Abstract

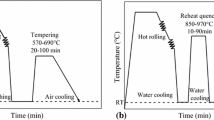

A superior combination of yield strength (1001 MPa) and − 20 °C impact toughness (166 J) was obtained in Nb–V–Ti-microalloyed Ni–Cr–Mo–Cu steel treated by direct quenching and tempering route (DQT). The tested steels treated by DQT route and re-austenitization and tempering route (QT) were compared with each other in terms of mechanical properties and microstructures characterized by optical microscopy, transmission electron microscopy, X-ray diffraction, electron back-scattered diffraction method and so on. Strength and Vickers hardness of the tested steel treated by the above two routes vary with isothermal aging temperature (400–600 °C), shown as under-aged state, peak-aged state and over-aged state. All DQT specimens show higher strength and Vickers hardness than QT specimens with the same aging condition. Furthermore, the largest difference of yield strength between DQT and QT specimens was shown in DQT600 and QT600 specimens. DQT600 or QT600 specimens refers to direct quenched (DQ) or quenched (Q) specimens isothermally aged at 600 °C. The main disparities in quenched microstructure between DQ and Q specimens are mainly in morphology of prior austenite grains, dislocation density of martensite matrix and solution amount of Nb and Mo elements dissolving in martensite matrix, which play key roles in affecting microstructure and mechanical properties of DQT and QT specimens. Higher dislocation density of matrix and finer average diameter of both MC (M is any combination of Nb, Mo and V) and Cu-rich particles were shown in DQT600 specimens than in QT600 specimens. Strengthening from dislocations and nanosized MC and Cu-rich particles mainly leads to the largest difference of yield strength between DQT600 and QT600 specimens. In addition, strong dislocation strengthening and precipitation strengthening in DQT600 specimen also elevated its ductile-to-brittle-transition-temperature, compared with QT600 specimen.

Similar content being viewed by others

References

D. Jain, D. Isheim, D.N. Seidman, Metall. Mater. Trans. A 48 (2017) 3205–3219.

Z.B. Jiao, J.H. Luan, M.K. Miller, C.T. Liu, Acta Mater. 97 (2015) 58–67.

R.P. Kolli, D.N. Seidman, Acta Mater. 56 (2008) 2073–2088.

S. Vaynman, D. Isheim, R.P. Kolli, S.P. Bhat, D.N. Seidman, M.E. Fine, Metall. Mater. Trans. A 39 (2008) 363–373.

S.K. Dhua, D. Mukerjee, D.S. Sarma, Metall. Mater. Trans. A 32 (2001) 2259–2270.

H. Su, X.B. Luo, C.F. Yang, F. Chai, H. Li, J. Iron Steel Res. Int. 21 (2014) 619–624.

M.K. Miller, K.F. Russell, P. Pareige, M.J. Starink, R.C. Thomson, Mater. Sci. Eng. A 250 (1998) 49–54.

W. Wang, B. Zhou, G. Xu, D.F. Chu, J.C. Peng, Mater. Charact. 62 (2011) 438–441.

K. Osamura, H. Okuda, S. Ochiai, M. Takashima, K. Asano, M. Furusaka, K. Kishida, F. Kurosawa, ISIJ Int. 34 (1994) 359–365.

C. Zhang, M. Enomoto, Acta Mater. 54 (2006) 4183–4191.

G.C. Hwang, S. Lee, J.Y. Yoo, W.Y. Choo, Mater. Sci. Eng. A 252 (1998) 256–268.

J.Y. Yoo, W.Y. Choo, T.W. Park, Y.W. Kim, ISIJ Int. 35 (1995) 1034–1040.

S.K. Dhua, S.K. Sen, Mater. Sci. Eng. A 528 (2011) 6356–6365.

Q.D. Liu, H.M. Wen, H. Zhang, J.F. Gu, C.W. Li, E.J. Lavernia, Metall. Mater. Trans. A 47 (2016) 1960–1974.

X.H. Xi, J.L. Wang, X. Li, L.Q. Chen, Z.D. Wang, Metall. Mater. Trans. A 50 (2019) 2912–2921.

D. Jain, D. Isheim, A.H. Hunter, D.N. Seidman, Metall. Mater. Trans. A 47 (2016) 3860–3872.

Y. Zhao, S.S. Xu, J.P. Li, J. Zhang, L.W. Sun, L. Chen, G.G. Sun, S.M. Peng, Z.W. Zhang, Mater. Sci. Eng. A 691 (2017) 162–167.

Z.J. Xie, C.J. Shang, X.L. Wang, X.P. Ma, S.V. Subramanian, R.D.K. Misra, Mater. Sci. Eng. A 727 (2018) 200–207.

C. Ouchi, ISIJ Int. 41 (2001) 542–553.

P. Gong, E.J. Palmiere, W.M. Rainforth, Acta Mater. 119 (2016) 43–54.

R.O. Ritchie, Nat. Mater. 10 (2011) 817–822.

S.C. Chen, C.Y. Huang, Y.T. Wang, H.W. Yen, Mater. Des. 134 (2017) 434–445.

R.L. Higginson, C.M. Sellars, Worked Examples in Quantitative Metallography, Maney, London, UK, 2003.

E.G. Dere, H. Sharma, R.H. Petrov, J. Sietsma, S.E. Offerman, Scripta Mater. 68 (2013) 651–654.

J.S. Wang, M.D. Mulholland, G.B. Olson, D.N. Seidman, Acta Mater. 61 (2013) 4939–4952.

G.K. Williamson, W.H. Hall, Acta Metall. 1 (1953) 22–31.

G.K. Williamson, R.E. Smallman, Philos. Mag. 1 (1956) 34–46.

X.B. Luo, C.F. Yang, H. Su, F. Chai, Trans. Mater. Heat Treat. 32 (2011) No. 6, 73–77.

B. Hutchinson, J. Hagström, O. Karlsson, D. Lindell, M. Tornberg, F. Lindberg, M. Thuvander, Acta Mater. 59 (2011) 5845–5858.

J. Liu, H. Yu, T. Zhou, C.H. Song, K. Zhang, Mater. Sci. Eng. A 619 (2014) 212–220.

R.H. Willens, E. Buehler, B.T. Matthias, Phys. Rev. 159 (1967) 327–330.

J.H. Jang, C.H. Lee, Y.U. Heo, D.W. Suh, Acta Mater. 60 (2012) 208–217.

Z.Y. Zhang, Z.D. Li, Q.L. Yong, X.J. Sun, Z.Q. Wang, G.D. Wang, Acta Metall. Sin. 51 (2015) 315–324.

J.Z. Zhao, Q.L. Wang, H.L. Li, J. He, Metall. Mater. Trans. A 42 (2011) 3200–3207.

D. Isheim, M.S. Gagliano, M.E. Fine, D.N. Seidman, Acta Mater. 54 (2006) 841–849.

L.Z. Han, Q.D. Liu, J.F. Gu, Chin. J. Mech. Eng. (Engl. Ed.) 32 (2019) 818.

R. Monzen, M.L. Jenkins, A.P. Sutton, Philos. Mag. A 80 (2000) 711–723.

X.L. Li, P. Wu, R.J. Yang, S.T. Zhao, S.P. Zhang, S. Chen, X.Z. Cao, X.M. Wang, Mater. Des. 115 (2017) 165–169.

D.S. Liu, M. Luo, B.B. Cheng, R. Cao, J.H. Chen, Metall. Mater. Trans. A 49 (2018) 4918–4936.

Q.L. Yong, Second phases in structural steels, Metallurgical industry press, Beijing, China, 2006.

Q.B. Yu, Z.D. Wang, X.H. Liu, G.D. Wang, Mater. Sci. Eng. A 379 (2004) 384–390.

S. Kang, J.G. Jung, Y.K. Lee, Mater. Trans. 53 (2012) 2187–2190.

Y.L. Zhao, Microstructure Control and Strengthening Mechanism of 1500MPa Grade Direct Quenched Martensitic Steel, Kunming University of Science and Technology, Kuming, China, 2010.

Z.T. Li, F. Chai, L. Yang, X.B. Luo, C.F. Yang, Mater. Des. 191 (2020) 108637.

A. Saastamoinen, A. Kaijalainen, D. Porter, P. Suikkanen, J.R. Yang, Y.T. Tsai, Mater. Charact. 139 (2018) 1–10.

Z.Y. Zhang, X.J. Sun, Q.L. Yong, Z.D. Li, Z.Q. Wang, G.D. Wang, Acta Metall. Sin. 52 (2016) 410–418.

K. Nakashima, Y. Futamura, T. Tsuchiyama, S. Takaki, ISIJ Int. 42 (2002) 1541–1545.

G. Han, Z.J. Xie, L. Xiong, C.J. Shang, R.D.K. Misra, Mater. Sci. Eng. A 705 (2017) 89–97.

Z.Y. Zhang, F. Chai, X.B. Luo, G. Chen, C.F. Chai, Acta Metall. Sin. 55 (2019) 783–791.

J.H. Chen, R. Cao, Chapter 2 – Methodology, in: J.H. Chen, R. Cao (Eds.), Micromechanism of Cleavage Fracture of Metals, Butterworth–Heinemann, Boston, USA, 2015, pp. 55–80.

J.W. Morris, ISIJ Int. 51 (2011) 1569–1575.

C.F. Wang, M.Q. Wang, J. Shi, W.J. Hui, H. Dong, Scripta Mater. 58 (2008) 492–495.

T. Hanamura, F. Yin, K. Nagai, ISIJ Int. 44 (2004) 610–617.

Acknowledgements

This work was supported by the National Key R&D Program of China (Nos. 2017YFB0701802, 2017YFB0703002 and 2017YFB0304501) and the National Natural Science Foundation of China (No. 51701044).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhu, F., Yang, L., Chai, F. et al. Effect of modifying matrix microstructures and nanosized precipitates on strengthening mechanisms and ductile-to-brittle-transition-temperature in a 1000 MPa Ni–Cr–Mo–Cu steel. J. Iron Steel Res. Int. 29, 1257–1276 (2022). https://doi.org/10.1007/s42243-021-00658-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s42243-021-00658-3