Abstract

Granular lateritic materials (GLM) suitability for road construction after the addition of crushed rock aggregates (CRA) in the sub-Saharan extensive urbanization context was evaluated. The urbanization rate was made by using Landsat7 and Landsat8 radar images. The studied materials were subject to petrographic description and geotechnical analysis. The urbanized surface in the Yaoundé area increased by 41.88% from 2004 to 2020. The studied rock are gneisses composed of quartz, garnet, biotite, pyroxene, and feldspars. The gneisses obtained CRA have fines content of less than 10%, maximum dry density value of more than 2.00 g/cm3, good bearing capacity (CBR = 88%), and excellent mechanical characteristics (Los Angeles < 40%). This recommend their use as base course for low to medium volume traffic pavements. Gneisses-derived GLM, less load-bearing (CBR = 39 to 42%) than CRA, have limited behaviour in road construction and can be used as sub-base for all volume traffics. Their use in base courses requires prior treatment. CRA addition to these GLM result in the plasticity index decrease and compaction parameters improvement. CBR values increase shows a perfect correlation (R2 > 0.90) with the addition of CRA. Litho-stabilised materials (CBR ≥ 60%) can be used as base course for low-volume trafficked pavements. The addition of a CRA percentage greater than or equal to 25% is efficient for the optimization of their use. By reducing the amount of quarry aggregates, the improved material could be an economical alternative for road projects. This reduces and controls the haulage of materials within crowded urban area.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Soil is important raw material in various development engineering projects especially in cities, including pavement construction [1, 2]. Among the development projects, road constructions that call for the use of materials such as crushed rock and, fine and granular lateritic materials or lateritic gravels [3]. Granular lateritic materials or lateritic gravels, which are widely present in tropical areas around the world, are widely used in road construction [3]. These materials -economically very viable products- are used in road construction according to their geotechnical characteristics and the type of traffic they are used for [4, 5]. Their systematic use as road construction materials is causing a progressive depletion of this resource in some parts of subtropical Africa [6]. Numerous works on the characterization of lateritic gravels for road use has been carried out in tropical Africa and more particularly in Cameroon [4, 7,8,9]. These have shown that, in terms of bearing capacity, the vast majority of these materials do not always meet the requirements for use of soils in pavement layers.

The majority of cities in the sub-Saharan zone have experienced a demographic explosion in recent decades, supporting strong urban dynamics [1]. This dynamic has led to disorderly and uncontrolled urbanisation resulting in a rapid expansion of the city dictated by the choices and options of individuals [1]. The rate of urbanisation in Cameroon is increasing exponentially, reaching 48.8% in 2005 [10]. This is above the world average of 47.5% [11]. In addition, the city of Yaoundé, which is the political capital of Cameroon, is ranked as the 20th fastest-growing urban area in the world [12]. The expansion or extensive urbanisation of a city severely restricts the extraction of local laterite resources, just as it occupies areas of potential deposits. This leads to the extension of the city's supply areas, and therefore to an increase in costs and in the environmental footprint [13]. Building materials are the second most consumed material in cities after water [14]. Their use for the development and renewal of cities sometimes leads to a situation of scarcity [14]. It is therefore important to study the relationship between the mobilisation and availability of materials and urbanisation processes. With the rampant urbanisation of cities, likely lateritic gravel deposits are being occupied by housing development. The consequence is a reduction in the number of exploitable deposits and an increase in the probability of having more access to poor quality lateritic materials.

This scarcity and/or absence of good quality materials against an abundance of poor-quality materials lead decision-makers and/or project managers to use the latter with improvement for optimization of their characteristics in road construction [15]. Soil improvement or stabilization refers to the procedure in which a special soil or other materials are added to a natural or single-use soil to improve its properties [16]. Among the improvement techniques commonly used in many African countries is litho-stabilisation. This method consists in improving the geotechnical parameters of a material of inferior quality and adding/blending it with better performing granular material of known properties [15, 17, 18]. It also has numerous outcrops of gneissic and migmatitic rocks [19]. This feature can contribute to the improvement of poor-quality lateritic materials using these crushed rock aggregates, which generally have good geotechnical characteristics suitable for litho-stabilisation [17]. Numerous litho-stabilisation studies of lateritic materials have been carried out in the sub-Saharan area. These studies have used rock aggregates from magmatic formations as additive materials [15, 18, 20,21,22].

Although granular lateritic materials developed on metamorphic rocks in the study area have been the subject of geotechnical studies [23,24,25], very few researchers have focused on their improvement through the addition of metamorphic rock crushed materials. The present study aims to evaluate the suitability of granular lateritic materials developed on metamorphic rocks after the addition of crushed rock aggregates within the context of extensive urbanisation in view of road construction purposes.

2 Geographical and geological setting—experimental procedure

2.1 Geographical and geological setting

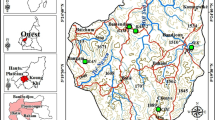

The studied materials come from the Yaoundé area (Fig. 1). This area belongs to the Mfoundi Division. The relief is hilly and the climate is equatorial with four seasons unevenly distributed throughout the year [26]. The formations encountered belong to the Pan-African chain and consist of migmatitic gneiss and mica schists [19]. Those formations belong to the Yaoundé series composed of low to high metamorphic grade rocks [19]. The soils developed on these rock formations are mainly ferralitics. The profiles of these soils generally consist of a weathering unit followed by a median unit with a superficial loose clay layer [27]. The median unit is made up of nodular or granular and hardpan materials. It is within this context that the granular lateritic materials of the study were collected from the localities of Awae (Aw), Nkolbisson (Nk) and Olembé (Ol), all in the outskirts of Yaoundé, where the urban centre has been urbanised. For each locality, 5 pits were opened in the considered granular lateritic materials quarry and 5 samples were obtained. In each quarry, the obtained materials having the same colour and the same structure, a mixture of all the 5 taken samples was carried out in the laboratory using a mixer for the continuation of the study. The additional material or litho-stabilisation product -0/31.5 crushed rock aggregates—comes from the Nomayos quarry, which is currently being exploited.

2.2 Experimental procedure

2.2.1 Soils occupation evaluation

Land use in the study area was assessed over a 16-year period (2004–2020). It is based on maps obtained by processing Landsat 7 and Landsat 8 images taken on 7 February 2004 and 26 January 2020 respectively (Table 1). These images were acquired from the United States Geological Survey (USGS) terrestrial navigation system. The processing method used is Supervised Classification of Satellite Images by Maximum Likelihood. This method is one of a common supervised classifiers [28]. It starts with image preprocessing by the radiometric correction which enhances the quality and interpretability of the satellite image [29]. The scan line errors on the Landsat 7 image were previously corrected using the 'Landsat-gapfill.sav' functionality integrated into the ENVI software. The spectral bands numbered 1 to 7 were then used with Arcgis 10.5 software to produce composite images. These images were used to identify and sample the objects using the RGB colour compositions. Generally, supervised classifiers require first to know the land cover types of the studied area [30]. The sampled objects were then grouped into classes and their properties interpolated over the entire area of interest. Based on the fact that the environment presented by the image is heterogeneous, information classification has enabled us to determine the entities or categories represented in this work by vegetation, buildings and water (rivers, ponds and lakes). Object properties were interpolated so that water was identified as blue, vegetation as green and buildings as orange. The spatial coverage of each object in the area of interest was estimated by converting the classification data into vector data, which is geometrically measurable.

2.2.2 Geological analysis

The geological work consisted of locating the sampling points, describing the materials and taking samples. Rock sampling for petrographic studies was carried out in the Nomayos quarry, using a sledgehammer. The 0/31.5 crushed rock aggregates were also obtained from the same site. The petrographic studies were carried out on thin sections prepared at the Department of Earth Sciences, University of Yaoundé I. Three (03) samples of granular lateritic materials (Aw, Nk and Ol) were collected by scraping with shovels and picks on the faces of the lateritic quarry trenches. After the macroscopic description, the collected samples were packed in coded bags and sent to the laboratory for analysis. For each sampling site, large quantities of samples were collected to allow the determination of the properties of natural granular lateritic materials as well as those to be improved upon by the addition of 0/31.5 crushed rock aggregate fractions.

2.2.3 Geotechnical analysis

The geotechnical tests were carried out at the Sol Solution Afrique Centrale (SSAC) laboratory following the AFNOR (Association Française de Normalisation) standards (Table 2). The specific gravity of the studied materials was determined by the NF P 94-054 standard [31]. The NF P 94-056 standard [32] was used to carry out particle size analysis by dry sieving. The determination of the liquid limit (LL) and plastic limit (PL) were carried out in accordance with NF P 94-051 standard [33]. The LL was determined according to the Casagrande apparatus while the roller technic was used to measure PL values. The Proctor parameters—optimum moisture content (OMC) and maximum dry density (MDD)—were determined according to the NF P94-093 standard [34]. The determination of California bearing ratio (CBR) followed the NF P94-078 standard [35]. The resistance to fragmentation by the impact of aggregates from massive rocks was evaluated by the Los Angeles test as prescribed by standard NF EN 1097–2 [36]. Wear resistance was determined by the Micro-Deval test following standard NF EN 1097–1 [37]. Geotechnical properties were determined according to the experimental procedure presented some in previous works [15, 18, 20]. The improvement proportions were randomly set from granular lateritic materials and 0/31.5 crushed rock aggregates in proportions of 80/20, 75/25, 70/30 and 65/35. The first number indicates the fraction of granular lateritic materials in the mixture and the second, the fraction of crushed rock aggregates 0/31.5.

3 Results and discussion

3.1 Urbanization evaluation

The rate of urbanisation in the Yaoundé area was assessed on the basis of land-use maps for the area. These are illustrated in Figs. 2 and 3. The urban dynamics of the city of Yaoundé can therefore be observed. The percentage of vegetation cover has decreased from 51.40% in 2004 to 9.52% in 2020 (Fig. 4). For the same period, the urbanised surface has increase moving from 48.54% in 2004 to 90.40% in 2020 (Fig. 4). These data confirm the rapid and regular urbanisation of the city of Yaoundé [12]. The rate of increase in the urbanised area is 41.88%, corresponding to the disappearance of vegetation. This increase in the urbanisation rate leads to an increase in the consumption of construction materials [14]. The increase in the urbanised area not only leads to a reduction in the reserves of lateritic materials, but also to a probable reduction in their exploitation areas (Fig. 5). This is borne out of on-site observations, which show that urbanisation spreads easily over good quality soils that can be used as building materials (Fig. 5). After water, construction materials are the most important flow entering urban areas [38, 39]. To limit this flow, and minimise transport costs and the associated environmental impacts, it is therefore imperative to use the materials available within the construction project area, subject in some cases to improvement or treatment.

3.2 Geological features

3.2.1 Rock

The rock observed at the Nomayos quarry, outcrops as a dome. It is light grey in colour and consists of millimetre-sized grains, characterized by foliated alternating dark beds of ferromagnesian and light quartz-feldspathic beds (Fig. 6). Microscopically, the main minerals observed are quartz, garnet, biotite, plagioclase, alkali feldspars (orthoclase and microcline), and pyroxene. Quartz (30–35%) is fairly abundant in the rock and occurs as xenomorphic to subautomorphic crystals around garnet blasts. Garnet (20–25%) occurs as cracked ovoid porphyroblasts (Fig. 7). Quartz and biotite inclusions are common (Fig. 7). In some places, porphyroblasts are moulded by biotite flakes (Fig. 7). Biotite (15–20%) occurs as elongated subautomorphic to xenomorphic lamellae (Fig. 7). In other places, it is altered to chlorite (Fig. 7). Pyroxene (8–10%) occurs as xenomorphic crystals and in association with garnet (Fig. 8). Potassium feldspars (8–10%) are represented by microcline and orthoclase (Fig. 8). They occur as xenomorphic crystals in association with all the minerals in the rock. It is worthy note the quartz inclusions in the orthoclase (Fig. 7). Plagioclases (3–5%) are recognisable by polysynthetic macles and occur as small subautomorphic patches in association with quartz (Fig. 7). The observation and microscopic analysis carried out show that the rock studied is a garnet and pyroxene gneiss. The composition of the rocks studied is close to that of the garnet and kyanite gneisses found in the Yaoundé area [20].

3.2.2 Granular lateritic materials

The studied granular lateritic materials come from the accumulation assemblage of ferralitic soil weathering profiles (Fig. 8). In the observed soil profiles, this assemblage consists of a fine nodular layer surmounted by a nodular layer with blocks of hardpan. This reddish-coloured unit is about 7 m thick. The fine nodular layer is about 2 m thick and consists of ferruginous nodules and quartz fragments packed in a clay matrix (30–35%). The nodules (about 55%) are millimetre-sized and rounded to sub-rounded. The boundary between the fine nodular layer and the nodular layer with blocks of hardpan is progressive. The nodular layer with blocks of hardpan is about 5 m thick. It consists of nodules (40–50%) and blocks of hardpan (25–30%) filled with a reddish clay matrix (25–30%). The nodules are millimetre to a centimetre in size, rounded to sub-rounded in shape and have a honeycomb structure.

3.3 Geotechnical properties of raw materials

3.3.1 Rock geotechnical properties

The specific gravity value of the studied 0/31.5 crushed rock aggregates is 3.00. The obtained value (3.00) is higher than those presented by chlorite schists of the Mbalmayo-Bengbis series (2.74) [40] and the granites of the Bonis area in East Cameroon (2.78) [16]. The specific gravity of the studied gneisses is in the order of those obtained on the migmatic gneisses of the Yaoundé area (2.82–3.32) [7]. The studied gneisses have a high value of specific gravity (3.00). Generally, the gneisses consist of ferromagnesian minerals (biotite, ortho pyroxene) and opaque oxides [19]. The density of the minerals has an impact on the density of the rock [41]. The high specific gravity value (3.00) of the studied crushed rock aggregates is in agreement with the density of the minerals (2.65–3.30) of the rock from which the crushed materials are derived. This high value of specific gravity is therefore related to the nature of the rock and the petrographic content.

The sieving data of the 0/31.5 crushed aggregates show that these materials consist of 27% of particles smaller than 2 mm, 15% of particles smaller than 0.425 mm and 5% of fines. The 0/31.5 studied crushed rock aggregates have a maximum diameter of less than 40 mm. The fine content is low, which corroborates the work done on this type of materials [4, 42]. The studied 0/31.5 crushed aggregates have an optimum moisture content (OMC) value of 6.4% and a maximum dry density (MDD) value of 2.35 g/cm3. The obtained OMC value is comparable to those presented by aggregates on granites from the Bonis area in East Cameroon (6%) [20] and basanites from Bafang in West Cameroon (6.6%) [21]. The MDD value is lower than that obtained on granite aggregates from the Bonis area in East Cameroon (2.42 g/cm3) [20]. This value is higher than that obtained on Bafang basanites in West Cameroon (2.15 g/cm3) [21]. The corresponding CBR value at 95% MDD is 88%. The CBR value at 95% MDD of the studied 0/31.5 crushed rock aggregates is lower than that obtained on the aggregates from the Bonis area in East Cameroon (130%) [20]. The CBR bearing capacity of gneissic aggregates in the Yaoundé area (88%) is higher than that obtained on Bafang basanites in West Cameroon (71%) [21].

The values of the micro Deval (MD) and Los Angeles (LA) coefficients of the studied 0/31.5 crushed rock aggregates are respectively 16 and 29%. The MD value of the studied gneisses (16%) is higher than those obtained on the Yobouékro (Côte d'Ivoire) granite aggregates (6%) [22]. The Los Angeles obtained value (28%) is higher than those presented by the West Cameroon basanites (19%) [21], the East Cameroon granites (22.45%) [20] and the Congo alluvial gravels (23%) [43]. This value is similar to that obtained on 0/31.5 granite crushed materials from Yobouékro in Côte d'Ivoire (28%) [22]. The LA values of the studied aggregates are lower than 30%. They, therefore, present a good resistance to fragmentation on impact [42].

3.3.2 Granular lateritic materials geotechnical properties

The specific gravity values of the studied granular lateritic materials (GLM) vary from 2.79 to 2.85 (Table 3). The average specific gravity value of the GLM in the Yaoundé area (2.82) is higher than those obtained in the Ngoumou area (2.78) [7], Boumpial in East Cameroon (2.76) [8] and on mica schists in Nigeria (2.76) [44]. It is higher than that obtained on lateritic gravels developed on gneiss in the humid savannah zone in Central Cameroon (2.63) [24]. The obtained average value of specific gravity is similar to that obtained on schistose rocks (2.84) [25] and gneiss in the dry savannah zone (2.81) [24] in central Cameroon. This value is also similar to that obtained on materials developed on quartz schists in Nigeria (2.84) [44]. The specific gravity values of the studied GLM are in the order of those generally encountered on this type of material (2.5–3.6) [45].

The studied GLM consist of 0 to 10% of pebbles and 64 to 68% of the skeleton averaging 66%. Skeleton content values of GLM generally vary between 20 and 60% [4]. The average skeleton (> 2 mm) content of the studied GLM (66%) is close to the maximum value generally found in this type of material [4]. The fine particles content varies from 29 to 32% (Table 3). The fine particles content of the studied GLM is in the order of those generally obtained for this type of material (5–40%) [46]. Values of fines content of the studied GLM below 35% are characteristic of this type of material [4]. According to the HRB classification, the studied GLM are gravels and silty or clayey sands belonging to classes A-2–6 (0) and A-2–7 (0). According to the CEBTP-ISTED classification, the lateritic gravels studied cover class GL1. The liquid limit values of the studied GLM vary between 53 and 56% (Table 3). The values of the plasticity index are between 18 and 24% (Table 3). The respective mean values of these parameters are 54% and 21%. The average value of the liquid limit (LL) of the studied GLM (54%) falls within the range of values obtained for the same type of material in West Africa (23–55%) [47,48,49]. This value is in the order of those found on materials developed on granite in Southern Cameroon (26–62%) [9, 20, 50]. The average plasticity index (PI) value of the studied GLM (21%) is higher than the value obtained on the lateritic gravels from Congo Brazzaville (19%) [43]. It is lower than the average values for lateritic gravels on schistose rocks in the Akonolinga area in Central Cameroon (27%) [25]. This value is lower than that obtained on materials developed on granite in East Cameroon (28%) [20] and South Cameroon (37%) [9]. The PI average value of the studied GLM is comparable to those obtained in the dry savannah (20%) and wet savannah (23%) zones in Central Cameroon [24]. The obtained average value (21%) is in the order of those obtained on lateritic gravels on granite in the Bonis area (22–32%) [20].

The studied GLM materials have OMC values varying between 15.80 and 18.00%. The MDD values are between 1.81 g/cm3 and 2.06 g/cm3 for CBR values varying between 39 and 42% (Table 4). The OMC average value of the studied GLM (16.60%) is within the range of those obtained on materials developed on schistose rocks in the Akonolinga area (7.20–18.00%) [25]. This value (16.60%) is higher than those obtained on lateritic gravels developed on metamorphic rocks in the southern Cameroonian plateau (10.70–12.80%) [8, 24]. The MDD average value of the studied GLM (1.94 g/cm3) is lower than that obtained on lateritic gravels on granites in Burkina Faso (2.17 g/cm3) [49] and comparable to that obtained on gneiss derived lateritic gravels in the humid savannah zone in Central Cameroon (1.95 g/cm3) [24]. This value is higher than that obtained on the same type of material in Côte d'Ivoire (1.85 g/cm3) [22]. The obtained MDD average value is in the order of those obtained on materials derived from metamorphic and plutonic rocks in South Cameroon (1.84–2.20 g/cm3) [9, 20, 23, 25]. The average CBR value of the studied GLM (40%) is lower than those of the same type of material developed on Bonis granites in East Cameroon (61%) [20], on chlorite schists of the Akonolinga area (50%) [25] and Congo granites (54%) [43]. It is comparable to those obtained on lateritic gravels in Burkina Faso (43%) [49] and South Cameroon (42%) [9]. The bearing capacity of the studied materials is higher than that of lateritic gravels on mica schists in the Mfou area in Central Cameroon (24%) [23] and natural lateritic gravels of type G3 (17%) in Côte d'Ivoire [22]. The average value obtained (40%) is in the order of those generally encountered in the forest sub-regions of Central and Southern Cameroon (35–60%) [51].

3.4 Effects of crushed rock aggregates addition on GLM

The addition of 0/31.5 crushed rock aggregates to the studied granular lateritic materials is accompanied by a decrease in fines content (Fig. 9). Increasing the percentage of crushed rock aggregates in the mix results in a decrease in fines content values from 32 to 21% (Fig. 9). The decrease in fines content is a function of the improvement rate. This development is similar to that observed in similar previous works [21, 22]. In litho-stabilisation studies, as the amount of granular crushed material in the mix increases, the fine content decreases to reach a threshold value [22]. The Atterberg limit values of the litho-stabilised materials are presented in Table 5. The LL values vary from 56 to 40% with the addition of aggregates. The PI values range from 24 to 10% (Table 5). The addition of 0/31.5 crushed rock aggregates on the studied GLM leads to a progressive decrease of the LL and PI values according to the addition percentage (Figs. 10 and 11). The progressive modification of the liquid limit and plasticity parameters would be due to the presence of the sandy particles brought by the crushed rock aggregates. The evolution of these parameters is consistent with litho-stabilisation work carried out in Cameroon [21], Côte d'Ivoire [22], Congo [43], Niger [6] and Sénégal [52]. The compaction parameters studied in the present improvement are the MDD, OMC and CBR.

The OMC values of the studied granular lateritic materials improved with 0/31.5 crushed rock aggregates varying from 18.00 to 8.50% (Table 6). The MDD values vary between 1.81 g/cm3 and 2.28 g/cm3 (Table 6). For the CBR bearing capacity, the values of this parameter vary from 39 to 77%. Figures 12 and 13 shows that the MDD values of the studied granular lateritic materials improved with 0/31.5 crushed rock aggregates increase while decreasing the OMC values. A similar evolution was obtained on the compaction parameters of lateritic gravels from Congo [43], Cameroon [21] and Côte d’Ivoire after aggregates addition [22]. As the proportion of crushed rock aggregates in the mixes is increased, MDD increases up to a value of 2.28 g/cm3 for the 65/35 mix formula (Fig. 12). The increase in MDD values is due to the addition of a denser rock material, with a MDD of 2.35 g/cm3, to a less dense granular lateritic material with a MDD of 1.94 g/cm3. The increase in MDD values indicates an improvement.

The addition of 0/31.5 crushed rock aggregates on GLM is accompanied by an increase in CBR values in proportion to the increase in the 0/31.5 crushed rock aggregates content (Fig. 14). This evolution is similar to that obtained after the addition of a percentage of crushed material lower than 30% to the Bonis lateritic gravels in East Cameroon [20]. CBR values at 95% MDD vary between 39 and 66% for a 25% addition. The increase in CBR values may be due to the reduction in fines content due to the addition of coarse aggregate and a resultant rearrangement of the particles in the mix [53]. The increase in CBR values with an increasing percentage of crushed rock aggregates can also be explained by the fact that the added aggregates are more resistant to crushing under continuous loading [53, 54]. These increases are less than those obtained after the addition of crushed rock aggregates to the G3 lateritic gravels of Côte d'Ivoire, with a CBR value that increases from 17 to 43%, i.e. an increase of 153% [22]. The variation obtained is less extensive than that observed on lateritic gravels in Congo after the addition of alluvial gravels, with the CBR index increasing from 54 to 110%, i.e. an increase of 104% [43]. The evolution diagrams of CBR bearing capacity as a function of crushed rock aggregates content are linear functions with R2 values close to 1 (R2 > 0.90) (Fig. 14). For all the studied GLM, there is a good correlation between CBR and the increasing content of crushed rock aggregates.

3.5 Road construction purposes

3.5.1 Crushed rock aggregates

The 0/31.5 crushed rock aggregates from the Nomayos quarry have a maximum diameter of less than 40 mm. These materials can be used in road construction without risks of segregation [42]. The fines content of these aggregates (6%) is less than 10%, which is the minimum value required for use in base courses [38]. The MDD value of the crushed rock aggregates (2.36 g/cm3) is higher than 2.00 g/cm3, the minimum required for use in base courses [42]. The bearing capacity value of the studied 0/31.5 crushed rock aggregates is higher than 80%. The CBR of the materials must be higher than 80% for use in base courses [42]. The studied 0/31.5 crushed rock aggregates are suitable for use in base courses for t pavements with high traffic volume [42]. This use in base courses is confirmed by a maximum diameter of less than 40 mm, a fines content of less than 10% and an MDD value greater than 2.00 g/cm3 [42]. Aggregates used in surface courses should have Micro Deval (MD) < 30% for cold mixes, and MD ≤ 15% for single double-layer surface dressings [42]. For use in base courses, the aggregates used must have an MD value less than or equal to 15 for traffic T1 to T3, and 12 for T4 and T5 traffic classes [42]. The studied crushed materials can be used for cold mixes [42]. The MD value (16%) close to 15% shows that the studied aggregates are to a lesser extent usable as a base course for T1 to T3 traffic classes [42]. The impact resistance of the materials is excellent when Los Angeles (LA) < 40%, good if 40% < LA < 50%, average when 50% < LA < 60% and poor when LA ˃ 60% [55]. The studied crushed rock aggregates (LA < 40%) have excellent impact resistance. An aggregate should have an LA ≤ 60% for use as a sub-base and, LA ≤ 45% for use as a base course for T1 to T3 traffic classes [4,5,, 5, 56]. For use as a base course for high trafficked pavements (T4 and T5), the LA value should be less than or equal to 30% [42]. The most suitable rock for road use are those with good hardness and sufficient wear resistance [57]. The studied aggregates have the necessary wear resistance for use in road construction. The 0/31.5 crushed rock aggregates from the Nomayos quarry can be used as a base course for all types of traffic. These materials have a good CBR and excellent mechanical characteristics. They can therefore be used for the treatment of less load-bearing lateritic materials. However, the use of crushed rock in road construction requires the mobilisation of equipment for the creation of new quarries, the provision of exploitation permits, and the logistic of haulage of materials to the site [57]. This leads to very high project costs in highly urbanised areas such as the city of Yaoundé. It would be interesting to reduce the quantity of crushed rock aggregates as much as possible to optimise the costs of road projects.

3.5.2 Natural granular lateritic materials

Lateritic gravels or GLM show poor performance if their specific gravity value is less than 2.75 and excellent performance if the value of this parameter is greater than or equal to 2.85 [58, 59]. The obtained average value (2.82), higher than 2.75, indicates that the studied granular lateritic materials have good behaviour in road construction [58]. The studied GLM have fines content values lower than 35%, the minimum required for use in subgrade [42]. The obtained average value of the plasticity index is higher than 20%, the maximum required for use as a sub-base for high trafficked pavements [42]. This value is less than 30%, the minimum required for use in sub-base for T1 and T2 traffic classes [42]. The studied materials, therefore, have a moderately clayey and very plastic particles smaller than 0.425 mm. Optimising their use requires a reduction in their plasticity by adding stabilisers. The use of materials in road construction calls for an increase in the maximum dry density from the subgrade to the base course [42]. Lateritic gravels must have a maximum dry density value greater than or equal to 1.90 g/cm3 and 2.00 g/cm3 for use in sub-base and base courses respectively [42, 51]. The obtained average value (1.94 g/cm3) is higher than the minimum (1.90 g/cm3) which is the recommended value for use in sub-base courses [42]. The OMC values of the studied GLM are in the order of those recommended for the use of materials in sub-base (8.00–15.00%) [51]. The lateritic gravels must have a CBR greater than 30 for use in sub-base and 80% for use as a base course [42]. All the studied materials can be used as a sub-base for all types of traffic. Optimisation of their use in road construction, particularly in base courses, requires prior treatment [4, 42]. CBR values of the studied GLM are less than 60% which is the minimum recommended value for use as base courses for pavements with low traffic volume, the addition of crushed rock aggregates would be indicated to enhanced their performance.

3.5.3 Granular lateritic material-crushed rock aggregate mixtures

The addition of 0/31.5 crushed rock aggregates to the studied GLM leads to a modification of the plasticity parameters. The plasticity index (PI) values decrease with the addition of the aggregates. The materials used in the base course must have PI values lower than 15% [42]. PI values below 15% are obtained for a percentage of aggregate addition above 25%. The use of materials in road construction calls for an increase in the maximum dry density values from the subgrade to the base course [42]. The increase in MDD values is a sign of improvement. The addition of 0/31.5 gneissic aggregates make it possible to obtain MDD values greater than or equal to 2.00 g/cm3, the minimum required for use in the base course [42]. Lateritic gravels must have a CBR value greater than or equal to 60% for use in base courses for T1 to T2 traffic classes [42]. For use as a base course for all types of traffic, the value of this parameter must be greater than or equal to 80%. Granular lateritic materials improved with 25% of 0/31.5 crushed rock aggregates have a CBR value higher than 60%. These materials can be used as a base course for light traffic volume respectively. The addition of a percentage of crushed rock aggregates greater than or equal to 25% makes it possible to obtain CBR values greater than or equal to 60%. The addition of 25% gneissic 0/31.5 crushed aggregates is therefore proposed for the improvement of granular lateritic materials in the Yaoundé area. The litho-stabilisation of the Yaoundé area GLM by adding 25% CRA gives convincing results for use in road construction. This proportion of 25% of crushed rock aggregates (CRA) shows a reduction of 75% of the volume of this material in favour of granular lateritic materials of average quality in the construction of certain road projects. Litho-stabilisation improves the suitability of poor-quality lateritic materials for road construction. In tropical areas, pavement base courses are generally built with CRA [42]. The mixtures obtained in this study − 25% of CRA + 75% of GLM- can be used as a base course for light traffic volume. The use of a such material makes it possible to reduce by approximately 75% the quantity of CRA to be used for the construction of base courses. In addition, CRA are more expensive than GLM [15]. By reducing the quantity of the required appropriate mixture which is blend of the GLM and the CRA could be an economic alrenative for road projects. This reduces the haulage of materials within crowded urban area.

4 Conclusions

The suitability of GLM for road construction after the addition of crushed rock materials was evaluated in a context of extensive urbanisation in sub-Saharan zone. The work carried out in the field consisted of locating the sampling points, describing the materials and taking samples. In the laboratory, the work focused on terrain utilization or urbanization rate evaluation, the petrographic properties of the rock and geotechnical tests on natural materials and those litho stabilized with 0/31.5 crushed rock aggregates. The obtained results show that Yaoundé city is highly urbanized. The urbanized surface has increased by 41.88% from 2004 to 2020. The rock in the Yaoundé area are gneisses composed of quartz, garnet, biotite, pyroxene and feldspars. The aggregates obtained from the crushing of these gneisses have a high specific gravity (3.00) and a maximum diameter value that allows them to be used in road construction, particularly as a base course. This is confirmed by a maximum diameter of less than 40 mm, a fines content of less than 10%, and MDD value of more than 2.00 g/cm3 and a good CBR value of 88%. The excellent mechanical characteristics of these materials (LA < 40%) make them suitable for use as a base course for low to medium volume traffic classes (T1 to T3). The MD value (16%) of these aggregates, which are close to 15%, shows that they are to a lesser extent usable in base courses for low to medium volume traffic roads. The GLM from the gneisses in the study area are very thick (5.00–7.00 m), very plastic to moderately clayey. These GLM have a lower CBR (39–42%) than CRA with a CBR of 88% and can be utilized as sub-base for for all types of traffic classes. Meanwhile their application as bas course requires some prior treatment. The addition of 0/31.5 gneissic aggregates on these GLM is accompanied by an increase in the plasticity index values and an improvement in the compaction parameters. It makes it possible to obtain MDD values greater than or equal to 2.00 g/cm3 and a CBR greater than or equal to 60%. The increase in CBR values correlates perfectly (R2 > 0.90) with the addition of crushed materials. Litho-stabilised materials (CBR ≥ 60%) can be used as a base course for low trafficked pavements. The addition of a percentage of crushed rock aggregates (CRA) greater than or equal to 25% makes it possible to obtain CBR values greater than or equal to 60%. This percentage of addition is therefore proposed for the improvement of the studied GLM. By reducing the amount of quarry materials, the crushed rock aggregates-enhanced GLM could be an economical alternative for road projects. This could also reduce and control the haulage of materials in urban expansion zones.

Data availability

All data used during the study appear in the submitted article.

References

Voundi E, Tsopbeng C, Tchindjang M. Restructuration urbaine et recomposition paysagère dans la ville de Yaoundé. VertigO. 2018. https://doi.org/10.4000/vertigo.23083.

Onyelowe KC, Amhadi T, Ezugwu C, Onukwugha E, Ugwuanyi H, Jideofor I, Ugorji B. Cemented lateritic soil as base material improvement using compression. In: International Congress and Exhibition" Sustainable Civil Infrastructures”. Cham: Springer; 2019, p. 51–61.

Sikali F, Djalal ME. Utilisation des latérites en technique routière au Cameroun. In: Séminaire Régional sur les Latérites: Sols, Matériaux, Minerais, Douala, Cameroun, 21–27 Jan, vol 1986. 1987, p. 277–288.

Bagarre E. Utilisation des graveleux latéritiques en technique routière. ISTED; 1990.

Autret P. Latérites et graveleux latéritiques, Études ISTED-LCPC. 1983.

Issiakou MS, Saiyouri N, Anguy Y, Gaborieau C, Fabre R. Etude des matériaux latéritiques utilisés en construction routière au Niger: méthode d’amélioration. Rencontres Universitaires de Génie Civil. 2015.

Ekodeck GE. L’altération des roches métamorphiques du Sud-Cameroun et ses aspects géotechniques. Thèse. Doct d’Etat ès Sci. Nat., IRIGM, Univ. Sci et Médic., Grenoble I, France. 1984

Onana VL, Nzabakurikiza A, Ndome Effoudou E, Likiby B, Kamgang Kabeyene V, Ekodeck GE. Geotechnical, mechanical and geological characterization of lateritic gravels of Boumpial (Cameroon) used in road construction. J Cameroon Acad Sci. 2015;76:1549–62.

Onana VL, Ngo’o Ze A, Medjo Eko R, Ntouala RFD, Nanga BMT, Ngono Owoudou B, Ekodeck GE. Geological identification, geotechnical and mechanical characterization of charnockite-derived lateritic gravels from Southern Cameroon for road construction purposes. Transp Geotechnics. 2017;10:35–46.

Bureau Central des Recensement et des Etudes de la Population (BUCREP). Rapport de présentation des résultats du 3ème Recensement Général de la Population et de l’Habitat (3e RGPH). 2005, p. 67.

Batoure BA, Tchotsoua M. Usage des logiciels pour la gestion des données à reference spatiale. Afrique Sci. 2017;13(3):377–89.

Monono E, Zinyemba T. The challenge of building sustainable cities in Cameroon: health issues associated with a rapid urban population increase in Buea municipality. Acad Res Community Publ. 2023. https://doi.org/10.21625/archive.v7i1.930.

Kennedy C, Cuddihy J, Engel-Yan J. The changing metabolism of cities. J Ind Ecol. 2007;11(2):43–59.

Augiseau V, Barles S. Studying construction materials flows and stock: a review. Resour Conserv Recycl. 2017;123:153–64.

Lobe Bille JF, Ngo’o Ze A, Onana VL, Ekodeck GE. Efects of pozzolana addition and geogrid reinforcement of lateritic clays in the sub-Saharan zone (West Cameroon): Implications for road construction. Bull Eng Geol Environ. 2022;81:272.

Abood TT, Kasa AB, Chik ZB. Stabilisation of silty clay soil using chloride compounds. J Eng Sci Technol. 2007;2(1):102–10.

Lompo P. Les matériaux utilisés en construction routière en Haute Volta. Un matériau non traditionnel ‘’Le lithostab’’ IVème Conf. Rout. Afri., 20–25 janvier-Nairobi, Kenya. 1980.

Ngo’o Ze A, Ndzié Mvindi AT, Lobe Bille JF, Mvindi Mvindi WP, Mebouinz DL, Onana VL. Ex situ and in situ manufacturing procedures for optimizing the characteristics of a soil concrete based on lateritic gravels and granitic aggregates: application in road construction. Int J Pavement Res Technol. 2022. https://doi.org/10.1007/s42947-022-00231-5.

Nzenti JP, Barbey P, Macaudier J, Soba D. Origin and evolution of the late Precambrian high grade Yaoundé gneiss (Cameroon). Precamb Res. 1988;38:91–109.

Nzabakurikiza A, Onana VL, Ngo’o Ze A, Ndzié Mvindi AT, Ekodeck GE. Geological, geotechnical, and mechanical characterization of lateritic gravels from Eastern Cameroon for road construction purposes. Bull Eng Geol Environ. 2017;76:1549–62.

Hyoumbi TW, Pizette P, Wouatong ASL, Abriak N-E, Borrel LR, Ramafmahatratra FN, Guiouillier T. Investigations of the crushed basanite aggregates efects on lateritic fine soils of Bafang area (West-Cameroon). Geotech Geol Eng. 2018;37:2147–64.

Niangoran KC, Thieblesson LM, Kouakou BSA, Kouadio KTS. European Journal of Scientific Research.;ISSN 1450-216X/1450-202X. 2020;155(2).

Kamtchueng BT, Onana VL, Fantong WY, Akira U, Ntouala RFD, Wongolo MHD, Ndongo GB, Ngo’o Ze A, Kamgang KBV, Ondoa JM. Geotechnical, chemical and mineralogical evaluation of lateritic soils in humid tropical area (Mfou, Central-Cameroon): implications for road construction. Int J Geo-Eng. 2015. https://doi.org/10.1186/s40703-014-0001-0.

Ndzié Mvindi AT, Onana VL, Ngo’o Ze A, Nyassa Ohandja H, Ekodeck GE. Influence of hydromorphic conditions in the variability of geotechnical parameters of gneiss-derived lateritic gravels in a savannah tropical humid area (Centre Cameroon), for road construction purposes. Transp Geotech. 2017;12:70–84.

Ngo’o Ze A, Onana VL, Ndzié Mvindi AT, Nyassa Ohandja H, Medjo Eko R, Ekodeck GE. Variability of geotechnical parameters of lateritic gravels overlying contrasted metamorphic rocks in a tropical humid area (Cameroon): implications for road construction. Bull Eng Geol Env. 2019. https://doi.org/10.1007/s10064-019-01488-0.

Ndam NJR, Braun JJ, Meybeck M, Bedimo BJP. Réactualisation des données hydroclimatiques des bassins fluviaux de la Sanaga et du Nyong (Sud Cameroun). Presses Universitaires Yaoundé. 1998;2:51–64.

Ekodeck GE, Kamgang KBV. L’altérologie normative et ses applications : une expression particulière des roches alumino-silicatées du point de vue de leur évolution supergène. Presses Universitaires de Yaoundé (Cameroun), Collection Connaissances; 2002.

Madhura M, Venkatachalam S. Comparison of supervised classification methods on remote sensed satellite data: an application in Chennai, South India. Int J Sci Res. 2015;4(2):1407.

Ahmed SM. Comparison of satellite images classification techniques using landsat-8 data for land cover extraction. Int J Intell Comput Inf Sci. 2021;21(3):29–43. https://doi.org/10.21608/ijicis.2021.78853.1098.

Thakur N, Maheshwari D. A review of image classification techniques. Int Res J Eng Technol. 2017;4(11):1588–91.

AFNOR. Norme française P 94-054, Sol: Reconnaissance et Essais. Détermination de la masse volumique des particules solides des sols. Association Française de Normalisation, Paris. 1991.

AFNOR. Norme française P 94-056, Sols: Reconnaissance et Essais - Analyse granulométrique. In: Méthode par tamisage à sec après lavage. Association Française de Normalisation, Paris, 1996a.

AFNOR. Norme française P 94-051, Sol: Reconnaissance et essais. Détermination des limites d’Atterberg: Limite de liquidité à la coupelle-Limites la plasticité au rouleau. Association Française de Normalisation, Paris, 1993.

AFNOR. Norme française P 94-093, Sols: Reconnaissance et essais-Détermination des références de compactage d’un matériau-Essai Proctor Normal-Essai Proctor Modifié. Association Française de Normalisation, Paris, 1999.

AFNOR. Norme française P 94-078, Sols: Reconnaissance et essais-Indice CBR après immersion Mesure sur échantillon compacté dans le moule CBR. Association Française de Normalisation, Paris, 1997.

AFNOR. Norme NF EN 1097–2, Essais pour déterminer les caractéristiques mécaniques et physiques des granulats. Partie 2: Méthodes pour la détermination de la résistance à la fragmentation. 1998.

AFNOR. Norme NF EN 1097–1, Essais pour déterminer les caractéristiques mécaniques et physiques des granulats Partie 1: Détermination de la résistance à l'usure (micro - Deval). 1996b

Adriaanse A, Bringezu S, Hammond A, Moriguchi Y, Rodenburg E, Rogich D, Schütz H. Ressouce flows: the material basis of industrial economies. Washington: World Resources Institute; 1997.

Matthews E, Bringezu S, Fischer-Kowalski M, Huetller W, Kleijn R, Moriguchi Y, Ottke C, Rodenburg E, Rogich D, Schandl H, Schuetz H, van der Voet E, Weisz H. The weight of nations. Material outflows from industrial economies. Washington: World Resources Institute; 2000.

Onana VL, Ndome Effoudou Priso E, Kamgang Kabeyene Beyala V, Ekodeck GE. Essai préliminaire de corrélations entre paramètres altérologiques normatifs et caractéristiques physico-mécaniques des roches et des produits d’altération de la série de Mbalmayo-Bengbis (Sud - Cameroun), à l’usage du génie civil. J Cameroon Acad Sci. 2009;8(2/3):81–90.

Tourenq C, Durville J-L, Massieu E. Les propriétés des roches: Guide et pratique. In Menmento des mines et carrières, nouvelle série N°3; 1997. pp. 35–63.

CEBTP. Guide pratique du dimensionnement des routes pour les pays tropicaux. Ministère de la Coopération; 1984.

Ahouet L, Elenga RG, Bouyila S, Ngoulou M, Kengue E. Amélioration des propriétés géotechniques du graveleux latéritique par ajout de la grave alluvionnaire concassée 0/31,5. Sci Appl de l’ing. 2018;3(1):1–6.

Ogunsanwo O. Basic geotechnical properties, chemistry and mineralogy of some laterite soils from S.W. Nigeria. Bull Int Assoc Eng Geol. 1988;37:131–5.

Indraratna B, Nutalaya P. Some engineering characteristics of a compacted lateritic residual soil. Geotech Geol Eng. 1991;9:125–37.

Akpokodje EG. The geotechnical properties of lateritic and non-lateritic soils of southeastern Nigeria and their evaluation for road construction. Bull Int Assoc Eng Geol. 1986;33(1):115–21.

Fall M, Tisot JP, Cissé IK. Stress-strain behaviour of three-compacted lateritic gravel from western Senegal using the shear box machine. Bull Int Assoc Eng Geol. 1995;52:59–73.

Frempong EM. Field compaction control studies on road bases in new settlement area in Ghana. Geotech Geol Eng. 1995;13:227–41.

Millogo Y, Karfa T, Raguilnaba O, Kalsibiri K, Blanchart P, Thomassin JH. Geotechnical, mechanical, chemical and mineralogical characterization of lateritic gravels of Sapouy (Burkina Faso) used in road construction. Constr Build Mater. 2008;22:70–6.

Katte YV, Mfoyet Moupe S, Manefouet B, Wouatong ASL, Aleh BL. Correlation of California bearing ratio (CBR) value with soil properties of road subgrade Soil. Geotech Geol Eng. 2018. https://doi.org/10.1007/S10706-018-0604-X.

DEGN. Recommandation pour l’utilisation en corps de chaussée des graveleux latéritiques naturels. Bulletin du Ministère de l’équipement. Direction des études générales et de la normalisation, Cameroun; 1987.

Ndiaye M, Magnan JP, Cissé. L’étude de l’amélioration de latérites du Sénégal par ajout de sable. Bulletin des laboratoires des ponts et Chaussées. 2013

Frempong EM, Tsidzi UKEN. Blending of marginally suitable tropical sub-base materials for use in base course construction. Constr Build Mater. 1999;13:129–41.

Jjuuko S, Kalumba D, Bbira S, Bamutenda JB. Blending of marginally suitable lateritic soils for use in base construction. XIV congreso colombiano de geotecnia & IV congreso suramericano de ingenieros jóvenes geotécnicos. Bogotá D.C. 15 al 18 de octubre de 2014. Conference Paper. 2014; https://doi.org/10.13140/RG.2.1.2366.4808

de Graft-Johnson JWS, Bhatia HS, Yeboa SL. Infuence of geology and physical properties on strength characteristics of lateritic gravels for road pavements. Building and Road Research Institute. 1972

Departemento Nacional de Infraestrutura de Transportes (DNIT). Pavimentacao –Base estabilizada granulometricamente com utilizacao de solo lateritico – Especifcacao de servico; 2007. Norma DNIT-098/2007-ES, 2007.

BCEOM-CEBTP. Les routes dans les zones tropicales et désertiques tome 2 : études techniques et construction. Ministère de la Coopération et du Développement; 1992.

Nwainwu CMO, Alkali JBK, Ahmed UA. Propaties of ironstone lateritic gravelin relation to gravelroad pavement construction. Géotech Geol Eng. 2006;24:283–98.

Paige-Green P, Pinard M, Netterberg F. A review of specifications for lateritic materials for low volume roads. Transp Geotech. 2015;5:86–98.

Acknowledgements

The authors thank Sol Solution Afrique Centrale (SSAC) laboratory for the quality of the geotechnical analysis performed. They are highly indebted to the anonymous reviewer who assisted greatly to improve the quality of this paper.

Originality statement

The work titled “Assessment of crushed rock aggregates addition on granular lateritic materials in sub-Saharan extensive urbanization context (Yaoundé Cameroon) for road construction purposes” has not been published elsewhere, in part, or another form.

Author information

Authors and Affiliations

Contributions

Dr Aloys Thierry Ndzié Mvindia, Mr Jean Francis Lobe Bille and Dr Arnaud Ngo'o Ze conceived the idea, performed field works and wrote the manuscript. Christophe Enock Embom and Emmanuel Tsoyi À Koung performed field works and made the analysis. Mrs Michèle Stella Ngono Mbenti made the analysis. Pr Vincent Laurent Onana proofread the paper and made suggestions.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests. We have no concurrent submissions on the same topic and with this data analysis and any conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Ndzié Mvindi, A.T., Lobe Bille, J.F., Ngo’o Ze, A. et al. Assessment of crushed rock aggregates addition to granular lateritic materials in sub-Saharan extensive urbanization context (Yaoundé Cameroon) for road construction purposes. Discov Civ Eng 1, 3 (2024). https://doi.org/10.1007/s44290-024-00004-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s44290-024-00004-y