Abstract

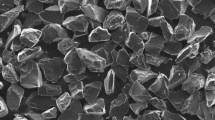

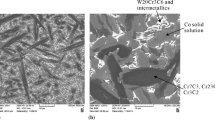

The aim of this study was to determine the effect of different ratios Cr particle reinforcement on the hardness and wear resistance of Cu matrix composites produced by using (P/M) method. Cr particles were added at different weight ratios of 5, 10 and 15%, in pure Cu dust. The prepared mixtures were shaped under a pressure of 400 MPa. The shaped pieces were sintered at 900 °C for 30 min. The success of the sintering process was evaluated by examining the intensity and SEM images. Microscope studies were performed using scanning electron microscopy (SEM). Hardness measurement method was used for determining hardness. In the SEM analysis, it was observed that the Cr phase was uniformly distributed in the Cu matrix composed of coaxial grains. In addition, an increase in the hardness was observed depending on the increase in the Cr ratio. The wear behaviors of the composite materials produced were investigated by pin-on-disk wear test. As the disk, a surface-hardened AISI 1050 steel was used. As a result of this examination, composite materials; depth of wear, losses in the weight, variation of friction coefficient, variation of wear diameters at 0.4 m/s shear rate and 1500 m shear distance were investigated by applying 50 N and 75 N loads. As a result of these investigations, it has been found that as the Cr particle reinforcement ratio in the Cu matrix composites increases, hardness and the wear resistance were increased positively.

Similar content being viewed by others

References

Yilmaz SS (2004) The effects of physical and mechanical properties of surface hardening treatments at ferrous based P/M parts. Ph.D. thesis, Manisa Celal Bayar University, Institute of Natural and Applied Sciences

Lawley A (1992) Atomization: the production of metal powders. Princeton, Metal Powder Industries Federation

Turan H, Saritas S Metal dust production with gas atomization. In: 6. International Machine Design and Manufacturing Congress, Ankara, Turkey, 1994. METU

Yilmaz SS, Unlu BS, Varol R (2008) Borlanmis ve bilyalı dovulmus demir esasli T/M malzemelerinin asinma ve mekanik ozellikleri. Makine Teknolojileri Elektronik Dergisi 1:7–16

Muratoglu M, Demirel M (2009) Influence of non-standart geometry of plastic gear on sliding velocities. In: 5. International Advanced Technologies Symposium, Karabuk, Turkey. pp 759–764

Alpas AT, Zhang J (1992) Effect of sic particulate reinforcement on the dry sliding wear of aluminum silicon alloys (A356). Wear 155(1):83–104. https://doi.org/10.1016/0043-1648(92)90111-K

Chen R, Iwabuchi A, Shimizu T, Shin HS, Mifune H (1997) The sliding wear resistance behavior of NiAl and SiC particles reinforced aluminum alloy matrix composites. Wear 213(1–2):175–184. https://doi.org/10.1016/S0043-1648(97)00123-3

Liang YH, Zhao Q, Zhang ZH, Li XJ, Ren LQ (2014) Effect of B4C particle size on the reaction behavior of self-propagation high-temperature synthesis of TiC-TiB2 ceramic/Cu composites from a Cu-Ti-B4C system. Int J Refract Met H 46:71–79. https://doi.org/10.1016/j.ijrmhm.2014.05.017

Bargel HJ (1980) Werkstoffkunde. VDI-Verlag

Tandon KN, Tian RZ (1993) Effect of Sb on the wear behavior of a Cu–Pb alloy. Scr Metall Mater 29(6):857–861. https://doi.org/10.1016/0956-716x(93)90241-J

Barmouz M, Asadi P, Givi MKB, Taherishargh M (2011) Investigation of mechanical properties of Cu/SiC composite fabricated by FSP: effect of SiC particles’ size and volume fraction. Mat Sci Eng a-Struct 528(3):1740–1749. https://doi.org/10.1016/j.msea.2010.11.006

Barmouz M, Givi MKB, Seyfi J (2011) On the role of processing parameters in producing Cu/SiC metal matrix composites via friction stir processing: investigating microstructure, microhardness, wear and tensile behavior. Mater Charact 62(1):108–117. https://doi.org/10.1016/j.matchar.2010.11.005

Chen Z, Liu P, Verhoeven JD, Gibson ED (1996) Sliding wear behavior of deformation-processed Cu-15vol. %Cr in situ composites. Wear 195(1–2):214–222. https://doi.org/10.1016/0043-1648(96)06949-9

Funkenbusch PD, Courtney TH, Kubisch DG (1984) Fabricability of an microstructural development in cold-worked metal matrix composites. Scripta Metall Mater 18(10):1099–1104. https://doi.org/10.1016/0036-9748(84)90186-8

Nath D, Biswas SK, Rohatgi PK (1980) Wear Characteristics and bearing performance of aluminum-mica particulate composite-material. Wear 60(1):61–73. https://doi.org/10.1016/0043-1648(80)90249-5

Saka N, Karalekas DP (1985) Friction and wear of particle-reinforced metal ceramic composites. In: Proceedings of the International Conference on Wear of Materials. Canada

Yonetken A, Erol A, Kaplan H Microwave sintering and characterization of Cu–Cr–SiC composite materials. In: 24th International Conference on Metallurgy and Materials, Metal 2015, Brno, Czech Republic

Turhan H, Yildiz T, Gulenc B (2007) Microstructure and mechanical properties of Cu/Fe Mnp and Cu/FeCrp matrix composites produced by powder metallurgy. Fırat Univ Sci and Eng Mag 19(4):569–574

Callister WD (2007) Materials science and engineering: an introduction. Wiley, New Jersey

Sawla S, Das S (2004) Combined effect of reinforcement and heat treatment on the two body abrasive wear of aluminum alloy and aluminum particle composites. Wear 257(5–6):555–561. https://doi.org/10.1016/j.wear.2004.02.001

Bektasoglu A, Savaskan T (2005) Zn-60Al-(1-5) Cu alaşımlarının kuru sürtünme durumundaki aşınma özelliklerinin incelenmesi. Mühendis ve Makina 46(544):31–39

Ahlatci H, Candan E, Cimenoglu H (2003) The effect of SiC size on the wear behaviour of 60 vol% SiC–Al composites. J Istanbul Tech Univ Ser D Eng 2(3):37–42

Ekrem M, Senyurt MA, Duzcukoglu H, Sahin OS, Avci A (2016) The effect of multiwall carbon nanotubes upon wear and thermal stability of epoxy resin. In: 16. International Materials Symposium, Pamukkale University. pp 470–477

ISO 20808:2016 (2016) Fine ceramics (advanced ceramics, advanced tehnical ceramics)—Determination of friction and wear characteristics of monolithic ceramics by ballon-disk method. Technical Committee, ISO/TC 206 Fine ceramics

Ozgun O, Balalan Z, Ekinci O (2016) Microstructure and mechanical properties of Cu matrix composites with SiC particle reinforcements at different ratios. In: International Material Science and Technology Conference, Nevsehir, Turkey. pp 229–233

Zhan YZ, Zhang G (2004) Mechanical mixing and wear-debris formation in the dry sliding wear of copper matrix composite. Tribol Lett 17(3):581–592. https://doi.org/10.1023/B:Tril.0000044508.54186.66

Zhan YZ, Zhang GD, Zhuang YH (2004) Wear transitions in particulate reinforced copper matrix composites. Mater Trans 45(7):2332–2338. https://doi.org/10.2320/matertrans.45.2332

Acknowledgements

This paper was produced from project (number: MMF.3.16.001) supported by The Scientific Research Projects Coordination Unit of Bingol University.

Author information

Authors and Affiliations

Corresponding author

Additional information

Technical Editor: Márcio Bacci da Silva.

Rights and permissions

About this article

Cite this article

Uzun, M., Usca, U.A. Effect of Cr particulate reinforcements in different ratios on wear performance and mechanical properties of Cu matrix composites. J Braz. Soc. Mech. Sci. Eng. 40, 197 (2018). https://doi.org/10.1007/s40430-018-1130-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s40430-018-1130-8