Abstract

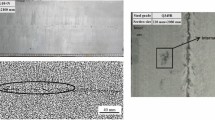

The propagation form of internal cracks induced by continuous casting soft reduction and the control strategy for enhancing the internal quality of 45 steel through industrial trials and a three-dimensional flow–heat transfer–solidification coupling model were investigated. The results showed that the internal cracks induced by soft reduction exhibited a characteristic of being “coarse in the middle and fine at both ends”, and displayed an elliptical arc distribution on the loose side of the strand cross section. The cracks originated within the brittle temperature range and propagated inward to the liquid impenetrable temperature and outward to the zero ductility temperature or below. The control strategy for enhancing the internal quality of the 45 steel strand through soft reduction is to adjust the casting speed or the reduction zone appropriately, ensuring that the central solid fraction of the reduction zone falls within the range of 0.33–0.99. At this point, a reasonable reduction amount is allocated to eliminate the center shrinkage cavities and center segregation, even if it results in minor reduction-induced cracks.

Similar content being viewed by others

References

Y. Chen, G.J. Li, S.B. Yang, M.Y. Zhu, J. Iron Steel Res. Int. 14 (2007) 13–17.

R.S. Chu, Z.J. Li, J.G. Liu, Y. Fan, Y. Liu, C.W. Ma, J. Iron Steel Res. Int. 28 (2021) 272–278.

N. Zong, H. Zhang, M. Wang, Z. Lu, Metall. Res. Technol. 116 (2019) 608.

C. Ji, S. Luo, M. Zhu, ISIJ Int. 54 (2014) 504–510.

H. Sun, L. Li, J. Wang, X. Cheng, F. Zhou, Ironmak. Steelmak. 45 (2018) 708–713.

V. Ludlow, A. Normanton, A. Anderson, M. Thiele, J. Ciriza, J. Laraudogoitia, W. van der Knoop, Ironmak. Steelmak. 32 (2005) 68–74.

H. Sun, L. Li, X. Cheng, W. Qiu, Z. Liu, L. Zeng, Ironmak. Steelmak. 42 (2015) 439–449.

N.K. Arakere, Int. J. Fatigue 93 (2016) 238–249.

K. Liu, Y.H. Chang, Z.G. Han, J.Q. Zhang, J. Iron Steel Res. Int. 20 (2013) 38–47.

X.B. Li, H. Ding, Z.Y. Tang, J.C. He, Int. J. Miner. Metall. Mater. 19 (2012) 21–29.

Y.M. Won, T.J. Yeo, D.J. Seol, K.H. Oh, Metall. Mater. Trans. B 31 (2000) 779–794.

M. Zeze, H. Misumi, S. Nagata, H.G. Suzuki, Tetsu-to-Hagane 87 (2001) 71–76.

R. Thome, K. Harste, ISIJ Int. 46 (2006) 1839–1844.

X. Zhong, J. Liu, Z. Zou, Ironmak. Steelmak. 45 (2018) 714–719.

N. Zong, J. Huang, Y. Liu, T. Jing, Z. Lu, Ironmak. Steelmak. 48 (2021) 944–952.

T.W. Clyne, M. Wolf, W. Kurz, Metall. Trans. B 13 (1982) 259–266.

N. Zong, H. Zhang, Y. Liu, Z. Lu, Ironmak. Steelmak. 46 (2019) 872–885.

W. Wang, L. Ning, R. Bülte, W. Bleck, J. Univ. Sci. Technol. Beijing 15 (2008) 114–119.

M. Reza Aboutalebi, R.I.L. Guthrie, S.H. Seyedein, Appl. Math. Model. 31 (2007) 1671–1689.

P. Wang, Z. Tie, S. Li, P. Lan, H. Tang, J. Zhang, Ironmak. Steelmak. 48 (2021) 779–787.

W.P. Jones, B.E. Launder, Int. J. Heat Mass Transf. 16 (1973) 1119–1130.

K.Y.M. Lai, M. Salcudean, S. Tanaka, R.I.L. Guthrie, Metall. Trans. B 17 (1986) 449–459.

P. Wang, Z. Zhang, Z.P. Tie, M. Qi, P. Lan, S.X. Li, Z.B. Yang, J.Q. Zhang, Metals 9 (2019) 1083.

T. Matsumiya, M. Ito, H. Kajioka, S. Yamaguchi, Y. Nakamura, ISIJ Int. 26 (1986) 540–546.

A. Yamanaka, K. Nakajima, K. Okamura, Ironmak. Steelmak. 22 (1995) 508–512.

L. Li, Z. Zhang, M. Luo, B. Li, P. Lan, J. Zhang, Metals 11 (2020) 9.

Y. Li, L. Li, J. Zhang, Steel Res. Int. 88 (2017) 1700176.

Acknowledgements

This work was financially supported by the National Natural Science Foundation of China (NSFC) (Grant No. U1860111).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wang, P., Chen, L., Tang, Qw. et al. Propagation form of internal cracks induced by continuous casting soft reduction and control strategy for internal quality. J. Iron Steel Res. Int. 31, 622–633 (2024). https://doi.org/10.1007/s42243-023-01144-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42243-023-01144-8