Abstract

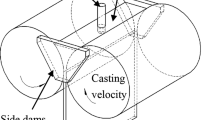

This study first investigated cracks on the surface of an actual steel strip. Formulating the Anand model in ANSYS software, we then simulated the stress field in the molten pool of type 304 stainless steel during the twin-roll casting process. Parameters affecting the stress distribution in the molten pool were analyzed in detail and optimized. After twin-roll casting, a large number of transgranular and intergranular cracks resided on the surface of the thin steel strip, and followed a tortuous path. In the molten pool, stress was enhanced at the exit and at the roller contact positions. The stress at the exit decreased with increasing casting speed and pouring temperature. To ensure high quality of the fabricated strips, the casting speed and pouring temperature should be controlled above 0.7 m/s and 1520°C, respectively.

Similar content being viewed by others

References

J.H. Bae, A.K.P. Rao, K.H. Kim, and N.J. Kim, Cladding of Mg alloy with Al by twin-roll casting, Scripta Mater., 64(2011), No. 9, p. 836.

S. Das, N.S. Lim, J.B. Seol, H.W. Kim, and C.G. Park, Effect of the rolling speed on microstructural and mechanical properties of aluminum-magnesium alloys prepared by twin roll casting, Mater. Des., 31(2010), No. 3, p. 1633.

H. Zhao, P.J. Li, and L.J. He, Kinetics of recrystallization for twin-roll casting AZ31 magnesium alloy during homogenization, Int. J. Miner. Metall. Mater., 18(2011), No. 5, p. 570.

Z.W. Chen, J. Zhao, and X.L. Hao, Microstructure and texture evolution of TRC A8006 alloy by homogenization, Int. J. Miner. Metall. Mater., 20(2013), No. 5, p. 433.

L.L. Chang, J.H. Cho, and S.K. Kang, Microstructure and mechanical properties of twin roll cast AM31 magnesium alloy sheet processed by differential speed rolling, Mater. Des., 34(2012), p. 746.

S. Das, N.S. Lim, H.W. Kim, and C.G. Park, Effect of rolling speed on microstructure and age-hardening behaviour of Al-Mg-Si alloy produced by twin roll casting process, Mater. Des., 32(2011), No. 8–9, p. 4603.

B. Wang, J.Y. Zhang, X.M. Li, and W.H. Qi, Simulation of solidification microstructure in twin-roll casting strip, Comput. Mater. Sci., 49(2010), Suppl., p. S135.

Y. Fang, Z.M. Wang, Q.X. Yang, Y.K. Zhang, L.G. Liu, H.Y. Hu, and Y. Zhang, Numerical simulation of the temperature fields of stainless steel with different roller parameters during twin-roll strip casting, Int. J. Miner. Metall. Mater., 16(2009), No. 3, p. 304.

H. Zhao, P.J. Li, and L.J. He, Coupled analysis of temperature and flow during twin-roll casting of magnesium alloy strip, J. Mater. Process. Technol., 211(2011), No. 6, p. 1197.

Y.C. Miao, X.M. Zhang, H.S. Di, and G.D. Wang, Numerical simulation of the fluid flow, heat transfer, and solidification of twin-roll strip casting, J. Mater. Process. Technol., 174(2006), No. 1–3, p. 7.

X.M. Zhang, Z.Y. Jiang, L.M. Yang, X.H. Liu, G.D. Wang, and A.K. Tieu, Modelling of coupling flow and temperature fields in molten pool during twin-roll strip casting process, J. Mater. Process. Technol., 187–188(2007), p. 339.

J. Zeng, R. Koitzsch, H. Pfeifer, and B. Friedrich, Numerical simulation of the twin-roll casting process of magnesium alloy strip, J. Mater. Process. Technol., 209(2009), No. 5, p. 2321.

A. Hadadzadeh and M.A. Wells, Mathematical modeling of thermo-mechanical behavior of strip during twin roll casting of an AZ31 magnesium alloy, J. Magnesium Alloys, 1(2013), No. 2, p. 101.

S. Amit and S. Yogeshwar, Modeling of thermo-mechanical stresses in twin-roll casting of aluminum alloys, Mater. Trans., 43(2002), No. 2, p. 214.

M. Gupta and Y. Sahai, Mathematical modeling of thermally induced stresses in two-roll melt drag thin strip casting of steel, ISIJ Int., 40(2000), No. 2, p. 137.

P. Zhang, Y.K. Zhang, L.G. Liu, X.J. Ren, Y. Zhang, Y. Fang, and Q.X. Yang, Numerical simulation on the stress field of austenite stainless steel during twin-roll strip casting process, Comput. Mater. Sci., 52(2012), No. 1, p. 61.

D.J. Yu, X. Chen, G. Chen, G.Q. Lu, and Z.Q. Wang, Applying Anand model to low-temperature sintered nanoscale silver paste chip attachment, Mater. Des., 30(2009), No. 10, p. 4574.

L.G. Liu, Q. Li, B. Liao, Y.K. Gao, Y.H. Wang, X.J. Ren, and Q.X. Yang, Stress-strain behaviors simulation of high chromium steel at elevated temperatures, J. Mater. Eng. Perform., 19(2010), No. 7, p. 921.

X.D. Hu and D.Y. Ju, Application of Anand’s constitutive model on twin roll casting process of AZ31 magnesium alloy, Trans. Nonferrous Met. Soc. China, 16(2006), Suppl. 1, p. s586.

L.L. Liu, B. Liao, J. Guo, L.G. Liu, H.Y Hu, Y. Fang, and Q.X. Yang, 3D numerical simulation on thermal flow coupling field of stainless steel during twin-roll casting, J. Mater. Eng. Perform., 23(2014), p. 39.

S.B. Brown, K.H. Kim, and L. Anand, An internal variable constitutive model for hot working of metals, Int. J. Plast., 5(1989), No. 2, p. 95.

A.M. Lush, G. Weber, and L. Anand, An implicit time-integration procedure for a set of internal variable constitutive equations for isotropic elasto-viscoplasticity, Int. J. Plast., 5(1989), No. 5, p. 521.

G.G. Weber, A.M. Lush, A. Zavaliangos, and L. Anand, An objective time-integration procedure for isotropic rate-independent and rate-dependent elastic-plastic constitutive equations, Int. J. Plast., 6(1990), No. 6, p. 701.

B. Forbord, B. Andersson, F. Ingvaldsen, O. Austevik, J.A. Horst, and I. Skauvik, The formation of surface segregates during twin roll casting of aluminium alloys, Mater. Sci. Eng. A, 415(2006), No. 1–2, p. 12.

A. Ramacciotti, Thermo-mechanical behavior of the solidified shell in a “funnel-shaped” mold for continuous casting of thin slabs, Steel Res., 59(1988), p. 438.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Guo, J., Liu, Yy., Liu, Lg. et al. 3D stress simulation and parameter design during twin-roll casting of 304 stainless steel based on the Anand model. Int J Miner Metall Mater 21, 666–673 (2014). https://doi.org/10.1007/s12613-014-0956-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12613-014-0956-z