Abstract

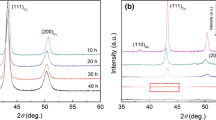

A fruitful combination of powder metallurgy and the mechanical alloying route is one of the most promising process for producing advanced Cu-based nanocomposites. In this study, three different material systems, namely, pure copper (Cu), 5 wt% Cr reinforced Cu matrix composites, and 1 wt% Y2O3 reinforced Cu–Cr matrix nanocomposites were synthesized by ball milling method at different milling times. The influence of different ball milling times (0.5, 2, and 4 h) and different types of reinforcements (Cr and Y2O3) on the powder and sintered parts properties were thoroughly analyzed with a holistic approach. The milled powders were then consolidated using a cold press followed by a liquid phase sintering process. Results revealed that the Cr and Y2O3 particles were fractionally dispersed and imbedded in the ductile Cu matrix with respect to increasing milling time. Milling for 4 h of Cu–Cr–Y2O3 powders produced the lowest level of particle size (28 µm) with reduced and flattened and uniformly distributed reinforcement phases due to intense plastic deformation induced shearing effect and dominant powder-ball-jar collisions. Besides, the ball milling process of the same powders concluded a decrement of crystallite size to 35 nm in concomitant with an increase of lattice strain and dislocation density ⁓ % 0.3 and 0.8 × 1015 line/m2, respectively. Brinell hardness of the sample produced by these powders increased from 39 to 95 HB. A ⁓%145 striking increase of hardness could be attributed to the strong hindrance of high-dense dislocations triggered by several concurrent strengthening mechanisms. Nevertheless, relative density results of sintered samples revealed that the addition of Cr and Y2O3 along with increasing milling time deteriorated the density due to the higher hardness and brittleness of milled powders and accompanying worsened compressibility and sinterability. The source of noticed differences between hardness and density results were discussed within the process-structure-performance framework.

Similar content being viewed by others

Availability of data and materials

Not applicable.

References

Şap S, Turgut A, Uzun M. Investigation of microstructure and mechanical properties of Cu/Ti–B–SiCp hybrid composites. Ceram Int. 2021;47:29919–29.

Şap S, Uzun M, Usca ÜA, Pimenov DY, Giasin K, Wojciechowski S. Investigation on microstructure, mechanical, and tribological performance of Cu base hybrid composite materials. J Market Res. 2021;15:6990–7003.

Chakraborty S, Gupta A, Roy D, Basumallick A. Studies on nano-metal dispersed Cu–Cr matrix composite. Mater Lett. 2019;257: 126739.

Yang H, Ma Z, Lei C, Meng L, Fang Y, Liu J, Wang H. High strength and high conductivity Cu alloys: a review. Sci China Technol Sci. 2020;63:2505–17.

Li J, Ding H, Li B, Gao W, Bai J, Sha G. Effect of Cr and Sn additions on microstructure, mechanical-electrical properties and softening resistance of Cu–Cr–Sn alloy. Mater Sci Eng A. 2021;802: 140628.

Pillari LK, Bakshi SR, Chaudhuri P, Murty B. Fabrication of W-Cu functionally graded composites using high energy ball milling and spark plasma sintering for plasma facing components. Adv Powder Technol. 2020;31:3657–66.

Qu X-H, Zhang L, Mao W, Ren S-B. Review of metal matrix composites with high thermal conductivity for thermal management applications. Prog Nat Sci Mater Int. 2011;21:189–97.

Sap E. Microstructural and mechanical properties of Cu-based Co-Mo-reinforced composites produced by the powder metallurgy method. J Mater Eng Perform. 2020;29:8461–72.

Şap E. Investigation of mechanical properties of Cu/Mo-SiCp composites produced with P/M, and their wear behaviour with the Taguchi method. Ceram Int. 2021. https://doi.org/10.1016/j.ceramint.2021.05.322.

Kim KT, Cha SI, Hong SH, Hong SH. Microstructures and tensile behavior of carbon nanotube reinforced Cu matrix nanocomposites. Mater Sci Eng, A. 2006;430:27–33.

Ying D, Zhang D. Processing of Cu–Al2O3 metal matrix nanocomposite materials by using high energy ball milling. Mater Sci Eng, A. 2000;286:152–6.

Salur E, Acarer M, Şavkliyildiz İ. Improving mechanical properties of nano-sized TiC particle reinforced AA7075 Al alloy composites produced by ball milling and hot pressing. Mater Today Commun. 2021;27: 102202.

Tekin M, Polat G, Kalay YE, Kotan H. Grain size stabilization of oxide dispersion strengthened CoCrFeNi-Y2O3 high entropy alloys synthesized by mechanical alloying. J Alloys Compd. 2021;887: 161363.

Salur E, Nazik C, Acarer M, Şavklıyıldız İ, Akdoğan EK. Ultrahigh hardness in Y2O3 dispersed ferrous multicomponent nanocomposites. Mater Today Commun. 2021;28: 102637.

Zimo G, Hao Y, Diancheng G, Yuchen L, Kondo S, Okuno Y, Kasada R. Effects of zirconium addition on the material properties and microstructure of ODS-Cu alloys. J Alloys Compd. 2021;899: 163328.

Aghamiri S, Oono N, Ukai S, Kasada R, Noto H, Hishinuma Y, Muroga T. Microstructure and mechanical properties of mechanically alloyed ODS copper alloy for fusion material application. Nucl Mater Energy. 2018;15:17–22.

Li G, Thomas BG, Stubbins J. Modeling creep and fatigue of copper alloys. Metall and Mater Trans A. 2000;31:2491–502.

Salur E, Aslan A, Kuntoğlu M, Acarer M. Effect of ball milling time on the structural characteristics and mechanical properties of nano-sized Y2O3 particle reinforced aluminum matrix composites produced by powder metallurgy route. Adv Powder Technol. 2021;32:3826–44.

Williamson G, Smallman R III. Dislocation densities in some annealed and cold-worked metals from measurements on the X-ray debye-scherrer spectrum. Philos Mag. 1956;1:34–46.

Krivoglaz MA. X-ray and neutron diffraction in nonideal crystals. Berlin: Springer Science & Business Media; 2012.

Uzun M, Usca UA. Effect of Cr particulate reinforcements in different ratios on wear performance and mechanical properties of Cu matrix composites. J Braz Soc Mech Sci Eng. 2018;40:1–9.

Akbarpour M, Mirabad HM, Alipour S, Kim H. Enhanced tensile properties and electrical conductivity of Cu-CNT nanocomposites processed via the combination of flake powder metallurgy and high pressure torsion methods. Mater Sci Eng A. 2020;773: 138888.

Varol T, Canakci A. The effect of type and ratio of reinforcement on the synthesis and characterization Cu-based nanocomposites by flake powder metallurgy. J Alloy Compd. 2015;649:1066–74.

Fathy A, Wagih A, Abu-Oqail A. Effect of ZrO2 content on properties of Cu-ZrO2 nanocomposites synthesized by optimized high energy ball milling. Ceram Int. 2019;45:2319–29.

Fan G, Jiang Y, Tan Z, Guo Q, Xiong D-B, Su Y, Lin R, Hu L, Li Z, Zhang D. Enhanced interfacial bonding and mechanical properties in CNT/Al composites fabricated by flake powder metallurgy. Carbon. 2018;130:333–9.

Biçer H, Akdoğan EK, Şavklıyıldız İ, Haines C, Zhong Z, Tsakalakos T. Thermal expansion of nano–boron carbide under constant DC electric field: an in situ energy dispersive X-ray diffraction study using a synchrotron probe. J Mater Res. 2020;35:90–7.

Mokdad F, Chen D, Liu Z, Xiao B, Ni D, Ma Z. Deformation and strengthening mechanisms of a carbon nanotube reinforced aluminum composite. Carbon. 2016;104:64–77.

Abu-Okail M, Shewakh W, Brisha AM, Abdelraouf YA, Abu-Oqail A. Effect of GNPs content at various compaction pressures and sintering temperatures on the mechanical and electrical properties of hybrid Cu/Al2O3/xGNPs nanocomposites synthesized by high energy ball milling. Ceram Int. 2020;46:18037–45.

Abu-Oqail A, Wagih A, Fathy A, Elkady O, Kabeel A. Effect of high energy ball milling on strengthening of Cu-ZrO2 nanocomposites. Ceram Int. 2019;45:5866–75.

Amirthagadeswaran K. Corrosion and wear behaviour of nano Al2O3 reinforced copper metal matrix composites synthesized by high energy ball milling. Particulate Sci Technol. 2020;38:228–35.

Zghal S, Twesten R, Wu F, Bellon P. Electron microscopy nanoscale characterization of ball milled Cu-Ag powders. Part II: nanocomposites synthesized by elevated temperature milling or annealing. Acta Mater. 2002;50:4711–26.

Branicio P, Zhang J, Srolovitz D. Effect of strain on the stacking fault energy of copper: a first-principles study. Phys Rev B. 2013;88: 064104.

Jiang H, Zhu YT, Butt DP, Alexandrov IV, Lowe TC. Microstructural evolution, microhardness and thermal stability of HPT-processed Cu. Mater Sci Eng, A. 2000;290:128–38.

Boytsov O, Ustinov A, Gaffet E, Bernard F. Correlation between milling parameters and microstructure characteristics of nanocrystalline copper powder prepared via a high energy planetary ball mill. J Alloy Compd. 2007;432:103–10.

Soni P. Mechanical alloying: fundamentals and applications. Cambridge: Cambridge International Science Publishing; 2000.

Shkodich N, Rogachev A, Vadchenko S, Moskovskikh D, Sachkova N, Rouvimov S, Mukasyan A. Bulk Cu–Cr nanocomposites by high-energy ball milling and spark plasma sintering. J Alloy Compd. 2014;617:39–46.

Gan K, Gu M. The compressibility of Cu/SiCp powder prepared by high-energy ball milling. J Mater Process Technol. 2008;199:173–7.

Xiong H, Li Z, Gan X, Chai L, Zhou K. High-energy ball-milling combined with annealing of TiC powders and its influence on the microstructure and mechanical properties of the TiC-based cermets. Mater Sci Eng, A. 2017;694:33–40.

Orowan E. A type of plastic deformation new in metals. Nature. 1942;149:643–4.

Wei X, Tao J, Liu Y, Bao R, Li F, Fang D, Li C, Yi J. High strength and electrical conductivity of copper matrix composites reinforced by carbon nanotube-graphene oxide hybrids with hierarchical structure and nanoscale twins. Diamond Relat Mater. 2019;99: 107537.

Carpenter HCH, Tamura S. The formation of twinned metallic crystals. Proc R Soc Lond Ser A (containing papers of a mathematical and physical character). 1926;113:161–82.

Chawake N, Varanasi RS, Jaswanth B, Pinto L, Kashyap S, Koundinya N, Srivastav AK, Jain A, Sundararaman M, Kottada RS. Evolution of morphology and texture during high energy ball milling of Ni and Ni-5 wt% Cu powders. Mater Charact. 2016;120:90–6.

Huang J, Wu Y, Ye H. Ball milling of ductile metals. Mater Sci Eng, A. 1995;199:165–72.

Li Y-J, Tu K-N, Chen C. Tensile properties and thermal stability of unidirectionally< 111>-oriented nanotwinned and< 110>-oriented microtwinned copper. Materials. 2020;13:1211.

Humphreys FJ, Hatherly M. Recrystallization and related annealing phenomena. Amsterdam: Elsevier; 2012.

Imrich PJ, Kirchlechner C, Dehm G. Influence of inclined twin boundaries on the deformation behavior of Cu micropillars. Mater Sci Eng, A. 2015;642:65–70.

Li X, Yan S, Chen X, Hong Q, Wang N. Microstructure and mechanical properties of graphene-reinforced copper matrix composites prepared by in-situ CVD, ball-milling, and spark plasma sintering. J Alloys Compd. 2020;834: 155182.

Wang F, Li Y, Wakoh K, Koizumi Y, Chiba A. Cu–Ti–C alloy with high strength and high electrical conductivity prepared by two-step ball-milling processes. Mater Des. 2014;61:70–4.

Uddin SM, Mahmud T, Wolf C, Glanz C, Kolaric I, Volkmer C, Höller H, Wienecke U, Roth S, Fecht H-J. Effect of size and shape of metal particles to improve hardness and electrical properties of carbon nanotube reinforced copper and copper alloy composites. Compos Sci Technol. 2010;70:2253–7.

Singh MK, Gautam RK. Synthesis of copper metal matrix hybrid composites using stir casting technique and its mechanical, optical and electrical behaviours. Trans Indian Inst Met. 2017;70:2415–28.

Varol T, Canakci A. Microstructure, electrical conductivity and hardness of multilayer graphene/copper nanocomposites synthesized by flake powder metallurgy. Met Mater Int. 2015;21:704–12.

Norouzifard V, Naeinzadeh H, Talebi A. Fabrication and investigation of mechanical properties of copper matrix nanocomposite reinforced by steel particle. J Alloys Compd. 2021;887: 161434.

Mai Y, Chen F, Lian W, Zhang L, Liu C, Jie X. Preparation and tribological behavior of copper matrix composites reinforced with nickel nanoparticles anchored graphene nanosheets. J Alloy Compd. 2018;756:1–7.

Şap E, Usca ÜA, Gupta MK, Kuntoğlu M, Sarıkaya M, Pimenov DY, Mia M. Parametric optimization for improving the machining process of cu/mo-sicp composites produced by powder metallurgy. Materials. 2021;14:1921.

German RM, Messing GL, Cornwall RG. Sintering technology. Boca Raton: CRC Press; 2020.

Samsonov GV. Handbook of the physicochemical properties of the elements. Berlin: Springer Science & Business Media; 2012.

Canakci A, Varol T, Erdemir F. The effect of flake powder metallurgy on the microstructure and densification behavior of B 4 C nanoparticle-reinforced Al–Cu–Mg alloy matrix nanocomposites. Arab J Sci Eng. 2016;41:1781–96.

Doğan K, Özgün Mİ, Sübütay H, Salur E, Eker Y, Kuntoğlu M, Aslan A, Gupta MK, Acarer M. Dispersion mechanism-induced variations in microstructural and mechanical behavior of CNT-reinforced aluminum nanocomposites. Arch Civil Mech Eng. 2022;22:1–17.

Li D, Liu Z, Yu Y, Wang E. The influence of mechanical milling on the properties of W–40 wt% Cu composite produced by hot extrusion. J Alloys Compd. 2008;462:94–8.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Ethics approval and consent to participate

Not applicable.

Consent for publication

The consent to submit this paper has been received explicitly from all co-authors.

Conflict of interest

The authors declare that they have no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Salur, E. Synergistic effect of ball milling time and nano-sized Y2O3 addition on hardening of Cu-based nanocomposites. Archiv.Civ.Mech.Eng 22, 103 (2022). https://doi.org/10.1007/s43452-022-00429-1

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s43452-022-00429-1