Abstract

Metal-free porous biochars are popularly utilized as catalysts for peroxydisulfate (PDS) activation. The enhancement effect of PDS activation of porous biochars fabricated by employing both hard template and alkali metal activating agent has not been explored completely. In addition, the role of the inherent carbon defect in PDS activation has not been clearly elucidated. Hence, a series of carbonaceous catalysts were fabricated using a sole template (KCl), a sole activating agent (Na2S2O3) or a combination of template and activating agent (KCl/Na2S2O3, KCl/KHCO3, KCl/NaHCO3, and KCl/Na2C2O4), to systematically investigate the effect of specific surface area (SSA) and intrinsic defect of porous biochar on its PDS activation ability. The biochar synthesized by KCl and Na2S2O3 (SK-C) exhibited the optimum degradation performance. The SK-C was found to possess an interconnected hollow cage with three-dimensional mesh structure showing the largest surface area, pore volume and C-sp3 edge defect content among all the catalysts, which explained its paramount catalytic ability. The SSA and C-sp3 content together can determine the catalytic performance in a quantitative relationship. The single electron transfer pathway from SDZ to inner-sphere bound SK-C/PDS* was the protagonist of pollutant oxidation. The degradation intermediates were detected and recognized and their toxicities were evaluated. This study for the first time comprehensively identified the synergistic effect between the SSA and inherent defects on improving the catalytic performance of biochar for PDS activation to removal contaminants.

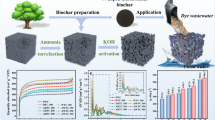

Graphical Abstract

Highlights

-

Several porous biochars with various surface area and defect degree were fabricated.

-

These catalysts were used for peroxydisulfate activation to degrade sulfadiazine.

-

The catalyst made by employing Na2S2O3 and KCl exhibited the optimum performance.

-

The surface area and C-sp3 together determined quantitatively the catalytic effect.

-

The single electron transfer from organic to inner-sphere catalyst/peroxodisulfate* was dominant.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

1 Introduction

Sulfonamide antibiotics are extensively used in poultry feeding and healthcare industry and they are hard to be completely metabolized by animals and humans. Therefore, various kinds of sulfonamide antibiotics have been detected in surface waters and wastewaters, among which sulfadiazine (SDZ) is a representative one with doughty durability. It can cause serious human health problems and environmental risks via inducing the formation of antibiotic-resistant bacteria/genes and altering microbial community composition (Guo et al. 2020; Meng et al. 2020; Pei et al. 2021; Zhang et al. 2020a). Recently, the advanced oxidation technology based on persulfate (PS) has become the research hotspot in the field of organic wastewater remediation. The heterogeneous activation of peroxydisulfate (PDS) by multitudinous catalysts has attracted an inordinate amount of attention because of its high efficiency, easy operation and intricate mechanism (Wang et al. 2019a, 2021; Zhang et al. 2020b). In the past few years, non-metallic carbon materials such as graphene, biochars and carbon nanotubes have been widely reported as hopeful alternatives to activate PS (Kasera et al. 2022; Leng et al. 2022; Luo et al. 2022). Especially, biochars have become the green and applicable alternatives to transition metal-based catalysts for PS activation due to their bulk availability, environmental friendliness, low price and ease of functionalization (Jin et al. 2022; Qiu et al. 2021; Yang et al. 2022). However, biochar obtained from the pyrolysis of biomass usually exhibited inferior PS activation performance possibly due to its low surface area and pore volume and scarce catalytic active sites (Huo et al. 2020a; Liu et al. 2022; Qiu et al. 2022). Therefore, it is imperative and significant to modify the original biochar properly to enhance its catalytic ability.

The pore-making (activation) is a very effective route to ameliorate the performance of biochar in pollutant adsorption and catalytic reactions. Chemical activation involving the co-pyrolysis of biomass and a certain activating agent such as KOH, ZnCl2 and H3PO4 can produce porous biochar conveniently (Li et al. 2021a, b). However, all of above common activating agents are caustic and toxic with storage and environment challenges restricting their industrial applications. Therefore, it is urgent to employ some mild activating agents to achieve a green and sustainable chemical activation strategy. Some harmless bicarbonates, organic salts and thiosulfates of alkali metal (MHCO3, M2C2O4 and M2S2O3, M = Na, K) with benign chemical properties have been used as activating agents (Sevilla et al. 2021). However, the organic pollutant adsorption and PS-driven degradation abilities of porous biochar activated by these agents especially M2C2O4 and M2S2O3 have not been explored completely. Furthermore, a combined strategy involving the KCl as a rigid skeleton and Na2S2O3 as an activating agent has been employed to fabricate interconnected hierarchical porous biochar which exhibited superior performances in tetracycline adsorption and lithium sulfur battery compared tothe one with only Na2S2O3 activation treatment (Díez et al. 2019; Fuertes et al. 2018). The KCl incorporated in the synthesis mixture acted as a skeleton in the development of porosity on the biochar. It melts at 770 °C and then provides a confined reaction medium for activation reactions. When the carbonized solid was washed with water, the KCl was completely removed and then biochar with sponge-like structure could be obtained (Díez et al. 2019). In addition, the biochar prepared by a combination of template and activating agent exhibited much thinner carbon sheets than those prepared by a single activating agent, which was beneficial to the exposure of more active catalytic sites (Fechler et al. 2013). However, whether the combination effect of KCl and Na2S2O3 can increase the PS activation capacity of porous carbonaceous materials is still unrevealed.

Based on the previous researches, although improving the surface area and pore volume of pure biochar could promote the PS-driven pollutant degradation of a catalyst, a specific quantitative relationship between them was difficult to be established (Anfar et al. 2021; Huo et al. 2020b; Lin and Zhang 2017; Tian et al. 2016). It is quite possible that the other factors or active sites of biochar have been overlooked. Introducing defects into the graphite framework has been regarded as a very effective route to improve the PS activation capacity of carbonaceous materials (Huo et al. 2020b). Defective sites of carbon catalysts include external defects (N, S, P or B doping) and intrinsic defects (edges, vacancies or topological defects). External defects, especially N doping, have been popularly reported as a useful approach to increasing PS activation capacity because of the generation of charge sites, disruption of inherent inert electron distribution of conjugated π system and modification of surface properties by doped N (Duan et al. 2018; Gao et al. 2020; Huo et al. 2020b; Tian et al. 2016). However, most reports seem to overlook the role of intrinsic defects toward the PS activation, despite the fact that they are ubiquitous in undoped carbon catalysts. It has been found that the intrinsic defects can facilitate the performance of carbon materials in fields of antibiotic adsorption, capacitive desalination of brackish water, and electrocatalytic reduction of carbon dioxide (Huo et al. 2020a ; Wang et al. 2019b, 2022a). For the porous biochar prepared via chemical activation, it is expected that the porogenic process will introduce large amounts of defects which can regulate the surface properties of biochar and the electronic configuration of adjacent carbon atoms. As far as we know, the role of intrinsic carbon defects on PS activation has not yet been clarified. The systematic investigation of the effect of intrinsic defects on the PS activation ability is imperative and meaningful, and will pave a new route for the elaborate fabrication of green and efficient PS activators.

Herein, a suite of pure porous biochars were prepared with the addition of a hard template, a porogenic agent or their combination. These biochars were utilized as catalysts for PDS activation to oxidized SDZ. The physiochemical characteristics including morphology, textural structure, microstructure and surface element chemical states of these biochars were investigated by scanning electron microscope (SEM), transmission electron microscope (TEM), Brunauer–Emmett–Teller (BET), Raman and X-ray photoelectron spectroscopy (XPS). The influences of common coexistence impurities towards the degradation were explored to examine the adaptability and resistance to various water qualities. The chemical scavengers and EPR test were conducted to clarify the crucial active oxidative species. A battery of electrochemical and spectroscopy techniques was utilized to elucidate the degradation pathway. The primary purposes of this study were: (1) to explore the influence of different common chemical activating agents on the PDS activation ability of porous biochar; (2) to establish the quantitative relationship between the key properties of pure biochar including surface area and defects and the degradation effect; (3) to select the optimum template for biochar in term of PDS activation and to discern the involved degradation pathways and mechanisms.

2 Experimental section

2.1 Chemicals and reagents

Sulfadiazine (SDZ), furfuryl alcohol (FFA), p-benzoquinone (BQ), and 5,5-dimethyl-1-pyrrolidine N-Oxide (DMPO) were purchased from Aladdin Industrial Co. Ltd., China. Potassium peroxydisulfate (PDS) was purchased from Beijing J&K Co., China. NaOH, H2SO4, KCl, KHCO3, Na2C2O4, NaCl, NaH2PO4·2H2O, Na2S2O3, methanol (MeOH), tert-butyl alcohol (TBA) and ethyl alcohol (EtOH) were purchased from Fuyu Fine Chemical Co. Ltd., China. Bisphenol S (BPS), bisphenol A (BPA), methyl phenyl sulfoxide (PMSO), carbamazepine (CBZ), benzoic acid (BA) and p-Nitrophenol (PNP) were obtained from Shanghai Aladdin Biochemical Industrial Co. Ltd., China. 4-hydroxybenzoic acid (HBAc), 4-hydroxybenzaldehyde (HBAl), 4-hydroxyacetophenone (HAP) and acetaminophen (AcP) were purchased from Tianjin Kermel Chemical Reagent Co. Ltd., China. Phenol (PE) was obtained from Shanghai Macklin Biochemical Technology Co. Ltd., China. All chemical reagents were of analytical grade and used without further purification.

2.2 Preparation of the catalysts

The catalysts were prepared using corn straw as the carbon precursor, KCl as a hard template, and Na2S2O3 as a porogenic agent. The corn straw was pulverized and sifted through a 100-mesh sieve. In a typical synthesis process, the mixture of 3 g of corn straw powder, 2 g Na2S2O3 and 10 g KCl was first ball-milled for 15 min to blend evenly. Then the mixture was annealed at 800 °C (5 °C/min) in N2 atmosphere (80 mL/min) for 2 h. The acquired carbonized solid was dispersed in a magnetic stirrer at 80 °C for 10 min and washed with distilled water to remove residual inorganic impurities, and dried at 60 °C in a vacuum drying oven for 12 h. The obtained material was named SK-C. For comparison, K-C and S-C samples were prepared by the same processes as SK-C, only without the addition of Na2S2O3 and KCl, respectively. At the same time, three kinds of materials were synthesized by the same preparation method as SK-C, replacing Na2S2O3 with the same molar of KHCO3, NaHCO3, and Na2C2O4, and the obtained materials were denoted as KK-C, NaK-C, Na2K-C, respectively. The specific synthesis process is shown in Fig. 1a.

Schematic illustrations of the synthesis procedure of the SK-C (a). SEM images of S-C (b), K-C (c) and SK-C (d). TEM images of S-C (e), K-C (f) and SK-C (g). High angle annular dark field scanning TEM image of (k) SK-C with energy-dispersive X-ray spectroscopy (EDS) elemental mapping of C (h), N (i) and O (j)

2.3 Characterization techniques

The morphological information of the obtained catalysts was investigated by transmission electron microscope (FEI TalosF200S, TEM), high angle annular dark field scanning TEM (Titan Themis G2, HAADFTEM) and scanning electron microscope (Zeiss/Auriga FIB, SEM). The crystal phase of the obtained catalysts was evaluated by X-ray diffraction (XRD) pattern using Bruker D8 Advance X-ray instrument (Cu Kα source). The surface defect characteristics of the catalysts were examined using laser Raman spectrometer (LabRAM HR Evolution). A surface area analyzer (MicrotracBEL Corp instrument) was used to estimate the pore size distribution and specific surface area of the catalysts by N2 adsorption–desorption isotherms. X-ray photoelectron spectroscopy (AXIS Supra Kratos Analytical Ltd, XPS) data were recorded to investigate the surface element composition and chemical states of the catalysts. The detailed operation methods of linear sweep voltammetry (LSV) and galvanic oxidation process (GOP) are shown in Additional file 1: Text S1 in Support Information. Radical generation and evolution processes were further investigated by radical quenching test and in-situ EPR capture (Additional file 1: Text S2).

2.4 Experimental procedures

SDZ was adopted as a model pollutant to evaluate the catalytic performance of various catalyst/PDS systems. All of the experiments were carried out in 50 mL glass flasks with magnetic stirring (25 °C, 700 rpm). PDS (2 mM) and catalyst (0.1 g L−1) were added in 30 mL SDZ solution (20 mg L−1) to trigger the degradation reaction. At each predetermined interval, 1 mL reaction solution was withdrawn and mixed with 1 mL methanol (MeOH) to quench the possible free radicals. Then the mixture was filtrated immediately to separate the catalyst from solution. After being filtered by a 0.22 μm Millipore film, the concentration of SDZ was determined by high-performance liquid chromatography (UHPLC, Thermo Fisher, Ultimate 3000) equipped with a C18 column and a UV detector (265 nm). The mobile phases of SDZ were acetonitrile and 0.1% formic acid and the corresponding volume ratio was 15:85. The SDZ adsorption tests of catalysts were carried out under the same conditions without the addition of PDS. All above experiments were performed three times and the error bars were the standard deviation of the experimental data.

3 Results and discussion

3.1 Characterization of prepared materials

The SEM and TEM images were used to study the effect of KCl and Na2S2O3 on the morphology of catalysts. From SEM images, the S-C catalyst exhibited an irregular carbon bulk with rough surface and visible pore structure (Fig. 1b). The K-C catalyst showed a sponge-like structure consisting of many smooth and thick carbon sheets without obvious pores (Fig. 1c). The SK-C exhibited an interconnected porous structure formed by the stacking of smooth and thin carbon sheets (Fig. 1d). The microscopic structures of these three catalysts were further detected by TEM (Fig. 1e–g). For S-C, abundant micropores and mesopores could be found on the thick carbon sheets because of the porogenic action of Na2S2O3. In the case of K-C, the whole carbon skeleton was made of stacked thick carbon sheets with less pores than those of S-C. It could be found that SK-C was composed of more thinner carbon sheets with large amounts of wrinkles at the edges and abundant pores on the whole sheets. It was proposed that the exceptional structure of SK-C was attributed to the cooperative effect between KCl and Na2S2O3.

During the annealing procedure, several successive processes took place using Na2S2O3 as a porogenic agent: (i) Na2S2O3 was decomposed to form Na2SO4 at temperatures above 250 °C, according to reaction (1), (ii) the carbonization of the corn straw (220–400 °C) and (iii) Na2SO4 could oxidize solid carbon at temperatures higher than 342 °C based on reaction (2). In addition, at temperatures greater than 520 °C, reaction (3) can also occur (Fuertes et al. 2018; Sevilla et al. 2021). The resulting Na2SO4 turned into the oxidizing agent which could react with the carbonaceous material by reactions (2) and (3) leaving pores. The residual solid slag would be consisted of porous carbon, Na2SO4, and Na2S/K2S/polysulfide. It is worth emphasizing that inorganic salts could be easily removed just using hot water. The inert salt KCl also played an important role in the synthesis process, because it melted at 770 °C and thus provided a confined reaction medium facilitating the development of porosity in carbon. Hence, when mixing Na2S2O3 and KCl, Na2S generated by reactions (2) and (3) would form a liquid phase at a temperature greater than 740 °C with the unreacted Na2SO4, while KCl will melt at about 770 °C. Based on such conditions, the melted KCl played an important role as a confinement medium, in which the contact between solid carbonaceous material and the Na2SO4–Na2S liquid system was strengthened, thereby promoting pore development and producing catalysts with high surface area and porosity. Due to the confinement effect of KCl, the release of volatile compounds was strictly limited, and a small fraction of the initially released gaseous substance was redeposited, so that up to 30–33 wt% of porous carbon yield could be achieved, which was much higher than that of the sole Na2S2O3 treatment of 16%.

As depicted in Additional file 1: Table S1 and Fig. 2, the surface area, pore volume and pore diameter distribution of all catalysts were calculated by the N2 adsorption–desorption isotherms. All the isotherms were attributed to the typical hybrid-type-IV isotherm suggesting the involvement of micropores and mesopores. All the hysteresis loops were H4-type, and there was no evident saturation adsorption platform, verifying that the pore structure was consisted of anomalous pores (Fig. 2a). With the sole introduction of KCl, the prepared catalyst achieved the lowest surface area and porosity, confirming the role of KCl as a hard template instead of an efficient activating agent. Compared with KCl, Na2S2O3 resulted in a higher surface area and porosity (Fig. 2b, c). In presence of KCl as a confined medium, the porogenic ability of Na2S2O3 was reinforced greatly, obtaining the highest surface area and pore volume compared with all the other KCl and activating agent combinations. The largest surface area and pore volume will be conducive to the mass transfer of reactants and exposure of the active sites over SK-C.

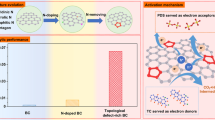

N2 adsorption–desorption isotherms (a), pore size distributions (b), and the values of specific surface area and pore volume (c) of prepared catalysts. The C content (at%) of different catalysts based on XPS spectra (d) and Raman spectra (e). The removal (f) efficiency of SDZ in various reaction systems. Experimental conditions: [PDS]0 = 2 mM, [Catalyst]0 = 0.1 g L−1, [SDZ]0 = 20 mg L−1, T = 25 °C

The characteristic peaks at approximately 25° and 44° in the XRD pattern were attributed to amorphous carbon (Additional file 1: Fig. S1), indicating the amorphous structure in all catalysts (Tian et al. 2016). The XPS analysis was carried out to differentiate the chemical states of C element on the surface of different catalysts. As shown in Additional file 1: Fig. S2, the high-resolution C 1 s spectra could be resolved to three deconvoluted peaks centered at around 284.8, 285.7 and 288.5 eV, corresponding to C-sp2, C-sp3 and O–C=O, respectively. The presence of C-sp3 species demonstrated that all these catalysts possessed abundant inherent defects (sp3 edge defects) (Wang et al. 2022c). Specifically, the contents of C-sp3 in S-C, K-C, SK-C, KK-C, NaK-C and Na2K-C were 21.7%, 21.3%, 23.8%, 19.8%, 20.5% and 20.7%, respectively, showing the most abundant sp3 edge defects on SK-C (Fig. 2d). This phenomenon was because the combination effect of KCl and Na2S2O3 could create affluent intrinsic structural defects, which could perform as active sites for PDS activation. The structural defects of prepared catalysts were further investigated by Raman spectra (Fig. 2e). All the catalysts had a typical D band (~ 1360 cm−1) and G band (~ 1570 cm−1). The D-band is derived from defects and disorder in carbon, while the G-band is closely related to the crystal and graphite structure (Anfar et al. 2021; Zhu et al. 2022). Therefore, their intensity ratios (ID/IG) can reflect the defective degree in catalyst lattice. As shown in Fig. 2e, the ID/IG was estimated to be 1.12, 1.05, 1.16, 1.19, 1.16 and 1.11 for S-C, K-C, SK-C, KK-C, NaK-C and Na2K-C, respectively.

The results of XPS and Raman spectra collectively indicated that the sole KCl as a molten medium had the worst ability for producing inherent defects. With the coexistence of KCl and Na2S2O3, the defect degree improved significantly compared with that of the sole Na2S2O3 treatment. In the presence of KCl, KHCO3 and Na2S2O3 exhibited comparable performance for inherent defect generation, which was superior to that of NaHCO3 and Na2C2O4. For KHCO3, NaHCO3 and Na2C2O4, all of them will decompose to M2CO3 and CO2 or CO at around 200 °C, so the actual activating agent is M2CO3. The porogenic effect of M2CO3 is derived from its redox reaction with the carbonaceous matter based on reaction (4). In contrast to Na2CO3, K2CO3 has stronger catalytic activity for carbon gasification. Because K ions have a unique intercalating effect and they can be intercalated into the graphene carbon sheets to incur tumidness and distortion of the carbon structure, thereby generating more pores (Jian et al. 2015; Raymundo-Piñero et al. 2005; Sevilla and Fuertes 2013). Therefore, taking into consideration of the better porogenic ability of K+ than Na+, the comparable capacity for producing defects between Na2S2O3 and KHCO3 was possibly attributed to the more outstanding ability of SO42− than CO32− in terms of the oxidation of carbonaceous matters.

3.2 Performance of catalysts on PDS activation for organic pollutant degradation

As displayed in Additional file 1: Fig. S3a, it could be found that the adsorption efficiency of S-C, K-C, SK-C, KK-C, NaK-C and Na2K-C was about 32.3%, 2.6%, 42.4%, 54.4%, 63.1% and 12.7% in 60 min, respectively. When only PDS was added, a negligible SDZ removal was found, indicating that PDS could not oxidize SDZ. In the presence of PDS molecules, 41.2%, 19.4%, 100.0%, 80.3%, 76.8% and 45.0% of SDZ could be removed in 60 min by S-C, K-C, SK-C, KK-C, NaK-C and Na2K-C, respectively (Fig. 2f). The kobs in the oxidation stage of different materials were determined based on the pseudo-first-order kinetic model (Additional file 1: Fig. S3b, Text S3). The kobs values kept the following order: SK-C (0.0993 min−1) > KK-C (0.0221 min−1) > NaK-C (0.0193 min−1) > Na2K-C (0.0073 min−1) > S-C (0.0067 min−1) > K-C (0.0028 min−1). It could be found that K-C and PDS obtained the worst degradation effect, which was consistent with its lowest surface area and defect degree. The SK-C and PDS system exhibited much enhanced degradation effect compared with that of S-C system, demonstrating the introduction of KCl during the fabrication process can elevate the catalytic effect of S-C. Among all the KCl and activating agent combination treatments, the catalyst with KCl/Na2S2O3 treatment achieved the preponderant effect in contrast to all the other combination treatments.

The effect of PDS concentration and SK-C dosage on SDZ degradation in PDS/SK-C system was studied in Additional file 1: Fig. S4. The removal rates of SDZ were 53.3%, 100.0% and 100.0% at SK-C dosages of 0.05, 0.1 and 0.2 g L−1, respectively. This might be due to the fact that the higher dose of SK-C, the more active sites for PDS activation would be provide (Tang et al. 2023; Zhu et al. 2019). However, with the increase of SK-C dosage from 0.1 to 0.2 g L−1, the degradation rate of SDZ increased slightly. This indicated that the optimal dosage of SK-C for degradation of SDZ was 0.1 g L−1 under the condition of 2 mM PDS. For a given SK-C dosage, it was observed that the degradation rate of SDZ was accelerated with the increase of PDS dosage from 1 to 4 mM. Generally speaking, a low dosage of PDS is a limiting element for contaminant degradation, so enhancing the dosage of PDS can improve the efficiency of reaction (Li et al. 2020). As shown in Additional file 1: Fig. S5, the presences of varied levels of NO3− H2PO4−, Cl− and HCO3− (1–50 mM) had very little influence on the SDZ degradation performance of SK-C/PDS system, indicating that the degradation effect was robust under varied water quality conditions. Nevertheless, HCO3− had a certain inhibitory effect on SDZ degradation in SK-C/PDS system. This can be explained by the tendency of HCO3− to interact with the surface of biochar via negatively charge assisted hydrogen bonding, and to compete against the –SO2NH– group of sulfonamides for adsorption sites (Sun et al. 2018). Another feasible interpretation was the quenching effect of HCO3− through Eqs. (5)–(6) (Tang et al. 2023; Yin et al. 2019;).

3.3 Degradation mechanism analysis

In order to determine the crucial active oxidative species in SK-C/PDS degradation system, quenching experiments were implemented with different chemical scavengers. The EtOH and TBA were used to quench SO4.– and ·OH radicals. As revealed in Fig. 3a, when introducing EtOH and TBA to the SK-C/PDS system, 99.0% and 94.6% of SDZ could be removed, indicating the negligible role of SO4.– and ·OH in the reaction system. FFA is a frequently-used scavenger for 1O2. The presence of FFA could not restrain the SDZ degradation (removal rate could reach 98.5%), demonstrating that 1O2 has insignificant role (Peng et al. 2021; Han et al. 2022).The p-BQ was used as a quencher for O2.−. It could be seen that when the concentration of p-BQ changed from 2 to 20 mM, the degradation efficiency of SDZ decreasesd from 93.6% to 69.8%. It seemed plausible that O2.− had a contribution to the degradation effect. Furthermore, the individual contribution of active oxidative species produced in SK-C/PDS system was verified by EPR technology with DMPO as a trapping agent for SO4.−/·OH (Fig. 3b). A group of complex signals including the obvious characteristic quartet of OH, the weak peaks of SO4.− and an unknown triplet with an intensity ratio of 1:1:1 could be detected in the EPR spectrum of sole PDS system. This unknown triple could also be found in all the catalyst/PDS systems with stronger intensity. This signal should be attributed to 5,5-dimethyl-2-oxopyrroline-1 which was an oxidation product of DMPO (Zhang et al. 2018). However, the typical peaks of •OH could not be found in the EPR spectra of all the three catalyst/PDS systems. Notably, the EPR test with DMPO as a trapping agent in MeOH could not detect the signals of O2.− (Additional file 1: Fig. S6). The above conflicting results indicated that p-BQ might inhibit the degradation of SDZ by other means instead of scavenging O2.−. As depicted in Additional file 1: Fig. S7, the presence of 2 mM and 20 mM p-BQ reduced the SDZ adsorption efficiency by SK-C from 42.4% to 40.7% and 32.0%, respectively. At the same time, the adsorption percentage of PDS in SK-C/PDS system was 21.9%, and when 2 mM and 20 mM p-BQ were added, the PDS adsorption percentage decreased to 19.9% and 9.1%, respectively. Similarly, the introduction of 2 mM and 20 mM p-BQ caused a declined PDS adsorption percentage in SK-C/PDS/SDZ system from 38.6% to 30.6% and 14.9%, separately. These phenomena together suggested that the deterioration of SDZ degradation in the presence of 20 mM p-BQ should be attributed to not only the quenching of O2.− but also the inhibitory effect of p-BQ on the interaction between SK-C and PDS/SDZ. Therefore, it can be concluded that these tested catalysts could not activate PDS for generating SO4−, OH and 1O2.

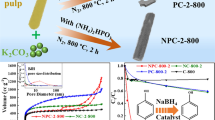

The effects of EtOH, TBA, FFA and p-BQ (a) on SDZ degradation in SK-C/PDS system and EPR patterns with DMPO as the spin-trapping agents (b). Current flowing from the PDS cell to the SDZ cell and SDZ removal in GOP system (c). LSV spectra (d). Experimental conditions: [PDS]0 = 2 mM, [Catalyst]0 = 0.1 g L−1, [SDZ]0 = 20 mg L−1, T = 25 °C

To further exclude the crucial role of radicals and 1O2, SK-C and PDS were pre-blended in the aqueous solution, and a given concentration of SDZ (20 mg L−1) was introduced at a predetermined time period (0, 1, 5 and 10 min). As revealed in Additional file 1: Fig. S8, with the increase of premixing time (from 0 to 10 min), the pre-blending treatment had a negligible effect on the final SDZ degradation. If radicals and/or 1O2 contributed vastly, the degradation effect should be deteriorated with the extension of preblending time because of the invalid consumption of PDS at the pre-blending stage. Therefore, the marginal role of radicals and/or 1O2 were verified during the removal of SDZ. Since there were no active metals contained in the carbonaceous catalyst herein, it is reasonable to speculate that the electron transfer pathway should be involved and predominated in the degradation process by SK-C/PDS system.

It has been reported that GOP can be used to demonstrate the existence of electron transfer process mediated by heterogeneous catalysts (Huang and Zhang 2019; Peng et al. 2021). A similar reaction system was constructed here as shown in Fig. 3c. The charge transfer between the two half cells and the concurrent contaminant degradation were monitored during the reaction (Fig. 3c and Additional file 1: Fig. S9). An increase in the current was recorded upon the addition of PDS, and the current quickly reached maximum and then decreased gradually with the progressing of reaction for both no coating and coating treatment. However, the coating treatment possessed much larger current value than that of the no coating one. As expected, a better SDZ degradation effect was also observed for the coating one. The above GOP result provided a direct proof for the occurrence of mediated electron transfer process in SK-C/PDS degradation system. The LSV curve has been utilized as an efficient approach to judge the interaction between catalyst and PDS (Fu et al. 2019; Li et al. 2022). As shown in Fig. 3d, when PDS was added to the electrolyte, the current was found to be significantly higher than that of SK-C alone which was an indicator of the production of metastable complexes between catalyst and PDS (SK-C/PDS*). With subsequent addition of SDZ into the same electrolyte, further increase in the current was observed, suggesting that the electron transfer occurred between SK-C/PDS* and SDZ. The above GOP and LSV results demonstrated collectively that the SK-C mediated electron transfer pathway dominated the SDZ degradation with the generation of SK-C/PDS* in the SK-C and PDS system.

The in-situ attenuated total reflectance Fourier transform infrared (ATR-FTIR) and in-situ Raman spectroscopy were applied to analyze the interaction between solid and liquid interface in the PDS/SK-C system (Jin et al. 2021; Wang et al. 2022b). As shown in Fig. 4a, two FTIR bands at 1285 cm−1 and 1066 cm−1 were attributed to the tensile vibration of S2O82−. For SK-C and PDS system, a novel peak at 1177 cm−1 could be observed which was derived from the S–O stretching vibration of SO42− produced by the decomposition of S2O82− (Jin et al. 2021; Yang et al. 2021) Moreover, a red shift of the peak at 1275 cm−1 could be found which was attributable to the generated SK-C/PDS* (Sun et al. 2022; Wang et al. 2022b). Furthermore, the decomposition of S2O82− and formation of SK-C/PDS* were identified by in situ Raman spectroscopy. As depicted in Fig. 4b, two peaks at 836 and 1076 cm−1 can be observed on the spectrum of PDS solution which were attributed to the O–O band in S2O82− (Liang et al. 2021). After the introduction of SK-C in the PDS solution, a new peak at approximately 809 cm−1 was detected due to the bending vibrations of the prolonged O–O bond in metastable SK-C/PDS* (Qi et al. 2021). At the same time, another new peak at 974 cm−1 belonging to SO42− could be identified in the SK-C/PDS system (Zhao et al. 2022). For SK-C/PDS/SDZ system, the intensity of the peak at 809 cm−1 decreased obviously while that of the peak at 974 cm−1 enhanced apparently, which was due to the consumption of SK-C/PDS* by SDZ molecules and concurrent generation of SO42−.

ATR-FTIR spectra (a) of various SK-C suspension. In situ Raman spectra (b) of PDS/SK-C/SDZ, PDS/SK-C, PDS and SK-C in the liquid solution. Removal (c) of different pollutants in SK-C/PDS system. Effects of ionic strength [NaClO4] (d) on the removal of SDZ in SK-C/PDS system. Experimental conditions: [PDS]0 = 2 mM, [Catalyst]0 = 0.1 g L−1, [SDZ]0 = 20 mg L−1, T = 25 °C

Furthermore, three kinds of organic pollutants were selected as target molecules to further understand the electron transfer mechanism in the SK-C/PDS degradation system. It is difficult for PNP and BA (electron-deficient pollutants) to conduct electron transfer degradation reaction; BPA and BPS are prone to be degraded via single electron transfer reactions, while the degradation of CBZ and PMSO are more likely to be through double electron transfer reactions (Peng et al. 2021). As depicted in Fig. 4c, the degradation of BPA and BPS by PDS/SK-C system was obvious, while the oxidation of CBZ, PMSO, PNP and BA was inferior. These results indicated that the SK-C/PDS system mainly exerted its catalytic degradation activity by single electron transfer pathway rather than a radical one or a double electron transfer one.

As known, the electron transfer pathway during the degradation process by carbonaceous catalyst and PDS relies on the formed metastable complexes between catalysts and PDS with strong oxidation ability (Ren et al. 2022). The complexation between catalyst and PDS can be classified into two types: outer-sphere complexation and inner-sphere complexation, which are attributed to the electrostatic bonding and covalent linkage or the association of ionic and covalent bonds, respectively (Feng et al. 2017; Zhang et al. 2013). Therefore, the augment of ionic strength can markedly affect the outer-sphere interactions both in equilibrium and kinetics, while the inner-sphere complexation cannot be influenced by the change of ionic strength. The influence of ionic strength on the degradation performance of SK-C/PDS system was investigated by the introduction of NaClO4 with concentration from 1 to 100 mM. As shown in Fig. 4d, the employment of NaClO4 had no significant effect on the degradation of SDZ, indicating a strong inner-sphere interaction between the catalyst and PDS.

3.4 The explanation of best performance of SK-C

The physicochemical characteristics of a certain catalyst should have some relationships with its catalytic ability. For pure carbonaceous catalysts prepared here, the typical properties including specific surface area (SSA) and defect degree (represented by the value of ID/IG or the content of C-sp3) were discussed in detail. Here, the relationship between SSA or defect degree and the kobs can be established to reveal the key property that influences the catalytic capacity. It couldbe found that the correlation between SSA and kobs was poor (R2 = 0.49) (Additional file 1: Fig. S10). The remarkable independence (R2 = 0.15) between ID/IG and kobs was discovered (Additional file 1: Fig. S11). A better but still unsatisfactory relationship between C-sp3 and kobs was also achieved with R2 of 0.61 (Additional file 1: Fig. S12). As known, the defects represented by D band are attributed to edge/space, topological defects, C-sp3, functional groups or heteroatoms. The lower correlation of ID/IG vs. kobs than C-sp3 vs. kobs indicates that C-sp3 has more intimate relationship with kobs than other types of defects. Based on the fact that poor relationships between the above single character and kobs, it is reasonable to speculate that these characters together can have interweaved influences on the catalytic degradation performance. The larger SSA and porosity can provide the catalyst with more spaces and channels to adsorb and transfer reactant and products. However, the catalyst with larger SSA and pore volume cannot ensure the higher degradation result because the amounts of reactive sites may not be enough to drive the degradation reactions. Therefore, a multivariate structure–activity relationship with both SSA and C-sp3 as independent variables and kobs as the dependent variable was established to evaluate completely the correlation between these inherent characters and catalytic performance. A good multivariate linear correlation (R2 = 0.91) could be found among the SSA, C-sp3 content and kobs as depicted in Eq. (7). This result suggested that the combination of SSA and C-sp3 content of these carbonaceous materials could determine the catalytic degradation performance in a quantitative relationship.

3.5 The selective degradation and reusability of SK-C and PDS system

The selective degradation of pollutants by SK-C and PDS system was investigated by employing several phenols compounds (PCs) with different functional groups as target pollutants. As shown in Fig. 5a, the SK-C/PDS system delivered different oxidation capacities toward these representative PCs. ACP and PE containing electron-donating groups were degraded with efficiency of 100.0% and 81.8% in 60 min, respectively. The removal percentages of HBAc, HBAl and HAP which electron-withdrawing groups were separately 51.8%, 65.7% and 63.5%. There was a good linear relationship between ln kobs and the standard electrode potential of pollutant [E0, Eq. (6)] (Fig. 5b, R2 = 0.98), indicating that oxidation of PCs was determined by energy barrier and effective collision (Ren et al. 2019). The coefficient (α) in Eq. (8) is the key parameter to evaluate the dynamic model of electron transport theory. Generally speaking, an α value around 1.0 manifests that the reaction efficiency is mainly limited by electron transfer process, while an α value under 0.5 indicates that the reaction rate may be controlled by mass transfer. To investigate thoroughly the rate-limiting step (electron transfer or mass transfer) during the SK-C/PDS degradation system, the α value was calculated on the basis of the slope demonstrated in Fig. 5b. The result showed that the α value was 0.19, revealing that the rate-determining step of the SK-C/PDS system was the mass transfer of PDS (and/or PC) to the catalyst. This result can be interpreted by the fact that the formation rate of SK-C/PDS* complex between SK-C and PDS or the contact rate between SK-C/PDS* complex and PCs played a crucial role on the degradation results.

where α is the transmission coefficient and β is a constant.

Degradation curves of different PCs (a) and correlation of kobs to the standard electrode potentials of pollutants (b) by the PDS/SK-C system. Reusability of SK-C/PDS system for SDZ degradation (c). C 1 s XPS spectra of SK-C, SK-Cused and SK-Cannealed (after three cycles) (d). Experimental conditions: [PDS]0 = 2 mM, [Catalyst]0 = 0.1 g L−1, [PCs]0 = 20 mg L−1, T = 25 °C

The stability and reusability of SK-C were examined through three successive runs of SDZ degradation. Compared with the fresh SK-C, the catalytic capacities of the spent one dropped to 53.51% in the second run and to 18.97% in the third run (Fig. 5c). This depressed reusability should be attributed to SDZ and the intermediates generated during the oxidation process adsorbing on the surface of catalyst and shielding the active catalytic sites. The used catalyst after three cycles was collected and washed by MeOH for 3 h (80 °C, water bath) to exclude the shielding effect of intermediate products on active sites of the catalyst. As shown in Additional file 1: Fig. S13, the used SK-C after thermal desorption by MeOH exhibited a prominent improvement in SDZ degradation efficiency (from 19.0% to 49.2%), indicating that organic intermediates indeed accumulated onto the surface of SK-C. The functional groups in the fresh and used SK-C were measured by FTIR (Additional file 1: Fig. S14). Different from the fresh SK-C, some new peaks were observed in the FITR spectrum of the used one. It could be distinctly detected the ~ 1456, 2852 and 2920 cm−1 vibration bands which were attributed to the bending and stretching of alkane bonds (Saha and Sengupta 2015; Sanchez et al. 2019). Therefore, these three peaks should be originated from the adsorption of degradation intermediates. Fortunately, the catalytic activity of used SK-C after three cycles could be greatly recovered from 18.97% to 96.23% after being annealed at 800 °C for 30 min due to the elimination of adsorbed SDZ by volatilization and oxidation effect. Moreover, it was found that the C-sp3 content of SK-C decreased obviously from 23.8% to 16.0% after three cycles while it augmented visibly to 25.4% after being annealed (Fig. 5d). These results further verified that C-sp3 edge defects were the active catalytic sites involved in SDZ degradation by SK-C/PDS system.

3.6 Transformation pathways of SDZ

The transformation products (TPs) of SDZ by SK-C/PDS system can be detected by UHPLC-MS technology and based on the m/z value, MS and MS2 spectrum, their possible structures were proposed. As shown in Fig. 6 and Additional file 1: Fig. S15, thirteen TPs were identified. According to previous studies, the feasible cleavage sites of SDZ were sites I–IV on the pyrimidine ring, which corresponded respectively to H–N, N–C, N–S and N–C bonds (Lu et al. 2020a; Pei et al. 2021; Yang et al. 2018). Therefore, four possible degradation routes of SDZ in the SK-C/PDS system were presented based on the thirteen conversion products determined by UHPLC-MS. In particular, the sulfur and nitrogen atoms affiliated to the benzene ring possess the most negative condensate two-fold descriptor values according to the Hirschfield charges, causing them the most vulnerable to be damaged by the nucleophiles (electrophiles) (Gou et al. 2020).

The first feasible route was that the S–N bond (III position) of SDZ (m/z 251) was directly cut with producing TP 97 (m/z 97) and TP 174 (m/z 174) because of the attack of SK-C/PDS* with strong oxidative capacity. TP 174 was hydroxylated rapidly and converted to intermediate product TP 114 (m/z 114). Then TP 114 was further oxidized by ring-opening of the pyrimidine ring to form a product TP 165 (m/z 165) (Zhang et al. 2020a). And TP 97 could be further transformed to TP 126 (m/z 126) by free radicals (Ma et al. 2021). For the second possible route, the nucleophilic attack reaction was first initiated on the carbon of the aniline-based positive ion having positive charge near the S–N bond, where the nitrogen on the highly electronegative pyrimidine annulus played as a nucleophile, leading to an intermolecular smile-type rearrangement. Then the SO2 extrusion reaction was triggered to form TP 187 (m/z 187) (Tang et al. 2023). TP 187 could be transformed to a product TP 199 (m/z 199) by amino oxidation reaction. The third likely way was the attack of N–C bond in the SDZ substituent by SK-C/PDS*. First, the N–C bond of SDZ was broke, followed by hydroxylation to form the compound TP 286 (m/z 286). Under constant attack, TP 286 could be converted to TP 200 (m/z 200) by breaking the pyrimidine ring and N–C bond (Lu et al. 2020b). According to previous studies, the formation of TP 214 (m/z 214) derived from the cleavage of the pyrimidine ring. In the fourth route, the SK-C/PDS* might break the pyrimidine ring in the SDZ, with consequent hydroxylation, leading to the production of intermediate TP 227 (m/z 227) (Lu et al. 2020b; Ma et al. 2021; Zhang et al. 2020a). In addition, the parent substance could be first protonated, and then the protonated SDZ was likely to undergo hydroxylation to generate TP 265 (m/z 265) (Sun et al. 2021).

ECOSAR was used to calculate the potential ecological toxicity of SDZ and its different TPs to three nutritional aquatic organisms (fish, fleas and green algae). As shown in Fig. 7, based on the classification of Global Chemical Classification and Labelling Coordination System, SDZ was ranged as extremely toxic to daphnid with a chronic toxicity value of 0.15 mg L−1. Compared with parent SDZ, most TPs produced were less toxic or harmless in acute and chronic toxicity (Ma et al. 2021). Though TP 97 was more toxic to Daphnia than SDZ, its conversion to TP 126 was much less toxic to all species. Similarly, TP 187 was more toxic than the original SDZ molecule, but its conversion product TP 199 had minimal harm to aquatic organisms.

4 Conclusions

In this study, several porous carbonaceous catalysts were synthesized by utilizing different hard templates and activating agent treatments. Among them, SK-C synthesized using KCl and Na2S2O3 obtained the best PDS activation performance for SDZ degradation. The SSA and C-sp3 content of SK-C had a cooperative effect on its exceptional capacity for activating PDS to degrade SDZ in a quantitative relationship. In addition, negligible effects of ·OH, SO4.− and 1O2 were revealed by scavenger and EPR tests. Through a series of electrochemical and spectroscopy technologies, the main degradation pathway of SDZ by SK-C activated PDS was discovered to be a single electron transfer pathway from SDZ to inner-sphere bound catalyst/PDS*. The SDZ degradation was discovered by four main pathways including S–N bond cleavage, Smile rearrangement, N–C bond cleavage, and pyrimidine ring open and hydroxylation and thirteen transformation products were identified with much less toxicity than the SDZ. This research not only provided a green approach for fabricating porous biochar but also greatly deepened the primary understanding of mediated electron transfer pathway in the porous carbonaceous materials and PDS degradation system.

Availability of data and materials

Data can be found in Additional file 1. Additional file associated with this article can be found in the online version.

References

Anfar Z, El Fakir AA, Zbair M, Hafidi Z, Amedlous A, Majdoub M, Farsad S, Amjlef A, Jada A, El Alem N (2021) New functionalization approach synthesis of sulfur doped, nitrogen doped and Co-doped porous carbon: superior metal-free carbocatalyst for the catalytic oxidation of aqueous organics pollutants. Chem Eng J 405:126660. https://doi.org/10.1016/j.cej.2020.126660

Díez N, Ferrero GA, Sevilla M, Fuertes AB (2019) A simple and general approach for in situ synthesis of sulfur–porous carbon composites for lithium–sulfur batteries. Sustain Energy Fuels 3:3498–3509. https://doi.org/10.1039/c9se00722a

Duan X, Sun H, Wang S (2018) Metal-free carbocatalysis in advanced oxidation reactions. Acc Chem Res 51:678–687. https://doi.org/10.1021/acs.accounts.7b00535

Fechler N, Fellinger TP, Antonietti M (2013) “Salt templating”: a simple and sustainable pathway toward highly porous functional carbons from ionic liquids. Adv Mater 25:75–79. https://doi.org/10.1002/adma.201203422

Feng Y, Lee PH, Wu D, Shih K (2017) Surface-bound sulfate radical-dominated degradation of 1,4-dioxane by alumina-supported palladium (Pd/Al2O3) catalyzed peroxymonosulfate. Water Res 120:12–21. https://doi.org/10.1016/j.watres.2017.04.070

Fu H, Zhao P, Xu S, Cheng G, Li Z, Li Y, Li K, Ma S (2019) Fabrication of Fe3O4 and graphitized porous biochar composites for activating peroxymonosulfate to degrade p-hydroxybenzoic acid: insights on the mechanism. Chem Eng J 375:121980. https://doi.org/10.1016/j.cej.2019.121980

Fuertes AB, Ferrero GA, Diez N, Sevilla M (2018) A green route to high-surface area carbons by chemical activation of biomass-based products with sodium thiosulfate. ACS Sustain Chem Eng 6:16323–16331. https://doi.org/10.1021/acssuschemeng.8b03264

Gao Y, Li T, Zhu Y, Chen Z, Liang J, Zeng Q, Lyu L, Hu C (2020) Highly nitrogen-doped porous carbon transformed from graphitic carbon nitride for efficient metal-free catalysis. J Hazard Mater 393:121280. https://doi.org/10.1016/j.jhazmat.2019.121280

Guo W, Zhao Q, Du J, Wang H, Li X, Ren N (2020) Enhanced removal of sulfadiazine by sulfidated ZVI activated persulfate process: performance, mechanisms and degradation pathways. Chem Eng J 388:124303. https://doi.org/10.1016/j.cej.2020.124303

Han Y, Gan L, Gong H, Han J, Qiao W, Xu L (2022) Photoactivation of peroxymonosulfate by wood pulp cellulose biochar/g-C3N4 composite for diclofenac degradation: the radical and nonradical pathways. Biochar 4:1–19. https://doi.org/10.1007/s42773-022-00155-0

Huang KZ, Zhang H (2019) Direct electron-transfer-based peroxymonosulfate activation by iron-doped manganese oxide (delta-MnO2) and the development of galvanic oxidation processes (GOPs). Environ Sci Technol 53:12610–12620. https://doi.org/10.1021/acs.est.9b03648

Huo S, Song X, Zhao Y, Ni W, Wang H, Li K (2020a) Insight into the significant contribution of intrinsic carbon defects for the high-performance capacitive desalination of brackish water. J Mater Chem A 8:19927–19937. https://doi.org/10.1039/d0ta07014a

Huo X, Zhou P, Zhang J, Liu Y, Cheng X, Liu Y, Li W, Zhang Y (2020b) N, S-Doped porous carbons for persulfate activation to remove tetracycline: nonradical mechanism. J Hazard Mater 391:122055. https://doi.org/10.1016/j.jhazmat.2020.122055

Jian Z, Luo W, Ji X (2015) Carbon electrodes for K-Ion batteries. J Am Chem Soc 137:11566–11569. https://doi.org/10.1021/jacs.5b06809

Jin H, Cang Z, Ding W, Wu W, Ma H, Wang C, Qi Z, Li Z, Zhang L (2021) Oxidative removal of antibiotic resistant E. coli by sulfidated zero-valent iron: homogeneous vs heterogeneous activation. J Hazard Mater 408:124411. https://doi.org/10.1016/j.jhazmat.2020.124411

Jin X, Liu R, Wang H, Han L, Qiu M, Hu B (2022) Functionalized porous nanoscale Fe3O4 particles supported biochar from peanut shell for Pb (II) ions removal from landscape wastewater. Environ Sci Pollut Res Int 29:37159–37169. https://doi.org/10.1007/s11356-021-18432-z

Kasera N, Kolar P, Hall SG (2022) Nitrogen-doped biochars as adsorbents for mitigation of heavy metals and organics from water: a review. Biochar 4:17. https://doi.org/10.1007/s42773-022-00145-2

Leng L, Yang L, Lei X, Zhang W, Ai Z, Yang Z, Zhan H, Yang J, Yuan X, Peng H, Li H (2022) Machine learning predicting and engineering the yield, N content, and specific surface area of biochar derived from pyrolysis of biomass. Biochar 4:63. https://doi.org/10.1007/s42773-022-00183-w

Li W, Liu B, Wang Z, Wang K, Lan Y, Zhou L (2020) Efficient activation of peroxydisulfate (PDS) by rice straw biochar modified by copper oxide (RSBC-CuO) for the degradation of phenacetin (PNT). Chem Eng J 395:125094. https://doi.org/10.1016/j.cej.2020.125094

Li B, Zhang Y, Xu J, Mei Y, Fan S, Xu H (2021a) Effect of carbonization methods on the properties of tea waste biochars and their application in tetracycline removal from aqueous solutions. Chemosphere 267:129283. https://doi.org/10.1016/j.chemosphere.2020.129283

Li X, Wang J, Duan X, Li Y, Fan X, Zhang G, Zhang F, Peng W (2021b) Fine-tuning radical/nonradical pathways on graphene by porous engineering and doping strategies. ACS Catal 11:4848–4861. https://doi.org/10.1021/acscatal.0c05089

Li K, Xu S, Liu X, Li H, Zhan S, Ma S, Huang Y, Liu S, Zhuang X (2022) The organic contaminants degradation in Mn-NRGO and peroxymonosulfate system: the significant synergistic effect between Mn nanoparticles and doped nitrogen. Chem Eng J 438:135630. https://doi.org/10.1016/j.cej.2022.135630

Liang J, Duan X, Xu X, Chen K, Zhang Y, Zhao L, Qiu H, Wang S, Cao X (2021) Persulfate oxidation of sulfamethoxazole by magnetic iron-char composites via nonradical pathways: Fe(IV) versus surface-mediated electron transfer. Environ Sci Technol 55:10077–10086. https://doi.org/10.1021/acs.est.1c01618

Lin K, Zhang Z (2017) Degradation of Bisphenol A using peroxymonosulfate activated by one-step prepared sulfur-doped carbon nitride as a metal-free heterogeneous catalyst. Chem Eng J 313:1320–1327. https://doi.org/10.1016/j.cej.2016.11.025

Liu R, Zhang Y, Hu B, Wang H (2022) Improved Pb (II) removal in aqueous solution by sulfide@biochar and polysaccharose-FeS@ biochar composites: efficiencies and mechanisms. Chemosphere 287:132087. https://doi.org/10.1016/j.chemosphere.2021.132087

Lu L, Yu W, Wang Y, Zhang K, Zhu X, Zhang Y, Wu Y, Ullah H, Xiao X, Chen B (2020a) Application of biochar-based materials in environmental remediation: from multi-level structures to specific devices. Biochar 2:1–31. https://doi.org/10.1007/s42773-020-00041-7

Lu J, Wang T, Zhou Y, Cui C, Ao Z, Zhou Y (2020b) Dramatic enhancement effects of l-cysteine on the degradation of sulfadiazine in Fe3+/CaO2 system. J Hazard Mater 383:121133. https://doi.org/10.1016/j.jhazmat.2019.121133

Luo Y, Wang Y, Zhu Y, Xue M, Zheng A, Han Y, Yin Z, Hong Z, Xie C, Li X, Lei S, Gao B (2022) Ball-milled bismuth oxychloride/biochar nanocomposites with rich oxygen vacancies for reactive red-120 adsorption in aqueous solution. Biochar 4:21. https://doi.org/10.1007/s42773-022-00147-0

Ma D, Yang Y, Liu B, Xie G, Chen C, Ren N, Xing D (2021) Zero-valent iron and biochar composite with high specific surface area via K2FeO4 fabrication enhances sulfadiazine removal by persulfate activation. Chem Eng J 408:127992. https://doi.org/10.1016/j.cej.2020.127992

Meng Q, Zhang Y, Meng D, Liu X, Zhang Z, Gao P, Lin A, Hou L (2020) Removal of sulfadiazine from aqueous solution by in-situ activated biochar derived from cotton shell. Environ Res 191:110104. https://doi.org/10.1016/j.envres.2020.110104

Pei X, Peng X, Jia X, Wong PK (2021) N-doped biochar from sewage sludge for catalytic peroxydisulfate activation toward sulfadiazine: efficiency, mechanism, and stability. J Hazard Mater 419:126446. https://doi.org/10.1016/j.jhazmat.2021.126446

Peng J, Zhou P, Zhou H, Liu W, Zhang H, Zhou C, Lai L, Ao Z, Su S, Lai B (2021) Insights into the electron-transfer mechanism of permanganate activation by graphite for enhanced oxidation of sulfamethoxazole. Environ Sci Technol 55:9189–9198. https://doi.org/10.1021/acs.est.1c00020

Qi F, Zeng Z, Wen Q, Huang Z (2021) Enhanced organics degradation by three-dimensional (3D) electrochemical activation of persulfate using sulfur-doped carbon particle electrode: the role of thiophene sulfur functional group and specific capacitance. J Hazard Mater 416:125810. https://doi.org/10.1016/j.jhazmat.2021.125810

Qiu M, Hu B, Chen Z, Yang H, Zhuang L, Wang X (2021) Challenges of organic pollutant photocatalysis by biochar-based catalysts. Biochar 3:117–123. https://doi.org/10.1007/s42773-021-00098-y

Qiu M, Liu L, Ling Q, Cai Y, Yu S, Wang S, Fu D, Hu B, Wang X (2022) Biochar for the removal of contaminants from soil and water: a review. Biochar 4:19. https://doi.org/10.1007/s42773-022-00146-1

Raymundo-Piñero E, Azaïs P, Cacciaguerra T, Cazorla-Amorós D, Linares-Solano A, Béguin F (2005) KOH and NaOH activation mechanisms of multiwalled carbon nanotubes with different structural organisation. Carbon 43:786–795. https://doi.org/10.1016/j.carbon.2004.11.005

Ren W, Xiong L, Yuan X, Yu Z, Zhang H, Duan X, Wang S (2019) Activation of peroxydisulfate on carbon nanotubes: electron-transfer mechanism. Environ Sci Technol 53:14595–14603. https://doi.org/10.1021/acs.est.9b05475

Ren W, Cheng C, Shao P, Luo X, Zhang H, Wang S, Duan X (2022) Origins of electron-transfer regime in persulfate-based nonradical oxidation processes. Environ Sci Technol 56:78–97. https://doi.org/10.1021/acs.est.1c05374

Saha B, Sengupta S (2015) Influence of different hydrocarbon components in fuel on the oxidative desulfurisation of thiophene: deactivation of catalyst. Fuel 150:679–686. https://doi.org/10.1016/j.fuel.2015.02.078

Sanchez M, Vicerich M, Mazzieri V, Gioria E, Gutierrez L, Pieck C (2019) Deactivation study of Ru-Sn-Al2O3 catalysts during selective hydrogenation of methyl oleate to fatty alcohol. Can J Chem Eng 97:23333–23339. https://doi.org/10.1002/cjce.23444

Sevilla M, Fuertes AB (2013) A general and facile synthesis strategy towards highly porous carbons: carbonization of organic salts. J Hazard Mater A 1:13738–13741. https://doi.org/10.1039/c3ta13149a

Sevilla M, Diez N, Fuertes AB (2021) More sustainable chemical activation strategies for the production of porous carbons. ChemSusChem 14:94–117. https://doi.org/10.1002/cssc.202001838

Sun P, Li Y, Meng T, Zhang R, Song M, Ren J (2018) Removal of sulfonamide antibiotics and human metabolite by biochar and biochar/H2O2 in synthetic urine. Water Res 147:91–100. https://doi.org/10.1016/j.watres.2018.09.051

Sun F, Chen T, Liu H, Zou X, Zhai P, Chu Z, Shu D, Wang H, Chen D (2021) The pH-dependent degradation of sulfadiazine using natural siderite activating PDS: the role of singlet oxygen. Sci Total Environ 784:147117. https://doi.org/10.1016/j.scitotenv.2021.147117

Sun F, Chen T, Chu Z, Zhai P, Liu H, Wang Q, Zou X, Chen D (2022) The synergistic effect of calcite and Cu2+ on the degradation of sulfadiazine via PDS activation: a role of Cu(III). Water Res 219:118529. https://doi.org/10.1016/j.watres.2022.118529

Tang X, Ma S, Xu S, Yang Q, Huang Y, Wang J, Hua D (2023) Effects of different pretreatment strategies during porous carbonaceous materials fabrication on their peroxydisulfate activation for organic pollutant degradation: focus on mechanism. Chem Eng J 451:138576. https://doi.org/10.1016/j.cej.2022.138576

Tian W, Zhang H, Duan X, Sun H, Tade MO, Ang HM, Wang S (2016) Nitrogen- and sulfur-codoped hierarchically porous carbon for adsorptive and oxidative removal of pharmaceutical contaminants. ACS Appl Mater Interfaces 8:7184–7193. https://doi.org/10.1021/acsami.6b01748

Wang H, Guo W, Liu B, Wu Q, Luo H, Zhao Q, Si Q, Sseguya F, Ren N (2019a) Edge-nitrogenated biochar for efficient peroxydisulfate activation: an electron transfer mechanism. Water Res 160:405–414. https://doi.org/10.1016/j.watres.2019.05.059

Wang W, Shang L, Chang G, Yan C, Shi R, Zhao Y, Waterhouse GIN, Yang D, Zhang T (2019b) Intrinsic carbon-defect-driven electrocatalytic reduction of carbon dioxide. Adv Mater 31:1808276. https://doi.org/10.1002/adma.201808276

Wang B, Li Q, Lv Y, Fu H, Liu D, Feng Y, Xie H, Qu H (2021) Insights into the mechanism of peroxydisulfate activated by magnetic spinel CuFe2O4/SBC as a heterogeneous catalyst for bisphenol S degradation. Chem Eng J 416:129162. https://doi.org/10.1016/j.cej.2021.129162

Wang G, Ge L, Liu Z, Zhu X, Yang S, Wu K, Jin P, Zeng X, Zhang X (2022b) Activation of peroxydisulfate by defect-rich CuO nanoparticles supported on layered MgO for organic pollutants degradation: an electron transfer mechanism. Chem Eng J 431:134026. https://doi.org/10.1016/j.cej.2021.134026

Wang T, Xue L, Liu Y, Fang T, Zhang L, Xing B (2022c) Insight into the significant contribution of intrinsic defects of carbon-based materials for the efficient removal of tetracycline antibiotics. Chem Eng J 435:134822. https://doi.org/10.1016/j.cej.2022.134822

Wang T, Xue L, Liu Y, Fang T, Zhang L, Xing B (2022a) Ring defects-rich and pyridinic N-doped graphene aerogel as floating adsorbent for efficient removal of tetracycline: evidence from NEXAFS measurements and theoretical calculations. J Hazard Mater 435:128940. https://doi.org/10.1016/j.jhazmat.2022.128940

Yang Y, He M, Wu T, Hao A, Zhang S, Chen Y, Zhou S, Zhen L, Wang R, Yuan Z, Deng L (2018) Sulfadiazine oxidation by permanganate: kinetics, mechanistic investigation and toxicity evaluation. Chem Eng J 349:56–65. https://doi.org/10.1016/j.cej.2018.05.018

Yang M, Ren X, Hu L, Guo W, Zhan J (2021) Facet-controlled activation of persulfate by goethite for tetracycline degradation in aqueous solution. Chem Eng J 412:1808276. https://doi.org/10.1016/j.cej.2021.128628

Yang B, Dai J, Zhao Y, Wu J, Ji C, Zhang Y (2022) Advances in preparation, application in contaminant removal, and environmental risks of biochar-based catalysts: a review. Biochar 4:1–31. https://doi.org/10.1007/s42773-022-00169-8

Yin R, Guo W, Wang H, Du J, Wu Q, Chang J, Ren N (2019) Singlet oxygen-dominated peroxydisulfate activation by sludge-derived biochar for sulfamethoxazole degradation through a nonradical oxidation pathway: performance and mechanism. Chem Eng J 357:589–599. https://doi.org/10.1016/j.cej.2018.09.184

Zhang T, Zhu H, Croue JP (2013) Production of sulfate radical from peroxymonosulfate induced by a magnetically separable CuFe2O4 spinel in water: efficiency, stability, and mechanism. Environ Sci Technol 47:2784–2791. https://doi.org/10.1021/es304721g

Zhang W, Fernandez-Fueyo E, Ni Y, van Schie M, Gacs J, Renirie R, Wever R, Mutti FG, Rother D, Alcalde M, Hollmann F (2018) Selective aerobic oxidation reactions using a combination of photocatalytic water oxidation and enzymatic oxyfunctionalisations. Nat Catal 1:55–62. https://doi.org/10.1038/s41929-017-0001-5

Zhang R, Li Y, Wang Z, Tong Y, Sun P (2020a) Biochar-activated peroxydisulfate as an effective process to eliminate pharmaceutical and metabolite in hydrolyzed urine. Water Res 177:115809. https://doi.org/10.1016/j.watres.2020.115809

Zhang H, Zhou C, Zeng H, Deng L, Shi Z (2020b) Can Cu2ZnSnS4 nanoparticles be used as heterogeneous catalysts for sulfadiazine degradation? J Hazard Mater 395:122613. https://doi.org/10.1016/j.jhazmat.2020.122613

Zhao Y, Yu L, Song C, Chen Z, Meng F, Song M (2022) Selective degradation of electron-rich organic pollutants induced by CuO@Biochar: the key role of outer-sphere interaction and singlet oxygen. Environ Sci Technol 56:10710–10720. https://doi.org/10.1021/acs.est.2c01759

Zhu K, Wang X, Geng M, Chen D, Lin H, Zhang H (2019) Catalytic oxidation of clofibric acid by peroxydisulfate activated with wood-based biochar: effect of biochar pyrolysis temperature, performance and mechanism. Chem Eng J 374:1253–1263. https://doi.org/10.1016/j.cej.2019.06.006

Zhu H, Liu X, Jiang Y, Lin D, Yang K (2022) Sorption kinetics of 1,3,5-trinitrobenzene to biochars produced at various temperatures. Biochar 4:1–13. https://doi.org/10.1007/s42773-022-00157-y

Acknowledgements

Not applicable.

Funding

This work is supported by the Youth Program of National Natural Science Foundation of China (41907150), the Special Fund for Topnotch Talents in Henan Agricultural University (30500600), and Open Project of Key Laboratory of Environmental Biotechnology, CAS (kf2021001).

Author information

Authors and Affiliations

Contributions

SW: conceptualization, methodology, investigation, data curation, formal analysis, writing—original draft, visualization. SM: conceptualization, methodology, resources, funding acquisition, writing—review and editing, supervision, investigation. YH, KG, SZ, JW, BG, XT, RD, QZ, SX, XZ: investigation, writing—review and editing. All authors read and approved the final manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Handling Editor: Jun Meng

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Additional file 1: Text S1.

The detailed operation methods of linear sweep voltammetry (LSV) and galvanic oxidation process (GOP). Text S2. The detailed operation methods of in-situ EPR capture. Text S3. The equation of pseudo-first-order kinetic model. Table S1. Textural properties of different samples. Table S2. HPLC conditions for different substrates. Table S3. Toxicity classification based on the Global System for Classification and Labelling of Chemicals. Figure S1. XRD spectra of S-C, K-C and SK-C. Figure S2. XPS spectra of C 1s of catalysts (a–h). Figure S3. The absorption (a) efficiency of SDZ in various reaction systems and the corresponding kobs (b) of different catalysts. Figure S4. The effect of catalyst dosage (a) and PDS concentration (b) on SDZ degradation efficiency in SK-C/PDS system. Figure S5. The effect of NO3– (a), H2PO4– (b), Cl– (c) and HCO3– (d) on SDZ degradation efficiency in SK-C/PDS system. Figure S6. EPR of different systems in the presence of DMPO (in methanol). Figure S7. The effect of p-BQ on the adsorption efficiency of SDZ (a) and the consumption of PDS (b) in different systems. Figure S8. Premixed test (a) and the corresponding kobs of different treatments (b). Figure S9. SDZ degradation and PDS consumption in the GOP system. Figure S10. The linear relationship between kobs and the SSA. Figure S11. The linear relationship between kobs and ID/IG. Figure S12. The linear relationship between kobs and C-sp3 content (at%). Figure S13. The degradation of SDZ in the used SK-C/PDS system and after methyl alcohol washing SK-C/PDS system. Figure S14. FTIR of the fresh and used SK-C. Figure S15. Mass spectra of SDZ.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Wang, S., Huang, Y., Ma, S. et al. A green strategy for porous biochar fabrication with superior capacity for peroxydisulfate activation to degrade sulfadiazine: the cooperative role of C-sp3 and specific surface area. Biochar 5, 24 (2023). https://doi.org/10.1007/s42773-023-00223-z

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s42773-023-00223-z