Abstract

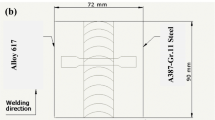

Microstructure and tensile properties of dissimilar weld joint (DWJ) between Alloy 800 and ‘IN82 buttered’ Grade 91 (Gr. 91), fabricated using IN182 electrode and shielded metal arc welding (SMAW) technique, were investigated. Tensile properties of DWJ were evaluated at temperatures 298 K, 773 K and 823 K and at strain rates of 3 × 10–3, 3 × 10–4 and 3 × 10–5 s−1. Dendritic microstructure is observed in both IN82 buttered zone and IN182 weld. In the buttered zone, Type-II boundary (parallel to the fusion line) is noticed near the fusion boundary between buttered zone and Gr. 91. Further, in the heat affected zone of Gr. 91, adjacent to this fusion boundary, maximum hardness in the range of 240–350 VHN is observed up to a distance of ~ 1.25 mm from the fusion boundary, with a peak in hardness of ~ 345 ± 5 VHN at ~ 0.5 mm distance from fusion boundary. Under tensile loading, DWJ exhibits characteristic work hardening and post-necking elongation similar to that of Alloy 800 K at 298 K. At 773 K and 823 K, DWJ retains work hardening and exhibits extended post-necking elongation similar to that in Gr. 91. At high temperatures, yield strength of DWJ is intermediate to that of Gr. 91 and Alloy 800, while ultimate tensile strength of DWJ remains lower than that of the base metals. Similarly, uniform elongation decreases in the order of Alloy 800, DWJ and Gr. 91 at all the test conditions. It must be emphasized that, at high temperatures, DWJ exhibited tensile fractures in Gr. 91 base metal, irrespective of the strain rate. In contrast, at room temperature, tensile failures of DWJ have been predominantly observed in Alloy 800 base metal, except at the lowest strain rate wherein fracture occurred in buttered zone with small fraction of interface between buttered zone and Gr. 91 on the fractured surface.

Similar content being viewed by others

References

S.L. Mannan, S.C. Chetal, B. Raj, and S.B. Bhoje: Trans. Indian Inst. Met., 2003, vol. 56(2003), pp. 155–78.

H. Li and D. Mitchell: Steel Res. Int., 2013, vol. 84(12), pp. 1302–08.

C.D. Lundin: Weld. J., 1982, vol. 61, pp. 58–63.

A.K. Bhaduri, S. Venkadesan, P. Rodriguez, and P.G. Mukunda: Int. J. Pres. Ves. Piping, 1994, vol. 58, pp. 251–65.

S. K. Albert and A. K. Bhaduri: 38th MPA-Seminar, 2012, pp. 195–208.

R. Nandakumar, S. Athmalingam, V. Balasubramaniyan, and S.C. Chetal: Energy Procedia, 2011, vol. 7, pp. 351–58.

V. Lakshmanan and P. Sathiya: Trans. Indian Inst. Met., 2019, vol. 72(10), pp. 2673–86.

M. Sireesha, S.K. Albert, and S. Sundaresan: Metall. Mater. Trans. A, 2005, vol. 36A, pp. 1495–1506.

L. Vellaichamya, P.B.T. Gerarda, and S. Paulraj: Mater. Res., 2018, vol. 21(2), pp. 1–5.

K. Laha, K.S. Chandravathi, P. Parameswaran, S. Goyal, and M.D. Mathew: Metall. Mater. Trans. A, 2012, vol. 43A, pp. 1174–86.

ASTM E8M: Standard test methods for tension testing of metallic materials.

M. Sireesha, V. Shankar, S.K. Albert, and S. Sundaresan: Mater. Sci. Eng. A, 2000, vol. 292, pp. 74–82.

R. Dehmolaei, M. Shamanian, and A. Kermanpur: Mater. Charact., 2009, vol. 60, pp. 246–50.

T. W. Nelson, J. C. Lippold and M. J. Mills: Weld. J., 2000, pp. 267–77

A.J. Ramirez and J.C. Lippold: Mater. Sci. Eng. A, 2004, vol. 380, pp. 245–58.

S.C. Yoo, K.J. Choi, C.B. Bahn, S.H. Kim, J.Y. Kim, and J.H. Kim: J. Nucl. Mater., 2015, vol. 459, pp. 5–12.

S. Kumar, P.K. Singh, K.N. Karn, and V. Bhasin: Fatigue Fract. Eng. Mater. Struct., 2017, vol. 40, pp. 190–206.

K. Karthick, S. Malarvizhi, V. Balasubramanian, S.A. Krishnan, G. Sasikala, and S.K. Albert: Nucl. Eng. Technol., 2018, vol. 50(1), pp. 116–25.

M. Sireesha, S.K. Albert, V. Shankar, and S. Sundaresan: J. Nucl. Mater., 2000, vol. 279, pp. 65–76.

H.C. Dey, S.K. Albert, A.K. Bhaduri, G.G. Roy, R. Balakrishnan, and S. Panneerselvi: Weld World, 2014, vol. 58, pp. 389–95.

P. Rodriguez: Bull. Mater. Sci., 1984, vol. 6, pp. 653–63.

Yu. Cao, C. Zhang, C. Zhang, H. Di, G. Huang, and Q. Liu: Mater. Sci. Eng. A, 2018, vol. 724, pp. 37–44.

R. L. Klueh and J. F. King, Report numbered ORNL-5354, Oak Ridge National Laboratory, Oak Ridge, Tennessee, 1977.

B.K. Choudhary, M.D. Mathew, E. Isaac Samuel, J. Christopher, and T. Jayakumar: J. Nucl. Mater., 2013, vol. 443, pp. 242–49.

Acknowledgments

The authors would like to acknowledge Dr. Shaju K. Albert, Former Director, Materials and Metallurgy Group, Indira Gandhi Centre for Atomic Rersearch, Kalpakkam and Dr. M. Vasudevan, Associate Director, Materials Development and Technology Group, Indira Gandhi Centre for Atomic Rersearch, Kalpakkam for their kind support and encouragement.

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Panneer Selvi, S., Prasad Reddy, G.V. Microstructure and Tensile Properties of Dissimilar Weld Joint Between Alloy 800 and Buttered Grade 91. Metall Mater Trans A 54, 939–951 (2023). https://doi.org/10.1007/s11661-022-06941-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-022-06941-6