Abstract

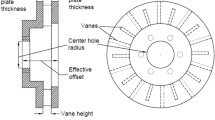

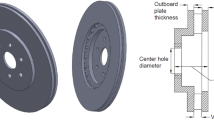

The brake discs are subjected to thermal load due to sliding by the brake pad and fluctuating loads because of the braking load. This combined loading problem requires simulation using coupled thermo-mechanical analysis for design evaluation. This work presents a combined thermal and mechanical finite element analysis and evolutionary optimization-based novel approach for estimating the optimal design parameters of the ventilated brake disc. Five parameters controlling the design: Inboard plate thickness, outboard plate thickness, vane height, effective offset, and center hole radius were considered, and simulation runs were planned. 27 brake disc designs with design parameters as recommended by the Taguchi method (L27) were modeled using SOLIDWORKS, and the FEA simulation runs were carried out using ANSYS thermal & structural analysis tool. The fatigue life results were analyzed using a 3D surface plot for the effect of the design parameters on the response, contour plots for the determination of maximum response, and statistical regression analysis for model interpretation and predictive modeling. Finally, the two most accurate and widely used evolutionary optimization algorithms: genetic algorithm (GA) and particle swarm optimization (PSO) were applied to determine the optimal design parameters for the ventilated brake disc. The brake disc of design parameters predicted by GA and (PSO), gives 12.74% higher fatigue life compared to parametric analysis. These results have shown that the developed approach can be utilized effectively and reliably for solving, design ventilated brake disc problem in the industry.

Graphical abstract

Similar content being viewed by others

References

S. Yim, Y.H. Jo, Integrated chassis control with AFS, ARS and ESC under lateral force constraint on AFS. JMST Adv. 1, 13–21 (2019)

S. Aguib, Mathematical modeling and finite element analysis of the mechanical behavior of hybrid structures in complex materials. JMST Adv. 2, 1–8 (2020)

Y. Chen, D. Vasiukov, L. Gélébart, C.H. Park, Fast Fourier transform solver for damage modeling of composite materials. JMST Adv. 1, 49–55 (2019)

A. Belhocine, O.I. Abdullah, Design and thermomechanical finite element analysis of frictional contact mechanism on automotive disc brake assembly. J. Fail. Anal. Prev. 20, 270–301 (2020)

A. Khan, N. Kim, J.K. Shin, H.S. Kim, B.D. Youn, Damage assessment of smart composite structures via machine learning: a review. JMST Adv. 1, 107–124 (2019)

A. Belhocine, M. Bouchetara, Thermal analysis of a solid brake disc. Appl. Therm. Eng. 32, 59–67 (2012)

A. Belhocine, A. Afzal, A predictive tool to evaluate braking system performance using a fully coupled thermo-mechanical finite element model. Int. J. Interact. Des. Manuf. (IJIDeM) 14, 225–253 (2020)

M. Pevec, I. Potrc, G. Bombek, D. Vranesevic, Prediction of the cooling factors of a vehicle brake disc and its influence on the results of a thermal numerical simulation. Int. J. Automot. Technol. 13, 725–733 (2012)

A. Belhocine, A.R.A. Bakar, O.I. Abdullah, Structural and contact analysis of disc brake assembly during single stop braking event. Trans. Indian Inst. Met. 68, 403–410 (2015)

L. Zhang, D. Meng, Z. Yu, Theoretical modeling and FEM analysis of the thermo-mechanical dynamics of ventilated disc brakes. SAE Technical Paper, Tech. Rep. 2010

Q. Jian, Y. Shui, Numerical and experimental analysis of transient temperature field of ventilated disc brake under the condition of hard braking. Int. J. Therm. Sci. 122, 115–123 (2017)

M. Duzgun, Investigation of thermo-structural behaviors of different ventilation applications on brake discs. J. Mech. Sci. Technol. 26, 235–240 (2012)

P. Hwang, X. Wu, Investigation of temperature and thermal stress in ventilated disc brake based on 3D thermo-mechanical coupling model. J. Mech. Sci. Technol. 24, 81–84 (2010)

T. Mahmoudi, A. Parvizi, E. Poursaeidi, A. Rahi, Thermo-mechanical analysis of functionally graded wheel-mounted brake disk. J. Mech. Sci. Technol. 29, 4197–4204 (2015)

S.P. Jung, T.W. Park, J.B. Chai, W.S. Chung, Thermo-mechanical finite element analysis of hot judder phenomenon of a ventilated disc brake system. Int. J. Precis. Eng. Manuf. 12, 821–828 (2011)

M.-J. Han, C.-H. Lee, T.-W. Park, S.-P. Lee, Low and high cycle fatigue of automotive brake discs using coupled thermo-mechanical finite element analysis under thermal loading. J. Mech. Sci. Technol. 32, 5777–5784 (2018)

L. Zhang, Q. Yang, D. Weichert, N. Tan, Simulation and analysis of thermal fatigue based on imperfection model of brake discs. Proc. Appl. Math. Mech. (PAMM) 9, 533–534 (2009)

E. Kakander, R. Roy, J. Mehnen, A simulation based approach to model design influence on the fatigue life of a vented brake disc. Proc. CIRP 59, 41–46 (2017)

H. Lü, Yu. Dejie, Optimization design of a disc brake system with hybrid uncertainties. Adv. Eng. Softw. 98, 112–122 (2016)

H. Lü, Yu. Dejie, Brake squeal reduction of vehicle disc brake system with interval parameters by uncertain optimization. J. Sound Vib. 333, 7313–7325 (2014)

H.M. Abbas, M.M. Bayoumi, Volterra-system identification using adaptive real-coded genetic algorithm. IEEE Trans. Syst. Man Cybern. A Syst. Hum. 36, 671–684 (2006)

M. Bagheri, A.A. Jafari, M. Sadeghifar, A genetic algorithm optimization of ring-stiffened cylindrical shells for axial and radial buckling loads. Arch. Appl. Mech. 81, 1639–1649 (2011)

R. Brighenti, A. Carpinteri, S. Vantadori, A genetic algorithm applied to optimisation of patch repairs for cracked plates. Comput. Methods Appl. Mech. Eng. 196, 466–475 (2006)

Y. Alperen, C. Sertac, Multi objective optimization of a micro-channel heat sink through genetic algorithm. Int. J. Heat Mass Transf. 146, 118847 (2020)

M.G. Sahab, V.V. Toropov, and A.H. Gandomi, Metaheuristic Applications in Structures and Infrastructures (Elsevier, 2013), pp. 25–47

S. Klancnik, M. Brezocnik, J. Balic, I. Karabegovic, Programming of CNC milling machines using particle swarm optimization. Mater. Manuf. Process. 28, 811–815 (2013)

X.Y. Kou, G.T. Parks, S.T. Tan, Optimal design of functionally graded materials using a procedural model and particle swarm optimization. Comput. Aided Des. 44, 300–310 (2012)

T.P. Latchoumi, K. Balamurugan, K. Dinesh, T.P. Ezhilarasi, Particle swarm optimization approach for waterjet cavitation peening. Measurement 141, 184–189 (2019)

P.J. Pawar, R.V. Rao, J.P. Davim, Multiobjective optimization of grinding process parameters using particle swarm optimization algorithm. Mater. Manuf. Process. 25, 424–431 (2010)

V. Balasubramanian, A.K. Lakshminarayanan, R. Varahamoorthy, S. Babu, Understanding the parameters controlling plasma transferred arc hardfacing using response surface methodology. Mater. Manuf. Process. 23, 674–682 (2008)

K. Kalita, I. Shivakoti, R.K. Ghadai, Optimizing process parameters for laser beam micro-marking using genetic algorithm and particle swarm optimization. Mater. Manuf. Process. 32, 1101–1108 (2017)

R.K. Ghadai, K. Kalita, S.C. Mondal, B.P. Swain, PECVD process parameter optimization: towards increased hardness of diamond-like carbon thin films. Mater. Manuf. Process. 33, 1905–1913 (2018)

V.K. Garlapati, P.R. Vundavilli, R. Banerjee, Evaluation of lipase production by genetic algorithm and particle swarm optimization and their comparative study. Appl. Biochem. Biotechnol. 162, 1350–1361 (2010)

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Belhocine, A., Shinde, D. & Patil, R. Thermo-mechanical coupled analysis based design of ventilated brake disc using genetic algorithm and particle swarm optimization. JMST Adv. 3, 41–54 (2021). https://doi.org/10.1007/s42791-021-00040-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42791-021-00040-0