Abstract

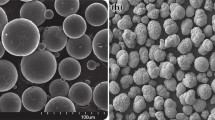

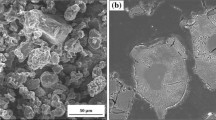

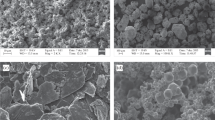

In the present paper, the use of spark plasma sintering on Ti6Al4V powder was investigated. Sintering experiments were conducted at the temperature of 10008C for 5 min. The simultaneous effect of compaction pressures of 5, 25 and 50 MPa and heating rates of 200, 300 and 4008C/min on the structure, density, microhardness, elastic modulus and compressive strength were analyzed and ranged between 4.14 and 4.43 g/cm3, 293 and 373 HV0.05, 116 and 142 GPa, 1169 and 1414 MPa respectively. With increasing compaction pressure, the effect of an increase in grain size was observed. The obtained results show that very good mechanical properties can be achieved using spark plasma sintering at a rapid heating rate and already with the 25 MPa compaction pressure. The best results of microhardness (373 HV0.05) and compressive strength (1414 MPa) with an elastic modulus of 138 GPa were obtained by the compacts sintered under the compaction pressure of 50 MPa and at the heating rate of 3008C/min.

Similar content being viewed by others

References

Y. Quan, F. Zhang, H. Rebl, B. Nebe, Ol. Kessler, E. Burkel, Ti6Al4V foams fabricated by spark plasma sintering with post-heat treatment, Materials Science and Engineering: A 565 (2013) 118–125.

S.G. Tabrizi, S.A. Sajjadi, A. Babakhani, W. Lu, Influence of spark plasma sintering and subsequent hot rolling on microstructure and flexural behavior of in-situ TiB and TiC reinforced Ti6Al4V composite, Materials Science and Engineering: A 624 (2015) 271–278.

X. Li, Q. Zhou, S. Zhao, J. Chen, Effect of pulse current on bending behavior of Ti6Al4V alloy, Procedia Engineering 81 (2014) 1799–1804.

M. Wojtaszek, T. Śleboda, Design and verification of thermochemical parameters of P/M Ti6Al4V alloy forging, Journal of Alloys and Compounds 615 (1) (2014) 546–550.

Z. Doni, A.C. Alves, F. Toptan, J.R. Gomes, A. Ramalho, M. Buciumeanu, L. Palaghian, F.S. Silva, Dry sliding and tribocorrosion behavior of hot pressed CoCrMo biomedical alloy as compared with the cast CoCrMo and Ti6Al4V alloys, Materials & Design 52 (2013) 47–57.

P. Vlack, F. Cerny, J. Drahokoupil, J. Sepitka, Z. Tolde, The microstructure and surface hardness of Ti6Al4V alloy implanted with nitrogen ions at an elevated temperature, Journal of Alloys and Compounds 620 (2015) 48–54.

H. Yanjun, L. Jinxu, L. Jianchong, L. Shukui, Z. Qinghe, Ch. Xingwang, Rapid preparation of TiC reinforced Ti6Al4V based composites by carburizing method through spark plasma sintering technique, Materials & Design 65 (2015) 94–97.

F. Zhang, M. Reich, O. Kessler, E. Burkel, The potential of rapid cooling spark plasma sintering for metallic materials, Materials Today 16 (5) (2013) 192–197.

M. Eriksson, M. Radwan, Z. Shen, Spark plasma sintering of WC, cemented carbide and functional graded materials, International Journal of Refractory Metals and Hard Materials 36 (2013) 31–37.

L. Liu, Z. Hou, B. Zhang, F. Ye, Z. Zhang, Y. Zhou, A new heating route of spark plasma sintering and its effect on alumina ceramic densification, Materials Science and Engineering: A 559 (2013) 462–466.

F. Despang, A. Bernhardt, A. Lode, Th. Hanke, D. Handtrack, B. Kieback, M. Gelinsky, Response of human bone marrow stomal cells to a novel ultra-fine-grained and dispersion-strengthened titanium-based material, Acta Biomaterialia 6 (3) (2010) 1006–1013.

D. Garbiec, F. Heyduk, T. Wiśniewski, The influence of sintering temperature on the density, microstructure and strength properties of the Ti6Al4V alloy produced using the spark plasma sintering method (SPS), Metal Forming 23 (4) (2012) 265–275.

D. Garbiec, F. Heyduk, Sintering of titanium and hydroxyapatite by spark plasma sintering, Metallurgy - Metallurgical Engineering News 79 (8) (2012) 569–574.

K. Crosby, L.L. Shaw, C. Estournes, G. Chevallier, A.W. Fliflet, M.A. Imam, Enhancement in Ti-6Al-4V sintering via nanostructured powder and spark plasma sintering, Powder Metallurgy 57 (2) (2014) 147–154.

Y.F. Yang, M. Qian, in: M. Qian, F.H. Froes (Eds.), Titanium Powder Metallurgy, Elsevier Inc., 2015 219–235.

http://asm.matweb.com/search/SpecificMaterial.asp?bassnum=MTP641 (12.04.16).

I. Yadroitsev, P. Krakhmalev, I. Yadroitsava, Selective laser melting of Ti6Al4V alloy for biomedical applications: temperature monitoring and microstructural evolution, Journal of Alloys and Compounds 583 (2014) 404–409.

R. Dabrowski, The Kinetics of phase transformations during continuous cooling of the Ti6Al4V alloy from the singlephase b range, Archives of Metallurgy and Materials 56 (3) (2011) 703–707.

I. Cadoff, J.P. Nielsen, Titanium-carbon phase diagrams, Transactions of the American Institute of Mining Engineers 197 (1953) 248–252.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Garbiec, D., Siwak, P. & Mróz, A. Effect of compaction pressure and heating rate on microstructure and mechanical properties of spark plasma sintered Ti6Al4V alloy. Archiv.Civ.Mech.Eng 16, 702–707 (2016). https://doi.org/10.1016/j.acme.2016.04.009

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1016/j.acme.2016.04.009