Abstract

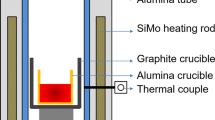

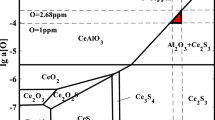

Effects of varied levels of cerium (28 × 10–6, 65 × 10–6 and 150 × 10–6) on inclusions in a high-carbon chromium bearing steel at different stages (before adding cerium, after adding cerium for 1, 5, 10 min and ingot) were studied using laboratory experiments. An automatic scanning electron microscope system with energy-dispersive spectroscopy was used to analyze the amount, composition, size and morphology of inclusions in the steel at different stages. When the cerium content in the molten steel increased from 0 to 150 × 10–6, the evolution sequence of inclusions was as follows: Al2O3 → CeAl11O18 → CeAlO3 → Ce2O2S. After 28 × 10–6 cerium was added, Al2O3 inclusions were modified into CeAl11O18 inclusions in the molten steel and then were further transformed into Al2O3 and CeAlO3 inclusions in the solid steel during cooling. With the addition of 65 × 10–6 cerium, inclusions in the molten steel were modified into CeAlO3 and a small number of Ce2O2S inclusions. When the addition amount of cerium increased to 150 × 10–6, inclusions were transformed to Ce2O2S. The size of inclusions in the molten steel decreased obviously with cerium addition. On the other hand, the size of inclusions increased during the cooling process in solid steels of No. 1 steel (with 28 × 10–6 cerium) and No. 2 steel (with 65 × 10–6 cerium). During the cooling process, unmodified MnS inclusions were precipitated in the solid steel of No. 1 steel and wrapped outside the Al2O3 and CeAlO3 inclusions to form large complex inclusions. During the cooling process of No. 2 steel, the inclusion size of CeAlO3 increased due to the collision and polymerization. In the No. 3 steel (with 150 × 10–6 cerium), the average size of inclusions decreased rapidly and remained at a lower size during the cooling process, which was beneficial to improving the fatigue life of the steel.

Similar content being viewed by others

References

H. Bhadeshia, Prog. Mater. Sci. 57 (2012) 268–435.

P. Wang, B. Wang, Y. Liu, P. Zhang, Y. Luan, D. Li, Z. Zhang, Scripta Mater. 206 (2022) 114232.

K. Hashimoto, T. Fujimatsu, N. Tsunekage, K. Hiraoka, K. Kida, E.C. Santos, Mater. Des. 32 (2011) 1605–1611.

J. Guan, L. Wang, C. Zhang, X. Ma, Tribol. Int. 106 (2017) 123–131.

S.M. Moghaddam, F. Sadeghi, K. Paulson, N. Weinzapfel, M. Correns, V. Bakolas, M. Dinkel, Int. J. Fatigue 80 (2015) 203–215.

K. Hashimoto, K. Hiraoka, K. Kida, E. Costa Santos, Mater. Sci. Technol. 28 (2012) 39–43.

D. Spriestersbach, P. Grad, E. Kerscher, Int. J. Fatigue 64 (2014) 114–120.

Z. Cao, Z. Shi, F. Yu, G. Wu, W. Cao, Y. Weng, Int. J. Fatigue 126 (2019) 1–5.

Y. Yamashita, Y. Murakami, Int. J. Fatigue 93 (2016) 406–414.

G. Donzella, M. Faccoli, A. Mazzù, C. Petrogalli, H. Desimone, Eng. Fract. Mech. 78 (2011) 2761–2774.

H. Li, Y. Yu, X. Ren, S. Zhang, S. Wang, J. Iron Steel Res. Int. 24 (2017) 925–934.

Z. Shaohua, Y. Yanchong, W. Shebin, L. Hao, J. Rare Earths 35 (2017) 518–524.

Q. Ren, L. Zhang, Metall. Mater. Trans. B 51 (2020) 589–600.

Q. Ren, L. Zhang, Y. Liu, L. Cui, W. Yang, J. Mater. Res. Technol. 9 (2020) 8197–8206.

C. Yang, Y. Luan, D. Li, Y. Li, Int. J. Fatigue 116 (2018) 396–408.

Y. Liu, Z. Yang, Y. Li, S. Chen, S. Li, W. Hui, Y. Weng, Mater. Sci. Eng. A 517 (2009) 180–184.

H. Mayer, W. Haydn, R. Schuller, S. Issler, B. Furtner, M. Bacher-Höchst, Int. J. Fatigue 31 (2009) 242–249.

A. Katsumata, H. Todoroki, Iron Steelmak. 29 (2002) 51–57.

Q. Wang, L. Wang, Y. Liu, K. Chou, J. Min. Metall. B Metall. 53 (2017) 365–372.

H. Wang, S. Jiang, P. Yu, L. Sun, Y. Wang, ISIJ Int. 60 (2020) 2316–2324.

Y. Meng, C. Yan, X. Yang, X. Ju, ISIJ Int. 60 (2020) 534–538.

S. Imashuku, K. Wagatsuma, Metall. Mater. Trans. B 51 (2020) 79–84.

X.Y. Wu, B.B. Liu, Q.R. Tian, J.B. Xie, J.X. Fu, Trans. Indian Inst. Met. 75 (2022) 2031–2039.

X. Wang, G. Li, Y. Liu, F. Wang, Q. Wang, ISIJ Int. 61 (2021) 1850–1859.

C. Yang, Y. Luan, D. Li, Y. Li, J. Mater. Sci. Technol. 35 (2019) 1298–1308.

C. Yang, Y. Luan, D. Li, Y. Li, Int. J. Fatigue 131 (2020) 105263.

J. Wang, W. Li, Y. Ren, L. Zhang, Steel Res. Int. 90 (2019) 1800600.

J.J. Hoo, Effect of steel manufacturing processes on the quality of bearing steels, ASTM International, Pennsylvania, USA, 1988.

Y. Murakami, Int. J. Fatigue 3 (1994) 345–351.

J. Monnot, B. Heritier, J.Y. Cogne, Relationship of melting practice, inclusion type, and size with fatigue resistance of bearing steels, ASTM International, Pennsylvania, USA, 1988.

T. Sakai, Y. Sato, N. Oguma, Fatig. Fract. Eng. Mater. Struct. 25 (2002) 765–773.

K. Hashimoto, T. Fujimatsu, N. Tsunekage, K. Hiraoka, K. Kida, E.C. Santos, Mater. Des. 32 (2011) 4980–4985.

S.M. Moghaddam, F. Sadeghi, Tribol. Trans. 59 (2016) 1142–1156.

A. Vahed, D. Kay, Metall. Trans. B 7 (1976) 375–383.

Y. Liu, L. Zhang, Metall. Mater. Trans. B 49 (2018) 1624–1631.

N. Verma, P.C. Pistorius, R.J. Fruehan, M.S. Potter, H.G. Oltmann, E.B. Pretorius, Metall. Mater. Trans. B 43 (2012) 830–840.

Acknowledgements

The authors are grateful for the support from the Natural Science Foundation of Hebei Province (Grant No. E2021203062), S&T Program of Hebei (Grant No. 20311006D) and the High Steel Center (HSC) at North China University of Technology, Yanshan University and University of Science and Technology Beijing.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors have no competing interests to declare that are relevant to the content of this article.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Li, H., Ren, Q. & Zhang, Lf. Effect of cerium addition on non-metallic inclusions in a high-carbon chromium bearing steel. J. Iron Steel Res. Int. 30, 2254–2266 (2023). https://doi.org/10.1007/s42243-022-00887-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42243-022-00887-0