Abstract

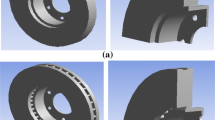

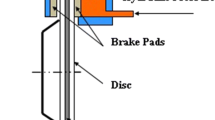

The braking phenomenon is an aspect of vehicle stopping performance where with kinetic energy due to speed of the vehicle is transformed to thermal energy via the friction between the brake disc and its pads. The heat must then be dissipated into the surrounding structure and into airflow around the brake system. The frictional thermal field during the braking phase between the disc and the brake pads can lead to excessive temperatures. In our work, we presented a numerical modeling using ANSYS software adapted in the finite element method, to follow the evolution of the global temperatures for the two types of brake discs, full and ventilated disc during braking scenario. Also, numerical simulation of the transient thermal and the static structural analysis were performed here sequentially, with coupled thermo-structural method. Numerical procedure of calculation relies on important steps such that the Computational Fluid Dynamics (CFD) and thermal analysis have been well illustrated in 3D, showing the effects of heat distribution over the brake disc. This CFD approach helped in the calculation of the values of the thermal coefficients (h) that have been exploited in the 3D transient evolution of the brake disc temperatures. Three different brake disc materials were tested and comparative analysis of the results was conducted in order, to derive the one with the best thermal behavior. Finally, the resolution of the coupled thermomechanical model allows us to visualize other important results of this research such as; the deformations, and the equivalent stresses of Von Mises of the disc, as well as the contact pressure of the brake pads. Following our analysis and results we draw from it, we derive several conclusions. The choice allowed us to deliver the rotor design excellence to ensure and guarantee the good braking performance of the vehicles.

Similar content being viewed by others

References

Abdullah, O.I., Schlattmann, J., Majeed, M.H., Sabri, L.A.: The distribution of frictional heat generated between the contacting surfaces of the friction clutch system. Int. J. Interact. Des. Manuf. 13(2), 487–498 (2019)

Cagin, S., Fischer, X., Delacourt, E., Bourabaa, N., Morin, C., Coutelier, D., Carré, B., Loumé, S.: β-NTF reduction and fast kriging simulation of optimal engine configurations. Mech. Ind. 18(5), 509 (2017)

Sébastian, P., Chenouard, R., Nadeau, J.P., Fischer, X.: The embodiment design constraint satisfaction problem of the BOOTSTRAP facing interval analysis and genetic algorithm based decision support tools. Int. J. Interact Des. Manuf. 1(2), 99–106 (2007)

Ordaz-Hernandez, K., Fischer, X., Bennis, F.: A mathematical representation for mechanical model assessment: numerical model qualification method. Int. J. Ind. Manuf. Eng. 1(1), 23–33 (2007)

Ryberg, A.B., Bäckryd, R.D., Nilsson, L.: A meta model-based multidisciplinary design optimization process for automotive structures. Eng. Comput. 31(4), 711–728 (2015)

Fischer, X., Coutellier, D.: Research in Interactive Design, vol. 2. Springer, Berlin (2006)

Ordaz-Hernandez, K., Fischer, X., Bennis, F.: Validity domains of beams behavioral models: efficiency and reduction with artificial neural networks. Int. J. Comput. Intell. 4(1), 80–87 (2008)

Ordaz-Hernandez, K., Fischer, X., Bennis, F.: Towards a modeling methodology for virtual prototyping in interactive design. In: Proceedings of Virtual Concept 2005

Botkin, M.E.: Structural optimization of automotive body components based on parametric solid modeling. Eng. Comput. 18(2), 109–115 (2002)

Makrahy, M.M., Ghazaly, N.M., Abd El-Gwwad, K.A., Mahmoud, K.R., Abd-El-Tawwab, Ali M.: Optimization of a new wedge disc brake using taguchi approach. Int. J. Mod. Eng. Res. 3(6), 3461–3465 (2013)

Singh, K.H., Kumar, A., Kumar, R.: Optimization of quality and performance of brake pads using Taguchi’s approach. Int. J. Sci. Eng. Res. 5(7), 632–639 (2014)

Bhat, R., Lee, K.S.: optimization of the brake parameter for a disc brake system to improve the heat dissipation using Taguchi method. Int. J. Mech. Eng. Technol. 8(7), 44–52 (2017)

Botkin, M.E.: Modelling and optimal design of a carbon fibre reinforced composite automotive roof. Eng. Comput. 16(1), 16–23 (2000)

Kothawade, S., Patankar, A., Kulkarni, R., Ingale, S.: Determination of heat transfer coefficient of brake rotor disc using CFD simulation. Int. J. Mech. Eng. Technol. (IJMET) 7(3), 276–284 (2016)

Belhocine, A., Abdullah, O.I.: Numerical simulation of thermally developing turbulent flow through a cylindrical tube. Int. J. Interact. Des. Manuf. 13(2), 633–644 (2019)

Fischer, X.: The interaction: a new way of designing. Res. Interact. Des. 2, 1–15 (2006)

García, M., Duque, J., Pierre, B., Figueroa, P.: Computational steering of CFD simulations using a grid computing environment. Int. J. Interact. Des. Manuf. 9(3), 235–245 (2015)

Cucinotta, F., Nigrelli, V., Sfravara, F.: Numerical prediction of ventilated planing flat plates for the design of Air Cavity Ships. Int. J. Interact. Des. Manuf. 1, 1–12 (2017)

Tang, J., Bryant, D., Qi, H.: Coupled CFD and FE thermal mechanical simulation of disc brake. In: Proceedings of the Eurobrake Conference, Lille, France (2014)

Carfagni, M., Governi, L., Volpe, Y.: Comfort assessment of motorcycle saddles: a methodology based on virtual prototypes. Int. J. Interact. Des. Manuf. 1, 155–167 (2007)

Adamowicz, A., Grześ, P.: Convective cooling of a disc brake during single braking. Acta Mechanica et Automatica 6(2), 5–10 (2012)

Ishak, M.R., Abu Bakar, A.R., Belhocine, A., Taib, J.M., Wan Omar, W.Z.: Brake torque analysis of fully mechanical parking brake system: theoretical and experimental approach. Ingenieria Investigacion y Tecnologia 19(1), 37–49 (2018)

Belhocine, A., Ghazaly, N.M.: Effects of young’s modulus on disc brake squeal using finite element analysis. Int. J. Acoust. Vib. 31(3), 292300 (2016)

Atkins, M.D., Kienhöfer, F.W., Kim, T.: Flow behavior in radial vane disk brake rotors at low rotational speeds. J. Fluids Eng. 141(8), 1–13 (2019)

Zhang, W., Cheng, C., Du, X., Chen, X.: Experiment and simulation of milling temperature field on hardened steel die with sinusoidal surface. Int. J. Interact. Des. Manuf. 12, 1–9 (2017)

Devanuri, J.K.: Numerical investigation of aerodynamic braking for a ground vehicle. J. Inst. Eng. (India) Ser. C 99(3), 329–337 (2018)

Morel, A., Bignonnet, A., Germain, G., Morel, F.: Teaching durability in automotive applications using a reliability approach. Int. J. Interact. Des. Manuf. 4, 281–287 (2010)

Dulcey, G.F., Fischer, X., Joyot, P.: An experiment-based method for parameter identification of a reduced multiscale parametric viscoelastic model of a laminated composite beam. Multisc. Multidiscip Model Exp Des 1, 291–305 (2018)

Cagin, S., Bourabaa, N., Delacourt, E., Morin, C., Fischer, X., Coutellier, D., Carré, B., Loumé, S.: Scavenging process analysis in a 2-stroke engine by CFD approach for a parametric 0D model development. J. Appl. Fluid Mech. 9(1), 69–80 (2016)

Cagin, S., Fischer, X., Delacourt, E., Bourabaa, N., Morin, C., Coutellier, D., Carré, B., Loumé, S.: A new reduced model of scavenging to optimize cylinder design. Simul. Trans. Soc. Model. Simul. Int. 92(6), 507–520 (2016)

Palmer, E., Mishra, R., Fieldhouse, J.D.: An optimization study of a multiple row pin vented brake disc to promote brake cooling using computational fluid dynamics. Proc. Inst. Mech. Eng. Part D. J. Automob. Eng. 223(7), 865–875 (2009)

Reimpel, J.: Braking technology. Vogel Verlag, Würzburg (1998)

Cruceanu, C.: Frâne pentru vehicle feroviare (Brakes for railway vehicles), Ed. Matrixrom, Bucureşti, (ISBN 978-973-755-200-6, 388) (2007)

Dittrich, H., Lang, R.: Finite-element analysis of the thermal loads acting on a passenger car brake disk. Automobiltechnische Zeitschrift 86(6), 265–269 (1984)

Fukano, A., Matsui, H.: Development of Disc- Brake Design Method Using Computer Simulation of Heat Phenomena, SAE 860634 (1986)

Gotowicki, P.F., Nigrelli, V., Mariotti, G.V., Aleksendric, D., Duboka, C.: Numerical and experimental analysis of a pegs-wing ventilated disk brake rotor with pads and cylinders. In: 10th EAEC Eur. Automot. Cong.–Paper EAEC05YUAS04–P5 (2005)

Khalid, M.K., Mansor, M.R., Abdul Kudus, S.I., Tahir, M.M., Hassan, M.Z.: Performance investigation of the UTeM Eco-car disc brake. Syst. Int. J. Eng. Technol. 11(6), 1–6 (2011)

Limpert, R.: Brake Design and Safety, 2nd edn, pp. 137–144. Society of Automotive Engineering Inc., Warrendale (1999)

Stephens, A.: Aerodynamic Cooling of Automotive Disc Brakes, Masters thesis,.School of Aerospace, Mechanical & Manufacturing Engineering, RMIT University (2006)

Zhang, J., Xia, C.: Research of the Transient Temperature Field and Friction Properties on Disc Brakes. In: Proceedings of the 2012 2nd International Conference on Computer and Information Application (ICCIA 2012), pp. 201–204 (2012)

Mackin, T.J., Noe, S.C., Ball, K.J., Bedell, B.C., Bim-Merle, D.P., Bingaman, M.C., Bomleny, D.M., Chemlir, G.J., Clayton, D.B., Evans, H.A.: Thermal cracking in disc brakes. Eng. Fail. Anal. 9, 63–76 (2002)

Oder, G., Reibenschuh, M., Lerher, T., Šraml, M., Šamec, B., Potrč, I.: Thermal and stress analysis of brake discs in railway vehicles. Adv. Eng. 3(1), 1 (2009)

Coudeyras, N.: Non-linear analysis of multiple instabilities to the rubbing interfaces:application to the squealing of brake, PhD Thesis, Central school of Lyon-speciality: mechanics (2009)

Abu Bakar, A.R., Ouyang, H., Khai, L.C., Abdullah, M.S.: Thermal analysis of a disc brake model considering a real brake pad surface and wear. Int. J. Veh. Struct. Syst. 2(1), 20–27 (2010)

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflicts of interest

The authors declare that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix A

Appendix A

1.1 A.1. Analysis of disc rotor force

A free body diagram of a front wheel-rotor system, Fig. 43 , is used to drive the equation of equilibrium. Since large amount of the braking load is born by the front brakes, that amount of kinetic energy and potential energy into a single disc is given by

But \( S_{b} {\kern 1pt} = \frac{{v_{0}^{2} }}{2\,a} \)

The power dissipated by each rotor face is equal to the heat flux into the rotor face.

But from kinematic relationships.

\( F_{rotor} {\kern 1pt} \) is constant with respect to time, and \( v_{rotor} \) varies only linearly with time so the energy balance equation becomes:

When braking on a straight/flat track (α = 0), k is estimated to be about 0.30. Therefore, equation (A.6) should be modified to be:

Rights and permissions

About this article

Cite this article

Belhocine, A., Afzal, A. A predictive tool to evaluate braking system performance using a fully coupled thermo-mechanical finite element model. Int J Interact Des Manuf 14, 225–253 (2020). https://doi.org/10.1007/s12008-020-00650-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12008-020-00650-3