Abstract

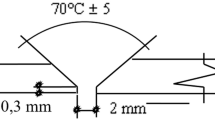

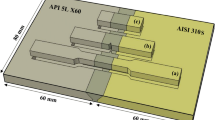

Unfavourable operating conditions of equipment in the energy industry resulting from high-temperature loads determine the need to use special materials and technological solutions, including welding procedures. In this article, buttering using IN82 (ERNiCr-3) consumables was proposed as a method to improve the weldability of grade 92 steel joined by the gas tungsten arc welding (GTAW) process with AISI 304L (IN617 filler). The microstructural characterization of samples was carried out using an optical microscope, scanning electron microscope (SEM) and energy-dispersive X-ray spectroscopy. The welded joint was further characterized by hardness, tensile (room temperature and at 620 °C temperature) and impact tests. Additionally, the fracture surfaces of tensile and impact tests were studied by SEM. Despite the confirmation of the diffusion of alloying elements and significant changes in their concentration, which indicates the formation of Ti and Nb-rich phases, no welding imperfections were detected and favourable joint structures and acceptable properties were obtained. In particular, this concerns the limitation of the formation of brittle structures and the elimination of the untempered martensitic layer. At the same time, there was a significant decrease in the maximum hardness of heat-affected zone (HAZ) on the grade 92 steel side to a relatively low value of 310 HV, and a minimum tensile strength criterion of 600 MPa was achieved with a simultaneous increase in ductility (35% elongation) of the joint. Comparatively, when compared to a non-buttered welded joint, the joint produced with a buttering layer exhibited an increase in the elongation and impact toughness of the welded joint without any compromise in ultimate tensile strength (Sut). The fracture surface of tensile and impact-tested specimens was also characterized using SEM/EDS. Summarizing all the results, it can be concluded that the proposed GTAW procedure of grade 92 and 304L steels can be used in extreme working conditions, in ultra-supercritical power units or the petrochemical and chemical industries.

Similar content being viewed by others

Data and code availability

The raw/processed data required to reproduce these findings cannot be shared at this time due to technical or time limitations.

References

Abe F. Research and development of heat-resistant materials for advanced USC power plants with steam temperatures of 700 °C and above. Engineering. 2015;1:211–24. https://doi.org/10.15302/J-ENG-2015031.

Pandey C, Mahapatra MM, Kumar P, Thakre JG, Saini N. Role of evolving microstructure on the mechanical behaviour of P92 steel welded joint in as-welded and post weld heat treated state. J Mater Process Technol. 2019;263:241–55. https://doi.org/10.1016/j.jmatprotec.2018.08.032.

Vaillant JC, Vandenberghe B, Hahn B, Heuser H, Jochum C. T/P23, 24, 911 and 92: new grades for advanced coal-fired power plants-properties and experience. Int J Press Vessel Pip. 2008;85:38–46. https://doi.org/10.1016/j.ijpvp.2007.06.011.

Panneer Selvi S, Prasad Reddy GV. Microstructure and tensile properties of dissimilar weld joint between alloy 800 and buttered Grade 91. Metall Mater Trans A Phys Metall Mater Sci. 2023;54:939–51. https://doi.org/10.1007/s11661-022-06941-6.

Singh P, Arora N, Sharma A. Enhancing mechanical properties and creep performance of 304H and inconel 617 superalloy dissimilar welds for advanced ultra super critical power plants. Int J Press Vessel Pip. 2023;201:104882. https://doi.org/10.1016/j.ijpvp.2022.104882.

Kumar S, Pandey C, Goyal A. A microstructural and mechanical behavior study of heterogeneous P91 welded joint. Int J Press Vessel Pip. 2020;185:104128. https://doi.org/10.1016/j.ijpvp.2020.104128.

Li S, Li J, Sun G, Deng D. Modeling of welding residual stress in a dissimilar metal butt-welded joint between P92 ferritic steel and SUS304 austenitic stainless steel. J Mater Res Technol. 2023;23:4938–54. https://doi.org/10.1016/j.jmrt.2023.02.123.

Taraphdar PK, Kumar R, Pandey C, Mahapatra MM. Significance of finite element models and solid-state phase transformation on the evaluation of weld induced residual stresses. Met Mater Int. 2021;27:3478–92. https://doi.org/10.1007/s12540-020-00921-4.

Kulkarni A, Dwivedi DK, Vasudevan M. Dissimilar metal welding of P91 steel-AISI 316L SS with Incoloy 800 and Inconel 600 interlayers by using activated TIG welding process and its effect on the microstructure and mechanical properties. J Mater Process Technol. 2019;274:116280. https://doi.org/10.1016/j.jmatprotec.2019.116280.

Cao J, Gong Y, Yang ZG, Luo XM, Gu FM, Hu ZF. Creep fracture behavior of dissimilar weld joints between T92 martensitic and HR3C austenitic steels. Int J Press Vessel Pip. 2011;88:94–8. https://doi.org/10.1016/j.ijpvp.2011.01.003.

Pavan AHV, Ravibharath R, Singh K. Creep-rupture behavior of SUS 304H – IN 617 dissimilar metal welds for AUSC boiler applications. Mater Sci Forum. 2015;830–831:199–202. https://doi.org/10.4028/www.scientific.net/MSF.830-831.199.

Chitturi V, Pedapati SR, Awang M. Mathematical model for friction stir lap welded AA5052 and SS304 joints and process parameters optimization for high joint strength. Adv Mater Sci. 2022;22:5–22. https://doi.org/10.2478/adms-2022-0001.

Shah Hosseini H, Shamanian M, Kermanpur A. Characterization of microstructures and mechanical properties of Inconel 617/310 stainless steel dissimilar welds. Mater Charact. 2011;62:425–31. https://doi.org/10.1016/j.matchar.2011.02.003.

Shah Hosseini H, Shamanian M, Kermanpur A. Microstructural and weldability analysis of Inconel617/AISI 310 stainless steel dissimilar welds. Int J Press Vessel Pip. 2016;144:18–24. https://doi.org/10.1016/j.ijpvp.2016.05.004.

Cao J, Gong Y, Zhu K, Yang ZG, Luo XM, Gu FM. Microstructure and mechanical properties of dissimilar materials joints between T92 martensitic and S304H austenitic steels. Mater Des. 2011;32:2763–70. https://doi.org/10.1016/j.matdes.2011.01.008.

Cao J, Gong Y, Yang Z. Microstructural analysis on creep properties of dissimilar materials joints between T92 martensitic and HR3C austenitic steels. Mater Sci Eng A. 2011;528:6103–11. https://doi.org/10.1016/j.msea.2011.04.057.

Kim MY, Kwak SC, Choi IS, Lee YK, Suh JY, Fleury E, Jung WS, Son TH. High-temperature tensile and creep deformation of cross-weld specimens of weld joint between T92 martensitic and Super304H austenitic steels. Mater Charact. 2014;97:161–8. https://doi.org/10.1016/j.matchar.2014.09.011.

Kumar A, Pandey SM, Bhattacharya A, Fydrych D, Sirohi S, Pandey C. Selection of electrode material for inconel 617/P92 Steel SMAW dissimilar welds. J Press Vessel Technol. 2023;145:1–11. https://doi.org/10.1115/1.4062794.

Naffakh H, Shamanian M, Ashrafizadeh F. Dissimilar welding of AISI 310 austenitic stainless steel to nickel-based alloy Inconel 657. J Mater Process Technol. 2009;209:3628–39. https://doi.org/10.1016/j.jmatprotec.2008.08.019.

J.M. Race, Carbon Diffusion Across Dissimilar Steel Welds, PhD Thesis. (1992).

Zhao Y, Gong J, Wang X, Gao W, Li Q. Carbon diffusion in dissimilar joints between P91 and 12Cr1MoV steels welded by different consumables at high temperature. Mater High Temp. 2015;32:557–65. https://doi.org/10.1179/1878641315Y.0000000002.

Sudha C, Paul VT, Terrance ALE, Saroja S, Vijayalakshmi M, Microstructure and microchemistry of hard zone in dissimilar weldments of Cr-Mo steels, Weld. J. (Miami, Fla). 85 (2006).

Guo X, He P, Xu K, Lv XC, Zhang JB, Gu Y. Microstructure investigation on the fusion zone of steel/nickel-alloy dissimilar weld joint for nozzle buttering in nuclear power industry. Weld World. 2021. https://doi.org/10.1007/s40194-021-01199-9.

Shariatpanahi AM, Farhangi H. Microstructure and mechanical properties of dissimilar ferritic and austenitic steel joints with an intermediate Inconel-182 buttering layer. Adv Mater Res. 2010;83–86:449–56. https://doi.org/10.4028/www.scientific.net/AMR.83-86.449.

Hytönen N, Ge Y, Que Z, Lindqvist S, Nevasmaa P, Virkkunen I, Efsing P. Study of fusion boundary microstructure and local mismatch of SA508/alloy 52 dissimilar metal weld with buttering. J Nucl Mater. 2023. https://doi.org/10.1016/j.jnucmat.2023.154558.

Bhaduri AK, Venkadesan S, Rodriguez P, Mukunda PG. Transition metal joints for steam generators—an overview. Int J Press Vessel Pip. 1994;58:251–65. https://doi.org/10.1016/0308-0161(94)90061-2.

Pavan AHV, Vikrant KSN, Ravibharath R, Singh K. Development and evaluation of SUS 304H—IN 617 welds for advanced ultra supercritical boiler applications. Mater Sci Eng A. 2015;642:32–41. https://doi.org/10.1016/j.msea.2015.06.065.

Dak G, Pandey SM, Pandey C. Residual stress analysis, microstructural characterization, and mechanical properties of tungsten inert gas-welded P92/AISI 304L dissimilar steel joints. Proc Inst Mech Eng Part L J Mater Des Appl. 2023;237:767–90. https://doi.org/10.1177/14644207221124494.

Kumar A, Pandey C. Autogenous laser-welded dissimilar joint of ferritic/martensitic P92 steel and Inconel 617 alloy: mechanism, microstructure, and mechanical properties. Arch Civ Mech Eng. 2022;22:39. https://doi.org/10.1007/s43452-021-00365-6.

Rathod DW, Pandey S, Aravindan S, Singh PK. Metallurgical behaviour and carbon diffusion in buttering deposits prepared with and without buffer layers. Acta Metall Sin (English) Lett. 2017;30:120–32. https://doi.org/10.1007/s40195-016-0487-x.

Rathod DW, Pandey S, Aravindan S, Singh PK. Diffusion control and metallurgical behavior of successive buttering on SA508 steel using Ni–Fe alloy and inconel 182. Metallogr Microstruct Anal. 2016;5:450–60. https://doi.org/10.1007/s13632-016-0311-z.

Saffari H, Shamanian M, Bahrami A, Szpunar JA. Effects of ERNiCr-3 butter layer on the microstructure and mechanical properties of API 5L X65/AISI304 dissimilar joint. J Manuf Process. 2020;50:305–18. https://doi.org/10.1016/j.jmapro.2019.12.028.

Ahmad HW, Chaudry UM, Tariq MR, Shoukat AA, Bae DH. Assessment of fatigue and electrochemical corrosion characteristics of dissimilar materials weld between alloy 617 and 12 Cr steel. J Manuf Process. 2020;53:275–82. https://doi.org/10.1016/j.jmapro.2020.02.038.

Dak G, Singh V, Kumar A, Sirohi S, Bhattacharyya A, Pandey C, Pandey SM. Microstructure and mechanical behaviour study of the dissimilar weldment of ‘IN82 buttered’ P92 steel and AISI 304L steel for ultra super critical power plants. Mater Today Commun. 2023;37:107552. https://doi.org/10.1016/j.mtcomm.2023.107552.

DuPont JN, Lippold JC, Kiser SD. Welding metallurgy and weldability of nickel-base alloys. Wiley. 2009. https://doi.org/10.1002/9780470500262.

Dak G, Khanna N, Pandey C. Study on narrow gap welding of martensitic grade P92 and austenitic grade AISI 304L SS steel for ultra-supercritical power plant application. Arch Civ Mech Eng. 2023;23:14. https://doi.org/10.1007/s43452-022-00540-3.

Kumar A, Pandey C. Development and evaluation of dissimilar gas tungsten arc-welded joint of P92 steel/inconel 617 alloy for advanced ultra-supercritical boiler applications. Metall Mater Trans A. 2022;53:3245–73. https://doi.org/10.1007/s11661-022-06723-0.

Elongation P, ERNiCrCoMo-1 DATA SHEET, 1 (n.d.) 0–1.

ASTM E8. ASTM E8/E8M standard test methods for tension testing of metallic materials 1. Annu B ASTM Stand. 2010;4:1–27. https://doi.org/10.1520/E0008.

Akram J, Kalvala PR, Chalavadi P, Misra M. Dissimilar metal weld joints of P91/Ni alloy: microstructural characterization of HAZ of P91 and stress analysis at the weld interfaces. J Mater Eng Perform. 2018;27:4115–28. https://doi.org/10.1007/s11665-018-3502-8.

A. E23-02a, ASTM E23-02a - Notched Bar Impact Testing of Metallic Materials . pdf, ASTM Int. (2002).

Dak G, Pandey C. Microstructure anomaly during welding and its influence on the mechanical properties of dissimilar weldments of P92 martensitic steel and AISI 304L austenitic stainless steel. J Manuf Process. 2022;80:829–51.

Rojas D, Garcia J, Prat O, Sauthoff G, Kaysser-Pyzalla AR. 9%Cr heat resistant steels: alloy design, microstructure evolution and creep response at 650°C. Mater Sci Eng A. 2011;528:5164–76. https://doi.org/10.1016/j.msea.2011.03.037.

Laha K, Chandravathi KS, Parameswaran P, Goyal S, Mathew MD. A comparison of creep rupture strength of ferritic/austenitic dissimilar weld joints of different grades of Cr-Mo ferritic steels. Metall Mater Trans A. 2012;43:1174–86. https://doi.org/10.1007/s11661-011-0957-8.

Hou J, Peng Q, Takeda Y, Kuniya J, Shoji T. Microstructure and stress corrosion cracking of the fusion boundary region in an alloy 182–A533B low alloy steel dissimilar weld joint. Corros Sci. 2010;52:3949–54. https://doi.org/10.1016/j.corsci.2010.08.002.

Ming H, Zhu R, Zhang Z, Wang J, Han EH, Ke W, Su M. Microstructure, local mechanical properties and stress corrosion cracking susceptibility of an SA508-52M-316LN safe-end dissimilar metal weld joint by GTAW. Mater Sci Eng A. 2016;669:279–90. https://doi.org/10.1016/j.msea.2016.05.101.

Mouginot R, Hänninen H, Microstructures of nickel- base alloy dissimilar metal welds, n.d.

Soysal T, Kou S, Tat D, Pasang T. Macrosegregation in dissimilar-metal fusion welding. Acta Mater. 2016;110:149–60. https://doi.org/10.1016/j.actamat.2016.03.004.

Kumar S, Pandey C, Goyal A. Microstructure and mechanical behavior of P91 steel dissimilar welded joints made with IN718 filler. Int J Press Vessel Pip. 2021;190:104290. https://doi.org/10.1016/j.ijpvp.2020.104290.

Dupont JN, Kusko CS. Technical note: martensite formation in austenitic/ferritic dissimilar alloy welds. Weld J. 2007;86:51s.

Zhang Y, Jing H, Xu L, Han Y, Zhao L, Xiao B. Microstructure and mechanical performance of welded joint between a novel heat-resistant steel and Inconel 617 weld metal. Mater Charact. 2018;139:279–92. https://doi.org/10.1016/j.matchar.2018.03.012.

Sirohi S, Taraphdar PK, Dak G, Pandey C, Sharma SK, Goyal A. Study on evaluation of through-thickness residual stresses and microstructure-mechanical property relation for dissimilar welded joint of modified 9Cr–1Mo and SS304H steel. Int J Press Vessel Pip. 2021;194:104557. https://doi.org/10.1016/j.ijpvp.2021.104557.

Kulkarni A, Dwivedi DK, Vasudevan M. Study of mechanism, microstructure and mechanical properties of activated flux TIG welded P91 Steel-P22 steel dissimilar metal joint. Mater Sci Eng A. 2018;731:309–23. https://doi.org/10.1016/j.msea.2018.06.054.

Funding

No funding is received for the work.

Author information

Authors and Affiliations

Contributions

Hardik Sanjay Surkar: Conceptualization; Data curation; Formal analysis; Investigation; Methodology; Roles/Writing -original draft; Writing—review & editing. Amit Kumar: Formal analysis; Investigation; Methodology; Roles/Writing -original draft; Writing—review & editing. Sachin Sirohi: Conceptualization; Data curation; Formal analysis; Investigation; Methodology; Roles/Writing -original draft; Writing—review & editing. Shailesh M Pandey: Conceptualization; Project administration; Resources; Software; Supervision; Validation; Visualisation; Funding acquisition; Investigation; Roles/Writing—original draft. Aleksandra Świerczyńska: Conceptualization; Data curation; Formal analysis; Investigation; Methodology; Roles/Writing -original draft; Writing—review & editing. Dariusz Fydrych: Conceptualization; Project administration; Resources; Software; Supervision; Validation; Visualisation; Funding acquisition; Investigation; Roles/Writing—original draft; Writing—review & editing. Chandan Pandey: Conceptualization; Project administration; Resources; Software; Supervision; Validation; Visualisation; Funding acquisition; Investigation; Roles/Writing—original draft; Writing—review & editing.

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Ethical approval

Not Applicable.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Surkar, H.S., Kumar, A., Sirohi, S. et al. A dissimilar welded joint of grade 92 steel and AISI 304L steel obtained using IN82 buttering and IN617 filler: relationship of microstructure and mechanical properties. Archiv.Civ.Mech.Eng 24, 109 (2024). https://doi.org/10.1007/s43452-024-00920-x

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s43452-024-00920-x