Abstract

Wearable devices redefine the way people interact with machines. Despite the intensive effort in the design and fabrication of synthetic fibers to improve wearable device properties in terms of electronic and ionic conductivity, stretchability, comfort, and washability, challenges remain in fabricating single fiber materials that optimize all properties simultaneously. In this work, we demonstrate a highly stretchable, ionic, and electronic conductive fabric via (1) the natural nanoscale channels in fibers for effective ion transportation, (2) confining the electronic conductive material with the cellulose fibers, and (3) decoupling the property degradation of the fiber from deformation using the knitted pattern. The hierarchical structure created by cotton fibers can serve as ionic conductive channels as well as a robust multiscale scaffold to host infiltrated electronic conductive materials. Cotton strands with ionic and electronic conductivity can be knitted into fabrics that are highly stretchable (~ 300%). Moreover, high ionic and electronic conductivity are observed with 2 S/m and 5 S/m, respectively, even under a strain of 175%. With the inherent advantages of cotton fabrics such as moisture-wicking, washability, comfort, and light-weightiness for wearable applications, our approach of directly functionalized cellulose can potentially be a promising route towards highly stretchable and wearable mixed conductors.

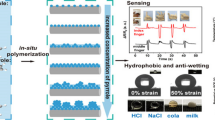

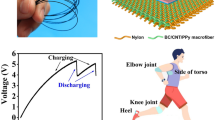

Graphical Abstract

Similar content being viewed by others

References

Li L, Liu Y, Song C, Sheng S, Yang L, Yan Z, Hu DJJ, Sun Q. Wearable alignment-free microfiber-based sensor chip for precise vital signs monitoring and cardiovascular assessment. Adv Fiber Mater 2022;4:475.

Wang J, Wang L, Feng J, Tang C, Sun X, Peng H. Long-term In Vivo Monitoring of Chemicals with Fiber Sensors. Adv Fiber Mater 2021;3:47.

Kang S, Zhao K, Yu D-G, Zheng X, Huang C. Advances in biosensing and environmental monitoring based on electrospun nanofibers. Adv Fiber Mater 2022;4:404.

Wang W, Yu A, Zhai J, Wang ZL. Recent progress of functional fiber and textile triboelectric nanogenerators: towards electricity power generation and intelligent sensing. Adv Fiber Mater 2021;3:394.

Cao R, Pu X, Du X, Yang W, Wang J, Guo H, Zhao S, Yuan Z, Zhang C, Li C, Wang ZL. Screen-printed washable electronic textiles as self-powered touch/gesture tribo-sensors for intelligent human-machine interaction. ACS Nano 2018;12:5190.

Loke G, Alain J, Yan W, Khudiyev T, Noel G, Yuan R, Missakian A, Fink Y. Computing Fabrics. Matter 2020;2:786.

Xue Z, Song H, Rogers JA, Zhang Y, Huang Y. Mechanically guided structural designs in stretchable inorganic electronics. Adv Mater 2020;32:e1902254.

Fan JA, Yeo WH, Su Y, Hattori Y, Lee W, Jung SY, Zhang Y, Liu Z, Cheng H, Falgout L, Bajema M, Coleman T, Gregoire D, Larsen RJ, Huang Y, Rogers JA. Fractal design concepts for stretchable electronics. Nat Commun 2014;5:3266.

Shyu TC, Damasceno PF, Dodd PM, Lamoureux A, Xu L, Shlian M, Shtein M, Glotzer SC, Kotov NA. A Kirigami approach to engineering elasticity in nanocomposites through patterned defects. Nat Mater 2015;14:785.

Xu J, Wu HC, Zhu C, Ehrlich A, Shaw L, Nikolka M, Wang S, Molina-Lopez F, Gu X, Luo S, Zhou D, Kim YH, Wang GN, Gu K, Feig VR, Chen S, Kim Y, Katsumata T, Zheng YQ, Yan H, Chung JW, Lopez J, Murmann B, Bao Z. Multi-scale ordering in highly stretchable polymer semiconducting films. Nat Mater 2019;18:594.

Oh JY, Rondeau-Gagne S, Chiu YC, Chortos A, Lissel F, Wang GN, Schroeder BC, Kurosawa T, Lopez J, Katsumata T, Xu J, Zhu C, Gu X, Bae WG, Kim Y, Jin L, Chung JW, Tok JB, Bao Z. Intrinsically stretchable and healable semiconducting polymer for organic transistors. Nature 2016;539:411.

Wang GJN, Gasperini A, Bao Z. Stretchable polymer semiconductors for plastic electronics. Adv Electron Mater 2018;4:1700429.

Ohayon D, Inal S. Organic bioelectronics: from functional materials to next-generation devices and power sources. Adv Mater 2020;32:e2001439.

Zhu Y, Peng L, Fang Z, Yan C, Zhang X, Yu G. Structural engineering of 2D nanomaterials for energy storage and catalysis. Adv Mater 2018;30:e1706347.

Inal S, Malliaras GG, Rivnay J. Benchmarking organic mixed conductors for transistors. Nat Commun 2017;8:1767.

Han S, Alvi NUH, Granlof L, Granberg H, Berggren M, Fabiano S, Crispin X. A multiparameter pressure-temperature-humidity sensor based on mixed ionic-electronic cellulose aerogels. Adv Sci (Weinh) 2019;6:128.

Tan STM, Gumyusenge A, Quill TJ, LeCroy GS, Bonacchini GE, Denti I, Salleo A. Mixed ionic-electronic conduction, a multifunctional property in organic conductors. Adv Mater 2022;34:e2110406.

Lei Z, Wu P. A highly transparent and ultra-stretchable conductor with stable conductivity during large deformation. Nat Commun 2019;10:3429.

Martin-Martinez FJ. Designing nanocellulose materials from the molecular scale. Proc Natl Acad Sci USA 2018;115:7174.

Li T, Zhang X, Lacey SD, Mi R, Zhao X, Jiang F, Song J, Liu Z, Chen G, Dai J, Yao Y, Das S, Yang R, Briber RM, Hu L. Cellulose ionic conductors with high differential thermal voltage for low-grade heat harvesting. Nat Mater 2019;18:608.

Zhang C, Chen M, Keten S, Coasne B, Derome D, Carmeliet J. Hygromechanical mechanisms of wood cell wall revealed by molecular modeling and mixture rule analysis. Sci Adv 2021;7:1.

Moon RJ, Martini A, Nairn J, Simonsen J, Youngblood J. Cellulose nanomaterials review: structure, properties and nanocomposites. Chem Soc Rev 2011;40:3941.

Varghese AM, Mittal V. Surface modification of natural fibers. In: Shimpi NG, editor. Biodegradable and biocompatible polymer composites. 2018; pp. 115–186.

Han X, Ye Y, Lam F, Pu J, Jiang F. Hydrogen-bonding-induced assembly of aligned cellulose nanofibers into ultrastrong and tough bulk materials. J Mater Chem A Mater 2019;7:27023.

Xie Y, Gao H, Zhang P, Qin C, Nie Y, Liu X. Preparation of degradable wood cellulose films using ionic liquids. ACS Appl Polym Mater 2022;4:3598.

Putnam CD, Hammel M, Hura GL, Tainer JA. X-ray solution scattering (SAXS) combined with crystallography and computation: defining accurate macromolecular structures, conformations and assemblies in solution. Q Rev Biophys 2007;40:191.

Fu K, Yang Z, Pei Y, Wang Y, Xu B, Wang Y, Yang B, Hu L. Designing textile architectures for high energy-efficiency human body sweat- and cooling-management. Adv Fiber Mater 2019;1:61.

Liu X, Miao J, Fan Q, Zhang W, Zuo X, Tian M, Zhu S, Zhang X, Qu L. Recent progress on smart fiber and textile based wearable strain sensors: materials, fabrications and applications. Adv Fiber Mater 2022;4:361.

Chen N, Luo B, Patil AC, Wang J, Gammad GGL, Yi Z, Liu X, Yen SC, Ramakrishna S, Thakor NV. Nanotunnels within poly(3,4-ethylenedioxythiophene)-carbon nanotube composite for highly sensitive neural interfacing. ACS Nano 2020;14:8059.

Li T, Li SX, Kong W, Chen C, Hitz E, Jia C, et al. A nanofluidic ion regulation membrane with aligned cellulose nanofibers. Sci Adv 2019;5:1.

Li T, Chen C, Brozena AH, Zhu JY, Xu L, Driemeier C, Dai J, Rojas OJ, Isogai A, Wagberg L, Hu L. Developing fibrillated cellulose as a sustainable technological material. Nature 2021;590:47.

Ostler D, Kannam SK, Frascoli F, Daivis PJ, Todd BD. Efficiency of electropumping in nanochannels. Nano Lett 2020;20:3396.

Liu M, Weston PJ, Hurt RH. Controlling nanochannel orientation and dimensions in graphene-based nanofluidic membranes. Nat Commun 2021;12:507.

Min SK, Kim WY, Cho Y, Kim KS. Fast DNA sequencing with a graphene-based nanochannel device. Nat Nanotechnol 2011;6:162.

Kobayashi Y, Honjo K, Kitagawa S, Uemura T. Preparation of porous polysaccharides templated by coordination polymer with three-dimensional nanochannels. ACS Appl Mater Interfaces 2017;9:11373.

Zhu Z, Chen Y, Xu Z, Yu Z, Luo X, Zhou J, Tian Y, Jiang L. Super-spreading on superamphiphilic micro-organized nanochannel anodic aluminum oxide surfaces for heat dissipation. iScience 2021;24:102334.

Rivnay J, Inal S, Salleo A, Owens RM, Berggren M, Malliaras GG. Organic electrochemical transistors. Nat Rev Mater 2018;3:17086.

Acknowledgements

The authors acknowledge Dr. Kejie Zhao and Xiaokang Wang for their helpful discussion.

We acknowledge the Start-up fund from Purdue University.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors have no conflict of interest to declare.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Deng, P., Li, X., Wang, Y. et al. Highly Stretchable Ionic and Electronic Conductive Fabric. Adv. Fiber Mater. 5, 198–208 (2023). https://doi.org/10.1007/s42765-022-00208-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42765-022-00208-w