solar cells. Mater. Sci. Semiconduct. Process. 120, 105267 (2020).

Yan Zhang, Z. Z., Liu, Y., Liu, Y., Gao, H. & Mao, Y. An inorganic hole-transport material of CuInSe2 for stable and efficient perovskite solar cells. Organ. Electron. 67, 168–174 (2019).

Joo Sung Kim, S. K. B. et al. Copper indium selenide water splitting photoanodes with artificially designed heterophasic blended structure and their high photoelectrochemical performances. Nano Energy 18, 30033–30038 (2018).

Raja Azadar Hussain, I. H. Copper selenide thin films from growth to applications. Solid State Sci. 100, 106101 (2020).

Zonghui Duan, J. N. et al. Broad-band photodetectors based on copper indium diselenide quantum dots in a methylammonium lead iodide perovskite matrix. ACS Appl. Mater. Interfaces 12, 35201–35210 (2020).

Tao Shen, F. L., Zhang, Z., Xu, L. & Qi, J. High-performance broadband photodetector based on monolayer MoS2 hybridized with environment-friendly CuInSe2 quantum dots. ACS Appl. Mater. Interfaces 12, 54927–54935 (2020).

Anuraj, A. G., Kshirsagar, S. & Khanna, P. K. Efficient photo-catalytic oxidative degradation of organic dyes using CuInSe2/TiO2 hybrid hetero-nanostructures. Photochem. Photobiol. A Chem. 349, 73–90 (2017).

Metwally Madkour, H. A. E. N. & Abdel-Monem, Y. K. Use of chalcogenides-based nanomaterials for photocatalytic heavy metal reduction and ions removal. Chalcogenide Based Nanomater. Photocatal. 21, 261–283 (2021).

Madhuri, P. K. K. K., Yadav, B. S., Chaudhari, S., Dhage, S. R. & Dey, S. R. Investigation on effects of precursor pre-heat treatments on CIGS formation using spin-coated CIG precursor. Mater. Sci. Mater. Electron. 32, 1521–1527 (2021).

Phindani Dube, A. O. J. & Muiva, C. M. Dispersive optical constants and electrical properties of nanocrystalline CuInS2 thin films prepared by chemical spray pyrolysis. Ceram. Int. 46, 7396–7402 (2020).

Vipin Shrotriya, M. B. Z. & Poolla, R. Low cost sprayed CuIn(SxSe1−x)2 thin films for photovoltaic applications. Mater. Lett. 236, 428–431 (2019).

Madhuri, P. K. K. K., Chaudhari, S., Dhage, S. R. & Dey, S. R. Effect of annealing time and heat flux on solvothermal synthesis of CIGS nanoparticles. Mater. Today Proc. 21, 1882–1887 (2020).

Shalini Menezes, A. P. S. B. W. L. Quantized electronic transitions in electrodeposited copper indium selenide nanocrystalline homojunctions. Sci. Rep. 11, 3957 (2021).

Shanshan Ji, M. A., Yang, P. & Zhang, J. Improved ionic liquid-based mixed electrolyte by incorporating alcohols for CuInxGa1–xSe2 films deposition. Surf. Coat. Technol. 325, 722–728 (2017).

Daniel Siopa, K. E. H. et al. Micro sized thin film solar cells via area selective electrochemical deposition for concentrator photovoltaics application. Sci. Rep. 10, 1–13 (2020).

Bruna, G. B., Gonçalves, F., Lanceros-Méndez, S. & Kolen’ko, Y. V. Eco-friendly and cost-efficient inks for screen-printed fabrication of copper indium gallium diselenide photoabsorber thin films. Colloid Interface Sci. 598, 388–397 (2021).

Lokhande, H. M. P. A. C. D. Deposition of metal chalcogenide thin films by successive ionic layer adsorption and reaction (SILAR) method. Bull. Mater. Sci. 27, 85–111 (2004).

Parul Chawla, M. A., Sharma, C., Sharma, M. K. & Sharma, S. N. A comparative study exploring the ligand binding capabilities of quarternary chalcopyrite copper indium gallium diselenide (CIGSe) nanocrystals. Mol. Struct. 1245, 131055 (2021).

Jin Leng, Z. W. et al. Advances in nanostructures fabricated via spray pyrolysis and their applications in energy storage and conversion. Chem. Soc. Rev. 48, 3015–3073 (2019).

Neetu Bansal, B. C. M. & Singh, K. Designing composition tuned glasses with enhanced properties for use as substrate in Cu2ZnSnS4 based thin film solar cells. Alloys Compd. 819, 152984 (2020).

Maryam Hashemi, S. M. B. G., Tajabadi, F. & Taghavinia, N. Aqueous spray pyrolysis of CuInSe2 thin films: Study of different indium salts in precursor solution on physical and electrical properties of sprayed thin films. Mater. Sci. Semiconduct. Process. 126, 105676 (2021).

Maryam Hashemi, S. M. B. G., Tajabadi, F. & Taghavinia, N. Investigation of precursors concentration in spray solution on the optoelectronic properties of CuInSe2 thin films deposited by spray pyrolysis method. Mater. Sci. Mater. Electron. 32, 25748 (2020).

Ramkumar Chandran, C. K. B. & Mallik, A. Electrochemical impedance (EIS) behavior of CuInSe2 (CIS) thin films on high resistance ITO/PET flexible substrates. Mater. Today Proc. 4, 12473–12479 (2017).

Haroon Rashid, K. S. R., Hossain, M. I., Ammar Ahmed Nasser, F. H. A., Akhtaruzzaman, M. & Amin, N. Physical and electrical properties of molybdenum thin films grown by DC magnetron sputtering for photovoltaic application. Results Phys. 14, 102515 (2019).

Weimin Li, X. Y., Xu, W.-L., Long, J., Aberle, A. G. & Venkataraj, S. Efficiency improvement of CIGS solar cells by a modified rear contact. Sol. Energy 157, 486–495 (2017).

Briot, M. M. O. et al. Optimization of the properties of the molybdenum back contact deposited by radiofrequency sputtering for Cu(In1-xGax) Se2 solar cells. Sol. Energy Mater. Sol. Cells 174, 418–422 (2018).

WeiminLi, X. Y., Aberle, A. G. & Venkataraj, S. Effect of sodium diffusion on the properties of CIGS solar absorbers prepared using elemental Se in a two-step process. Sci. Rep. 9, 1–11 (2019).

NicholasCavallari, F. P. et al. Low temperature deposition of bifacial CIGS solar cells on Al-doped zinc oxide back contacts. Appl. Surf. Sci. 412, 52–57 (2017).

Mazzer, S. R. M. et al. Bifacial CIGS solar cells grown by low temperature pulsed electron deposition. Sol. Energy Mater. Sol. Cells 166, 247–253 (2017).

Jeyakumar Ramanujam, D. M., Teodor, B. & Todorov, K. Flexible CIGS, CdTe and a-Si: H based thin film solar cells: A review. Prog. Mater. Sci. 110, 100619 (2020).

Tokio Nakada, Y. H., Tokado, T. & DaiskeOhmori, T. M. Novel device structure for Cu(In, Ga)Se2 thin film solar cells using transparent conducting oxide back and front contacts. Sol. Energy 77, 739–747 (2004).

Nakada, T. Microstructural and diffusion properties of CIGS thin film solar cells fabricated using transparent conducting oxide back contacts. Thin Solid Films 480–481, 419–425 (2005).

Min Jeong Shin, J. H. J. et al. Semi-transparent photovoltaics using ultra-thin Cu(In, Ga)Se2 absorber layers prepared by single-stage co-evaporation. Sol. Energy 181, 276–284 (2019).

Ruckh, D. S. M., Kaiser, M., Schiffler, R., Walter, T. & Schock, H. W. Influence of substrates on the electrical properties of Cu(In, Ga)Se2 thin films. Solar Energy Mater. Solar Cells 4142, 335–343 (1996).

Tokio Nakada, Y. H. A. Cu(In1–x, Gax)Se2-based thin film solar cells using transparent conducting back contacts. Jpn. J. Appl. Phys. 41, 1209–1211 (2002).

Hamed Simchi, B. E. M., Meng, T. & Shafarman, W. N. Structure and interface chemistry of MoO3 back contacts in Cu(In, Ga)Se2 thin film solar cells. Appl. Phys. 115, 033514 (2014).

Ghezal, T. B. F. & Tala-ighil Zair, R. Fabrication and characterization of CuInSe2 thin film solar cells with fluorine doped ZnO as new buffer layer. Chalcogenide Lett. 17, 521–527 (2020).

Nikhilesh, R. A. J. & Bajaj, S. Growth and characterization of CuInSe2 thin films. Open Access Int. J. Sci. Eng. 2, 1–4 (2017).

Douglas, M. G. et al. Plastic microgroove solar cells using CuInSe2 nanocrystals. ACS Energy Lett. 1, 1021–1027 (2016).

Jr, B. J. B. A. C. W. B. The effect of substrate on the morphology of CulnSe2 films prepared by chemical spray pyrolysis for CulnSe2/CdS solar cells. Appl. Phys. 68, 2517 (1990).

Kamoun Allouche, N. J. N., Guasch, C. & Kamoun Turki, N. Influence of aluminum doping in CuInS2 prepared by spray pyrolysis on different substrates. Alloys Compd. 501, 85–88 (2010).

Valdés, M. B. M. H., Goossens, A. & Vázquez, M. Spray deposition of CuInS2 on electrodeposited ZnO for low-cost solar cells. Surf. Coat. Technol. 204, 3995–40000 (2010).

Xiaobao Xu, Z. L. et al. Hole selective NiO contact for efficient perovskite solar cells with carbon electrode. Nano Lett. 15, 2402–2408 (2015).

Weibo Yan, S. Y. et al. Hole-transporting materials in inverted planar perovskite solar cells. Adv. Energy Mater. 6, 600474 (2016).

Zahra Saki, K. S., Boschloo, G. & Taghavinia, N. The effect of lithium doping in solution-processed nickel oxide films for perovskite solar cells. ChemPhysChem 20, 1–7 (2019).

Jin Cui, C. C. et al. Surface plasmon resonance effect in inverted perovskite solar cells. Adv. Sci. 3, 1500312 (2016).

Ümmühan Akýn, H. S. Thickness dependence of dispersion parameters of the MoOx thin films prepared using the vacuum evaporation technique. Alloys Compd. 647, 146–151 (2015).

Nicolau Lopez-Pinto, T. T., Bertomeu, J., Asensi, J. M., Ros, E. & Pablo Ortega, C. V. Deposition and characterisation of sputtered molybdenum oxide thin films with hydrogen atmosphere. Appl. Surf. Sci. 563, 150285 (2021).

Yongshuai Gong, S. Z., Gao, H., Ma, Z., Hu, S. & Tan, Z. Recent advances and comprehensive insights of nickel oxide in emerging optoelectronic devices. Sustain. Energy Fuels 4, 4415–4458 (2020).

Zahra Saki, K. A. et al. The synergistic effect of dimethyl sulfoxide vapor treatment and C60 electron transporting layer towards enhancing current collection in mixed-ion inverted perovskite solar cells. Power Sour. 405, 70–79 (2018).

Bon-Ryul Koo, D.-H.O., Riu, D.-H. & Ahn, H.-J. Improvement of transparent conducting performance on oxygen-activated fluorine-doped tin oxide electrodes formed by horizontal ultrasonic spray pyrolysis deposition. ACS Appl. Mater. Interfaces 9, 44584–44592 (2017).

Morteza Asadzadeh, F. T., Dastan, D., Sangpour, P., Zhicheng, & Shi, N. T. Facile deposition of porous fluorine doped tin oxide by Dr. Blade method for capacitive applications. Ceram. Int. 47, 5487–5494 (2020).

Khakpour, H. P. Z., Maghsoudipour, A. & Ebadzadeh, T. Synthesis and deposition of hematite nanoparticles on fluorine-doped tin oxide (FTO) glass substrates. Mater. Today Proc. 5, 15828–15835 (2018).

Fateme Mohamadkhani, S. J. & Taghavinia, N. Improvement of planar perovskite solar cells by using solution processed SnO2/CdS as electron transport layer. Sol. Energy 191, 647–653 (2019).

Ara Cho, S. J. A. et al. Non-vacuum processed CuInSe2 thin films fabricated with a hybrid ink. Solar Energy Mater. Solar Cells 109, 17–25 (2013).

SeJin Ahn, C. W. K. et al. CuInSe2 (CIS) thin film solar cells by direct coating and selenization of solution precursors. Phys. Chem. C 114, 8108–8113 (2010).

Jihyun Moon, S. R., Rana, T. R., Byungsung, O., Ahn, S. K. & Ahn, S. Na-induced conversion of a notorious fine-grained residue layer into a working absorber in solution-processed CuInSe2 devices. Solar RRL 3, 1900260 (2019).

Shanza Rehan, K. Y. K. et al. Carbon-impurity affected depth elemental distribution in solution-processed inorganic thin films for solar cell application. ACS Appl. Mater. Interfaces 8, 5261–5272 (2016).

Ara Cho, S. A., Yun, J. H., Gwak, J., Song, H. & Yoon, K. A hybrid ink of binary copper sulfide nanoparticles and indium precursor solution for a dense CuInSe2 absorber thin film and its photovoltaic performance. J. Mater. Chem. 22, 17893–17899 (2012).

SeJin Ahn, C., Yun, J. H., Chul Lee, J. & Hoon Yoon, K. Effects of heat treatments on the properties of Cu(In, Ga)Se2 nanoparticles. Solar Energy Mater. Solar Cells 91, 1836–1841 (2007).

Willi Kogler, T. S., Ahlswede, E. & Powalla, M. Study on formation and characterization of CZTSSe-based absorber layer from a green solution based approach. Solar Energy Mater. Solar Cells 200, 109959 (2019).

Sanjaysinh, S. H. C. et al. Synthesis, characterization and antimicrobial study of wet chemical synthesized CuInSe2 nanoparticles. Nano-Struct. Nano-Obj. 16, 200–208 (2018).

Saïdi, M. F. B. H., Durand, B., Lazzari, J.-L. & Bouaïcha, M. Elaboration and characterization of CuInSe2 thin films using onestep electrodeposition method on silicon substrate for photovoltaic application. Mater. Res. Exp. 5, 016414 (2018).

Ziaul Raza Khan, M. Z. & Shahid Khan, M. Optical and structural properties of thermally evaporated cadmium sulphide thin films on silicon (1 0 0) wafers. Mater. Sci. Eng. B 174, 145–149 (2010).

Babua, S. V. B. J., Kassiba, A., Asomoza, R. & Chavez-Carvayar, J. A. Deposition and characterization of graded Cu(In1-xGax)Se2 thin films by spray pyrolysis. Mater. Chem. Phys. 162, 59–68 (2015).

Mejda Ajili, M. C. & Kamoun Turki, N. Characteristics of CuIn1–xGaxS2 thin films synthesized by chemical spray pyrolysis. Luminescence 150, 1–7 (2014).

Erkan Aydin, M. S. & Sankir, N. D. Conventional and rapid thermal annealing of spray pyrolyzed copper indium gallium sulfide thin films. Alloys Compd. 615, 461–468 (2014).

Jackson Lontchi, B. K. & Abaab, M. Thermal evaporated undoped and Na-doped CuInS2 with copper contact for photovoltaic applications. Int. J. Renew. Energy Res. 6, 520 (2016).

John, T. Z. et al. Spray pyrolysis of CuIn(S, Se)2 solar cells with 59% efficiency: A method to prevent Mo oxidation in ambient atmosphere. ACS Appl. Mater. Interfaces 6, 6638–6643 (2014).

Zhongdong Zhao, Y. Q. et al. Solution-based synthesis of dense, large grained CuIn(S, Se)2 thin films using elemental precurcer. Ceram. Int. 17, 0272–8842 (2017).

Samantilleke, S. M. A. Formation of unique nanocrystalline Cu–In–Se bulk p–n homojunctions for opto-electronic devices. Sci. Rep. 8, 11350 (2018).

Wei Liu, D. B. M., Yuan, M., Kellock, A. J., Jay Chey, S. & Gunawan, O. 12% efficiency CuIn(Se, S)2 photovoltaic device prepared using a hydrazine solution process. Chem. Mater. 22, 1010–1014 (2010).

Elham Mazalan, K. T. C., Nayan, N. & Ali, J. Influence of antimony dopant on CuIn(S, Se)2 solar thin absorber layer deposited via solution-processed route. J. Alloys Compd. 19, 710–718 (2019).

Ahmet Tumbul, F. A., Göktaş, A. & Mutlu, I. H. All solution processed superstrate type Cu2ZnSnS4 (CZTS) thin film solar cell: Effect of absorber layer thickness. J. Alloys Compd. 19, 2185 (2018).

Braiek, I. B. A. Z., Gannouni, M., Alem, H., Roques-Carmes, T. & Chtourou, R. Impact of In2S3 shells thickness on the electrochemical and optical properties of oriented ZnO/In2S3 core/shell nanowires. Int. J. Hydrogen Energy 42, 5694–5707 (2017).

Bachir Eddine Messaid, C. L. P. et al. Optimization of a rear system based on titanium nitride for a flexible CuInSe2 solar cell. Optik 206, 164305 (2020).

Abdurashid Mavlonov, T. R. et al. A review of Sb2Se3 photovoltaic absorber materials and thin-film solar cells. Sol. Energy 201, 227–246 (2020).

Mingqing Wang, M.A.H.K.-L.C. Effect of sodium treatment on the performance of electrostatic spray assisted vapour deposited copper poor Cu(In, Ga)(S, Se)2 solar cells. Sci. Rep. 7, 6788–6798 (2017).

Valérie Deprédurand, D. T., Aida, Y., Carlberg, M., Fèvre, N. & Siebentritt, S. Current loss due to recombination in Cu-rich CuInSe2 solar cells. Appl. Phys. 115, 044503 (2014).

Jitendra, R. B. K. & Sawant, P. Chemical spray pyrolysis of copper indium disulphide thin films for solar cell application: Review. Int. J. Eng. Res. Gen. Sci. 3, 533–542 (2015).

Werner, D. C. F. et al. Doping mechanism in pure CuInSe2. J. Appl. Phys. 119, 173103 (2016).

Siebentritt, S. Chalcopyrite compound semiconductors for thin film solar cells, current opinion in green and sustainable. Chemistry 4, 1–7 (2017).

Valdés, M. V. M. H. Pulsed electrodeposition of p-type CuInSe2 thin films. Electrochim. Acta 56, 6866–6873 (2011).

Djellal, A. B. L. & Trari, M. Physical and photoelectrochemical properties of p-CuInSe2 bulk material. Mater. Chem. Phys. 109, 99–104 (2008).

Suzan Saber, M. M., El Nahrawy, A., Khattab, N., Eid, A. & Marí, M. A. A. B. Annealing study of electrodeposited CuInSe2 and CuInS2 thin films. Opt. Quant. Electron. 50, 248 (2018).

Birkmire, A. R. A. R. W. CuInSe2 for photovoltaic applications. Appl. Phys. https://doi.org/10.1063/1061.349175 (1991).

Chung-Hsin Lu, S. H. L. Microstructures and photovoltaic performances of bismuth-ion doped Cu(In, Ga)Se2 films prepared via sputtering process. Am. Ceram. Soc. 102, 3578–3587 (2018).

Raffaelle, H. F. R. P. et al. Sol. Energy Mater. Sol. 57, 167 (1999).

Gelderman, L. L. K. & Donne, S. W. Flat-band potential of a semiconductor: Using the Mott–Schottky equation. J. Chem. Educ. 84, 685 (2007).

Shelke, A. M. P. H. D., Lokhande, A. C., Kim, J. H. & Lokhande, C. D. Electrochemical impedance analysis of SILAR deposited Cu2SnS3 (CTS) thin film. Int. J. Eng. Res. Technol. 10, 0974–3154 (2017).

Gomaa, M. M. Y., Ali, A. M., Shaaban, E. R. & Chong, K. F. High performance MnO2 nanoflower supercapacitor electrode by electrochemical recycling of spent batteries. Ceram. Int. 43, 8440–8448 (2017).

Exarhos, C. F. W. A. G. J. Mott–Schottky analysis of thin ZnO films. Vac. Sci. Technol. A 18, 1677 (2000).

Marie Buffiere, A. E. Z. et al. Effect of binder content in Cu–In–Se precursor Ink on the physical and electrical properties of printed CuInSe2 solar cells. Phys. Chem. C 118, 27201–27209 (2014).

Attia, A. A. Space-charge-limited currents in evaporated GaS thin films. J. Sol. 24, 235–244 (2001).

Nina Winkler, S. E., Kaur, J., Wibowo, R. A., Kautek, W. & Dimopoulos, A. T. Solution-processed all-oxide solar cell based on electrodeposited Cu2O and ZnMgO by spray pyrolysis. J. Mater Sci. 53, 12231–12243 (2018).

Yoshitaka Ogawa, S. U., Tohyama, K. & Ito, K. Preparation and properties of CuInS2 thin films. Solar Energy Mater. Solar Cells 35, 157–163 (1994).

Barote, A. A. Y. M. A., Chavan, T. V. & Masumdar, E. U. Characterization and photoelectrochemical properties of chemical bath deposited n-PbS thin films. J. Nanomater. Biostruct. 6, 979–990 (2011).

Jian-Chiun Liou, C.-C.D., Lin, J.-J., Chen, Y.-L. & Yang, C.-F. Prepare dispersed CIS nano-scale particles and spray coating CIS absorber layers using nano-scale precursors. Nanoscale Res. Lett. 9, 1–7 (2014).

Sekhar Babu Mitta, M. S. C. et al. Electrical characterization of 2D materials-based field-effect transistors. 2D Mater. 8, 012002 (2020).

Ben Rabeh, N. C. M. & Kanzari, M. Effect of antimony incorporation in CuInS2 thin films. Chalcogenide Lett. 6, 155–161 (2009).

Tamil Illakkiya Jayaraj, U. R. P. & Oommen, R. Enhanced optoelectronic and photoelectrochemical characteristics of nebulised spray pyrolysed ‘Cu’ rich CuInS2 thin film. Mater. Sci. Semiconduct. Process. 49, 84–91 (2016).

Kamat, G. H. A. P. V. Understanding the implication of carrier diffusion length in photovoltaic cells. Phys. Chem. Lett. 6, 4090–4092 (2015).

Chandu, M.V.-H. et al. Improving the performance of quantum dot sensitized solar cells through CdNiS quantum dots with reduced recombination and enhanced electron lifetime. Dalton Trans. 45, 8447–8457 (2016).

Birkmire, J. T. A. Sulfur incorporation into copper indium diselenide single crystals through annealing in hydrogen sulfide. Appl. Phys. 99, 043502 (2006).

Geula Dagan, F.A.-E., Dunlavy, D. J., Matson, R. J. & Cahen, D. Defect level identification in copper indium selenide (CuInSe2) from photoluminescence studies. Chem. Mater. 2, 286–293 (1990).

Muziwenkosi Memela, U. F. et al. Electro-photovoltaics of polymer-stabilized copper indium selenide quantum dot. Electroanalysis 32, 3086–3097 (2020).

Valderrama, M.M.-H.R.C., Sebastian, P. J. & Ocampo, A. L. Electrodeposition of indium onto Mo/Cu for the deposition of Cu(In, Ga)Se2 thin films. Electrochim. Acta 53, 3714–3721 (2008).

Acknowledgements

The authors are grateful for the support of this work by the Nanoparticles and Coatings Lab (NCL) of the Sharif University of Technology, Tehran.

Author information

Authors and Affiliations

Contributions

M.H.: Investigation, Resources, Deposition of CuInSe2 thin films, Writing—original draft & Editing; Z.S.: Investigation, Conceptualization, Deposition of NiOx thin films & Editing; M.D.: Conceptualization, Deposition of MoO3 thin films Resources & Editing; F.T.: Conceptualization, Writing, Editing, Resources & Supervision; S.M.B.G.: Conceptualization, Editing, Resources & Supervision; N.T.: Conceptualization, Writing, Editing, Resources & Supervision.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Hashemi, M., Saki, Z., Dehghani, M. et al. Effect of transparent substrate on properties of CuInSe2 thin films prepared by chemical spray pyrolysis. Sci Rep 12, 14715 (2022). https://doi.org/10.1038/s41598-022-18579-w

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-022-18579-w

- Springer Nature Limited

This article is cited by

-

Exploring the electronic, optical, and thermometric properties of novel AlCuX2 (X = S, Se, Te) semiconductors: a first-principles study

Journal of Materials Science (2023)

-

Effect of cyclic voltammetry on the deposition of Ni cocatalyst on CuInS2 photoelectrode for water splitting under solar light irradiation

Research on Chemical Intermediates (2023)