Abstract

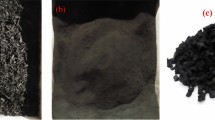

In the past, researchers focused mainly on the potential use of recycled rubber tyres, in the form of aggregates in construction materials. This process provided a viable environmentally friendly solution for the disposal of waste tyres. These days, the use of different shapes and sizes of rubber aggregates in rubberised self-compacting concrete requires extensive durability checks. In this study, work has been carried out on a new self-compacting sand concrete incorporated with rubber aggregates in three different forms and sizes. The sustainability qualification requires the determination of some specific durability indicators such as the resistance to chemical attacks. It was observed that the presence of rubber aggregates reduced the penetration of ions from acid solutions into the concrete matrix. All the studied characteristics were completed by microscopic analysis of adhesion of different rubber aggregates in the cement matrix. SEM analyses showed clear differences in the homogeneity of the rubber particles in the concrete material.

Similar content being viewed by others

References

Gupta T, Siddique S, Sharma RK, Chaudhary S (2019) Behaviour of waste rubber powder and hybrid rubber concrete in aggressive environment. Constr Build Mater 217:283–291

Zaouai S, Tafraoui A, Makani A, Benmerioul F (2020) Hardened and transfer properties of self-compacting concretes containing pre-coated rubber aggregates with crushed dune sand. J Rubber Res 23(1):5–12

Barnabas S, Geethan K, Perumal M (2021) Recycling of waste crumb rubber into a commercial materials. J Rubber Res. https://doi.org/10.1007/s42464-021-00103-w

Oikonomou N, Mavridou S (2009) The use of waste tyre rubber in civil engineering works. Sustainability of construction materials. Woodhead Publishing, pp 213–238

Djadouni H, Trouzine H, Gomes Correia A, Miranda TFDS (2021) 2D numerical analysis of a cantilever retaining wall backfilled with sand–tire chips mixtures. Eur J Environ Civ Eng 25(6):1119–1135

Khaloo AR, Dehestani M, Rahmatabadi P (2008) Mechanical properties of concrete containing a high volume of tire–rubber particles. Waste Manage 28(12):2472–2482

Alaloul WS, Musarat MA, Haruna S, Law K, Rafiq W, Ayub W, Rafiq SW, Ayub S (2021) Mechanical properties of silica fume modified high-volume fly ash rubberized self-compacting concrete. Sustainability 13(10):5571

Medine M (2018) Etude expérimentale des bétons légers incorporant des granulats issus du broyage des pneus usés, Thèse de doctorat, Université Djilali Liabes

Fedroff D, Ahmad S, Savas BZ (1996) Mechanical properties of concrete with ground waste tyre rubber. Transp Res Rec TRR. https://doi.org/10.1177/0361198196153200110

Khatib ZK, Bayomy FM (1999) Rubberized Portland cement concrete. J Mater Civ Eng 11(3):206–213

Ali U, Shahid S, Ali S (2021) Combined effects of styrene–butadiene rubber (SBR) latex and recycled aggregates on compressive strength of concrete. J Rubber Res 24(1):107–120

Cuong Ho A (2010) Optimisation de la composition et caractérisation d'un béton incorporant des granulats issus du broyage de pneus usagés: application aux éléments de grande surface, (Doctoral dissertation, Toulouse, INSA)

Garros M (2007) Composites cimentaires incorporant des granulats caoutchouc issus du broyage de pneus usagés : optimisation de la formulation et caractérisation, PhD thesis, Université Toulouse III Paul Sabatier

Youssf O, Hassanli R, Skinner W, Mills J, Ma X, Zhuge Y, Gravina R (2018) Experimental study on enhancing the main characteristics of crumb rubber concrete, In Proceedings of the Australian Structural Engineering Conference (ASEC 2018)

Li Y, Zhang X, Wang R, Lei Y (2019) Performance enhancement of rubberised concrete via surface modification of rubber: a review. Constr Build Mater 227:116691

Saleh FAH, Kaid N, Ayed K, Soltani R, Kerdal D (2021) Mechanical and physical properties of concrete incorporating rubber. Spec Publ 349:432–445

Aslani F, Ma G, Wan D, Le V (2018) Experimental investigation into rubber granules and their effects on the fresh and hardened properties of self-compacting concrete. J Clean Prod 172:1835–1847

Rahman M, Usman M, Ali AA (2012) Fundamental properties of rubber modified self-compacting concrete (RMSCC). Constr Build Mater 36:630–637

Kim KH, Jeon SE, Kim JK, Yang S (2003) An experimental study on thermal conductivity of concrete. Cem Concr Res 33(3):363–371

Girskas G, Nagrockienė D (2017) Crushed rubber waste impact of concrete basic properties. Constr Build Mater 140:36–42

Thomas B, Chandra-Gupta R, Panicker V (2015) Recycling of waste tire rubber as aggregate in concrete: durability-related performance. J Clean Prod 112:504–513

Thomas B, Chandra-Gupta R, Panicker V (2015) Experimental and modelling studies on high strength concrete containing waste tire rubber. Sustain Cities Soc 19:68–73

IANOR, NA 442 (2003) Liants Hydrauliques - Ciments Courants, Composition, Spécification et Critères de Conformité, Algiers, is equivalent to EN 197-1 (p 15-101-1). https://fr.calameo.com/read/001496329437503a35a15

ASTM-C-1012-89 (1991) Recommended acceptance limits for sulfate resistance of hydraulic cements. The development of ASTM method C 1012, Vol 13, Issue 1. https://www.astm.org/cca10549j.html

ASTM-C267-97 (2001) Standard test methods for chemical resistance of mortars, grouts, and monolithic surfacings and polymer concretes. ASTM International, West Conshohocken

EN12390-4 (2019) Essais pour béton durci - Partie 4 : résistance à la compression - Caractéristiques des machines d'essai, European committee for standardization, p 18

Dezhampanah S, Nikbin I, Charkhtab S, Fakhimi F, Bazkiaei SM, Mohebbi R (2020) Environmental performance and durability of concrete incorporating waste tire rubber and steel fiber subjected to acid attack. J Clean Prod 268:122216

Colom X, Carrillo F, Canavate J (2007) Composites reinforced with reused tyres: surface oxidant treatment to improve the interfacial compatibility. Compos Part A Appl Sci Manuf 38(1):44–50

Ong HR, Khan MR, Yousuf A, Jeyaratnam N, Prasad DR (2015) Effect of waste rubber powder as filler for plywood application. Pol J Chem Technol 17(1):41–47

Hewlett P, Liska M et al (2019) Lea’s chemistry of cement and concrete. Butterworth-Heinemann

Zivica V, Bajza A (2001) Acidic attack of cement based materials—a review.: part 1. Principle of acidic attack. Constr Build Mater 15(8):331–340

Samimi K, Kamali-Bernard S, Maghsoudi AA (2018) Durability of self-compacting concrete containing pumice and zeolite against acid attack, carbonation and marine environment. Constr Build Mater 165:247–263

Lee ST, Moon HY, Swamy RN (2005) Sulfate attack and role of silica fume in resisting strength loss. Cement Concr Compos 27(1):65–76

Kladnig WF (2004) Synthetic Fe2O3 pigments derived by spray roasting hydrochloric solutions-a review. Int J Mater Prod Technol 21(6):555–564

Wu YF, Kazmi S, Munir MJ, Zhou Y, Xing F (2020) Effect of compression casting method on the compressive strength, elastic modulus and microstructure of rubber concrete. J Clean Prod 264:121746

Karakurt C (2015) Microstructure properties of waste tire rubber composites: an overview. J Mater Cycles Waste Manage 17(3):422–433

Acknowledgements

The authors would like to thank Mr. T. Sahraoui of the Laboratory of Electron Microscopy and Material Sciences, Department of Physics, USTO-MB, Oran-Algeria, who facilitated the microscopic analyses (SEM) of the concrete samples of the present research. We also thank staff of the “Laboratory of Mechanical of structures and Stability of Constructions (LM2SC) of Faculty of Architecture and Civil Engineering, USTO-MB and Directorate General for Scientific Research and Technological Development DGSRTD” for providing us with the chemical products.

Funding

The authors declare that they have no relevant financial or non-financial competing interests or personal relationships that could have appeared to influence the work reported in this paper.

The authors declare that they have no sponsor for this scientific paper or any funding from grant-awarding bodies.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Saleh, F.A.H., Kaid, N., Ayed, K. et al. Influence of waste tyre rubber of different aggregate forms and sizes on the sustainable behaviour of self-compacting sand concrete in aggressive environment. J Rubber Res 25, 89–104 (2022). https://doi.org/10.1007/s42464-022-00160-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42464-022-00160-9