Abstract

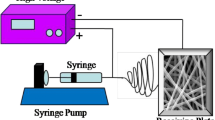

Micro- and nano-fibers of shape memory polymers (SMP) offer multiple advantages like high specific surface area, porosity, and intelligence, and are suitable for biomedical applications. In this study, biodegradable poly (p-dioxanone) (PPDO) materials were incorporated to improve the brittleness of shape memory polylactic acid (PLA), and plasticizers were used to reduce the transition temperature of SMP composites such that their transitions could be induced close to body temperature. Furthermore, an electrostatic spinning technology was applied to prepare SMP fibers with wrinkled structures and regulate their microstructures and morphologies such that the intelligent transition of wrinkled and smooth morphologies can be achieved on the fiber surface. The application of this controllable-morphology fiber membrane in intelligent controlled drug release and scar inhibition after Ahmed Glaucoma Valve (AGV) implantation was also studied. The drug release from the stretched and deformed drug-loaded fiber membranes was faster than those from membranes with the original shape. This membrane with micro- and nano-fibers had good anti-scarring effects that improved after drug loading. The achievement of intelligent controlled drug release and the evident anti-scarring effects of the membrane broaden the application of SMP fibers in the biomedical field.

Graphical Abstract

Similar content being viewed by others

References

Wu S, Guo J, Wang Y, Xie H, Zhou S. Cryopolymerized polyampholyte gel with antidehydration, self-healing, and shape-memory properties for sustainable and tunable sensing electronics. ACS Appl Mater Interfaces 2022;14:42317–27.

Huang J, Wang Y, Guo J, Wu S, Xie H, Zhou S. Anisotropic conductive shape-memory aerogels as adaptive reprogrammable wearable electronics for accurate long-term pressure sensing. J Mater Chem A 2022;10:3933–43.

Li C, Cui W. 3D Bioprinting of cell-laden constructs for regenerative medicine. Eng Regen 2021;2:195–205.

Zhang F, Xia Y, Liu Y, Leng J. Nano/microstructures of shape memory polymers: from materials to applications. Nanoscale Horiz 2020;5:1155–73.

Zhang F, Wang L, Zheng Z, Liu Y, Leng J. Magnetic programming of 4D printed shape memory composite structures. Compos Part Appl Sci Manuf 2019;125:105571.

Zhang F, Zhao T, Ruiz-Molina D, Liu Y, Roscini C, Leng J, Smoukov SK. Shape memory polyurethane microcapsules with active deformation. ACS Appl Mater Interfaces 2020;12:47059–64.

Allonas X, Pierrel J, Ibrahim A, Croutxé-Barghorn C. On-demand photopolymerization of fiber-reinforced polymers exhibiting the shape memory effect. Polymers 2021;13:4300.

Akman R, Ramaraju H, Hollister SJ. Development of photocrosslinked poly(glycerol dodecanedioate)—a biodegradable shape memory polymer for 3D-printed tissue engineering applications. Adv Eng Mater 2021;23:2100219.

Sarvari R, Keyhanvar P, Agbolaghi S, Gholami Farashah MS, Sadrhaghighi A, Nouri M, Roshangar L. Shape-memory materials and their clinical applications. Int J Polym Mater Polym Biomater 2022;71:315–35.

Yang X, Wang L, Wang W, Chen H, Yang G, Zhou S. Triple shape memory effect of star-shaped polyurethane. ACS Appl Mater Interfaces 2014;6:6545–54.

Furtado M, Chen L, Chen Z, Chen A, Cui W. Development of fish collagen in tissue regeneration and drug delivery. Eng Regen 2022;3:217–31.

Chen H, Zhang F, Sun Y, Sun B, Gu B, Leng J, Zhang W. Electrothermal shape memory behavior and recovery force of four-dimensional printed continuous carbon fiber/polylactic acid composite. Smart Mater Struct 2021;30:025040.

Cha DI, Kim HY, Lee KH, Jung YC, Cho JW, Chun BC. Electrospun nonwovens of shape-memory polyurethane block copolymers. J Appl Polym Sci 2005;96:460–5.

Gong T, Li W, Chen H, Wang L, Shao S, Zhou S. Remotely actuated shape memory effect of electrospun composite nanofibers. Acta Biomater 2012;8:1248–59.

Zhang FH, Zhang ZC, Luo CJ, Lin I-T, Liu Y, Leng J, Smoukov SK. Remote, fast actuation of programmable multiple shape memory composites by magnetic fields. J Mater Chem C 2015;3:11290–3.

Lv H, Tang D, Sun Z, Gao J, Yang X, Jia S, Peng J. Electrospun PCL-based polyurethane/HA microfibers as drug carrier of dexamethasone with enhanced biodegradability and shape memory performances. Colloid Polym Sci 2020;298:103–11.

Chen W, Xu Y, Liu Y, Wang Z, Li Y, Jiang G, Mo X, Zhou G. Three-dimensional printed electrospun fiber-based scaffold for cartilage regeneration. Mater Des 2019;179:107886.

Liverani L, Liguori A, Zezza P, Gualandi C, Toselli M, Boccaccini AR, Focarete ML. Nanocomposite electrospun fibers of poly(ε-caprolactone)/bioactive glass with shape memory properties. Bioact Mater 2022;11:230.

Yao Y, Xu Y, Wang B, Yin W, Lu H. Recent development in electrospun polymer fiber and their composites with shape memory property: a review. Pigment Resin Technol 2018;47:47–54.

Shirole A, Sapkota J, Foster EJ, Weder C. Shape memory composites based on electrospun poly(vinyl alcohol) fibers and a thermoplastic polyether block amide elastomer. ACS Appl Mater Interfaces 2016;8:6701–8.

Zhang F, Zhang Z, Liu Y, Leng J. Shape memory properties of electrospun nafion nanofibers. Fibers Polym 2014;15:534–9.

Xue J, Wu T, Dai Y, Xia Y. Electrospinning and electrospun nanofibers: methods, materials, and applications. Chem Rev 2019;119:5298–415.

Qi X, Dong Y, Islam MZ, Zhu Y, Fu Y, Fu S-Y. Excellent triple-shape memory effect and superior recovery stress of ethylene-vinyl acetate copolymer fiber. Compos Sci Technol 2021;203:108609.

Zhang C, Yuan X, Wu L, Han Y, Sheng J. Study on morphology of electrospun poly(vinyl alcohol) mats. Eur Polym J 2005;41:423–32.

Gong T, Zhao K, Wang W, Chen H, Wang L, Zhou S. Thermally activated reversible shape switch of polymer particles. J Mater Chem B 2014;2:6855–66.

Liu C, Xu X, Cui W, Zhang H. Metal-organic framework (mof)-based biomaterials in bone tissue engineering. Eng Regen 2021;2:105–8.

Wang L, Zhang F, Liu Y, Leng J. Shape memory polymer fibers: materials, structures, and applications. Adv Fiber Mater 2022;4:5–23.

Guo X, Wei X, Chen Z, Zhang X, Yang G, Zhou S. Multifunctional nanoplatforms for subcellular delivery of drugs in cancer therapy. Prog Mater Sci 2020;107:100599.

Sun J, Peng B, Lu Y, Zhang X, Wei J, Zhu C, Yu Y. A photoorganizable triple shape memory polymer for deployable devices. Small 2022;18:2106443.

Lv J, Liu Y, Wei J, Chen E, Qin L, Yu Y. Photocontrol of fluid slugs in liquid crystal polymer microactuators. Nature 2016;537:179–84.

Chen G, Dong J, Xu X, Zou W, Jin B, Peng W, Zhao Q, Xie T, Zheng N. Converse two-way shape memory effect through a dynamic covalent network design. J Mater Chem A 2022;10:10350–4.

Zhao Q, Qi HJ, Xie T. Recent progress in shape memory polymer: new behavior, enabling materials, and mechanistic understanding. Prog Polym Sci 2015;49–50:79–120.

Wei W, Zhang P, Cao F, Liu J, Qian K, Pan D, Yao Y, Li W. Ultrathin Flexible electrospun EVA nanofiber composite with electrothermally-driven shape memory effect for electromagnetic interference shielding. Chem Eng J 2022;446:137135.

Zhang Q, Rudolph T, Benitez AJ, Gould OEC, Behl M, Kratz K, Lendlein A. Temperature-controlled reversible pore size change of electrospun fibrous shape-memory polymer actuator based meshes. Smart Mater Struct 2019;28:055037.

Zhao J, Cui W. Functional electrospun fibers for local therapy of cancer. Adv Fiber Mater 2020;2:229–45.

Wang W, Yu A, Zhai J, Wang ZL. Recent progress of functional fiber and textile triboelectric nanogenerators: towards electricity power generation and intelligent sensing. Adv Fiber Mater 2021;3:394–412.

Yang X, Li L, Yang D, Nie J, Ma G. Electrospun core-shell fibrous 2D scaffold with biocompatible poly(glycerol sebacate) and poly-l-lactic acid for wound healing. Adv Fiber Mater 2020;2:105–17.

Herath M, Epaarachchi J, Islam M, Zhang F, Leng J, Fang L, Yan C, Peng GD, Schade W. Remote actuation of light activated shape memory polymers via d-shaped optical fibres. Smart Mater Struct 2020;29:047001.

Zhang F, Xia Y, Wang L, Liu L, Liu Y, Leng J. Conductive shape memory microfiber membranes with core-shell structures and electroactive performance. ACS Appl Mater Interfaces 2018;10:35526–32.

Lee J, Kang S-K. Principles for controlling the shape recovery and degradation behavior of biodegradable shape-memory polymers in biomedical applications. Micromachines 2021;12:757.

Niiyama E, Tanabe K, Uto K, Kikuchi A, Ebara M. Shape-memory nanofiber meshes with programmable cell orientation. Fibers 2019;7:20.

Wang X, Yan H, Shen Y, Tang H, Yi B, Qin C, Zhang Y. Shape memory and osteogenesis capabilities of the electrospun poly(3-hydroxybutyrate-Co-3-hydroxyvalerate) modified poly(l-lactide) fibrous mats. Tissue Eng Part A 2021;27:142–52.

Luo X, Mather PT. Shape memory assisted self-healing coating. ACS Macro Lett 2013;2:152–6.

Pai C-L, Boyce MC, Rutledge GC. Morphology of porous and wrinkled fibers of polystyrene electrospun from dimethylformamide. Macromolecules 2009;42:2102–14.

Huang T, Zhu Y, Zhu J, Yu H, Zhang Q, Zhu M. Self-reinforcement of light, temperature-resistant silica nanofibrous aerogels with tunable mechanical properties. Adv Fiber Mater 2020;2:338–47.

Guan X, Chen H, Xia H, Fu Y, Qiu Y, Ni Q-Q. Multifunctional Composite nanofibers with shape memory and piezoelectric properties for energy harvesting. J Intell Mater Syst Struct 2020;31:956–66.

Zhang F, Liu K, Pan Z, Cao M, Zhou D, Liu H, Huang Y, Duan X. Effects of rosiglitazone/PHBV drug delivery system on postoperative fibrosis in rabbit glaucoma filtration surgery model. Drug Deliv 2019;26:812–9.

Aydemir Sezer U, Sanko V, Gulmez M, Aru B, Sayman E, Aktekin A, Vardar Aker F, Yanıkkaya Demirel G, Sezer S. Polypropylene composite hernia mesh with anti-adhesion layer composed of polycaprolactone and oxidized regenerated cellulose. Mater Sci Eng C 2019;99:1141–52.

Guner MB, Dalgic AD, Tezcaner A, Yilanci S, Keskin D. A Dual-phase scaffold produced by rotary jet spinning and electrospinning for tendon tissue engineering. Biomed Mater Bristol Engl 2020;15:065014.

Ahn S, Chantre CO, Gannon AR, Lind JU, Campbell PH, Grevesse T, O’Connor BB, Parker KK. Soy protein/cellulose nanofiber scaffolds mimicking skin extracellular matrix for enhanced wound healing. Adv Healthc Mater 2018;7:e1701175.

Johnson R, Ding Y, Nagiah N, Monnet E, Tan W. Coaxially-structured fibres with tailored material properties for vascular graft implant. Mater Sci Eng C Mater Biol Appl 2019;97:1–11.

Acknowledgements

This work was supported by the National Natural Science Foundation of China (Grant No. 11802075, 12072094, 81870654, and 82070956),the Fundamental Research Funds for the Central Universities (No. IR2021106 and IR2021232), and Applied Technology Research and Development Program of Heilongjiang Provincial Science and Technology Department (GA20C008).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors state that there are no conflicts of interest to disclose.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wang, L., Ma, J., Guo, T. et al. Control of Surface Wrinkles on Shape Memory PLA/PPDO Micro-nanofibers and Their Applications in Drug Release and Anti-scarring. Adv. Fiber Mater. 5, 632–649 (2023). https://doi.org/10.1007/s42765-022-00249-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42765-022-00249-1