Abstract

This study was designed to develop a microemulsion formulation of norcantharidin for the control of the diamondback moth (DBM), Plutella xylostella (Linnaeus), a notorious pest of brassica crops worldwide. The oil phase was screened and selected based on norcantharidin solubility while the surfactants were selected on the basis of their efficiency to form microemulsion. Optimized batches were selected using pseudo ternary phase diagrams. The microemulsion system were stabilized using mixtures composed of norcantharidin, surfactants (Tx13 and Tw80), and cosurfactant (ethanol). Its physicochemical characteristics were also demonstrated to have a higher cloud point than 72 °C as well as good thermodynamic and dilution stability. In additon, a subsequent insecticidal bioassay indicated that the acute LC50 for norcantharidin microemulsion to P. xylostella was estimated to be 12.477 mg/L (11.58–13.41, 95% CL). Our results provide an environment-friendly promising alternative to control P. xylostella and possibly contribute to ameliorating any pesticide resistance in P. xylostella.

Similar content being viewed by others

Introduction

Pesticide formulations play important roles in delivering agrochemicals to target sites and increasing their efficacy. Conventional formulations (e.g., emulsifiable concentrate) based on petroleum and organic solvents are gradually being replaced by water-based pesticide formulations (such as microemulsions and nanoemulsions) which have drawn wide attention during recent years1. In particular, microemulsion has been extensively used as pesticide vehicles because of their unique advantages2,3,4,5. A microemulsion is a single optically isotropic and thermodynamically stable liquid solution, having an ultramicroscopic droplet size (typically below 100 nm) and being completely water-dilutable6,7. Generally, microemulsions are optically transparent or translucent dispersions of pesticides in water presenting solubilization of the surfactants and/or co-surfactants7,8. This small droplet size and lowered surface tension of the whole system may produce higher pesticide efficiency and ease any tendency to coalesce. Oil-in-water (O/W) and water in oil (W/O) are two basic types of microemulsions, within which the O/W microemulsion can improve the solubility of poorly water-soluble active ingredients. Some studies have shown that microemulsions are superior to traditional formulations and exhibit superior control efficiency when compared to traditional commercial pesticides3,7,9. Meanwhile, it has been reported that λ-cyhalothrin and triadimefon microemulsions possess better thermodynamic stability, properties and efficacy than their other formulations10,11.

The diamondback moth (Lepidoptera: Plutellidae) causes devastating losses of cruciferous vegetables such as cabbage, broccoli and cauliflower, and also damages a few other field crops12,13,14. Application of synthetic insecticides has become more prevalent as a control strategy than other methods. However, resistance and cross-resistance problems in Plutella xylostella are increasing whenever a chemical pesticide or mixture of pesticides are used intensively for any extended period because there are few classes of available insecticides with limited mode actions15. P. xylostella has developed resistance to over 94 active ingredients, including the newer insecticides spinosad and emamectin benzoate, based on a research by Michigan State University4. Insectile resistance and cross-resistance problems are increasing and the discovery of new products meeting the increasing standard of environmental and toxicological safety is urgent. But development of new synthetic pesticides becomes increasingly more expensive and difficult. In order to decrease insect resistivity,operational programmes may apply new biopesticides and other classes of insecticides in sequence, rotation or mosaics, using of compounds acting on different target sites to avoid selecting for any specific type of resistance.

Norcantharidin is a demethylated analogue of cantharidin; showing the same mode of action, norcantharidin is an inhibitor to protein serine/threonine phosphatases in vivo16. Protein serine/threonine phosphatases play important roles participating in a series of metabolic activities and their domain alignments show a high similarity in eukaryotic cells17. Chen et al. (2014) observed that norcantharidin strongly inhibited five protein serine/threonine phosphatase genes of P. xylostella in vitro18. Norcantharidin has also been utilized as a pesticide in pest control and against pathogenic fungi19,20. Norcantharidin therefore has potential to be an eco-friendly pesticide in the case of the control the diamondback moth for ecologically sustainable development because of its fast degradation rate and new mode of action21.

Lower compound loading capacity, high cost and various side effects are the significant shortcomings of currently available formulations. To avoid these shortcoming, the development of new pharmaceutical formulations of norcantharidin for agricultural administration is desirable. Given the above drawbacks, the main focus of this study is to establish a pharmaceutical microemulsion for the effective application of norcantharidin as a potentially effective and safe pesticide to control P. xylostella where cyclohexanone, ethyl butyrate and dimethyl formamide are used as solvents. The impact of emulsifiers (Tx13 and Tw80) and a cosurfactant (ethanol) on phase behavior was systematically studied by pseudo-ternary phase diagrams. Characterizations of the microemulsion–such as conductivity, dilution stability, cloud point and other physiochemical parameters–were selected to evaluate the optimal norcantharidin microemulsion system. Finally, insecticidal activity of the norcantharidin microemulsion was analyzed against 3rd instars of P. xylostella in a leaf-dip bioassay (48 h). In addition, norcantharidin microemulsion could contribute to decreasing the resistance of P. xylostella to mostly synthetic insecticides though mixing with other classes of insecticides, or by application in sequence or rotation in agricultural practice.

Results and Discussion

Component selection of microemulsions

The selection of appropriate solvents plays a key role in preparing microemulsions, as only the dissolved active compounds can be distributed on the leaves. Active ingredient’s solubility in the oil phase has a significant impact on the capability of the microemulsion to keep the compound in dissolved condition. In addition, an oil having low ingredient solubility would require a higher amount of oil to incorporate the desired dose of an active ingredient. In order to keep the miscibility of oils, higher amont of surfactants and cosurfactants would be needed which might increase both the side effects and the toxicity of the system22. Our results showed that norcantharidin attained a greater solubility of 50 g/L when dimethylformamide, cyclohexanone and ethyl butyrate were mixed in a ratio of 1 : 1 : 2 (v/v/v). Therefore, the content of norcantharidin was maintained at 50 g/L for the subsequent studies. The choice of surfactant is critical for the formulation of microemulsions, as it helps reduce the interfacial tension by forming a film at the oil-water interface resulting in the spontaneous formation of microemulsions23. It was reported that mixed surfactants decrease the minimum weight fraction of surfactant required to solubilize equal weights of water and oil into a single phase24. Meanwhile, Fanun reported that the mixture (blend) of surfactants improves the surfactant’s partitioning at the water-oil interface by increaing the solubility of mixed surfactants in both oil and water thus increasing the stability of the amphiphilic film25,26. Therefore, mixed surfactants were used in our study. As shown in Table 1, Tx13 and Tw80 were the most appropriate surfactants due to forming a single continuous phase with a transparent appearance. Various Tx13-to-Tw80 weight ratios (1 : 1, 1 : 2, 1 : 3, 2: 1, 2 : 3, 3 : 1 and 3 : 2) were chosen to determine the optimum norcantharidin formulation. The best ratio (w/w) of the surfactant Tx13 to Tw80 was 1 : 1 providing good thermodynamic stability (Table 2). Non-ionic surfactants are often used for the screening of surfactants because they are less influenced by ionic strength and changes in solution pH and generally are considered as biocompatible and safe to non-target organisms22.

Construction of pseudo-ternary phase diagrams

In this study, ethanol was used as the cosurfactant. As previously reported, the addition of proper mass short-chain alcohols into non-ionic o/w as a cosurfactants helps in decreasing interfacial free energy and tension and balancing hydrophilic and hydrophobic values of the system by insertion into the interfacial layer27. To seek the optimal proportion of surfactants and cosurfactants in ME, the pseudo-ternary phase diagrams were constructed by the water titration method23,28. The effects of different surfactants-to-cosurfactant ratios (Km = 4 : 1, 4 : 2, 4 : 3 and 4 : 4) on the phase behavior of the water/Tw80-Tx13/ethanol/norcantharidin system were investigated. The Tw80-Tx13 ratio was kept constant at 1 : 1. The translucent microemulsion regions were presented in the phase diagrams without a distinct phase inversion from w/o to o/w microemulsion29. As shown in Fig. 1, the microemulsion regions change with the addition of different ratios of cosurfactant. For the mono-phase region, the smallest (32.75%) was formed when Km was 4 : 1 (Fig. 1A), whereas the largest (39.47%) was detected when Km reached 4 : 4 (Fig. 1D), suggesting that 4 : 4 was the most appropriate Km to form a stable norcantharidin microemulsion. Their characteristics were assessed and the optimum formulation was determined to be a 5% norcantharidin microemulsion system with 12% (w/w) dimethyl formamide, cyclohexanone and ethyl butyrate (1 : 1 : 2), 15% (w/w) Tw80 and Tx13 (1 : 1), 15% (w/w) ethanol, and 58% (w/w) water (Table 3).

Conductometry and structure of norcantharidin microemulsion

Conductivity is a key technique to detect the percolation threshold in microemulsions30. With the fixed ratio of mixed oil/surfactants/co-surfactant, the weight ratio of water increases along with linear-type experimental paths by stepwise addition into the mixture. Obviously, four regions exist as indicated in Fig. 2. The electrical conductivity σ of the selected oily mixture was almost zero and only increased slightly when the volume fraction of water was low. When a water volume fraction (φw) reached a critical point (φp), termed the percolation threshod, a dramatic change in conductivity is recorded with any further increase in water content; this is when the structure of the microemulsions has converted to a biocontinuous type or reached the emulsification boundary30,31. We ascribe the linear increase in σ to the formation of water cylinders or channels in an oil phase due to the attractive interaction between the spherical micro droplets of the water phase in the w/o microemulsion27. Accordingly, this steady increase the conductance is attributed to the larger water channels and particle size. When σ reaches the maximum value (1.25 S m−1, φw ≈ 40%), then a phase inversion from reverse swollen micelles (w/o) to direct micelles (o/w) is suggested23,32. Thereafter, σ values then drop because of dilutional impacts33. The structure of the microemulsion from w/o to a discontinuous phase and then o/w using titration is indicated by the derivative of the conductivity (Fig. 2).

Stability of microemulsions

Low and high temperature storage stability

After storage at 0 and 54 °C for 14 days, the appearance of the prepared norcantharidin microemulsion remained transparent and uniform, without any precipitate or phase separation. The decomposition rates of norcantharidin was 2.13% and 2.51%, which means there is no significant change in the stability of the microemulsion.

Freeze-thaw cycles

For this obtained norcantharidin microemulsion, thermodynamic stress tests were conducted using freeze-thaw cycles between −21 °C and 25 °C. At each temperature, the samples were stored for no less than 48 h. No freezing or floating oil was detected in the tested samples.

Cloud point

Cloud point is one of the specific characteristics of microemulsions. As the temperature increases, the solubility of the non-surfactant decreases, resulting in a turbid mixture. The cloud point occurred at a temperature greater than 72 °C. After centrifuge tests, there was no precipitation or phase separation of norcantharidin microemulsion, suggesting a good physical stability.

Dilution stability

To ensure the homogenous distribution of a chemical during field application for pest management, agrochemical microemulsion formulations are required to retain their integrity against dilution with water34. DSL analysis was conducted to assess the homogeneity of the microemulsion sample. DSL analysis provided evidence for the presence of transparent microemulsion systems, with a narrow size distribution for all samples. The microemulsions remained homogeneous and transparent during the dilution process, although DSL results indicated an increase in the droplet size along with the augmented dilution ratio (Fig. 3). The increase of droplet radii against dilution may be attributed to a decrease in volume fraction or to an attractive influence between the diluted microemulsion droplets. In diluted microemulsion systems, the increase in the diffusion coefficient of the droplet may be largely due to the attractive interactions which may ultimaltely result in the increase of the hydrodynamic radii of diluted samples34. Similarily, cosurfactant may diffuse from the interface film into the water phase due to the dilution with hard water, leading to the coalescence of the oil phase reducing the increased free energy and interfacial area. Once the diluted microemulsion systems reached a new balance again, the droplet size tended to become stable with time. Therefore, a microemulsion possessing macroscopical dilution stability was obtained7,35.

Insecticidal activity

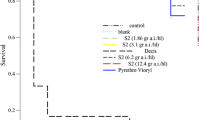

Norcantharidin, as an animal-derived variant compound of cantharidin, has shown insecticidal and anti-fungal activities19,20. But its agricultural use is restricted to some extent due to poor water solubility. Therefore, norcantharidin microemulsion has been developed in order to improve solubility and improve efficiency. According to Table 4, all 6 commercial insecticides are shown to be highly active against P. xylostella larvae, among which 5% emamectin benzoate ME had the minimal LC50 (0.07 mg/L; 0.06–0.09, 95% CL). Even though cantharidin and norcantharidin showed a higher LC50 (6.501 and 12.477 mg/L) to early-stage larvae of P. xylostella compared to the reminding insecticides, these compounds were used as an insecticide because of their new mode of action, fast degradation and non target effects21. Considering the complex and difficult synthesizing procedures36,37 as well as scarce origin38 of cantharidin, norcantharidin is a good alternative candidate. The 48 h LC50 value (95% confidence limits) of the 5% norcantharidin microemulsion for P. xylostella was found to be 12.477 (11.58–13.41) mg/L.

Both cantharidin EC and norcantharidin ME exhibited better activity against P. xylostella than did their pure products (on average, 163.16% and 300.41% higher as shown in LC50, respectively) (Table 4). Previous studies also demonstrated that commerical formulations often exhibited higher toxicity to the target pest than did the corresponding active ingredients39,40. One possbile reason is that marketed pesticides are composed of active ingredients and quite low amount of emulsifiers and/or short chain alcohols which would increase the bioavailability of the pesticide by increasing the solubility or compatibility of the active ingredients and also facilitate adsorption, penetration and translocation of the active ingredients into the targets41. Lei et al. (2012, 2014) and Wang et al. (2017) found that microemulsions showed a significantly higher lehtal activity than other types of formulations3,7,9. Another possible explanation is that as opposed to a single solvent, traditional chemical products are more effective when mixed solvents are employed3. Therefore, norcantharidin microemulsion showed a much better activity than a correspondingly pure active ingredient alone (Table 4).

When tested at the recommended rates, all six pesticides caused high mortality of third-instar larvae of P. xylostella (Table 5), especially spinosad and emamectin benzoate which showed the highest toxicities, with a larvae death rate up to 100% within 24 h. In contrast, the remaining pesticides caused over 60% mortality of the 3rd instars within 24 h and the larvae completely died during the next 24 h. These results are in accordance with Liu et al. (2003) and Zhao et al. (2006), who reported that emamectin benzoate and spinosad had high level of intrinsic toxicity to early-stage larvae of P. xylostella42,43.

Over the past decades, world wide and long-term use of synthetic pesticides has led to insect resurgence, pesticide resistance, biomagnifications and tremendous environmental damage although they aim to control pests, pathogen and weeds. The diamondack moth remains a notorious insect pest mainly resulting from its extremely easy to evolution of resistance to many classes of insecticides44,45 e. g., spinosad, indoxacrad and emamectin benzoate42,46,47. These challenges, coupled with negative effects on the environment and the high costs of the application and use of synthetic pesticides as well as consumers’ increasing demand of safe food are the main impetus to search for safer and biodegradable biopesticides. Biopesticides have attracted tremendous interest because they are eco-friendly48. Biopesticides and their derivatives are considered to be good alternatives to synthetic pesticides in controlling this harmful insect and have been successfully used in agriculture49,50,51,52.

In this study, we successfully developed an effective and novel norcantharidin microemulsion system with optimal characteristics, which showed a good control effect on the diamondback moth in the laboratory. Microemulsions can help in improving the bioavailability of poorly solube chemicals and ameliorating the adverse impacts of petroleum and organic solvent based-pesticides on the environment by way of altering their formulations. Further studies should be conducted to estimate the efficacy of practical application of norcantharidin microemulsions in the field and in combination with other insecticides to heighten pesticides’ effectiveness, reduce chemical consumption and lower agrochemical toxicity. Biopesticides are components of Integrated Pest Management (IPM) and contribute to delaying the development of insect resistance.

Materials and Methods

Insects and pesticides

Insecticide-susceptible stains of P. xylostella were reared under optimal growth conditions (25 ± 2 °C, 50% relative humidity and a photoperiod of 16 L : 8 D) without insecticide selection. Norcantharidin (>98%) was purchased from Alfa Aesar Chemical Co. Ltd (Haverhill, MA, USA). The emulsifiers Tx13 (alkylphenol polyoxyethylene) and Tw80 (polyoxyethylene sorbitan monooleate) (Hai’ an Petrochemicals, Jiangsu, China) were of commercial grade. Formulated insecticides used for bioassays included 1% azadirachtin microemulsion (ME) (Kepu Biochemical Co., Ltd), 5% emamectin benzoate microemulsion (ME) (Yinnong Technologies Co., Ltd), 60 g/L spinosad suspension concentrate (SC) (Dow AgroSciences LLC), 30% indoxacarb suspension concentrate (SC) (Jiangsu Jianpai Agrochemical Co., Ltd), 1% cantharidin emulsifiable concentrate (EC) (homemade) and 5% norcantharidin microemulsion (ME) (homemade).

Solvent screening

The solubility of norcantharidin in various solvents were determined to find out the appropriate solvents with a good capacity for norcantharidin in ME. The solubility of norcantharidin in mixed solvents was also measured. 0.5 g norcantharidin was added into 10 ml of each solvent at various temperatures, and the resultant mixtures were shaken reciprocally for 72 h followed by centrifugation for 30 min at 10000 rpm. The solvent (s) which can completely dissolve norcantharidin and the appearance always maintained transparent was chose for further experiments.

Surfactant screening

In order to screen and select the most effective surfactant (s), mixed solutions of equal masses of active ingredient (norcantharidin) and various surfactants were incubated using a thermobath at 20 °C for 24 h. The appearance of each mixture, the temperature range over which transparency was maintained, and low temperature and freezing stability were used to determine the quality of the obtained microemulsion formulation.

Pseudo-ternary phase diagram construction

To ascertain the concentration ranges of compositions in microemulsion range, pseudoternary phase diagrams were displayed using a water titration method at ambient temperature (25 ± 1 °C). The solution in which norcantharidin completely dissolved was the oil phase. At the desired Km (4 : 1, 4 : 2, 4 : 3 and 4 : 4), the mixture of surfactants (Tw80 and Tx13) and cosurfactant (ethanol) was set as an independent variable in the phase diagram. Then the weight ratios of the oil phase and the mixture (surfactant and co-surfactant) were varied from 1 : 9 to 9 : 1. Water was added to the oily mixture dropwise with gentle stirring. The appearance of the whole system underwent a change from transparent to turbid or the reverse, and a corresponding phase boundary was obtained.

Conductivity

The conductivity change of the microemulsion system with the increasing ratio of water was analyzed by a low frequency conductometer (DDS-307A, Shanghai Precision Scientific Instrument Co., Shanghai, China) at 25 ± 0.1 °C. The conductivity change has been typically used as an indicator to determine the phase inversion of the microemulsion from O/W to W/O.

Characterization of ME

Droplet size measurement

The average droplet size of the norcantharidin microemulsion and its changes against different multiples of dilution (100, 200, 500 and 1000 times) with standard hard water (content of Ca2+, Mg2+ were 342 mg/L) were measured by dynamic light scattering (DLS) using a Zetasizer Nano-ZS (Malvern Instruments). The backscatter measurement was performed at a fixed angle of 173° at 25 °C. The droplet size of each dilution was measured with four repetitions.

Centrifugation

The centrifugation of formulations at 13,000 rmp for 30 min and at 4000 rmp for 4 h was carried out to assess the physical stability of ME.

Thermodynamic stability

The microemulsion prepared according to the above methods was kept in place at 0 and 54 °C for 14 days; then the appearance, mobility, emulsifying properties and the extent of active material were measured. Meanwhile, samples were stored at −18 °C for 7 days to observe the stability of the microemulsion. Finally, the cloud point was measured by gently stirring the sample in a water bath, with the temperature set to increase at 2.0 °C/min intervals, until the microemulsion became observably turbid53.

Content of active ingredients in the microemulsion

The concentrations of norcantharidin were determined by GC analysis using an Agilent 4890D (Santa Clare, CA, USA) with a HP-5 capillary column (15 m × 0.53 mm × 1.5 μm) filled with 101 silylations supporter. The injector and detector temperature were 230 °C and 260 °C respectively. Nitrogen was the carrier gas at a constant flow-rate (30 ml/min), hydrogen at 2.0 kg/cm2 and air at 2.55 kg/cm2. The initial oven temperature was 150 °C for 3 min; then the temperature was raised at a rate of 10 °C/min to 260 °C. A standard concentration of norcantharidin was used to construct a calibration curve. Each microemulsion sample was repeated 4 times, with the concentration of norcantharidin was calculated according to the following formula:

Where: R1: ratio of the area of norcantharidin to the internal reference in the standard solution; R2: ratio of the area of norcantharidin to the internal reference in the sample solution; M1: the weight of standard norcantharidin (g); M2: the weight of the tested microemulsion sample (g).

Bioassays

Commercial pesticides (norcantharidin microemulsion, cantharidin emulsifiable concentrate, indoxacarb suspension concentrate, spinosad suspension concentrate, emamectin benzoate microemulsion and azadirachtin microemulsion) and active ingredients (norcantharidin and cantharidin) were prepared as serial dilutions with distilled water containing 0.1% TritonX-100; the solution containing 0.1% TritonX-100 only was taken as a control. Leaf discs (Ø 1.0 cm) of cabbage (Brassica oleracea) were dipped into prepared solutions for about 10 s and dried for about 1 h at ambient temperature. Ten dipped leaf discs and ten third-instar larvae were placed into a sterilized plastic petri dish (Ø 9.0 cm) containing a humid filter paper to maintain freshness. Four petri dishes with a total of 40 P. xylostella larvae of each sample were incubated in a growth chamber (25 ± 1 °C, 65% RH with a photoperiod of 16 : 8 (L: D)) and mortality of P. xylostella was determined after 24 and 48 h. Larvae that did move when gently touched with a brush were considered dead. Where the mortality of controls exceeded 10%, the experiments were repeated.

Statistical analysis

The pseudo-ternary phase diagram was constructed using Origin 9.1. Where necessary, bioassay data were corrected for the control mortality54. Values presented here represent a mean of four repetitions; concentration-response data were calculated by probit analysis. The other statistical analyses were conducted using SPSS 21.0. The mortality of different pesticide-treated samples were compared using a one-way ANOVA. Values were considered to be significantly different at P \( < \) 0.05.

References

Hazra, D. K. et al. Recent advances in pesticide formulations for eco-friendly and sustainable vegetable pest management: a review archives of agriculture and environmental science. Arch. Ag. Environ. Sci. 2, 232–237 (2017).

Bhowmick, D. N. Pesticides as microemulsion formulations. J. Disper. Sci. Technol. 29, 1325–1330 (2008).

Leng, P., Zhang, Z., Li, Q., Zhao, M. & Pan, G. Microemulsion formulation of carbendazim and its in vitro antifungal activities evaluation. PLoS One. 9, e109580 (2014).

Feng, Z., Xia, H. Y. & He, J. L. Formulation design of cyhalothrin pesticide microemulsion. Curr. Sci. India. 97, 1458–1462 (2009).

Skelton, P. R., Munk, B. H. & Collins, H. M. Formulation of pesticide microemulsions. In Pesticide Formulations and Application Systems: 8th Vol., ASTM STP 980; Hovde, D. A. & Beestman, G. B. Eds: American Society for Testing and Materials: Philadelphia, 36–45 (1989).

Hu, J., Akula, N. & Wang, N. Development of a microemulsion formulation for antimicrobial secA inhibitors. PLoS One. 11, e0150433 (2016).

Wang, C., Tai, X., Du, Z. & Liu, X. Formulation and physicochemical properties of promising avermectin microemulsion with biodegradable surfactant and oil. J. Disper. Sci. Technology. 38, 409–415 (2017).

Huang, Q. et al. Studies on the phase behavior of beta‐cypermethrion microemulsion. J. Disper. Sci. Technol. 27, 1065–1071 (2006).

Leng, P. et al. Development of a difenoconazole/propiconazole microemulsion and its antifungal activities against Rhizoctonia solani AG1-IA. Die Pharm. 67, 534–541 (2012).

Leng, P., Liu, L., Li, Q., Zhao, M. & Pan, G. Preparation of triadimefon microemulsion and its antifungal activity against Rhizoctonia solani AG1-IA analysis. Curr. Pharm. Anal. 9, 396–403 (2013).

Chin, C. P., Lan, C. W. & Wu, H. S. Study on the performance of lambda cyhalothrin microemulsion with biodiesel as an alternative solvent. Ind. Eng. Chem. Res. 51, 4710–4718 (2012).

Furlong, M. J., Wright, D. J. & Dosdall, L. M. Diamondback moth ecology and management: problems, progress, and prospects. Annu. Rev. Entomol. 58, 517–541 (2013).

Cao, G. & Han, Z. Tebufenozide resistance selected in Plutella xylostella and its cross-resistance and fitness cost. Pest Manag. Sci. 62, 746–751 (2006).

Zalucki, M. P. et al. Estimating the economic cost of one of the world’s major insect pests, Plutella xylostella (Lepidoptera: Plutellidae): just how long is a piece of string? J. Econ. Entomol. 105, 1115–1129 (2012).

Attique, M. N. R., Khaliq, A. & Sayyed, A. H. Could resistance to insecticides in Plutella xylostella (Lep., Plutellidae) be overcome by insecticide mixtures? J. Appl. Entomol. 130, 122–127 (2006).

Cousin, C. et al. Protein-serine/threonine/tyrosine kinases in bacterial signaling and regulation. FEMS Microbiol Lett. 346, 11–19 (2013).

Shi, Y. Serine/threonine phosphatases: mechanism through structure. Cell. 139, 468–484 (2009).

Chen, X. E., Liu, J. & Zhang, Y. Cantharidin impedes the activity of protein serine/threonine phosphatase in Plutella xylostella. Mol. Bio. Syst. 10, 240–250 (2014).

Wang, Y., Sun, W., Zha, S., Wang, H. & Zhang, Y. Synthesis and biological evaluation of norcantharidin derivatives possessing an aromatic amine moiety as antifungal agents. Molecules. 20, 21464–21480 (2015).

Sun, W., Liu, Z. & Zhang, Y. Cantharidin and its anhydride-modified derivatives: relation of structure to insecticidal activity. Int. J. Mol. Sci. 14, 1–16 (2012).

Shao, H. & Zhang, Y. Non-target effects on soil microbial parameters of the synthetic pesticide carbendazim with the biopesticides cantharidin and norcantharidin. Sci. Rep.-UK. 7 (2017).

Butani, D., Yewale, C. & Misra, A. Amphotericin B topical microemulsion: formulation, characterization and evaluation. Colloid. Surface B. 116, 351–358 (2014).

Aggarwal, N., Goindi, S. & Khurana, R. Formulation, characterization and evaluation of an optimized microemulsion formulation of griseofulvin for topical application. Colloid. Surface B. 105, 158–166 (2013).

Kunieda, H., Nakano, A. & Akimaru, M. The effect of mixing of surfactants on solubilization in a microemulsion system. J. Colloid. Interf. Sci. 170, 78–84 (1995).

Fanun, M. Conductivity, viscosity, NMR and diclofenac solubilization capacity studies of mixed nonionic surfactants microemulsions. J. Mol. Liq. 135, 5–13 (2007).

Fanun, M. A study of the properties of mixed nonionic surfactants microemulsions by NMR, SAXS, viscosity and conductivity. J. Mol. Liq. 142, 103–110 (2008).

Mehta, S. K., Kaur, G., Mutneja, R. & Bhasin, K. K. Solubilization, microstructure, and thermodynamics of fully dilutable U-type Brij microemulsion. J. Colloid. Interf. Sci. 338, 542–549 (2009).

Dong, X. et al. Encapsulation artocarpanone and ascorbic acid in O/W microemulsions: preparation, characterization, and antibrowning effects in apple juice. Food Chem. 192 (2016).

Chen, H. et al. A study of microemulsion systems for transdermal delivery of triptolide. J. Control Release. 98, 427–436 (2004).

Chiappisi, L., Noirez, L. & Gradzielski, M. A journey through the phase diagram of a pharmaceutically relevant microemulsion system. J. Colloid. Interf. Sci. 473, 52–59 (2016).

Kotmakçı, M., Akbaba, H., Erel, G., Ertan, G. & Kantarcı, G. Improved method for solid lipid nanoparticle preparation based on hot microemulsions: preparation, characterization, cytotoxicity, and hemocompatibility evaluation. AAPS Pharm. Sci. Tech. 18, 1–11 (2016).

Hathout, R. M. et al. Microemulsion formulations for the transdermal delivery of testosterone. Eur. J. Pharm Sci. 40, 188–196 (2010).

Wang, C., Tai, X., Du, Z. & Liu, X. Formulation and physicochemical properties of promising avermectin microemulsion with biodegradable surfactant and oil. J. Disper. Sci. Technol. 38, 409–415 (2016).

Singla, M. & Patanjali, P. K. Phase behaviour of neem oil based microemulsion formulations. Ind. Crop. Prod. 44, 421–426 (2013).

Du, Z., Wang, C., Tai, X., Wang, G. & Liu, X. Optimization and characterization of biocompatible Oil-in-Water nanoemulsion for pesticide delivery. ACS Sustain. Chem. Eng. 4, 983–991 (2016).

Dauben, W. G., Kessel, C. R. & Takemura, K. H. Simple, efficient total synthesis of cantharidin via a high-pressure Diels-Alder reaction. J. Am. Chem. Soc. 102, 6893–6894 (1980).

Stork, G., Tamelen, E. E. V., Friedman, L. J. & Burgstahler, A. W. A stereospecific synthesis of cantharidin. J. Am. Chem. Soc. 75, 384–392 (1953).

Jiang, M., Lü, S. & Zhang, Y. The potential organ involved in cantharidin biosynthesis in Epicauta chinensis Laporte (Coleoptera: Meloidae). J. Insect Sci. 17 (2017).

Pereira, J. L. et al. Toxicity evaluation of three pesticides on non-target aquatic and soil organisms: commercial formulation versus active ingredient. Ecotoxicology. 18, 455–463 (2009).

Sundaram, K. & Sloane, L. Effects of pure and formulated azadirachtin, a neem‐based biopesticide, on the phytophagous spider mite, Tetranychus urticae Koch. J. Environ. Sci. Heal. B. 30, 801–814 (1995).

Krogh, K. A., Halling-Sørensen, B., Mogensen, B. B. & Vejrup, K. V. Environmental properties and effects of nonionic surfactant adjuvants in pesticides: a review. Chemosphere. 50, 871–901 (2003).

Zhao, J. Z. et al. Monitoring of diamondback moth (Lepidoptera: Plutellidae) resistance to spinosad, indoxacarb, and emamectin benzoate. J. Econ. Entomol. 99, 176–181 (2006).

Liu, T., Sparks, A. & Chen, W. Toxicity, persistence and efficacy of indoxacarb and two other insecticides on Plutella xylostella (Lepidoptera: Plutellidae) immatures in cabbage. Int. J. Pest Manage. 49, 235–241 (2003).

Bautista, M. A. M., Miyata, T., Miura, K. & Tanaka, T. RNA interference-mediated knockdown of a cytochrome P450, CYP6BG1, from the diamondback moth, Plutella xylostella, reduces larval resistance to permethrin. Insect Biochem. Molec. 39, 38–46 (2009).

Wang, X., Li, X., Shen, A. & Wu, Y. Baseline susceptibility of the diamondback moth (Lepidoptera: Plutellidae) to chlorantraniliprole in China. J. Econ. Entomol. 103, 843–848 (2010).

Grzywacz, D. et al. Current control methods for diamondback moth and other brassica insect pests and the prospects for improved management with lepidopteran-resistant Bt vegetable brassicas in Asia and Africa. Crop Prot. 29, 68–79 (2010).

Sayyed, A. H. & Wright, D. J. Genetics and evidence for an esterase-associated mechanism of resistance to indoxacarb in a field population of diamondback moth (Lepidoptera: Plutellidae). Pest Manag. Sci. 62, 1045–1051 (2006).

Moshi, A. P. & Matoju, I. The status of research on and application of biopesticides in Tanzania. Crop Prot. 92, 16–28 (2017).

Chitrampalam, P., Wu, B. M., Koike, S. T. & Subbarao, K. V. Interactions between Coniothyrium minitans and Sclerotinia minor affect biocontrol efficacy of C. minitans. Phytopathology. 101, 358–366 (2011).

Mnif, I. & Ghribi, D. Potential of bacterial derived biopesticides in pest management. Crop Prot. 77, 52–64 (2015).

Zanardi, O. Z. et al. Bioactivity of a matrine-based biopesticide against four pest species of agricultural importance. Crop Prot. 67, 160–167 (2015).

Ma, D. L., Gordh, G. & Zalucki, M. P. Biological effects of azadirachtin on Helicoverpa armigera (Hübner) (Lepidoptera: Noctuidae) fed on cotton and artificial diet. Aust. Entomol. 39, 301–304 (2014).

Chen, F., Wang, Y., Zheng, F., Wu, Y. & Liang, W. Studies on cloud point of agrochemical microemulsions. Colloid. Surface A. 175, 257–262 (2000).

Abbott, W. A method of computing the effectiveness of an insecticide. J. Econ. Entomol. 18, 265–267 (1925).

Acknowledgements

We sincerely appreciate Prof. John Richard Schrock (Emporia State University, USA) for revising the manuscript. This research is supported by the Special Fund for the Public Interest (Agriculture) (200903052) by The Ministry of Science and Technology and The Ministry of Agriculture of China and the ‘13115’ Sci-Tech Innovation Project of Shaanxi Province (2007ZDKG-14).

Author information

Authors and Affiliations

Contributions

Yalin Zhang and Hainan Shao conceived the project and designed the experiment. Hainan Shao and Na Xi performed the experiments and wrote the paper. Yalin Zhang supervised the study and contributed reagents/materials. All authors contributed to data analysis.

Corresponding author

Ethics declarations

Competing Interests

The authors declare no competing interests.

Additional information

Publisher's note: Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Shao, H., Xi, N. & Zhang, Y. Microemulsion formulation of a new biopesticide to control the diamondback moth (Lepidoptera: Plutellidae). Sci Rep 8, 10565 (2018). https://doi.org/10.1038/s41598-018-28626-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s41598-018-28626-0

- Springer Nature Limited